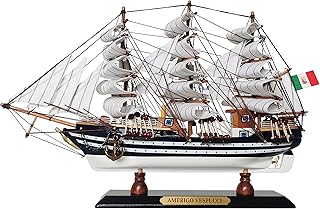

The longevity of a wooden ship is a fascinating subject that intertwines craftsmanship, environmental factors, and maintenance practices. Typically, a well-constructed wooden vessel could last anywhere from 20 to 100 years, depending on its usage, the quality of materials, and how diligently it is cared for. Ships built with durable hardwoods like oak and teak, combined with regular maintenance to combat rot, pests, and seawater damage, tend to endure longer. Historical examples, such as the USS Constitution, have survived centuries due to meticulous preservation efforts. However, without proper care, exposure to harsh marine conditions can significantly shorten a wooden ship's lifespan, making its durability a testament to both human ingenuity and the relentless forces of nature.

Explore related products

What You'll Learn

- Wood Type & Durability: Different woods decay at varying rates; hardwoods like oak last longer than softwoods

- Environmental Factors: Saltwater, humidity, and temperature accelerate wood degradation compared to freshwater or dry climates

- Maintenance Practices: Regular care, such as sealing and repairs, significantly extends a wooden ship’s lifespan

- Marine Borers & Pests: Shipworms and termites can rapidly destroy untreated wood, shortening the ship’s life

- Usage Intensity: Frequent use and exposure to harsh conditions wear down wooden ships faster than occasional use

Wood Type & Durability: Different woods decay at varying rates; hardwoods like oak last longer than softwoods

The lifespan of a wooden ship hinges significantly on the type of wood used in its construction. Not all woods are created equal when it comes to durability, and this disparity plays a pivotal role in determining how long a vessel can withstand the relentless forces of nature. Hardwoods, such as oak, have long been favored for shipbuilding due to their inherent strength and resistance to decay. These dense woods contain natural oils and tannins that act as preservatives, slowing the onset of rot and insect damage. In contrast, softwoods like pine, while lighter and easier to work with, lack these protective compounds and are more susceptible to deterioration, especially in harsh marine environments.

Consider the iconic Viking longships, primarily constructed from oak, which have been unearthed in remarkably preserved states after centuries buried in the earth. Oak’s longevity is not merely anecdotal; it is rooted in its cellular structure. The tight grain and high lignin content of oak create a formidable barrier against water infiltration and fungal growth. For instance, oak can last upwards of 100 years in shipbuilding applications, provided it is properly maintained. Softwoods, on the other hand, typically degrade within 20 to 40 years, even under ideal conditions. This stark difference underscores the importance of wood selection in determining a ship’s durability.

However, durability is not solely a matter of wood type; environmental factors and maintenance practices also play critical roles. Hardwoods like teak, another favorite in shipbuilding, thrive in tropical climates due to their natural resistance to termites and fungi. Yet, even teak requires regular treatment with preservatives to maintain its integrity in saltwater. Softwoods, while less durable, can be treated with modern chemicals like creosote or copper-based compounds to extend their lifespan. For example, pressure-treating pine with chromated copper arsenate (CCA) can increase its resistance to decay, though this method is less sustainable and environmentally friendly compared to using naturally durable hardwoods.

The choice between hardwood and softwood ultimately depends on the intended use of the ship and the resources available. For long-haul voyages or ships exposed to harsh conditions, hardwoods are the clear choice despite their higher cost and weight. Softwoods, however, remain a viable option for smaller, short-lived vessels or those operating in less demanding environments. Builders must weigh factors like availability, cost, and environmental impact when selecting wood, ensuring that the material aligns with the ship’s expected lifespan and operational demands.

In practice, shipbuilders can maximize durability by combining wood types strategically. For instance, using oak for the keel and framing, where strength and longevity are paramount, while employing lighter softwoods for the decking or interior components. Regular inspections and maintenance, such as re-caulking seams and applying protective coatings, are equally essential. By understanding the unique properties of different woods and adapting construction techniques accordingly, builders can significantly extend the life of wooden ships, preserving both their functionality and historical value for generations to come.

