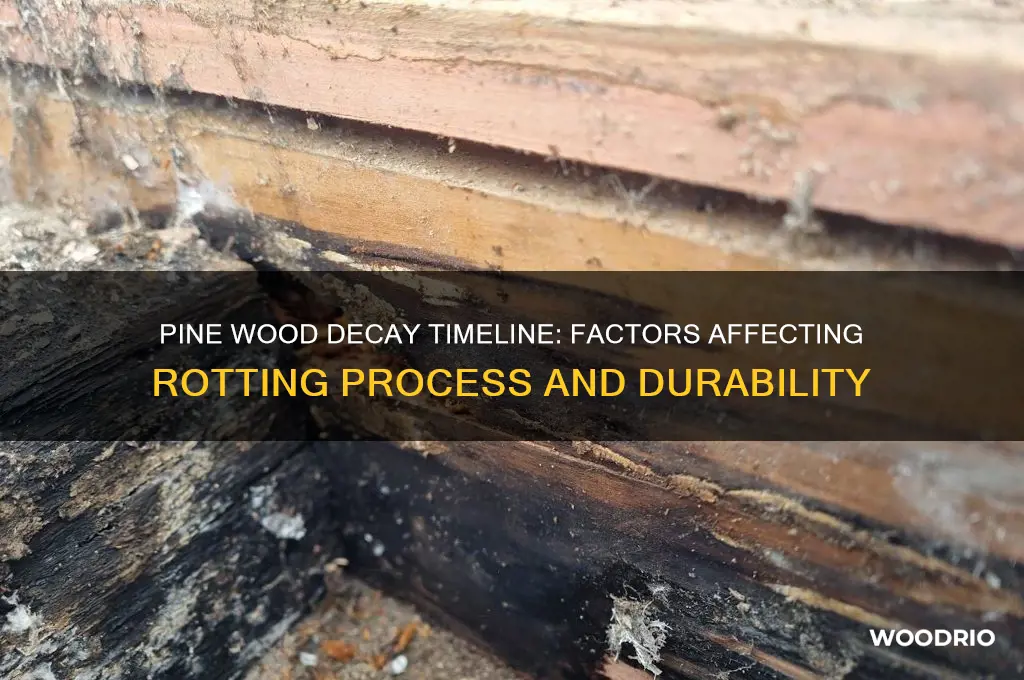

Pine wood, a popular choice for construction and outdoor projects due to its affordability and versatility, is often subject to environmental factors that influence its durability. One of the most common concerns is how long it takes for pine wood to rot, as this directly impacts its lifespan and structural integrity. The rate at which pine wood deteriorates depends on several factors, including moisture exposure, soil contact, and the presence of fungi or insects. In ideal conditions, such as a dry, well-ventilated environment, pine wood can last for decades, but in damp or humid settings, it may begin to rot within 5 to 10 years. Understanding these variables is essential for anyone using pine wood in applications where longevity is critical.

| Characteristics | Values |

|---|---|

| Rot Resistance | Pine wood is not naturally rot-resistant and is prone to decay. |

| Time to Rot (Above Ground) | 5–10 years without treatment, depending on exposure to moisture. |

| Time to Rot (In Ground) | 2–5 years without treatment, due to constant soil moisture. |

| Time to Rot (Treated Pine) | 10–40+ years, depending on the type and quality of treatment. |

| Factors Affecting Decay | Moisture, insects (e.g., termites), fungi, and soil contact. |

| Common Treatments | Pressure-treating with chemicals like CCA, ACQ, or CA-B. |

| Durability Class | Typically rated as non-durable to moderately durable (Class 4–5). |

| Optimal Conditions for Longevity | Keep dry, apply sealants, and use in above-ground applications. |

| Comparative Lifespan | Shorter than naturally rot-resistant woods like cedar or redwood. |

Explore related products

What You'll Learn

Climate Impact on Pine Rot

Pine wood's longevity is significantly influenced by climate, with moisture and temperature acting as primary catalysts for rot. In humid environments, pine can begin to decay within 5–10 years when exposed to constant dampness, such as in soil or waterlogged conditions. Conversely, in arid climates with low humidity and minimal rainfall, untreated pine can endure for 20–30 years or more, as dry air slows fungal growth and insect activity. This stark contrast underscores the role of climate in accelerating or delaying the degradation process.

