When working with wood glue, clamping time is a critical factor in ensuring a strong and durable bond. The duration for which wood glue needs to be clamped depends on several factors, including the type of glue used, the wood species, and the environmental conditions such as temperature and humidity. Typically, most wood glues require clamping for at least 30 minutes to an hour to achieve an initial bond, but for maximum strength, it is recommended to leave the clamps in place for 24 hours or longer. PVA (polyvinyl acetate) glues, which are the most common type used in woodworking, generally cure fully within 24 hours, though some manufacturers suggest waiting up to 48 hours for optimal results. Always refer to the specific instructions provided by the glue manufacturer to ensure the best outcome for your project.

| Characteristics | Values |

|---|---|

| Clamp Time (Initial) | 30 minutes to 1 hour (varies by glue type and humidity) |

| Full Cure Time | 24 hours (PVA wood glue) to 72 hours (epoxy or specialized glues) |

| Clamp Pressure | 100-200 psi (pounds per square inch) for optimal bonding |

| Optimal Temperature | 60°F to 80°F (15°C to 27°C) for best glue performance |

| Humidity Impact | High humidity shortens clamp time; low humidity prolongs it |

| Glue Types | PVA (white/yellow glue), epoxy, polyurethane, hide glue |

| Wood Moisture Content | 6%-12% for best results; avoid gluing wet or overly dry wood |

| Clamp Removal | Safe to remove after initial clamp time, but full strength after cure |

| Joint Strength | Stronger than wood itself when fully cured |

| Gap Filling | PVA glue fills gaps up to 0.005 inches (0.13 mm) |

| Shelf Life of Glue | 1-2 years (unopened); 6 months (opened, stored properly) |

| Environmental Factors | Avoid extreme temperatures and direct sunlight during curing |

| Sandability | Excess glue can be sanded after fully cured |

| Finish Compatibility | Most wood glues are compatible with paints, stains, and finishes |

| Toxicity | PVA glues are non-toxic; epoxy and polyurethane may require ventilation |

Explore related products

What You'll Learn

- Clamp Time Factors: Wood type, glue brand, humidity, and joint size affect clamping duration

- Minimum Clamping Time: Most wood glues require at least 30 minutes to 1 hour

- Maximum Clamping Time: Clamps can stay on for 24 hours for optimal bond strength

- Quick-Setting Glues: Some glues allow clamp removal in 10-15 minutes for small joints

- Over-Clamping Risks: Leaving clamps too long can cause wood distortion or glue squeeze-out

Clamp Time Factors: Wood type, glue brand, humidity, and joint size affect clamping duration

Wood type significantly influences how long you need to clamp your glue joints. Dense hardwoods like maple or oak absorb moisture more slowly than softwoods like pine, which means glue dries faster in softwoods. For example, a pine joint might only require 30 minutes of clamping, while oak could need up to 2 hours. Always check the glue manufacturer’s recommendations for specific wood types, as some glues bond more effectively with certain woods. If you’re unsure, test a small piece first to gauge drying time.

Glue brand and formulation play a critical role in clamping duration. Polyvinyl acetate (PVA) glues, like Titebond II, typically cure in 30 minutes to 1 hour under ideal conditions, but epoxy glues can take 8–24 hours. Cyanoacrylate (super glue) sets in seconds but lacks the strength for structural joints. Always read the label for curing times, and factor in additional time for larger joints or humid conditions. Pro tip: Apply glue thinly and evenly to avoid prolonging drying time unnecessarily.

Humidity levels can either speed up or slow down glue curing. High humidity (above 60%) accelerates the drying of water-based glues like PVA, but it can also weaken the bond by causing the wood to swell. Conversely, low humidity (below 30%) slows drying and may require extended clamping. Ideal conditions are around 50% humidity and 70°F (21°C). If you’re working in a humid environment, use a dehumidifier; in dry conditions, a humidifier can help maintain optimal moisture levels.

Joint size and complexity directly impact clamping time. Small, edge-glued joints may only need 30–60 minutes, while large panels or intricate dovetail joints could require 2–4 hours or more. The rule of thumb is to clamp for at least twice the glue’s initial cure time for larger joints. For example, if a glue cures in 30 minutes, clamp a large joint for at least 1 hour. Always err on the side of caution—removing clamps too early can weaken the bond permanently.

In summary, clamping duration isn’t one-size-fits-all. Consider wood type, glue brand, humidity, and joint size to determine the right time. Test small samples, follow manufacturer guidelines, and adjust for environmental conditions. Patience pays off—a properly clamped joint ensures strength and longevity in your woodworking projects.