Wet Wood Warping Timeline: Factors Affecting Drying and Distortion

You may want to see also

Explore related products

Environmental Factors: Saltwater, humidity, and temperature accelerate wood degradation compared to freshwater or dry climates

Saltwater is a relentless adversary for wooden ships, acting as a catalyst for decay that freshwater cannot match. The high salinity of seawater draws moisture from the wood, causing it to swell and contract as it dries, a process that weakens the cellular structure over time. This cycle of absorption and desiccation is further exacerbated by the presence of marine borers, such as shipworms, which thrive in saltwater environments and tunnel through the wood, compromising its integrity. For instance, untreated oak submerged in saltwater can show signs of significant degradation within 5 to 10 years, compared to decades in freshwater. To mitigate this, shipbuilders often use naturally resistant woods like teak or apply protective coatings, though these measures only delay the inevitable.

Humidity plays a dual role in wood degradation, particularly in tropical climates where wooden ships are exposed to high moisture levels both in the air and water. Prolonged exposure to humidity encourages the growth of fungi and mold, which break down cellulose and lignin, the primary components of wood. A relative humidity above 70% creates ideal conditions for fungal growth, accelerating decay exponentially. In contrast, dry climates inhibit these biological agents, preserving wood for longer periods. Practical steps to combat humidity include ensuring proper ventilation in storage areas and using dehumidifiers, though these are less feasible for ships at sea. The Vasa, a Swedish warship that sank in 1628, survived centuries in the cold, low-oxygen waters of Stockholm harbor, a testament to how reduced humidity and biological activity can preserve wood.

Temperature fluctuations act as a silent but potent force in wood degradation, particularly when combined with saltwater and humidity. Extreme heat can cause wood to dry out and crack, while cold temperatures slow biological activity but increase the risk of frost damage. For example, wooden ships in temperate climates with moderate temperature variations may last 20–30 years with regular maintenance, whereas those in tropical regions with constant high temperatures and humidity may degrade in half that time. To counteract temperature effects, shipbuilders often incorporate thermal insulation or choose woods with natural resilience to temperature changes, such as cedar or mahogany. However, no measure can entirely halt the cumulative impact of environmental stressors.

The interplay of saltwater, humidity, and temperature creates a perfect storm for wood degradation, making it critical to understand their combined effects. For instance, a wooden ship in the Caribbean, where temperatures average 80°F (27°C) and humidity hovers around 80%, will face far more rapid decay than one in the Mediterranean, with its drier summers and cooler winters. Shipowners can extend the lifespan of wooden vessels by monitoring these factors and implementing targeted interventions, such as regular inspections for marine borers, antifouling treatments, and controlled storage conditions during periods of disuse. While no wooden ship is immortal, strategic management of environmental factors can significantly delay its inevitable decline.

Aquarium Wood Sinking Time: Factors Affecting How Long It Takes to Submerge

You may want to see also

Explore related products

$12.99

Maintenance Practices: Regular care, such as sealing and repairs, significantly extends a wooden ship’s lifespan

Wooden ships, when left unattended, can succumb to the elements within a decade or two, but with diligent maintenance, their lifespan can stretch into centuries. The key lies in understanding that wood, though resilient, is inherently vulnerable to water, sunlight, and biological decay. Regular care, particularly sealing and timely repairs, acts as a shield against these threats, preserving the vessel's structural integrity and aesthetic appeal.

Sealing: The First Line of Defense

Sealing is not a one-time task but a recurring necessity. Every 1–2 years, depending on exposure to water and weather, wooden ships require a fresh coat of marine-grade sealant. Epoxy resins or traditional linseed oil treatments penetrate the wood, creating a barrier against moisture infiltration. For areas prone to wear, such as the hull and deck, consider applying a thicker epoxy coating, followed by a UV-resistant varnish to combat sun damage. Neglecting this step allows water to seep into the wood, leading to rot, swelling, and eventual structural failure.