To mitigate rot in pine, consider the climate-specific strategies. In wet regions, elevate pine structures using pressure-treated posts or apply water-repellent sealants to reduce moisture absorption. For example, a pine deck in a rainy Pacific Northwest climate should be sealed annually and inspected for mold or mildew. In dry areas, focus on UV protection by using stains or paints with UV inhibitors to prevent cracking and splintering, which can expose vulnerable inner layers to moisture.

Analyzing the science behind climate’s impact reveals that rot in pine is driven by fungi like *Serpula lacrymans* (dry rot) and *Coniophora puteana* (wet rot), both of which thrive in specific humidity ranges. Dry rot fungi can survive in wood with moisture content as low as 20%, while wet rot requires at least 30%. Warmer climates also accelerate decay by increasing fungal metabolic rates, meaning pine in tropical regions may rot 2–3 times faster than in temperate zones. Understanding these thresholds helps in predicting and preventing rot.

A comparative study of pine in coastal versus inland climates highlights the role of salt exposure. Coastal pine, subjected to saltwater spray, deteriorates 40–50% faster due to salt’s corrosive effect on cellulose fibers. Inland pine, protected from saline conditions but exposed to temperature extremes, may crack from freeze-thaw cycles, creating entry points for moisture and fungi. This comparison emphasizes the need for climate-tailored preservation methods, such as using salt-resistant coatings in coastal areas.

Finally, for those seeking practical takeaways, monitor local climate data to anticipate rot risks. In regions with annual rainfall over 40 inches, prioritize regular inspections and maintenance. In areas with high UV exposure, reapply protective finishes every 1–2 years. Combining climate awareness with proactive measures can extend pine’s lifespan by decades, turning a potentially short-lived material into a durable resource.

Rudolph's Woodland Life: Uncovering the Duration of His Forest Stay

You may want to see also

Explore related products

$12.96 $19.49

Moisture Levels and Decay Rate

Pine wood, like all organic materials, is susceptible to decay, and moisture is the primary catalyst in this process. The relationship between moisture levels and decay rate is not linear but rather a delicate balance that can accelerate or slow down the rotting process significantly. For instance, pine wood exposed to constant moisture, such as in waterlogged soil or areas with high humidity, can begin to show signs of decay within 5 to 10 years. Conversely, pine wood kept in dry conditions, with moisture levels below 20%, can remain structurally sound for decades, often exceeding 50 years.

To mitigate decay, controlling moisture levels is paramount. One effective method is to treat pine wood with water-repellent preservatives, which can reduce moisture absorption by up to 80%. Additionally, ensuring proper ventilation around wooden structures prevents moisture accumulation. For example, elevating wooden decks or fences at least 6 inches above ground level allows air circulation, reducing ground moisture contact. Regular inspections for leaks, cracks, or gaps in protective coatings are also crucial, as even small breaches can lead to localized moisture buildup and accelerated decay.

A comparative analysis reveals that the decay rate of pine wood increases exponentially as moisture content surpasses 20%. At 25% moisture, fungal growth becomes likely, and at 30%, decay fungi thrive, halving the wood’s lifespan. In contrast, kiln-dried pine, with moisture levels reduced to 12–15%, is significantly more resistant to decay. This highlights the importance of initial moisture management during wood processing and installation. For outdoor applications, combining kiln-dried wood with moisture barriers, such as sealants or paints, can extend durability by 2–3 times compared to untreated wood.

Practical tips for homeowners include monitoring relative humidity levels in indoor spaces, ideally keeping them below 50% to protect wooden structures. For outdoor projects, timing installations during dry seasons minimizes initial moisture exposure. Applying a breathable wood sealant annually can reduce moisture penetration by 50%, while periodic reapplication of preservatives every 2–3 years maintains long-term protection. By understanding and actively managing moisture levels, the decay rate of pine wood can be significantly slowed, preserving its structural integrity and aesthetic appeal.

