Wood engraving, a meticulous and detailed craft, involves carving intricate designs or patterns into a wooden surface using specialized tools. When considering the duration of a project like wood engrave 24, the time required can vary significantly depending on several factors, including the complexity of the design, the type of wood, the skill level of the engraver, and the tools being used. A simple design on a softwood might take only a few hours, while a highly detailed, large-scale engraving on hardwood could span several days or even weeks. The term 24 could refer to the size of the piece (e.g., 24 inches), the number of items being engraved, or a specific time constraint, each influencing the overall timeline. Understanding these variables is crucial for planning and executing a successful wood engraving project.

| Characteristics | Values |

|---|---|

| Engraving Time for 24" Wood | Varies significantly based on factors below |

| Machine Type | Laser: 15 minutes - 2 hours CNC Router: 30 minutes - 4 hours Hand Engraving: 2-6 hours |

| Wood Type | Hardwoods (Oak, Maple): Slower Softwoods (Pine, Cedar): Faster |

| Design Complexity | Simple Text: Faster Detailed Images: Slower |

| Depth of Engraving | Shallow: Faster Deep: Slower |

| Machine Power/Speed | Higher Power/Speed: Faster |

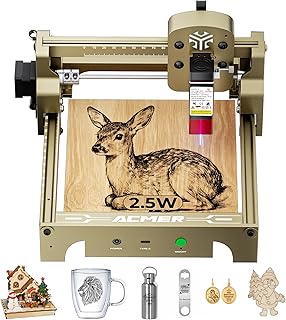

Explore related products

$13.38 $26.99

What You'll Learn

- Laser Power Settings: Optimal wattage for engraving wood in 24 hours

- Wood Type Impact: How different woods affect engraving duration

- Design Complexity: Time variations based on intricate vs. simple designs

- Machine Speed: Engraving speed settings for 24-hour projects

- Maintenance Tips: Keeping the engraver efficient for long-duration tasks

Laser Power Settings: Optimal wattage for engraving wood in 24 hours

Engraving wood with a laser requires precise control over power settings to achieve the desired depth and detail within a 24-hour timeframe. The optimal wattage depends on the wood type, thickness, and the intricacy of the design. For softwoods like pine or cedar, a 10W to 20W laser typically suffices, allowing for faster engraving speeds while maintaining clarity. Harder woods such as oak or walnut demand higher power, often requiring 30W to 50W lasers to penetrate effectively without compromising precision. Always test on a scrap piece to calibrate settings before starting the final project.

Balancing speed and quality is critical when engraving wood within 24 hours. Higher wattage lasers can reduce engraving time significantly but risk burning or charring the wood if not properly controlled. For instance, a 40W laser can engrave a 12" x 12" design on medium-density hardwood in approximately 4 hours, while a 15W laser might take 8 hours for the same result. To maximize efficiency, adjust the laser’s speed and power in tandem—higher power allows for faster movement without sacrificing depth. Use a cooling system or air assist to minimize heat buildup, especially during extended sessions.

The intricacy of the design also influences optimal wattage. Fine details and tight patterns require lower power settings to avoid over-engraving or blurring. For example, a 20W laser set at 10% power can delicately etch intricate patterns on balsa wood, while a 50W laser at 30% power is better suited for bold, deep engravings on walnut. Layering passes can achieve depth without increasing wattage, ensuring the wood remains intact. Always prioritize precision over speed for complex designs to maintain the integrity of the artwork.

Practical tips can further optimize engraving within 24 hours. Pre-treat the wood by sanding it to a smooth finish to ensure even laser absorption. Use masking tape or a sacrificial layer to protect the surface from smoke residue. For large projects, divide the design into sections and engrave sequentially, allowing the laser to cool between segments. Monitor the process closely, especially during the first few hours, to adjust settings as needed. By combining the right wattage with these techniques, you can achieve professional-quality engravings efficiently within the desired timeframe.