Repairs: Addressing Issues Before They Escalate

Small cracks, splintered planks, or loose fasteners are not mere cosmetic flaws—they are precursors to larger problems. Inspect the ship quarterly, focusing on high-stress areas like the keel and gunwales. Use marine-grade adhesives and screws to mend minor damage, ensuring replacements match the original wood type for compatibility. For more extensive repairs, consult a shipwright to avoid compromising the vessel’s historical or structural authenticity. A stitch in time not only saves nine but also decades of the ship’s life.

Preventive Measures: Beyond Sealing and Repairs

Maintenance extends beyond reactive fixes. Regular cleaning with mild, pH-neutral solutions prevents the buildup of salt, algae, and barnacles, which can corrode wood and attract pests. Store the ship in a covered area or use breathable tarpaulins to minimize exposure to rain and UV rays. For ships in water, periodic antifouling treatments reduce hull degradation. Additionally, monitor humidity levels in storage areas; wood thrives in environments with 40–60% humidity, so dehumidifiers or proper ventilation are essential.

The Long-Term Payoff

The Vasa, a 17th-century Swedish warship, lay submerged for 333 years before its recovery, yet its oak hull remained remarkably intact due to the anaerobic conditions of the seabed. While such preservation is rare, it underscores wood’s durability when shielded from decay. Modern maintenance practices emulate this principle, ensuring wooden ships endure not just decades, but generations. By investing time and resources into sealing, repairs, and preventive care, owners transform their vessels from temporary artifacts into enduring legacies.

Sausalito to Muir Woods Shuttle Ride: Duration and Tips

You may want to see also

Explore related products

$37.85 $39.85

$36.85 $38.85

Marine Borers & Pests: Shipworms and termites can rapidly destroy untreated wood, shortening the ship’s life

The lifespan of a wooden ship is dramatically shortened by marine borers and pests, particularly shipworms and termites, which can turn a sturdy vessel into a fragile shell within years. Shipworms, not worms but bivalve mollusks, secrete acids to bore into wood, creating tunnels that compromise structural integrity. Termites, though less common in marine environments, can infest ships docked in tropical regions, feeding on cellulose and accelerating decay. Without treatment, these pests can render a ship unsafe in as little as 5 to 10 years, compared to the potential 50+ years of a well-maintained, treated vessel.

To combat these threats, historical and modern shipbuilders employ specific strategies. Creosote, a tar-based preservative, was widely used in the 19th century to repel shipworms, though its toxicity limits modern application. Today, eco-friendly alternatives like copper-based antifouling paints and synthetic preservatives are preferred. For termites, regular inspections and localized treatments with borate solutions can prevent infestations. Shipowners must also consider environmental factors: warm, shallow waters accelerate borer activity, while dry-docking reduces exposure but increases termite risk.

A comparative analysis reveals the stark difference between treated and untreated wood. Untreated oak, a common shipbuilding material, can last 20–30 years in ideal conditions but deteriorates within a decade when exposed to shipworms. In contrast, treated wood, such as that used in the *USS Constitution*, has survived over 200 years due to regular maintenance and preservative applications. This highlights the critical role of proactive measures in extending a ship’s life.

For those maintaining wooden ships, a step-by-step approach is essential. First, inspect hulls annually for borer holes or termite damage, focusing on submerged areas. Second, apply antifouling coatings every 1–2 years, ensuring full coverage. Third, store ships in cooler, deeper waters when possible to minimize borer activity. Finally, consult marine biologists or preservation experts for tailored treatment plans. Neglecting these steps risks not only the ship’s longevity but also the safety of its crew and cargo.

The takeaway is clear: marine borers and pests are silent but relentless enemies of wooden ships. Their impact is preventable, however, with the right knowledge and action. By understanding their behavior and employing targeted treatments, shipowners can safeguard their vessels for decades, preserving both history and functionality in the face of nature’s relentless assault.

Minwax Wood Filler Durability: Outdoor Lifespan and Longevity Explained

You may want to see also

Explore related products

Usage Intensity: Frequent use and exposure to harsh conditions wear down wooden ships faster than occasional use

Wooden ships, like any vessel, are subject to the relentless forces of nature and human activity. The lifespan of these maritime marvels is significantly influenced by how often they sail and the environments they navigate. A ship that embarks on daily voyages through turbulent seas will inevitably age faster than one that remains docked or undertakes infrequent, gentle journeys. This principle of usage intensity is a critical factor in understanding the longevity of wooden ships.

