Unfinished wood, due to its porous nature, is not inherently designed to hold water for extended periods. When considering how long an unfinished wood cup can hold water, several factors come into play, including the type of wood, its density, and the presence of natural resins or oils. Softwoods, like pine, tend to absorb water quickly, causing the wood to swell and potentially leak, while hardwoods, such as oak or maple, may fare slightly better due to their tighter grain structure. However, without a protective sealant or finish, even hardwood cups will eventually allow water to seep through or evaporate, making them impractical for long-term water storage. Understanding these limitations is essential for anyone experimenting with or using unfinished wood containers for liquids.

| Characteristics | Values |

|---|---|

| Type of Wood | Softwoods (e.g., pine) absorb water faster than hardwoods (e.g., oak). |

| Porosity | Higher porosity leads to quicker water absorption and shorter hold time. |

| Surface Finish | Unfinished wood has no protective layer, allowing water to penetrate easily. |

| Duration of Water Hold | Typically holds water for 10–30 minutes before significant leakage. |

| Factors Affecting Duration | Wood density, moisture content, temperature, and cup thickness. |

| Water Absorption Rate | Varies; softwoods may absorb water within 5–15 minutes. |

| Leakage Onset | Visible leakage often begins after 10–20 minutes. |

| Structural Integrity | Prolonged exposure weakens wood, causing warping or cracking. |

| Mold/Mildew Risk | High risk after 24–48 hours of water exposure. |

| Practical Use | Not suitable for holding water long-term; primarily decorative or temporary use. |

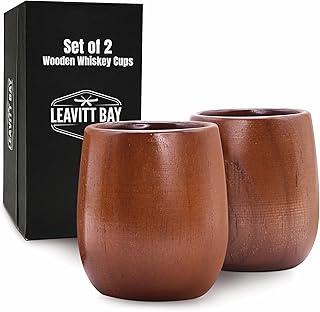

Explore related products

What You'll Learn

Wood Porosity and Water Absorption

Unfinished wood, with its natural pores and fibers, behaves like a sponge when exposed to water. Its ability to hold liquid depends on a critical factor: porosity. This inherent characteristic varies widely among wood species, dictating how much water they can absorb and retain. Dense hardwoods like teak or oak, with their tightly packed cells, resist water penetration, while softwoods like pine or cedar, with larger, more open cell structures, readily soak up moisture.

Understanding porosity is crucial when considering the water-holding capacity of an unfinished wood cup.

Imagine a cross-section of wood under a microscope. The tiny, straw-like vessels and fibers form a network of channels. These channels, when open and interconnected, allow water to seep in through capillary action. The more numerous and larger these channels, the greater the wood's porosity and, consequently, its water absorption rate. This principle explains why a pine cup might quickly become waterlogged, while an oak cup remains relatively dry.

Wood density, a measure of mass per unit volume, is directly linked to porosity. Higher density generally indicates lower porosity, as the cells are packed tighter, leaving less space for water infiltration.

The time an unfinished wood cup can hold water is not a fixed value but a spectrum influenced by porosity and external factors. A highly porous pine cup might leak noticeably within minutes, while a less porous maple cup could hold water for hours, slowly releasing moisture through evaporation and seepage. Humidity plays a role too; drier air accelerates evaporation, shortening the cup's water-holding time.

To maximize water retention, consider treating the wood with a natural sealant like linseed oil or beeswax. These substances penetrate the wood fibers, filling some of the pores and creating a barrier against water absorption. However, remember that this alters the wood's natural state and may affect its aesthetic appeal.

Ultimately, the water-holding capacity of an unfinished wood cup is a delicate balance between its inherent porosity and environmental conditions. Understanding this relationship allows us to appreciate the unique characteristics of different wood species and make informed choices when using them for water-related purposes. Whether crafting a decorative cup or simply observing the interaction between wood and water, porosity remains the key to unlocking the secrets of this natural material's behavior.

Wood Conditioner Drying Time: A Quick Guide for Perfect Results

You may want to see also

Explore related products

Sealing Methods for Water Resistance

Unfinished wood, by its nature, is porous and absorbent, making it ill-suited for holding water without proper treatment. Sealing methods are essential to enhance water resistance, ensuring the wood can withstand moisture without warping, cracking, or rotting. The choice of sealant depends on the intended use, durability requirements, and aesthetic preferences. Here’s a focused guide on effective sealing methods for water resistance.

Analytical Perspective:

Wood’s cellular structure allows it to absorb water, which can lead to swelling and structural degradation. To counteract this, sealants create a barrier that repels moisture. Common options include linseed oil, polyurethane, and epoxy resins. Linseed oil penetrates the wood fibers, providing a natural, breathable finish, but it requires multiple coats and regular reapplication. Polyurethane forms a hard, durable surface ideal for high-moisture environments, though it can yellow over time. Epoxy resins offer superior water resistance and clarity, making them suitable for decorative pieces, but they are more expensive and labor-intensive to apply. Each method has trade-offs, and the best choice depends on the specific demands of the project.

