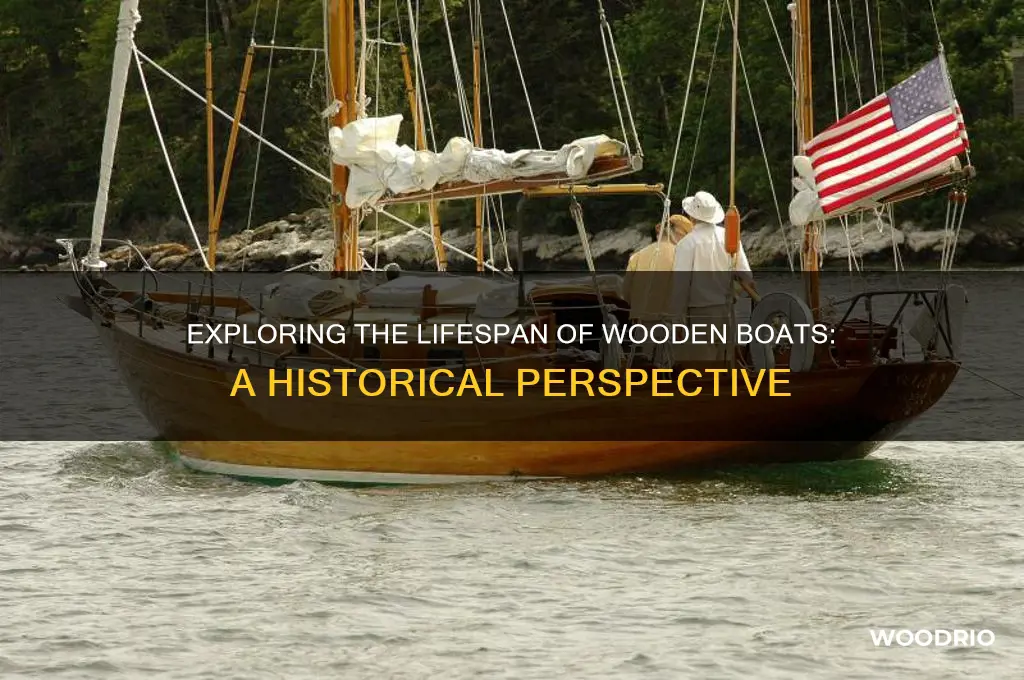

Wooden boats have been a cornerstone of human maritime history, with their origins dating back thousands of years. The length of wooden boats varied widely depending on their purpose, from small, single-person canoes used for fishing to massive warships and cargo vessels that spanned over 100 feet. Early wooden boats, such as those built by ancient Egyptians and Vikings, were often between 20 to 60 feet long, designed for river navigation and coastal travel. As shipbuilding techniques advanced, larger wooden vessels emerged, with some 18th and 19th-century sailing ships reaching lengths of 200 feet or more. The durability and craftsmanship of wooden boats allowed them to serve as vital tools for exploration, trade, and warfare, shaping civilizations and connecting distant lands. Understanding the lengths of these vessels provides insight into their capabilities, the technological advancements of their time, and their enduring legacy in maritime history.

Explore related products

What You'll Learn

- Early Wooden Boat Construction: Techniques and materials used in ancient shipbuilding, focusing on durability and design

- Lifespan of Wooden Vessels: Factors affecting longevity, including maintenance, wood type, and environmental conditions

- Historical Wooden Boat Examples: Notable ships like the *Mary Rose* and their operational durations

- Modern Wooden Boat Preservation: Methods to extend lifespan, including restoration and protective coatings

- Wooden Boats vs. Modern Materials: Comparison of durability and lifespan with steel, fiberglass, and aluminum

Early Wooden Boat Construction: Techniques and materials used in ancient shipbuilding, focusing on durability and design

Wooden boats have been humanity's vessels of exploration, trade, and survival for millennia, with evidence of their use dating back to prehistoric times. The durability and design of these early boats were critical to their longevity, often enabling them to withstand harsh maritime conditions for decades, if not centuries. Ancient shipbuilders relied on a combination of locally available materials and innovative techniques to craft vessels that could endure the test of time and the rigors of the sea.