Wood Shrimp Lifespan: Understanding Their Survival in Captivity and the Wild

You may want to see also

Explore related products

Wood Type Impact: How different woods affect engraving duration

The density and hardness of wood significantly influence engraving duration, with softer woods like pine or cedar allowing for faster engraving times compared to harder woods such as oak or walnut. For instance, engraving a 24-inch design on a pine plank might take approximately 30-45 minutes, whereas the same design on walnut could extend to 1.5-2 hours due to the increased resistance of the wood fibers. Understanding these material properties is crucial for planning projects and optimizing time efficiency.

Analyzing the grain pattern of different woods reveals another layer of complexity in engraving duration. Woods with open, porous grains like ash or mahogany may require slower engraving speeds to maintain precision, as the laser can catch on uneven surfaces. In contrast, fine-grained woods like maple or cherry allow for faster, smoother engraving but may necessitate higher laser power settings to achieve the same depth. A practical tip is to test engraving speeds on scrap pieces of the chosen wood to find the optimal balance between speed and quality.

From a persuasive standpoint, selecting the right wood type can not only save time but also enhance the final product’s aesthetic appeal. Softer woods are ideal for intricate designs where speed is a priority, while harder woods are better suited for bold, deep engravings that require durability. For a 24-inch project, consider the trade-off between the desired outcome and the time investment—a walnut piece may take longer but will yield a more striking, long-lasting result compared to a quicker pine engraving.

Comparatively, exotic woods like teak or ebony present unique challenges due to their density and natural oils, which can affect laser absorption and engraving speed. Engraving a 24-inch design on ebony, for example, might require reducing the laser speed by 20-30% and increasing power by 10-15% to achieve consistent results. These adjustments highlight the importance of tailoring settings to the wood type, ensuring both efficiency and quality in the final engraving.

Instructively, to minimize engraving duration while maintaining quality, follow these steps: first, choose a wood type aligned with your project’s complexity and desired finish. Second, adjust laser settings based on the wood’s hardness and grain—softer woods can handle higher speeds, while harder woods require slower, more powerful passes. Finally, always perform a test run on a small section of the wood to fine-tune settings before committing to the full 24-inch design. This methodical approach ensures optimal results without unnecessary delays.

Mastering Wood Sublimation: Optimal Time for Durable, Vibrant Results

You may want to see also

Explore related products

Design Complexity: Time variations based on intricate vs. simple designs

Engraving time on wood scales dramatically with design complexity. A minimalist logo with clean lines and sparse detail might take as little as 15 minutes to engrave on a 24-inch plank, while an intricate landscape with fine shading and textured elements could demand 2-3 hours or more. This disparity highlights the direct correlation between design intricacy and production time, a critical factor for both hobbyists and professionals managing project timelines.

Consider the laser engraver's path: simple designs require fewer passes, allowing the machine to move swiftly and efficiently. Complex designs, however, necessitate multiple layers, intricate details, and potentially slower speeds to achieve precision. For instance, a basic monogram might involve a single pass at 100 inches per minute, while a detailed portrait could require 5-10 passes at 50 inches per minute, significantly extending the engraving duration.

Tip: When designing for time efficiency, prioritize bold, simplified shapes and minimize fine details.

Material thickness also plays a role. Engraving deeper into the wood for a 3D effect or cutting through the material entirely will naturally take longer than surface-level engraving. A 24-inch plank with a 1/8-inch depth might take twice as long to engrave a complex design compared to a 1/4-inch plank, as the laser needs to make more passes to achieve the desired depth.

Caution: Be mindful of the wood's grain direction. Engraving against the grain can cause splintering and require slower speeds, further increasing time.

Ultimately, understanding the relationship between design complexity and engraving time empowers you to make informed decisions. For time-sensitive projects, opt for simpler designs and shallower engraving depths. When time is less of a constraint, embrace intricate details and explore the full potential of wood engraving, knowing the process will be more time-consuming but yield stunning results.

Mastering Preheat Times for Your Wood Pellet Grill: A Guide

You may want to see also

Explore related products

Machine Speed: Engraving speed settings for 24-hour projects

Engraving wood within a 24-hour timeframe demands precise control over machine speed to balance efficiency and quality. Faster speeds reduce project duration but risk burning or rough edges, while slower speeds ensure precision at the cost of time. The optimal setting hinges on wood type, laser power, and desired depth, requiring a calibrated approach to meet deadlines without compromising results.