Mineral Spirits Drying Time on Wood: What to Expect

You may want to see also

Explore related products

$19.99

Treated vs. Untreated Pine Lifespan

Pine wood, left untreated, typically begins to show signs of decay within 5 to 7 years when exposed to moisture and soil. This rapid deterioration is due to pine’s susceptibility to rot-causing fungi and insects. For outdoor projects like decks, fences, or garden beds, untreated pine is a short-term solution at best. However, when pine undergoes pressure treatment with preservatives like chromated copper arsenate (CCA) or alkaline copper quaternary (ACQ), its lifespan extends dramatically. Treated pine can last 20 to 40 years or more, depending on environmental conditions and maintenance. This stark contrast highlights the critical role of treatment in preserving pine’s structural integrity.

The treatment process involves forcing preservatives deep into the wood’s cellular structure, creating a barrier against moisture, fungi, and pests. For instance, ACQ-treated pine is commonly used in residential construction due to its low toxicity and effectiveness. When selecting treated pine, look for labels indicating the retention level of preservatives, measured in pounds per cubic foot (lbs/ft³). A retention of 0.25 lbs/ft³ is standard for above-ground use, while 0.40 lbs/ft³ is recommended for ground contact. Proper installation, such as ensuring treated wood is not in direct contact with soil or standing water, further maximizes its lifespan.

Untreated pine, while cost-effective upfront, requires vigilant maintenance to prolong its life. Regular sealing with water-repellent stains or paints can slow decay, but this is a temporary fix. For example, a pine fence post left untreated might last 5 years, but with annual sealing, it could survive up to 10. However, this pales in comparison to treated pine, which requires minimal upkeep. Untreated pine is best reserved for indoor projects or temporary outdoor structures where replacement is feasible.

The choice between treated and untreated pine ultimately depends on the project’s intended lifespan and exposure to elements. Treated pine is an investment that pays off in longevity, particularly for load-bearing structures like decks or retaining walls. Untreated pine, while cheaper, demands constant care and is prone to premature failure outdoors. For those prioritizing sustainability, consider that treated pine, despite its chemical preservatives, often outlasts untreated wood, reducing the need for frequent replacements and associated resource consumption.

In practice, combining treated pine for structural components with untreated pine for aesthetic or non-load-bearing elements can balance cost and durability. For example, use treated pine for deck joists and posts, while opting for untreated pine for railing caps or planters, which can be sealed and replaced as needed. This hybrid approach leverages the strengths of both materials, ensuring longevity where it matters most while maintaining flexibility for design elements. Always follow manufacturer guidelines for treated wood disposal, as some preservatives may require special handling.

Gorilla Wood Glue Drying Time: A Comprehensive Guide for Woodworkers

You may want to see also

Explore related products

Soil Type Influence on Rotting

Pine wood's decay rate is significantly influenced by the soil it rests in, with soil type acting as a critical determinant of its longevity. Clay-rich soils, for instance, tend to retain more moisture due to their dense structure, creating an environment conducive to fungal growth—a primary agent of wood rot. In contrast, sandy soils drain quickly, reducing moisture levels and slowing the rotting process. This fundamental difference highlights the importance of understanding soil composition when assessing pine wood durability.

Consider the practical implications for landscaping or construction projects. If you're installing pine wood posts in a garden, test the soil's texture by squeezing a damp sample in your hand. If it holds together firmly, it’s likely clay-heavy, and you should consider using pressure-treated wood or elevating the wood above ground to mitigate moisture exposure. For sandy soils, while natural drainage reduces rot risk, ensure proper compaction to avoid shifting that could damage structures over time.

From an analytical perspective, the pH level of the soil also plays a role. Acidic soils (pH below 6.0) accelerate pine wood decay by promoting the activity of acid-tolerant fungi, whereas alkaline soils (pH above 7.5) can inhibit fungal growth. For example, pine wood buried in the acidic soils of a coniferous forest may rot within 5–10 years, compared to 15–20 years in the more alkaline soils of a grassland. Testing soil pH with a home kit (available for $10–$20) can guide decisions on wood treatment or placement.

A comparative analysis reveals that loamy soils, which balance sand, silt, and clay, offer a middle ground. Their moderate drainage and nutrient retention create a less extreme environment for pine wood. However, even in loamy soils, factors like compaction and organic matter content can tip the scale. For instance, loam enriched with compost may retain more moisture, slightly increasing rot risk, while well-drained loam with minimal organic matter can extend pine wood life to 25–30 years.