One of the most notable examples of early wooden boat construction is the dugout canoe, a simple yet effective design created by hollowing out a single tree trunk. This technique, used by cultures from the Americas to Africa, prioritized durability by minimizing the need for complex joinery. The natural strength of hardwoods like oak or cedar provided inherent resilience, while the absence of seams reduced the risk of leaks. For added stability, some builders reinforced the hull with animal fats or plant resins, early forms of waterproofing that extended the boat's lifespan.

In contrast, the stitch-and-glue method employed by ancient Egyptians and other Mediterranean civilizations showcased a more sophisticated approach. Builders would carve wooden planks, stitch them together with natural fibers, and seal the gaps with pitch or tar. This technique allowed for larger, more complex vessels like the Khufu ship, a ceremonial boat buried alongside the Great Pyramid of Giza, which has survived over 4,500 years. The use of lightweight yet sturdy woods such as cedar, combined with meticulous craftsmanship, ensured these boats could navigate both rivers and open seas.

The clinker-built design, popularized by the Vikings, exemplifies another innovative approach to durability. By overlapping planks and fastening them with iron rivets, shipbuilders created flexible yet robust hulls capable of withstanding the stormy North Atlantic. The choice of oak for its strength and resistance to decay, coupled with the aerodynamic shape of longships, allowed these vessels to remain seaworthy for generations. Archaeological findings, such as the Gokstad ship, reveal that these boats could last for over a century with proper maintenance.

To replicate or appreciate these ancient techniques today, consider the following practical tips: use locally sourced hardwoods for smaller projects, experiment with natural sealants like pine tar or linseed oil, and study historical blueprints to understand the principles of hull design. While modern materials offer advantages, the ingenuity of early wooden boat construction remains a testament to human adaptability and the enduring relationship between craftsmanship and longevity.

Understanding Wood Stud Lengths: A Comprehensive Guide for Builders

You may want to see also

Explore related products

Lifespan of Wooden Vessels: Factors affecting longevity, including maintenance, wood type, and environmental conditions

The lifespan of wooden vessels is a testament to the interplay of craftsmanship, material choice, and environmental stewardship. A well-maintained wooden boat can endure for centuries, as evidenced by the *Viking longships* and *Chinese junks* that have survived over a millennium. However, longevity is not guaranteed; it hinges on meticulous care, the inherent qualities of the wood, and the conditions in which the vessel operates. For instance, teak, known for its natural oils and resistance to decay, can last 100 years or more, while softer woods like pine may degrade within 20–30 years without proper treatment.

Maintenance is the cornerstone of preserving wooden boats. Regular inspection for cracks, rot, and marine borer infestations is essential. Applying epoxy resins or traditional linseed oil treatments every 1–2 years can seal the wood against moisture, a primary cause of deterioration. For example, the *HMS Victory*, launched in 1765, remains intact due to continuous restoration efforts, including replacing deteriorated oak planks with matching timber. Neglect, on the other hand, accelerates decay; untreated wooden hulls exposed to saltwater can succumb to rot within 5–10 years.

Wood type plays a pivotal role in determining a vessel’s durability. Hardwoods like oak and mahogany are prized for their strength and resistance to rot, making them ideal for structural components. Lighter woods like cedar are favored for their buoyancy and ease of carving but require protective coatings to combat environmental wear. Composite constructions, combining wood with fiberglass or metal, offer enhanced longevity by mitigating wood’s susceptibility to moisture and pests. For instance, modern wooden sailboats often incorporate epoxy-saturated cores to extend their lifespan to 50–70 years.

Environmental conditions are the wildcard in a wooden boat’s longevity. Saltwater is more corrosive than freshwater, necessitating frequent maintenance for coastal vessels. Prolonged exposure to UV radiation can dry and crack wood, while extreme temperature fluctuations cause warping. Storing boats in covered, dry environments during off-seasons can add decades to their life. The *Dugout Canoes* of the Pacific Northwest, carved from cedar and used in sheltered waters, have lasted over 200 years, illustrating how environment and usage patterns influence durability.

In conclusion, the lifespan of wooden vessels is not predetermined but shaped by proactive care, material selection, and environmental management. By understanding these factors, owners can ensure their boats remain seaworthy for generations. Whether through traditional methods or modern innovations, the art of preserving wooden boats is a blend of science and craftsmanship, honoring their timeless appeal.