Step 1: Assess Material and Design Complexity

Softwoods like pine or cedar tolerate higher speeds (800–1200 mm/min) due to their lower density, while hardwoods such as oak or walnut require slower speeds (400–800 mm/min) to prevent charring. Factor in design intricacy: fine details necessitate reduced speeds (300–500 mm/min) to maintain sharpness, whereas simpler patterns allow for faster execution. Use a test piece to determine the threshold where speed and quality intersect.

Caution: Avoid Overheating

Pushing speed beyond material limits generates excessive heat, leading to scorched surfaces or uneven engraving. For 24-hour projects, prioritize consistent passes over aggressive speed settings. If using a 40W laser, cap speeds at 600 mm/min for hardwoods and 1000 mm/min for softwoods to balance time and thermal control. Monitor progress hourly to adjust settings if signs of burning appear.

Pro Tip: Layered Engraving for Efficiency

Break complex designs into layers, assigning faster speeds to rough passes and slower speeds to final detailing. For instance, start at 800 mm/min for initial depth, then reduce to 400 mm/min for precision. This hybrid approach saves time while preserving quality, ideal for tight deadlines. Ensure your software supports layered workflows to streamline execution.

No universal speed setting exists for 24-hour wood engraving projects. Success relies on iterative testing, material-specific adjustments, and strategic layering. Start with conservative speeds, gradually increasing until the optimal balance is found. By prioritizing adaptability over speed, you’ll deliver polished results within the timeframe, turning constraints into opportunities for innovation.

Cedar Wood Deck Lifespan: Durability, Maintenance, and Longevity Explained

You may want to see also

Explore related products

Maintenance Tips: Keeping the engraver efficient for long-duration tasks

Engraving wood for extended periods, such as a 24-hour project, pushes your engraver to its limits. Overheating, material buildup, and mechanical wear become significant risks. To ensure consistent performance, prioritize a maintenance routine that addresses these challenges directly.

Step 1: Coolant Management

Laser engravers generate intense heat, especially during prolonged use. Apply a coolant mist system or pause every 4–6 hours to allow the machine to cool naturally. For CNC routers, ensure the spindle’s cooling system is functioning optimally; replace coolant every 12 hours if using a liquid-based system. Overlooking this step risks warping the wood or damaging the engraver’s internal components.

Step 2: Debris Removal Protocol

Wood dust and charred residue accumulate rapidly during long tasks, clogging nozzles and reducing precision. Use a compressed air canister to clear debris from the engraving head and work area every 2 hours. For deeper cleaning, disassemble the nozzle assembly daily and soak it in isopropyl alcohol to dissolve stubborn buildup. Neglecting this step leads to uneven engraving depth and increased friction.

Step 3: Mechanical Inspection Checklist

Vibrations and continuous motion strain moving parts. Inspect belts, bearings, and guide rails for wear daily. Tighten loose screws and lubricate moving components with a silicone-based lubricant (avoid oil-based products, which attract dust). Replace worn parts immediately—a single faulty bearing can derail an entire project.

Step 4: Material Preparation Strategies

Inconsistent wood density or moisture content can strain the engraver. Pre-treat wood by sanding surfaces and sealing edges with a clear coat to minimize splintering. For laser engravers, ensure the wood’s moisture level is below 12% to prevent excessive smoke. Proper material prep reduces the engraver’s workload, extending its lifespan.

By integrating these maintenance practices, you’ll not only sustain efficiency during a 24-hour engraving task but also prolong the engraver’s overall functionality. Each step addresses a specific stressor, ensuring the machine operates at peak performance without compromising quality.

Oven Cleaner on Wood: Safe Soaking Time and Tips

You may want to see also

Frequently asked questions

"Wood engrave 24" likely refers to engraving wood for 24 hours or using a 24-watt laser engraver on wood. The exact meaning depends on the context.

Engraving wood for 24 hours straight is the duration itself. The time taken depends on the complexity of the design, laser power, and wood type.

Yes, a 24-watt laser engraver can engrave wood, but the depth and speed depend on the wood type and engraving settings.

The time varies based on the design complexity, wood density, and desired depth. Simple designs may take minutes, while intricate ones can take hours.