Finally, a persuasive argument for proactive soil management is clear: investing time in soil preparation can double or triple the lifespan of pine wood structures. Elevating wood 6–8 inches above ground, using gravel bases for drainage, and applying water-repellent sealants are actionable steps that counteract soil-induced rot. For long-term projects, combining these methods with periodic inspections ensures early detection of decay, allowing for timely interventions before structural integrity is compromised.

Forming Agate Petrified Wood: Understanding the Time-Intensive Process

You may want to see also

Explore related products

Insect Damage Acceleration Factors

Pine wood, known for its versatility and affordability, is not immune to the relentless forces of decay. While moisture and fungi are often the primary culprits, insect damage plays a significant role in accelerating the rotting process. Understanding the factors that exacerbate insect-induced deterioration is crucial for anyone looking to preserve pine wood structures or furniture.

The Role of Insect Species and Life Cycles

Different insects attack pine wood at various stages of its life cycle, each contributing uniquely to decay. Termites, for instance, feed on cellulose, directly consuming the wood’s structural fibers. A mature termite colony can consume up to 15 pounds of wood in a year, significantly weakening the material. Powderpost beetles, on the other hand, lay eggs in cracks or crevices, and their larvae bore into the wood, creating tunnels that reduce its density. A single beetle infestation can reduce wood strength by up to 30% within 2–3 years. Carpenter ants, while not consuming wood, excavate galleries that increase moisture penetration, creating ideal conditions for fungal decay. Identifying the specific insect species is the first step in mitigating damage, as each requires targeted control measures.

Environmental Conditions That Amplify Insect Activity

Insects thrive in specific environmental conditions, and these factors directly influence the rate of wood decay. High humidity levels (above 50%) and temperatures between 75°F and 95°F create optimal breeding grounds for termites and beetles. Storing pine wood in damp, poorly ventilated areas can double the speed of insect infestation. Additionally, wood in direct contact with soil is 50% more likely to attract termites, as they build mud tubes to access it. To minimize risk, elevate wood structures at least 6 inches above ground and ensure proper ventilation to reduce moisture accumulation.

Preventive Measures and Treatment Options

Proactive measures can significantly slow insect-induced rot. Applying borate-based wood preservatives, such as sodium borate at a concentration of 10–15%, can deter termites and beetles by disrupting their metabolic processes. Pressure-treating pine wood with chromated copper arsenate (CCA) increases its resistance to insects and fungi, extending its lifespan by up to 40 years. For existing infestations, localized treatments like injecting termiticide foam (e.g., fipronil at 0.04%) into affected areas can eliminate colonies within 3 months. Regular inspections, particularly in older structures, are essential to catch infestations early, as untreated damage can render wood irreparable within 5 years.

Comparative Analysis: Treated vs. Untreated Pine

Untreated pine wood in insect-prone environments typically begins to show signs of decay within 2–5 years, while treated wood can last 15–20 years or more. For example, a study comparing untreated pine fence posts to those treated with CCA found that untreated posts exhibited structural failure after 3 years, whereas treated posts remained intact after 12 years. The initial cost of treatment (approximately $0.50–$1.00 per square foot) is offset by the reduced need for replacements and repairs. This highlights the importance of investing in preventive measures, especially in high-risk areas like coastal regions or humid climates.

Practical Tips for Long-Term Preservation

To maximize the lifespan of pine wood, combine multiple strategies. Seal all cracks and crevices with wood filler to prevent beetles from laying eggs. Use insect-repellent paints or stains containing permethrin, which provides up to 5 years of protection. For outdoor structures, install physical barriers like stainless steel mesh (0.5 mm openings) around the foundation to block termite entry. Finally, monitor wood moisture levels using a moisture meter, aiming to keep levels below 19% to discourage both insects and fungi. By addressing insect damage acceleration factors systematically, you can preserve pine wood’s integrity for decades.

Wooden Warship Durability: Factors Affecting Their Lifespan and Preservation

You may want to see also

Frequently asked questions

Pine wood typically begins to rot within 5 to 10 years when left untreated and exposed to moisture, soil, and insects.

Treated pine wood rots much slower than untreated pine, often lasting 20 to 40 years or more, depending on the type and quality of treatment.

Moisture, soil contact, insect activity, temperature, and exposure to sunlight are the primary factors that accelerate pine wood rot.

Yes, pine wood rot can be prevented or slowed by using pressure-treated wood, applying sealants or preservatives, keeping it dry, and elevating it off the ground.