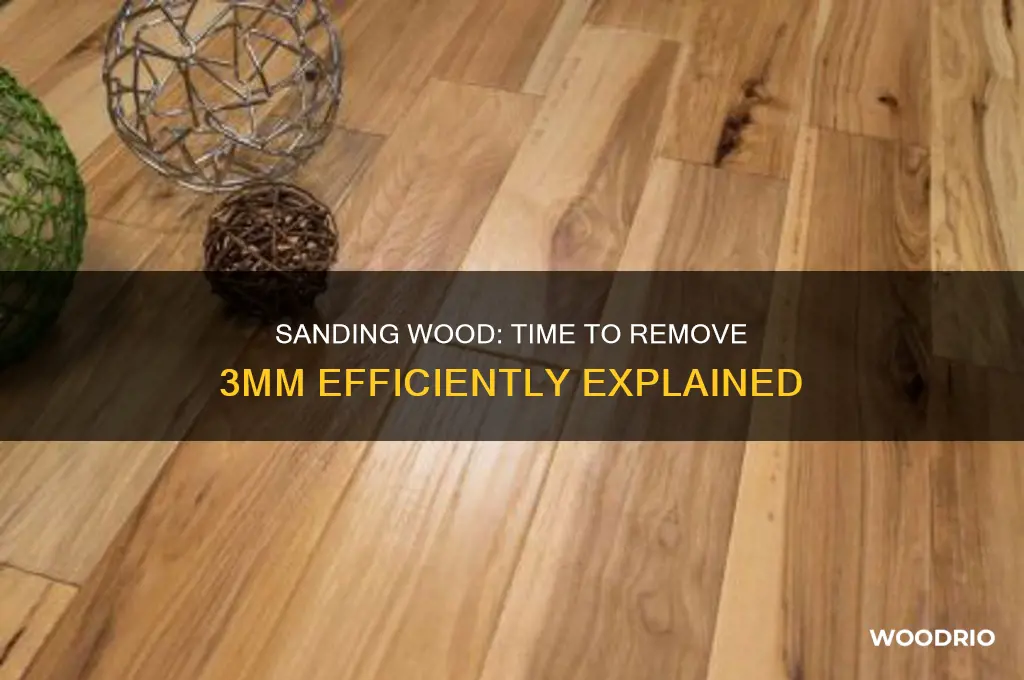

Sanding 3mm off wood is a task that requires careful consideration of the tools, techniques, and materials involved, as the time needed can vary significantly depending on factors such as the type of wood, the sanding equipment used, and the desired finish. Softwoods like pine may yield more quickly to sanding, while hardwoods like oak or maple can be more resistant, demanding more time and effort. The choice of sanding tool, whether it's a belt sander, orbital sander, or hand sanding, also plays a crucial role, with power tools generally speeding up the process but requiring more precision to avoid uneven results. Additionally, the grit of the sandpaper and the pressure applied will influence the sanding rate, making it essential to balance efficiency with the need for a smooth, consistent surface. As a rough estimate, sanding 3mm off a small wooden board with a power sander might take anywhere from 15 minutes to an hour, whereas larger projects or hand sanding could extend the time to several hours or even days.

| Characteristics | Values |

|---|---|

| Time to Sand 3mm Off Wood | Varies significantly based on tools, wood type, and technique |

| Hand Sanding (80-grit) | ~1-2 hours per square foot (slowest method) |

| Power Sander (Belt Sander) | ~15-30 minutes per square foot (fastest method) |

| Orbital Sander | ~30-60 minutes per square foot (moderate speed) |

| Wood Hardness | Softer woods (pine) sand faster; harder woods (oak) take longer |

| Grit Progression | Starting with coarse grit (40-80) and progressing to finer grits |

| Dust Extraction | Improves efficiency and reduces clogging, saving time |

| Surface Area | Larger areas take proportionally more time |

| Material Thickness | Thicker wood may require more passes to remove 3mm |

| User Experience | Experienced users work faster than beginners |

| Tool Quality | Higher-quality tools (e.g., industrial sanders) reduce time |

| Estimated Total Time | 1-4 hours for a small project (1-2 sq. ft) with a power sander |

