When installing a fence on wood posts, it’s crucial to allow adequate drying time for the concrete or setting material used to secure the posts in the ground. Typically, concrete takes about 24 to 48 hours to set sufficiently for light use, but it’s recommended to wait at least 3 to 4 days before hanging the fence to ensure the posts are fully stabilized and can bear the weight. For optimal strength and longevity, waiting a full week is ideal, especially in humid or cold conditions that may slow the curing process. Rushing this step can lead to unstable posts and potential fence failure over time.

| Characteristics | Values |

|---|---|

| Recommended Waiting Time | 24-48 hours after setting posts in concrete |

| Concrete Cure Time | 24-72 hours for initial set; 28 days for full strength |

| Post Material | Pressure-treated wood posts |

| Soil Type Impact | Sandy soil: shorter wait; Clay soil: longer wait |

| Weather Conditions | Dry, warm weather accelerates curing; wet/cold weather delays curing |

| Post Depth | Typically 1/3 of post height (e.g., 8-foot post = 2.5 feet in ground) |

| Fence Type | Lightweight fences can be hung sooner than heavy-duty fences |

| Additional Support | Bracing posts during curing may allow earlier fence hanging |

| Professional Advice | Always follow manufacturer or contractor recommendations |

| Risk of Premature Hanging | Posts may shift or lean if fence is hung too soon |

Explore related products

$17.29

What You'll Learn

- Drying Time for Concrete: Ensure concrete is fully cured before hanging fence for stability and strength

- Wood Moisture Content: Wait until wood posts are properly dried to prevent warping or shifting

- Weather Conditions: Avoid hanging fence in wet or freezing weather to ensure proper setting

- Post Setting Depth: Confirm posts are set deep enough and secure before attaching the fence

- Hardware Installation: Allow time for brackets and screws to settle firmly into the wood

Drying Time for Concrete: Ensure concrete is fully cured before hanging fence for stability and strength

Concrete curing is a chemical process, not just a drying one. While it may seem solid within hours, achieving full strength takes time. For fence posts, which bear significant weight and wind pressure, rushing this process compromises stability. Most concrete reaches 60% of its strength within 72 hours, but it continues to harden for weeks. Hanging a fence too soon risks shifting or cracking the post, undermining the entire structure.

The ideal waiting period depends on factors like concrete type, weather, and fence load. Standard concrete mixes typically require 28 days to reach 90% of their compressive strength. However, specialized fast-setting concretes can cure in as little as 24 hours, though they may lack the long-term durability of traditional mixes. Always check the manufacturer’s guidelines for specific curing times. In hot, dry conditions, concrete cures faster but risks cracking if not properly hydrated. Conversely, cold temperatures slow curing, potentially weakening the final product.

To ensure stability, follow a systematic approach. First, mix concrete thoroughly, maintaining a consistent water-to-cement ratio (typically 0.45 to 0.60 for optimal strength). Pour it into the post hole, ensuring the post is plumb and braced securely. Allow the concrete to set undisturbed for at least 48 hours before removing braces. For heavy-duty fences or high-wind areas, wait the full 28 days. Test readiness by gently tugging the post—if it moves, give it more time.

Practical tips can enhance curing efficiency. Cover the concrete with plastic sheeting or damp burlap to retain moisture, aiding the chemical reaction. Avoid foot traffic or heavy loads near the post during curing. In cold climates, use insulating blankets or heated enclosures to maintain optimal curing temperatures (above 50°F). These measures ensure the concrete reaches its maximum strength, providing a reliable foundation for your fence.

Skipping the curing process or cutting it short is a common mistake with costly consequences. A fence hung on under-cured concrete may appear stable initially but can lean, shift, or collapse over time. Investing patience in the curing phase saves time and money in the long run, ensuring a fence that stands strong for years. Remember, the strength of your fence is only as good as the foundation it’s built on.

Optimal Drying Time for Outdoor Wood Sealant: A Comprehensive Guide

You may want to see also

Explore related products

Wood Moisture Content: Wait until wood posts are properly dried to prevent warping or shifting

Freshly cut wood posts can hold up to 50% moisture content, a level far too high for structural stability in fencing. As the wood dries, this moisture evaporates, causing the posts to shrink and potentially warp or twist. Hanging a fence on posts that haven’t reached equilibrium moisture content (EMC) with their environment invites future headaches: sagging rails, misaligned pickets, and costly repairs.

Achieving proper drying time hinges on two factors: the wood species and environmental conditions. Dense hardwoods like oak or cedar naturally dry slower than softwoods like pine. In ideal conditions—low humidity, good airflow, and moderate temperatures—posts may reach a stable moisture content (around 12-15%) within 6-12 months. However, in humid climates or when stacked without adequate ventilation, drying can take 18 months or longer.

To expedite drying, store posts in a covered but well-ventilated area, elevating them off the ground to prevent moisture absorption. Consider using a moisture meter to test the wood periodically; readings above 19% indicate the posts aren’t ready. While pressure-treated wood is pre-dried during treatment, it still benefits from additional air-drying time to minimize movement.

Skipping this waiting period might seem efficient, but it’s a gamble. Warped posts not only compromise the fence’s appearance but also its structural integrity. The patience required to let wood dry naturally is a small investment compared to the long-term durability and stability of your fence.

In summary, treat wood moisture content as a non-negotiable factor in fence installation. Rushing this step undermines the entire project. By allowing posts to dry thoroughly, you ensure a fence that stands straight, strong, and secure for years to come.