Treated Wood Lifespan: Factors Affecting Rot and Decay Resistance

You may want to see also

Explore related products

Minimum Clamping Time: Most wood glues require at least 30 minutes to 1 hour

Wood glue manufacturers often recommend a minimum clamping time of 30 minutes to 1 hour, but this is just the starting point. The actual clamping duration depends on factors like glue type, wood species, joint design, and environmental conditions. For instance, polyvinyl acetate (PVA) glues, the most common type, typically cure sufficiently within this timeframe for light handling, but full strength may take up to 24 hours. Epoxy resins, on the other hand, may require 2–4 hours of clamping but offer superior strength and moisture resistance. Understanding these nuances ensures your joints are both secure and durable.

To maximize bond strength, follow a systematic approach during the clamping process. Apply glue evenly to both surfaces, ensuring full coverage without excess. Assemble the joint quickly to prevent premature drying, then apply clamps with consistent pressure—aim for 100–200 psi for most PVA glues. For larger or critical joints, use multiple clamps to distribute pressure evenly. Avoid over-tightening, as this can squeeze out too much glue or distort the wood. After the initial 30–60 minutes, the joint should be stable enough for light handling, but leave clamps in place for at least 8–12 hours to ensure a robust bond.

While 30 minutes to 1 hour is the standard minimum, environmental factors can significantly impact curing time. High humidity accelerates drying for water-based glues like PVA, but extreme heat can cause rapid surface drying, trapping moisture inside and weakening the bond. Conversely, cold temperatures slow curing, potentially extending clamping time to 2–3 hours or more. For optimal results, work in a controlled environment—ideally between 60°F and 80°F (15°C–27°C) with moderate humidity. If conditions are less than ideal, err on the side of longer clamping times to ensure the glue cures fully.

A common mistake is removing clamps too soon, assuming the joint is secure after the initial 30–60 minutes. While the glue may feel set, it’s still gaining strength. Premature removal can lead to joint failure under stress. For critical projects, such as furniture or structural components, leave clamps in place for the full curing period recommended by the manufacturer—often 24 hours for PVA glues. If time is a constraint, consider using a fast-setting glue, but be aware that these may sacrifice some long-term strength. Patience during clamping pays off in the form of a bond that lasts for years.

Durability of Wood Posts: Lifespan and Maintenance Tips Revealed

You may want to see also

Explore related products

Maximum Clamping Time: Clamps can stay on for 24 hours for optimal bond strength

Clamping time is a critical factor in achieving a strong, durable bond with wood glue. While it might be tempting to remove clamps as soon as the glue feels dry to the touch, rushing this process can compromise the joint's integrity. The 24-hour clamping recommendation isn't arbitrary; it's rooted in the chemical curing process of most wood glues.

Many wood glues, particularly PVA (polyvinyl acetate) types, achieve their maximum strength through a process called cross-linking. This involves the glue's molecules forming a network of bonds with each other and the wood fibers. This cross-linking takes time, and applying sustained pressure through clamping ensures the glue remains in intimate contact with the wood surface, maximizing the number of bonds formed.

Think of it like baking a cake. You wouldn't remove it from the oven the moment it looks done; you'd follow the recommended baking time to ensure it's cooked through. Similarly, the 24-hour clamping period allows the glue to fully cure, resulting in a bond that's as strong as the wood itself.

Shortening the clamping time can lead to weaker joints. The glue may appear dry on the surface, but internally, the cross-linking process might be incomplete. This can result in a bond that's more susceptible to stress, moisture, and temperature changes, potentially leading to joint failure over time.

While 24 hours is the gold standard, some factors can influence clamping time. Thicker glue lines may require slightly longer clamping times to ensure complete curing. Humidity levels can also play a role, with higher humidity potentially accelerating curing. However, it's always best to err on the side of caution and maintain the full 24-hour clamping period unless the glue manufacturer specifies otherwise.

Remember, patience is key when it comes to wood glue. By allowing the full 24-hour clamping time, you're investing in the long-term strength and durability of your woodworking project. This small investment of time will pay dividends in the form of a sturdy, reliable joint that will stand the test of time.

Curing Your Wood-Fired Oven: Time, Tips, and Techniques for Perfection

You may want to see also

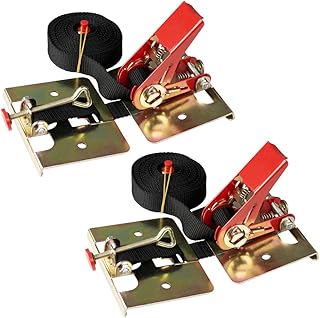

Explore related products

$17.99 $19.99

Quick-Setting Glues: Some glues allow clamp removal in 10-15 minutes for small joints

For woodworkers seeking efficiency without compromising strength, quick-setting wood glues are a game-changer. These formulations, often labeled as "fast-drying" or "rapid-set," allow clamps to be removed in as little as 10-15 minutes for small joints. This accelerated curing time is achieved through specialized additives that catalyze the bonding process, reducing the typical wait time from hours to mere minutes. Ideal for projects with tight deadlines or when working with smaller, less complex joints, these glues ensure productivity without sacrificing bond integrity.