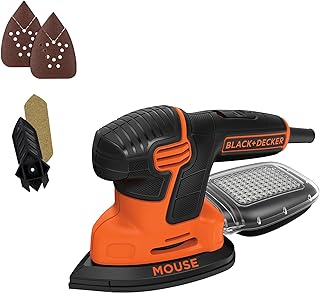

Explore related products

$32 $37.99

What You'll Learn

- Tool Selection: Impact of sander type (belt, orbital, hand) on sanding speed and efficiency

- Wood Hardness: How density and grain affect sanding time for different wood types

- Grit Progression: Optimal grit sequence (coarse to fine) for efficient material removal

- Technique & Pressure: Proper sanding methods to balance speed and surface quality

- Workpiece Size: How the wood’s dimensions influence total sanding time required

Tool Selection: Impact of sander type (belt, orbital, hand) on sanding speed and efficiency

The choice of sander significantly influences how long it takes to remove 3mm of wood, with belt, orbital, and hand sanders each offering distinct advantages and limitations. Belt sanders, powered by a continuous loop of abrasive material, are the most aggressive option. Their high material removal rate makes them ideal for rapid stock removal, but this comes at the cost of precision. A 3" x 21" belt sander with 40-grit paper can remove 3mm from softwood in as little as 10-15 minutes over a 1m² area, though this time increases for hardwoods or larger surfaces. However, the risk of over-sanding or creating uneven surfaces is higher, requiring careful technique.

Orbital sanders, in contrast, operate with a circular or elliptical motion, providing a balance between speed and control. They are less aggressive than belt sanders but more efficient than hand sanding. A 5" random orbital sander with 60-grit paper can remove 3mm from softwood in approximately 30-45 minutes over the same area, depending on wood density and operator skill. This method is less likely to cause gouges, making it suitable for projects requiring a smoother finish. However, the slower material removal rate demands patience, especially for thicker or harder woods.

Hand sanding, while the slowest method, offers unparalleled precision and is often necessary for delicate or intricate work. Using a sanding block with 80-grit paper, removing 3mm from softwood could take 2-3 hours for a 1m² area, with hardwoods extending this time significantly. This approach is best reserved for final touches or areas where power tools are impractical. Despite its inefficiency for large-scale material removal, hand sanding ensures minimal risk of damage, making it indispensable in certain scenarios.

Selecting the right tool depends on the project’s requirements. For rough stock removal, a belt sander’s speed justifies its potential drawbacks. For a balance of speed and finish quality, an orbital sander is often the best choice. Hand sanding, though time-consuming, remains essential for precision work. Understanding these trade-offs allows woodworkers to estimate time accurately and achieve desired results efficiently. Always start with a coarser grit and progress to finer grits to minimize effort and maximize surface quality.

Elmer's Wood Filler Drying Time: Quick Guide for DIY Enthusiasts

You may want to see also

Explore related products

Wood Hardness: How density and grain affect sanding time for different wood types

Wood hardness is a critical factor in determining how long it takes to sand 3mm off a surface, but it’s not just about density—grain pattern plays an equally pivotal role. Hardwoods like maple or oak, with their dense cellular structure, resist abrasion more than softwoods like pine or cedar. However, a straight, uniform grain in hardwoods can sometimes sand faster than an interlocking or wavy grain in softer woods, which tends to tear and splinter under pressure. This interplay between density and grain means sanding time can vary dramatically even within the same wood category.

Consider the sanding process as a battle between tool and material. For dense woods with tight grains, such as hickory or teak, coarse-grit sandpaper (40–60 grit) is essential to break through the surface, but progress will be slow—expect to spend 30–60 minutes per square meter to remove 1mm. In contrast, softwoods with open grains, like balsa or spruce, may yield to the same grit in half the time but risk over-sanding or gouging if pressure isn’t carefully controlled. The key is matching the sanding approach to the wood’s natural resistance, not just its hardness rating on the Janka scale.