Auchentoshan Three Wood Aging Process: Duration and Flavor Development

You may want to see also

Explore related products

Historical Wooden Boat Examples: Notable ships like the *Mary Rose* and their operational durations

Wooden boats have sailed the world’s oceans for millennia, their lifespans varying widely based on construction, purpose, and maintenance. Among the most iconic examples is the *Mary Rose*, Henry VIII’s flagship, which served the English navy for 34 years before sinking in 1545. Built in 1510, the *Mary Rose* exemplifies the durability of wooden ships during the Tudor era, despite its tragic end. Its operational duration highlights the balance between the material’s resilience and the demands of naval warfare, offering a benchmark for understanding wooden boat longevity.

To maximize the lifespan of wooden boats like the *Mary Rose*, shipwrights employed meticulous techniques. Oak, prized for its strength and resistance to rot, was the primary material, often seasoned for years to reduce warping. Caulking with tarred hemp ensured watertight seams, while regular maintenance—such as scraping barnacles and reapplying protective coatings—was critical. For modern enthusiasts restoring wooden vessels, replicating these practices can extend a boat’s life. For instance, using epoxy resins to seal wood can add decades of usability, though purists may prefer traditional methods for historical accuracy.

Comparing the *Mary Rose* to other wooden ships reveals diverse lifespans. The *USS Constitution*, launched in 1797, remains afloat today, a testament to superior maintenance and periodic restoration. In contrast, Viking longships, designed for speed and raiding, often lasted only 10–15 years due to their lightweight construction and harsh use. These examples underscore how purpose shapes durability: warships faced constant stress, while merchant vessels like the *Cutty Sark* (operational for 26 years) prioritized cargo capacity over combat readiness. Understanding these differences helps modern builders tailor wooden boats to specific needs.

For those considering wooden boat ownership, studying historical examples provides practical insights. The *Mary Rose*’s 34-year service suggests that with proper care, wooden boats can endure decades of use. However, environmental factors like saltwater exposure and climate play significant roles. In tropical regions, where humidity accelerates wood decay, regular inspections and treatments are essential. Conversely, colder climates can preserve wood longer, as seen in Arctic exploration vessels. By learning from the past, enthusiasts can ensure their wooden boats not only survive but thrive for generations.

Perfect Timing: When to Add Wood Chips in Your Smoker

You may want to see also

Explore related products

Modern Wooden Boat Preservation: Methods to extend lifespan, including restoration and protective coatings

Wooden boats, with their timeless elegance and historical significance, often outlive their modern fiberglass counterparts when properly maintained. However, their longevity hinges on proactive preservation methods that address both structural integrity and environmental exposure. Modern techniques combine traditional craftsmanship with advanced materials to extend their lifespan, ensuring these vessels remain seaworthy and aesthetically pleasing for generations.

Restoration: Breathing New Life into Aged Hulls

Restoration begins with a thorough assessment of the boat’s condition. Inspect for rot, delamination, and structural weaknesses, particularly in areas prone to moisture accumulation, such as the keel and gunwales. Replace damaged planks with matched hardwoods, ensuring grain direction aligns with the original construction. Epoxy resins, mixed at a ratio of 2:1 (resin to hardener), can stabilize weakened wood fibers and fill voids. For larger repairs, use marine-grade plywood or laminated wood composites, which offer enhanced durability without compromising authenticity. Always sand restored surfaces to a smooth finish before applying protective coatings.

Protective Coatings: The First Line of Defense

The right protective coating is critical to shielding wooden boats from UV radiation, moisture, and biological degradation. Traditional varnishes, while visually appealing, require frequent reapplication—typically every 6–12 months. For longer-lasting protection, consider two-part polyurethane coatings, which provide a harder finish and UV resistance for up to 3 years. Alternatively, epoxy-based systems, applied in thin layers with a 24-hour curing time between coats, create a waterproof barrier that penetrates the wood. For below-waterline protection, use antifouling paints containing copper or zinc pyrithione to deter marine growth, reapplying annually in high-fouling environments.

Preventive Maintenance: A Stitch in Time Saves Nine

Regular maintenance is key to preserving a wooden boat’s lifespan. Store the vessel in a covered, well-ventilated area to minimize moisture absorption. During winter months, remove standing water and apply a breathable moisture barrier to prevent freezing and cracking. Inspect seams and fasteners biannually, tightening screws and replacing rotten caulking with silicone or cotton-based compounds. For boats in saltwater environments, flush the hull with freshwater after each use to prevent salt crystallization, which can accelerate wood degradation.

