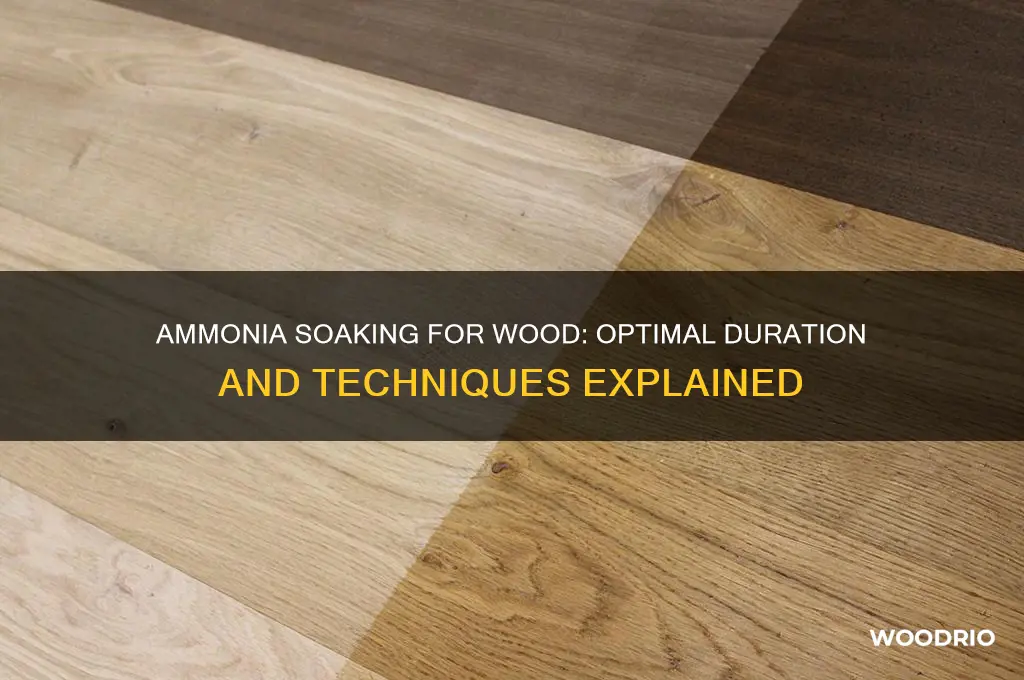

Soaking wood in ammonia is a popular technique used to lighten and age its appearance, often employed in woodworking and DIY projects to achieve a weathered or reclaimed look. The duration of soaking wood in ammonia can vary significantly depending on factors such as the type of wood, desired effect, and concentration of the ammonia solution. Typically, the process ranges from a few hours to several days, with softer woods like pine requiring less time compared to harder woods like oak. It’s essential to monitor the wood regularly during the soaking process to avoid over-lightening or damage, and safety precautions, such as proper ventilation and protective gear, should always be taken when working with ammonia.

| Characteristics | Values |

|---|---|

| Purpose | Stripping varnish, paint, or stain from wood |

| Ammonia Type | Household ammonia (clear, unscented) |

| Ammonia Concentration | 5-10% (check product label) |

| Wood Type | Suitable for most wood types, but test on a small area first |

| Soaking Time | 30 minutes to 24 hours (depending on finish thickness and desired results) |

| Typical Soaking Time Range | 1-4 hours for moderate finishes, up to 24 hours for heavy or multiple layers |

| Container Material | Plastic or glass (avoid metal, as ammonia can react with it) |

| Safety Precautions | Wear gloves, goggles, and work in a well-ventilated area |

| Disposal | Neutralize ammonia solution with vinegar before disposal, follow local regulations |

| Post-Soaking | Scrape off softened finish, rinse wood thoroughly with water, and allow to dry completely |

| Effectiveness | Highly effective for removing stubborn finishes, but may raise wood grain |

| Environmental Impact | Ammonia is toxic to aquatic life, dispose of properly |

| Alternatives | Commercial paint strippers, heat guns, or sanding (less environmentally impactful but more labor-intensive) |

Explore related products

What You'll Learn

- Ammonia type and concentration: Use clear ammonia (5-10%) for best results in wood soaking