Grain direction is another unsung variable. Sanding with the grain minimizes friction and reduces clogging of the abrasive, but cross-grain sanding—often unavoidable in complex shapes—can double or triple the time required. For example, sanding 3mm off a quarter-sawn oak tabletop might take 2–3 hours with a belt sander, while the same task on a flat-sawn pine board could be completed in under an hour. Always test a small area to gauge how the grain reacts before committing to a full sanding regimen.

Practical tips can streamline the process. For dense, fine-grained woods like walnut or cherry, alternate between orbital and belt sanding to balance speed and precision. Use a dust extraction system to prevent buildup, which slows progress and dulls abrasives. For softwoods with problematic grains, apply a grain-raising technique (lightly dampen the surface, let it dry, then sand again) to smooth out fibers before final passes. Remember, the goal isn’t just to remove material but to do so efficiently without compromising the wood’s integrity.

In conclusion, sanding 3mm off wood is a task where understanding the interplay of density and grain can save hours of labor. Hardwoods demand patience and aggressive grits, while softwoods require finesse to avoid damage. By tailoring your approach to the wood’s unique characteristics, you can predict and control sanding time more effectively, turning a potentially grueling task into a manageable—even rewarding—process.

Sealing Salt-Treated Wood: Optimal Waiting Time for Lasting Protection

You may want to see also

Explore related products

Grit Progression: Optimal grit sequence (coarse to fine) for efficient material removal

Sanding 3mm off wood is a task that demands precision, patience, and the right grit progression. The key to efficiency lies in selecting the optimal sequence of sandpaper grits, moving systematically from coarse to fine. Starting with a grit that’s too fine will waste time, while jumping grit sizes too quickly risks leaving scratches that are harder to remove. A well-planned grit progression not only speeds up material removal but also ensures a smoother, more professional finish.

Step-by-Step Grit Progression: Begin with a coarse grit, such as 40 or 60, to aggressively remove the bulk of the material. This stage is about efficiency, not finesse. Use a belt sander or orbital sander for larger surfaces, applying even pressure and moving in the direction of the wood grain. Once the 3mm depth is nearly achieved, switch to a medium grit like 120 to smooth out the coarse scratches. This step balances material removal with surface refinement. Finally, progress to a fine grit (220 or higher) to eliminate any remaining imperfections and prepare the wood for finishing. Each grit change should reduce the visibility of the previous scratches, gradually refining the surface.

Cautions and Considerations: Avoid skipping grit sizes, as this can leave deeper scratches that finer grits struggle to remove. For example, jumping from 60 grit to 220 grit will likely result in visible lines that mar the final finish. Additionally, monitor the condition of your sandpaper; clogged or worn grit loses effectiveness, slowing progress. For hardwoods, which are denser, consider starting with a slightly finer grit (e.g., 60 instead of 40) to avoid over-aggressive material removal. Softwoods, being less dense, may tolerate coarser grits but require gentler handling in finer stages.

Time Estimates and Practical Tips: The time required to sand 3mm off wood varies based on factors like wood type, tool power, and surface area. As a rule of thumb, coarse grits remove material faster but leave deeper scratches, while fine grits work slower but produce a smoother finish. For a 1m² area, expect to spend approximately 15–20 minutes per grit stage with a belt sander, or 30–40 minutes with an orbital sander. To save time, focus on consistent, overlapping strokes and avoid pressing too hard, which can burn the wood or wear out the sandpaper prematurely.

Soaking Wood Dowels in Fungi: Optimal Time for Effective Results

You may want to see also

Explore related products

Technique & Pressure: Proper sanding methods to balance speed and surface quality

Sanding 3mm off wood is a task that demands precision, patience, and the right technique. The time it takes varies widely—from hours to days—depending on the wood type, tool choice, and your approach. However, the real challenge lies in balancing speed with surface quality. Aggressive sanding might save time but risks uneven surfaces or damage, while overly cautious methods can drag out the process unnecessarily. The key? Mastering technique and pressure to achieve efficiency without sacrificing finish.