Selecting the right quick-setting glue requires attention to detail. Look for products specifically designed for woodworking, as they balance speed with the flexibility needed for wood’s natural movement. Apply a thin, even layer to both surfaces, ensuring full coverage without excess. For optimal results, use a clamping pressure of 100-150 psi, which promotes even adhesion without squeezing out excessive glue. Always follow the manufacturer’s instructions, as curing times can vary slightly between brands and environmental conditions.

While quick-setting glues offer convenience, they demand precision. Once applied, the glue begins to set rapidly, leaving little room for adjustments. Ensure your joint alignment is perfect before clamping, as repositioning after the initial bond forms can weaken the connection. Additionally, avoid using these glues for large or load-bearing joints, where slower-curing options provide better penetration and long-term stability. Quick-setting glues excel in small-scale applications, such as edge gluing, miter joints, or light repairs.

A practical tip for maximizing the efficiency of quick-setting glues is to prepare your workspace in advance. Have all pieces pre-cut, sanded, and aligned before applying the glue. Keep a damp cloth nearby to wipe away any excess immediately, as quick-setting glues can be difficult to remove once cured. For added precision, use a glue applicator bottle or roller to control the amount dispensed, minimizing waste and ensuring a clean finish. With these strategies, quick-setting glues become a reliable tool for streamlining your woodworking projects.

Durability of Oak Wood: Outdoor Lifespan and Preservation Tips

You may want to see also

Explore related products

Over-Clamping Risks: Leaving clamps too long can cause wood distortion or glue squeeze-out

Clamping time is a delicate balance in woodworking, and over-clamping can lead to unintended consequences. When clamps are left on glued joints for too long, the pressure can cause the wood to distort, particularly in softer or more porous species. This distortion may manifest as bowing, twisting, or even crushing of the wood fibers, compromising the integrity of the joint and the overall appearance of the piece. For instance, a study by the Forest Products Laboratory found that clamping pressure exceeding 250 psi can lead to permanent deformation in pine, a commonly used softwood.

To avoid over-clamping, it's essential to understand the recommended clamping times for different types of wood glue. PVA (polyvinyl acetate) glues, the most common type used in woodworking, typically require 30 minutes to 1 hour of clamping time for initial set, followed by 24 hours of curing time. However, this can vary depending on factors such as humidity, temperature, and the specific glue formulation. For example, Titebond III, a popular PVA glue, recommends a minimum of 30 minutes of clamping time, while Gorilla Wood Glue suggests 1-2 hours. Exceeding these times can increase the risk of distortion, especially if excessive pressure is applied.

A comparative analysis of clamping techniques reveals that the risk of over-clamping is higher when using high-pressure clamps, such as F-clamps or C-clamps, compared to lower-pressure options like bar clamps or strap clamps. To mitigate this risk, consider using a clamp pressure gauge to monitor the force applied, aiming for a range of 100-200 psi for most woodworking applications. Additionally, distributing the clamping pressure evenly across the joint using cauls or pads can help prevent localized distortion. For delicate or thin pieces, consider using a reduced clamping time, such as 15-30 minutes, followed by a longer curing period without clamps.

In practice, a step-by-step approach can help minimize over-clamping risks. First, apply a thin, even coat of glue to both joint surfaces, using a small brush or roller to ensure complete coverage. Next, assemble the joint and apply clamps, starting with a moderate pressure and gradually increasing it to the desired level. After the recommended clamping time has elapsed, remove the clamps and inspect the joint for any signs of distortion or glue squeeze-out. If excess glue is present, carefully remove it with a damp cloth or scraper before it fully cures. Finally, allow the joint to cure completely, following the glue manufacturer's recommendations, before subjecting it to stress or load.

A descriptive example illustrates the potential consequences of over-clamping. Imagine a scenario where a woodworker is gluing up a tabletop using high-pressure F-clamps. Despite the glue's recommended 30-minute clamping time, the worker leaves the clamps on for 2 hours, assuming that extra pressure will create a stronger joint. Upon removing the clamps, they notice that the tabletop has bowed slightly, with the wood fibers crushed in areas where the clamps were applied. This distortion not only affects the table's appearance but also compromises its structural integrity, requiring additional work to correct or, worse, rendering the piece unusable. By understanding the risks of over-clamping and following best practices, woodworkers can avoid such costly mistakes and achieve strong, durable joints.

Maximizing Wood Lathe Carbide Tool Lifespan: Durability and Maintenance Tips

You may want to see also

Frequently asked questions

Clamping time typically ranges from 30 minutes to 2 hours, depending on the type of wood glue used. Always refer to the manufacturer’s instructions for specific drying times.

No, removing clamps too early can result in weak joints or misalignment. It’s best to wait the full recommended time to ensure the glue sets properly.

Wood glue usually reaches full strength within 24 hours, though some types may take up to 48 hours. Avoid stressing the joint until the glue is fully cured.