- Soaking duration: 24-48 hours is ideal for most wood types to remove tannins

- Wood species considerations: Hardwoods may require longer soaking times than softwoods

- Safety precautions: Wear gloves, mask, and work in a well-ventilated area

- Post-soaking steps: Rinse wood thoroughly and let it dry completely before use

Ammonia type and concentration: Use clear ammonia (5-10%) for best results in wood soaking

Clear ammonia, specifically in the 5-10% concentration range, is the optimal choice for wood soaking. This concentration strikes a balance between effectiveness and safety, ensuring the ammonia penetrates the wood fibers without causing excessive damage. Stronger concentrations, such as industrial-grade ammonia (25-30%), can be too harsh, leading to uneven bleaching or even structural weakening of the wood. Conversely, weaker solutions may not yield the desired results, requiring longer soaking times or multiple treatments.

When preparing your ammonia solution, always use clear, household ammonia, which is readily available at most hardware or grocery stores. Avoid scented or colored varieties, as additives can interfere with the soaking process and leave unwanted residues. Mix the ammonia with water at a ratio of 1:1 for a 5-10% solution, ensuring thorough dissolution before submerging the wood. For smaller projects, a shallow tray or plastic container works well, while larger pieces may require a dedicated soaking tub or barrel.

The soaking duration depends on the desired outcome and the wood’s density. Softwoods, like pine, typically require 24-48 hours to achieve a noticeable lightening effect, while hardwoods, such as oak, may need 72 hours or more. Monitor the wood periodically during the process, as over-soaking can lead to brittleness or discoloration. Once the desired shade is achieved, remove the wood from the solution and neutralize it by rinsing with a mixture of water and white vinegar (1:1 ratio) to stop the chemical reaction.

Safety is paramount when working with ammonia. Always wear gloves, safety goggles, and work in a well-ventilated area to avoid skin irritation or respiratory issues. Keep the solution away from children and pets, and dispose of it responsibly, diluting it with water before pouring it down the drain. By adhering to these guidelines, you can effectively use clear ammonia to transform wood while preserving its integrity.

DAP Wood Filler Drying Time: Quick Guide for Perfect Results

You may want to see also

Explore related products

Soaking duration: 24-48 hours is ideal for most wood types to remove tannins

The ideal soaking duration for wood in ammonia to effectively remove tannins is 24 to 48 hours. This timeframe strikes a balance between thorough tannin extraction and preventing excessive wood degradation. Shorter periods may leave tannins behind, while longer soaks can weaken the wood fibers, particularly in softer species like pine or cedar. For hardwoods such as oak or walnut, the full 48 hours is often necessary to penetrate denser grain structures. Always use a 1:1 ratio of household ammonia to water, and ensure the wood is fully submerged in a sealed container to maintain ammonia fumes and maximize effectiveness.

Analyzing the process reveals why this duration is critical. Tannins, which cause discoloration and interfere with finishes, are stubborn compounds that require prolonged exposure to ammonia’s alkaline properties for breakdown. The first 12 hours typically loosen surface tannins, while the subsequent 12 to 24 hours address deeper layers. Monitoring the solution’s color change—from clear to amber or brown—indicates tannin release. However, leaving wood beyond 48 hours risks oversaturation, especially in thin or delicate pieces, which can lead to warping or splitting.

Practical tips can enhance the efficiency of this method. Pre-sand the wood lightly to open the pores, allowing ammonia to penetrate faster. For larger or thicker pieces, consider extending the soak to 36 hours, checking periodically for tannin release. After soaking, neutralize the wood by rinsing it in a vinegar-water solution (1:4 ratio) to halt the chemical reaction. Finally, air-dry the wood for 48 hours before finishing to ensure no ammonia residue remains. This meticulous approach ensures tannins are removed without compromising the wood’s integrity.

Comparing this method to alternatives highlights its advantages. Boiling wood to remove tannins is faster but risks damaging the wood’s structure, while using oxalic acid requires careful handling due to its toxicity. Ammonia soaking, though time-consuming, is cost-effective, eco-friendly, and safe when done in a well-ventilated area. It’s particularly suited for DIY enthusiasts working with reclaimed or naturally tannin-rich woods. By adhering to the 24-48 hour guideline, crafters can achieve professional-grade results without specialized equipment.