The Wear and Tear of Frequent Voyages

Imagine a wooden ship, its hull gleaming with fresh varnish, setting sail daily into the open ocean. Each journey exposes it to a barrage of elements: the relentless pounding of waves, the corrosive embrace of saltwater, and the scorching rays of the sun. Over time, the constant flexing of the hull with every wave can lead to structural fatigue, causing cracks and leaks. Saltwater, a formidable adversary, seeps into the wood, accelerating decay and weakening the ship's integrity. The sun's UV rays, though less obvious, contribute to the deterioration by drying out the wood, making it brittle and more susceptible to damage. A ship subjected to such conditions daily will require more frequent repairs and maintenance, and its overall lifespan will be considerably shorter.

Comparing the Fates of Two Sister Ships

Consider the fictional tale of two identical wooden ships, *Sea Spray* and *Harbor's Rest*. *Sea Spray* is a workhorse, ferrying goods and passengers across a busy trade route, enduring rough seas and unpredictable weather. In contrast, *Harbor's Rest* leads a more leisurely life, offering occasional coastal tours and spending most of its days moored in a protected bay. After a decade, the differences are stark. *Sea Spray*, despite regular maintenance, shows signs of advanced wear: its hull is patched with numerous repairs, the mast has been replaced twice, and the deck planks are warped and weathered. *Harbor's Rest*, on the other hand, retains much of its original splendor, with only minor touch-ups needed to maintain its pristine condition. This comparison illustrates how usage intensity can dramatically diverge the paths of even the most similar vessels.

Practical Tips for Prolonging Wooden Ship Lifespan

To maximize the life of a wooden ship, especially one in frequent use, a proactive approach is essential. Here are some practical strategies:

- Regular Maintenance: Implement a rigorous inspection and maintenance schedule. After each voyage, check for signs of wear, especially in high-stress areas like the keel and hull joints. Address issues promptly to prevent them from worsening.

- Protective Coatings: Apply high-quality marine varnish or paint to create a barrier against water and UV damage. Reapply these coatings at recommended intervals, typically every 1-2 years, depending on exposure.

- Moisture Management: Ensure proper ventilation below deck to prevent moisture buildup, which can lead to rot. Use dehumidifiers if necessary, especially in humid climates.

- Strategic Routing: When possible, plan routes to avoid known harsh conditions, such as areas prone to heavy storms or extreme temperatures.

- Crew Training: Educate the crew on the importance of gentle handling and the impact of their actions on the ship's longevity. Simple measures like securing cargo properly can reduce stress on the ship's structure.

The Balancing Act: Use vs. Preservation

While it's clear that frequent use accelerates the aging process of wooden ships, it's essential to strike a balance between utilization and preservation. A ship is, after all, meant to sail. By understanding the specific demands of different usage patterns, owners and captains can make informed decisions to extend the ship's life. This might involve accepting a shorter operational lifespan for a heavily used vessel or implementing more aggressive maintenance protocols. Ultimately, the key to longevity lies in recognizing the unique challenges posed by usage intensity and adapting strategies to meet them head-on.

Toro Crianza's Wood Aging: Duration and Flavor Development Explained

You may want to see also

Frequently asked questions

In ideal conditions, such as being preserved in a dry, controlled environment, a wooden ship could last for centuries. Examples like the ancient Egyptian Khufu ship, buried for over 4,500 years, demonstrate the potential longevity of wooden vessels when protected from decay.

A wooden ship actively used at sea typically lasts 20 to 50 years, depending on maintenance, construction quality, and exposure to harsh conditions like saltwater, storms, and marine organisms that accelerate decay.

The lifespan of a wooden ship is determined by factors such as the type of wood used, construction techniques, exposure to water and weather, maintenance practices, and protection against pests like shipworms and fungi.

While a wooden ship cannot last indefinitely, proper preservation techniques, such as regular maintenance, treatment with preservatives, and storage in controlled environments, can significantly extend its lifespan, potentially preserving it for hundreds of years.