Innovative Techniques: Merging Tradition with Technology

Modern preservation increasingly incorporates innovative techniques. Vacuum bagging, for instance, ensures epoxy resins penetrate deep into the wood, creating a stronger bond. Carbon fiber reinforcements can be integrated into high-stress areas like the stem and transom, adding strength without significant weight. For historical accuracy, laser scanning and 3D printing enable precise replication of original components, preserving the boat’s authenticity while enhancing durability. These methods, though more costly upfront, offer long-term savings by reducing the need for frequent repairs.

By combining meticulous restoration, advanced protective coatings, and proactive maintenance, wooden boats can defy their age, continuing to sail gracefully for decades. Each method plays a unique role in preserving not just the vessel’s functionality, but also its cultural and historical value. With the right care, these maritime treasures can remain afloat, bridging the past and present on the open water.

Pine Wood Decay Timeline: Factors Affecting Rotting Process and Durability

You may want to see also

Explore related products

Wooden Boats vs. Modern Materials: Comparison of durability and lifespan with steel, fiberglass, and aluminum

Wooden boats, with their timeless appeal and rich history, have sailed the seas for centuries, but their durability and lifespan are often questioned in comparison to modern materials. To understand this, let's delve into the characteristics of wood and how it stacks up against steel, fiberglass, and aluminum. Wood, when properly maintained, can last for decades, even centuries. The *Viking longships*, for instance, were constructed from oak and have remnants dating back over a thousand years. However, wood is susceptible to rot, insect damage, and warping if not treated with preservatives like epoxy resins or regularly varnished. Maintenance is key—annual inspections, immediate repair of leaks, and protection from prolonged exposure to moisture are essential to extend a wooden boat's life.

Steel, a stalwart in maritime construction, offers robustness and longevity but comes with its own set of challenges. Unlike wood, steel doesn’t rot, but it corrodes, especially in saltwater environments. To combat this, steel boats require regular anti-fouling treatments and cathodic protection systems. A well-maintained steel hull can last 50–100 years, but the weight of steel limits its use in smaller vessels. For larger boats, steel’s durability makes it a preferred choice, though its maintenance demands are higher than those of wood. Fiberglass, introduced in the mid-20th century, revolutionized boating with its lightweight, low-maintenance properties. Fiberglass boats are resistant to rot and corrosion, and their lifespan typically ranges from 30–50 years. However, they are prone to osmotic blistering, where water penetrates the gel coat, causing bubbles and weakening the structure. Repairing fiberglass requires specialized skills and materials, but its overall ease of care makes it a popular choice for recreational boaters.

Aluminum boats, known for their lightweight and corrosion-resistant properties, are ideal for freshwater environments but less suited for saltwater due to galvanic corrosion. Aluminum’s lifespan averages 20–40 years, depending on usage and maintenance. Unlike wood, aluminum doesn’t require varnishing or painting for protection, but it can dent easily and may require welding for structural repairs. For those prioritizing low maintenance and durability in freshwater, aluminum is a strong contender. When comparing these materials, the choice depends on the intended use, environment, and maintenance commitment. Wooden boats offer unparalleled aesthetic appeal and historical charm but demand meticulous care. Steel provides unmatched strength but requires significant upkeep. Fiberglass balances durability and ease of maintenance, while aluminum excels in lightweight versatility.

To maximize the lifespan of any boat, regardless of material, follow these practical tips: keep the hull clean, store the boat in a dry, covered area when not in use, and address any damage promptly. For wooden boats, apply marine-grade varnish annually; for steel, inspect for rust and apply anti-corrosive coatings; for fiberglass, monitor for blistering and repair as needed; and for aluminum, avoid abrasive cleaners that can scratch the surface. By understanding the strengths and weaknesses of each material, boat owners can make informed decisions to ensure their vessel stands the test of time.

Wood Pigeon Hatching Timeline: From Egg to Chick Explained

You may want to see also

Frequently asked questions

Wooden boats were used for thousands of years, from prehistoric times until the 19th and early 20th centuries, when they were gradually replaced by steel and fiberglass vessels.

The lifespan of a wooden boat varied widely depending on maintenance, usage, and construction quality, but well-cared-for vessels could last 50 to 100 years or more.

Wooden boats were the primary vessels for long-distance voyages, including exploration and trade, until the mid-19th century, with some still in use for specific purposes into the early 20th century.