In conclusion, the 24-48 hour soaking duration in ammonia is a tried-and-true method for tannin removal, backed by both chemistry and practical experience. It’s a testament to the adage that patience yields precision. Whether preparing wood for staining, finishing, or artistic projects, this technique ensures a clean, tannin-free surface ready for transformation. Always prioritize safety by wearing gloves and working in ventilated spaces, and remember: the goal is not just to remove tannins but to preserve the wood’s natural beauty and strength.

Treated Wood Lifespan: How Long Does Two-Season Wood Last?

You may want to see also

Explore related products

Wood species considerations: Hardwoods may require longer soaking times than softwoods

The density and porosity of wood species significantly influence ammonia soaking times, with hardwoods often demanding more patience than their softwood counterparts. This disparity arises from the inherent structural differences between the two categories. Hardwoods, such as oak, maple, and walnut, possess tighter grain patterns and higher lignin content, making them less permeable to liquids. Consequently, ammonia, a potent but slow-acting agent, requires extended contact time to penetrate and react with the wood's cellular structure, typically ranging from 7 to 14 days. Softwoods like pine or cedar, with their looser grain and lower density, may achieve similar results in just 3 to 5 days.

When embarking on an ammonia soaking project, it's crucial to tailor the process to the specific wood species. For instance, soaking a hardwood like teak might necessitate a 10-day immersion in a 10% ammonia solution, whereas a softwood like spruce could be adequately treated in 4 days with the same concentration. However, these are general guidelines, and factors like wood thickness, desired effect, and ambient temperature can further modify soaking durations. A thicker hardwood plank, for example, may require an additional 2-3 days to ensure the ammonia reaches the core.

The science behind this phenomenon lies in the chemical interaction between ammonia and the wood's components. Ammonia reacts with the wood's tannins and lignin, causing a color change and altering the wood's pH. Hardwoods, with their higher lignin content, present a more complex substrate for this reaction, hence the longer processing time. Softwoods, being less dense and more resinous, allow for quicker ammonia penetration and reaction, often resulting in a more pronounced color change in a shorter period.

Practical considerations for woodworkers and enthusiasts include monitoring the soaking process regularly. For hardwoods, this might involve checking the wood's color change every 2-3 days after the initial 7-day mark. With softwoods, daily inspections post the 3-day mark can help prevent over-soaking, which could lead to excessive color alteration or structural weakening. Additionally, maintaining a consistent temperature, ideally around 70°F (21°C), can optimize the reaction rate, ensuring more predictable results.

In conclusion, understanding the wood species' characteristics is paramount when determining ammonia soaking times. Hardwoods' denser nature dictates a more extended and careful approach, while softwoods' permeability allows for a quicker process. By respecting these differences and adjusting the treatment accordingly, craftsmen can achieve the desired aesthetic and structural modifications without compromising the wood's integrity. This tailored approach not only enhances the wood's natural beauty but also ensures the longevity of the treated pieces.

Crafting a Wood Bat: Understanding the Time and Process

You may want to see also

Explore related products

Safety precautions: Wear gloves, mask, and work in a well-ventilated area

Ammonia is a powerful chemical that can cause skin irritation, respiratory issues, and eye damage if not handled properly. When soaking wood in ammonia, the fumes released can be particularly hazardous, making safety precautions non-negotiable. Wearing gloves, a mask, and working in a well-ventilated area are essential steps to protect yourself from these risks. Nitrile or rubber gloves provide a barrier against skin contact, while a respirator mask with ammonia-specific filters ensures you don’t inhale harmful vapors. Ventilation is equally critical; open windows, use fans, or work outdoors to disperse fumes and maintain a safe breathing environment.

Consider the concentration of ammonia you’re using, as household ammonia (typically 5-10% solution) is less potent than industrial-grade versions. Even at lower concentrations, prolonged exposure can be dangerous. For example, a 10% ammonia solution can cause respiratory distress within minutes if inhaled in a confined space. Always dilute ammonia according to the project’s requirements and avoid splashing by using a container with a secure lid. If working indoors, ensure the area is free of ignition sources, as ammonia is flammable in high concentrations.