Instructive Approach:

To seal unfinished wood for water resistance, follow these steps: First, sand the wood to a smooth finish, removing any rough spots or splinters. Clean the surface thoroughly to ensure the sealant adheres properly. Apply the chosen sealant evenly, using a brush, roller, or sprayer, depending on the product. For oils, apply thin coats, allowing each layer to dry before adding the next. For polyurethane or epoxy, follow the manufacturer’s instructions for drying times and application techniques. After the final coat, allow the wood to cure fully—typically 24 to 72 hours—before exposing it to water. Regular maintenance, such as reapplying sealant annually, will prolong water resistance.

Comparative Analysis:

Natural oils like linseed or tung oil are eco-friendly and enhance the wood’s grain, but they offer limited water resistance compared to synthetic options. Polyurethane provides a robust, long-lasting barrier but can alter the wood’s appearance with its glossy finish. Epoxy resins excel in water resistance and clarity but are more challenging to apply and less forgiving of mistakes. For outdoor projects, consider marine-grade sealants, which are formulated to withstand harsh conditions. Indoor items may benefit from water-based polyurethanes, which are low-odor and dry quickly. The key is matching the sealant to the wood’s intended use and environment.

Practical Tips:

When sealing wood for water resistance, test the sealant on a small, inconspicuous area first to ensure compatibility. Use a wood conditioner before applying oil-based sealants to prevent blotching, especially on softwoods like pine. For maximum durability, combine methods—apply a penetrating oil first, followed by a topcoat of polyurethane. Store sealants in a cool, dry place to maintain their effectiveness. Finally, avoid overloading the wood with sealant, as excess can pool and create an uneven finish. With proper technique and maintenance, sealed wood can hold water effectively for years.

Exploring the Timeless Length of Under Milk Wood: A Comprehensive Guide

You may want to see also

Explore related products

Wood Type and Durability

Unfinished wood's ability to hold water varies dramatically by species, with density and natural oils playing pivotal roles. Tropical hardwoods like teak or mahogany, prized for their high oil content, can resist moisture absorption for hours or even days, making them ideal for water-adjacent applications. In contrast, softwoods such as pine or cedar, while less dense, contain natural resins that slow water penetration, though their longevity pales in comparison to denser options. For instance, a teak cup might retain structural integrity for weeks when exposed to water, whereas pine would warp or crack within days.

Selecting the right wood type for water-holding applications requires balancing durability with practicality. Hardwoods like oak or maple offer moderate water resistance due to their tight grain structure, but their heavier weight and higher cost may limit utility. Alternatively, cedar, with its aromatic oils, provides decent short-term resistance, making it suitable for temporary or decorative uses. For DIY projects, consider the intended lifespan: if the cup is for occasional use, cedar or pine suffices; for long-term exposure, invest in teak or mahogany.

To maximize an unfinished wood cup’s water-holding capacity, apply a protective treatment. While this section focuses on untreated wood, understanding species-specific traits helps predict performance. For example, applying a light coat of food-safe mineral oil to a maple cup can enhance its resistance, extending its usability from hours to days. However, this is a temporary solution; untreated wood will eventually succumb to moisture. Always test the wood’s reaction to water before committing to a project, as even within the same species, variations in grain and oil distribution can affect performance.

Comparing wood types reveals a clear hierarchy in water resistance. Tropical hardwoods dominate, followed by resinous softwoods, with open-grained species like balsa or aspen ranking lowest. For instance, a balsa cup might fail within minutes, while a mahogany one could last months under intermittent exposure. This comparison underscores the importance of matching wood type to application. If crafting a functional water cup, prioritize density and natural oils; for decorative purposes, aesthetic appeal and short-term durability may suffice.

Finally, environmental factors significantly influence how long unfinished wood holds water. Humidity, temperature, and exposure duration accelerate degradation, even in naturally resistant woods. In high-humidity environments, even teak may show signs of wear after prolonged use. To mitigate this, store wood cups in dry, cool conditions when not in use. For outdoor applications, consider pre-treating the wood with a natural sealant or choosing a species like cypress, which combines moderate density with rot resistance. Always weigh the wood’s natural properties against the demands of its intended use to ensure longevity.

Understanding Standard Wood Fence Picket Lengths for Your Project

You may want to see also

Explore related products

Environmental Factors Affecting Wood

Wood's ability to hold water is a delicate balance influenced by environmental factors that act as silent sculptors, shaping its performance over time. Humidity, the stealthy infiltrator, plays a pivotal role. In regions with high humidity, wood absorbs moisture from the air, causing it to expand and potentially warp. This swelling can compromise the integrity of an unfinished wood cup, reducing its water-holding capacity. Conversely, in arid climates, wood dries out, leading to shrinkage and the formation of cracks. These fissures not only weaken the structure but also create pathways for water to escape, shortening the time the cup can retain liquid. To mitigate these effects, consider storing wood cups in controlled environments with humidity levels between 40-60%, a range that minimizes dimensional changes.