Drying Wet Seasoned Wood: Understanding the Timeframe for Optimal Results

You may want to see also

Explore related products

Weather Conditions: Avoid hanging fence in wet or freezing weather to ensure proper setting

Wet or freezing weather can sabotage your fence installation before it even begins. Moisture compromises the integrity of wood posts, preventing proper adhesion of concrete and increasing the risk of rot. In freezing temperatures, concrete sets too slowly or not at all, leaving posts unstable and vulnerable to shifting. These conditions create a weak foundation, leading to a fence that leans, sags, or collapses prematurely.

Perfectly Grilled Salmon: Wood Pellet Grill Cooking Time Guide

You may want to see also

Explore related products

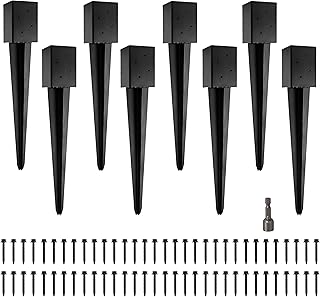

Post Setting Depth: Confirm posts are set deep enough and secure before attaching the fence

Before hanging a fence, ensuring the posts are set at the correct depth is crucial for stability and longevity. The general rule of thumb is to bury one-third of the post’s total length underground. For a standard 8-foot post, this means digging a hole 32 inches deep. This depth provides sufficient anchorage to withstand wind, soil shifts, and lateral pressure from the fence itself. However, local climate and soil type can influence this requirement. In areas prone to high winds or loose soil, consider burying up to 40% of the post for added security.

Analyzing soil composition is key to determining post-setting depth. Sandy or loamy soils offer less resistance, requiring deeper holes or additional support like gravel or concrete. Clay-rich soils, while more stable, can expand and contract with moisture, potentially loosening posts over time. To mitigate this, compact the soil in layers as you backfill the hole. For added stability, pour 6 inches of gravel at the base of the hole to improve drainage and prevent waterlogging, which can accelerate wood rot.

A persuasive argument for proper post depth lies in its long-term benefits. Skimping on depth or rushing the process may save time initially but can lead to costly repairs or replacements later. A fence with insecure posts is more likely to lean, warp, or collapse, compromising both functionality and aesthetics. Investing in the right depth and materials upfront ensures the fence remains sturdy for years, reducing maintenance and extending its lifespan.

Comparatively, using concrete versus soil alone for setting posts highlights the importance of depth. While concrete provides superior stability, it’s not always necessary. For lighter fences, compacted soil with gravel can suffice, but the post must be buried deeper to compensate for the lack of concrete’s binding strength. If opting for concrete, allow it to cure for at least 48 to 72 hours before attaching the fence. This ensures the post is fully secured and reduces the risk of shifting under pressure.

Practically, confirming post security before hanging the fence involves a simple test. After backfilling the hole, brace the post temporarily and let it settle for 24 hours. Once settled, attempt to move the post by applying lateral pressure. If it remains firm, it’s ready for fencing. If not, dig deeper or add more support. This step, though time-consuming, is non-negotiable for a durable fence. Remember, a well-set post is the foundation of a reliable fence, and patience in this phase pays dividends in the long run.

Why Wood Prices Remain High: Factors Driving Prolonged Expense

You may want to see also

Explore related products

Hardware Installation: Allow time for brackets and screws to settle firmly into the wood

Wood, despite its strength, is a living material that responds to environmental changes. When you drive screws into wooden fence posts or attach brackets, the wood fibers compress and adjust to the new hardware. This settling process is crucial for long-term stability. Rushing to hang a fence before the wood has adapted can lead to loose brackets, wobbly panels, and eventual structural failure. Think of it as letting a joint cure in woodworking—patience ensures durability.

The waiting time varies depending on factors like wood type, moisture content, and hardware size. Softwoods like pine may settle within 24–48 hours, while denser hardwoods like cedar could take up to 72 hours. High humidity slows the process, as wood retains more moisture and resists compression. Larger screws and heavier brackets exert more force, requiring additional time for the fibers to stabilize. A good rule of thumb: if the wood feels warm to the touch after installation (a sign of friction from driving screws), give it at least 48 hours to cool and settle.

To test readiness, gently tug on the brackets or twist the screws. If there’s no give or movement, the wood has likely settled sufficiently. For added assurance, apply a small load (like leaning a single fence panel against the post) and observe for 12 hours. If the hardware holds firm without shifting, proceed with full installation. Avoid shortcuts like over-tightening screws, as this can strip the wood fibers and weaken the connection.

Practical tip: Plan hardware installation during dry, mild weather to minimize moisture-related delays. If time is a constraint, pre-drill holes slightly larger than the screw diameter to reduce initial compression. However, this method sacrifices some grip strength, so it’s best reserved for softwoods or temporary setups. Always prioritize settling time for permanent fences, as it’s the foundation for a sturdy, long-lasting structure.

Pine Beetle Lifespan in Dead Wood: Understanding Their Duration

You may want to see also

Frequently asked questions

Wait at least 24 to 48 hours for the concrete to set properly before hanging the fence on wood posts.

No, it’s best to wait until the concrete is fully cured, which typically takes 24 to 48 hours, to ensure stability.

It’s not recommended; wait at least 24 hours to ensure the concrete has hardened enough to support the fence.

Cold or humid weather can slow concrete curing, so you may need to wait longer than 48 hours in such conditions.

Yes, fast-setting concrete can reduce waiting time to as little as 4 hours, but always follow the manufacturer’s instructions.