The type of mask you choose matters. A simple dust mask won’t suffice; opt for a respirator with organic vapor cartridges rated for ammonia. These masks are designed to filter out harmful chemicals, providing a higher level of protection. Additionally, gloves should be thick enough to resist chemical permeation but flexible enough for dexterity. Inspect gloves for tears or leaks before use, as even small breaches can expose your skin to ammonia. If you experience dizziness, nausea, or difficulty breathing, immediately leave the area and seek fresh air.

Working in a well-ventilated area isn’t just about opening a window; it’s about creating airflow that carries fumes away from your breathing zone. Position fans to blow outward, not toward you, and avoid working in basements or enclosed spaces. If outdoor work isn’t possible, use exhaust systems or air purifiers with chemical filters. Remember, ventilation reduces the risk of inhaling concentrated fumes, which can accumulate quickly in stagnant air. For longer soaking periods, take breaks in fresh air every 30 minutes to avoid overexposure.

Finally, always prioritize safety over convenience. While it might be tempting to skip gloves or work in a garage with the door closed, the consequences of ammonia exposure far outweigh the minor inconveniences of proper precautions. Store ammonia in a cool, dry place, away from children and pets, and label containers clearly. By treating ammonia with respect and adhering to these safety measures, you can effectively soak wood without compromising your health. Safety isn’t optional—it’s the foundation of any successful project involving hazardous materials.

Polyurethane Drying Time: Factors Affecting Wood Finishing Process

You may want to see also

Explore related products

$11.99 $14.99

Post-soaking steps: Rinse wood thoroughly and let it dry completely before use

After soaking wood in ammonia, the post-soaking steps are critical to ensure the wood is safe, stable, and ready for use. Rinsing the wood thoroughly removes residual ammonia, which can cause discoloration, weaken adhesives, or release harmful fumes if left untreated. Use clean, lukewarm water and rinse until the runoff is clear, ensuring no ammonia remains on the surface or within the wood fibers. For larger pieces, consider using a hose or pressure washer to penetrate deep grain patterns effectively.

Once rinsed, allowing the wood to dry completely is equally essential. Ammonia-soaked wood retains moisture, which can lead to warping, mold growth, or compromised structural integrity if not addressed. Air-drying is the most common method, but specifics vary by wood type and climate. Hardwoods like oak or maple may take 2–4 weeks to dry fully, while softer woods like pine dry faster, typically within 1–2 weeks. In humid environments, use fans or dehumidifiers to expedite the process, ensuring the wood’s moisture content matches its intended use (typically 6–12% for indoor projects).

Skipping these steps can have tangible consequences. Residual ammonia can react with finishes, causing blotching or adhesion failure, while damp wood may shrink or expand unpredictably after installation. For example, a craftsman who neglected to rinse and dry ammonia-treated wood before applying polyurethane might notice the finish cracking or peeling within months. Conversely, a thorough rinse followed by patient drying ensures the wood remains dimensionally stable and chemically neutral, ready for staining, painting, or assembly.

Practical tips can streamline this process. For intricate carvings or detailed pieces, use a soft brush during rinsing to dislodge ammonia from crevices. If time is a constraint, kiln-drying or oven-drying at low temperatures (100–150°F) can accelerate moisture removal, but monitor closely to avoid scorching. Always test a small area first to confirm the wood responds well to the drying method. By prioritizing these post-soaking steps, you safeguard both the material’s integrity and the success of your project.

Understanding Morning Woods Duration: How Long Does It Typically Last?

You may want to see also

Frequently asked questions

Soak wood in ammonia for 24 to 48 hours to effectively remove tannins, darken the wood, or achieve a weathered look.

Leaving wood in ammonia for more than 48 hours may not yield additional benefits and could potentially weaken the wood fibers.

Soaking for less than 24 hours may not produce the desired effect, as the ammonia needs time to react with the wood tannins.

Yes, dilute ammonia with water (1:1 ratio) before use. Dilution does not significantly affect soaking time, but it makes the process safer and less harsh on the wood.