Temperature, another environmental titan, exerts its influence through thermal stress. Extreme heat accelerates the evaporation of water from the wood, while repeated temperature fluctuations can cause internal stresses, leading to splitting or checking. For instance, leaving a wood cup near a heat source like a stove or in direct sunlight can drastically reduce its water retention time. Similarly, freezing temperatures can cause trapped moisture within the wood to expand, leading to cell damage. To preserve the cup's functionality, avoid exposing it to temperatures outside the range of 50°F to 90°F (10°C to 32°C). If the cup must be used outdoors, apply a protective finish to act as a thermal buffer.

The presence of microorganisms in the environment poses a hidden threat to wood's water-holding ability. Fungi, bacteria, and insects thrive in damp, organic materials, and unfinished wood provides an ideal habitat. Prolonged exposure to moisture, especially in warm conditions, can lead to rot or infestation, compromising the cup's structural integrity. For example, a wood cup left with water overnight in a humid kitchen may develop mold within 24-48 hours, rendering it unsafe for use. To combat this, ensure the cup is thoroughly dried after each use and consider treating it with natural preservatives like linseed oil or vinegar solutions, which inhibit microbial growth without compromising its unfinished aesthetic.

Lastly, the type of water the wood cup holds can significantly impact its longevity. Hard water, rich in minerals like calcium and magnesium, can leave deposits that clog the wood's pores over time, reducing its ability to absorb and retain liquid. Soft water, while less damaging, can still lead to swelling if the wood is repeatedly saturated. To extend the cup's lifespan, periodically rinse it with distilled water to remove mineral buildup. Additionally, avoid using it for acidic or sugary beverages, as these can accelerate degradation by feeding microorganisms or causing chemical reactions within the wood fibers. By understanding and addressing these environmental factors, you can maximize the functional beauty of your unfinished wood cup.

Petrified Wood Tumbling: Understanding the Agatization Timeframe and Process

You may want to see also

Explore related products

Testing Water Retention Time

Unfinished wood, with its porous nature, absorbs and releases moisture, making its water retention time a fascinating subject for experimentation. To test how long an unfinished wood cup can hold water, start by selecting a cup made from a single type of wood, such as pine, oak, or cedar, as different woods have varying densities and grain patterns that affect absorption rates. Fill the cup to the brim with room-temperature water, ensuring no spills occur during the initial pour. Use a timer to track the duration from the moment the water is added. Observe the cup at regular intervals—every 15 minutes for the first hour, then hourly for the next few hours—noting any visible changes in water level, leakage, or signs of saturation on the wood’s surface.

The experimental setup should control for external factors like humidity and temperature, as these can influence evaporation and absorption rates. Place the cup in a stable environment, away from direct sunlight, drafts, or heat sources. For precise measurements, use a graduated cylinder to quantify the initial and remaining water volume at each interval. Record data systematically, noting the time elapsed, water volume, and any observable changes in the wood’s texture or color. This methodical approach ensures accurate results and allows for comparison across different wood types or cup designs.

Analyzing the data reveals patterns in water retention based on wood characteristics. Softer woods like pine may absorb water more quickly, leading to faster depletion, while denser woods like oak might retain water longer due to their tighter grain structure. However, absorption alone doesn’t determine retention time; evaporation from the wood’s surface also plays a role. For instance, a cup with a wider rim may lose water faster due to increased surface area exposed to air. Understanding these dynamics helps predict how long an unfinished wood cup can hold water under specific conditions.

Practical tips for maximizing water retention include pre-treating the wood to reduce porosity. Submerging the cup in water for 24 hours before testing can saturate the wood fibers, minimizing further absorption during the experiment. Alternatively, applying a thin layer of natural wax or oil to the interior surface can create a barrier, slowing both absorption and evaporation. These techniques are particularly useful for crafting functional wooden vessels, though they deviate from the "unfinished" state. For pure experimentation, however, keeping the wood untreated provides the most authentic results.

In conclusion, testing water retention time in an unfinished wood cup combines precision, observation, and an understanding of material properties. By controlling variables, measuring accurately, and analyzing results, one can uncover how wood type, design, and environmental factors influence performance. Whether for scientific inquiry or practical application, this experiment highlights the interplay between natural materials and their interaction with water, offering insights into both the strengths and limitations of unfinished wood as a container.

Perfectly Grilled Turkey Burgers: Timing Tips for Wood-Fired Flavor

You may want to see also

Frequently asked questions

Unfinished wood cups are not designed to hold water for extended periods. Water can be absorbed within minutes to hours, depending on the wood type and porosity.

Yes, denser woods like teak or oak may resist water absorption slightly longer than softer woods like pine, but all unfinished wood will eventually soak up water.

No, an unfinished wood cup will likely absorb water and become waterlogged within a few hours, making it unsuitable for holding water overnight.

Yes, sealing the wood with a waterproof finish or coating will significantly extend its ability to hold water, but unfinished wood will not hold water for long.

Prolonged exposure to water can cause the wood to warp, crack, or develop mold and mildew, rendering the cup unusable.