Technique Matters: The Path to Efficiency

Start with a coarse grit (e.g., 40-60) to remove material quickly, but avoid the temptation to press hard. Let the tool do the work, moving in consistent, overlapping strokes along the grain. This prevents gouging and ensures even material removal. Progress through grits (80, 120, 180, etc.) systematically, spending less time on finer grits to refine the surface. Orbital sanders are ideal for flat surfaces, while belt sanders tackle larger areas faster but require a lighter touch to avoid scorching or uneven wear. Hand sanding with a block gives control for delicate areas, though it’s slower. Each tool has its role—choose based on the surface and your tolerance for imperfections.

Pressure Control: The Fine Line Between Speed and Quality

Applying too much pressure accelerates material removal but increases the risk of heat buildup, which can darken wood or leave burn marks. Too little pressure slows progress and may leave scratches from inadequate grit action. Aim for consistent, moderate pressure, adjusting based on the tool and grit. For example, a belt sander requires a lighter touch than a hand-held block. Test on a scrap piece to find the sweet spot where the tool removes material efficiently without compromising the surface. Remember, pressure isn’t just about force—it’s about consistency and awareness of the wood’s response.

Practical Tips for Balancing Speed and Quality

Keep the sander moving at all times to avoid dwell marks. For large projects, divide the surface into sections, focusing on one area at a time to maintain control. Use a dust extractor to keep the surface visible and prevent grit clogging, which reduces efficiency. Periodically check progress with a straightedge or your hand to detect low spots or inconsistencies early. If time is critical, prioritize coarse grit work for bulk removal, then spend more time on finer grits to ensure a smooth finish. Finally, stay patient—rushing the final stages can undo hours of careful work.

The Takeaway: Time as a Byproduct of Skill

Sanding 3mm off wood isn’t a race against the clock but a test of technique and attention to detail. By mastering tool selection, grit progression, and pressure control, you’ll find the process becomes faster naturally. The goal isn’t to minimize time but to maximize efficiency without sacrificing quality. A well-executed sanding job not only saves rework but also ensures the wood is ready for finishing, whether staining, painting, or sealing. In the end, the time invested reflects the craftsmanship of the result.

Bamboo vs. Wood: Which Material Offers Superior Durability and Longevity?

You may want to see also

Explore related products

Workpiece Size: How the wood’s dimensions influence total sanding time required

The larger the wood's surface area, the longer it will take to sand 3mm off its surface. This relationship is directly proportional: double the surface area, and you'll likely double the sanding time, assuming consistent sanding pressure and grit. For instance, sanding 3mm off a 1m² wooden panel will take significantly longer than sanding the same depth off a 0.5m² panel using the same sanding tool and technique.

Consider a practical example: removing 3mm from a 2m x 1m wooden board (2m²) versus a 1m x 1m board (1m²). If it takes 2 hours to sand the smaller board, expect around 4 hours for the larger one, given the same sanding conditions. However, this linear relationship assumes uniform sanding efficiency across the entire surface, which may not always be the case due to factors like tool reach and operator fatigue.

When planning your sanding project, break down the workpiece into manageable sections. For example, divide a large tabletop into quadrants and estimate sanding time per section. This approach not only makes the task less daunting but also allows for more accurate time management. Remember, sanding time increases not just with surface area but also with the wood's length and width, as these dimensions dictate the number of passes required with your sander.

Thicker or wider wood pieces may require additional considerations. For instance, a 3mm removal from a 50mm thick beam might necessitate coarser grits initially, followed by finer grits for smoothing, whereas a thinner piece might allow for a more streamlined sanding process. Always account for the wood's overall dimensions and the sanding tool's efficiency across those dimensions to estimate total time accurately.

Finally, don’t overlook the impact of edge work. Sanding the edges of a larger workpiece adds to the total time, as these areas often require hand sanding or detail tools, which are slower than power sanders. For a 2m x 1m board, sanding the perimeter (6 linear meters) could add 30–60 minutes, depending on the tool and grit used. Factor in these details for a comprehensive time estimate.

Durability of Wooden Gravel Boards: Lifespan and Maintenance Tips

You may want to see also

Frequently asked questions

The time varies based on the wood type, sander power, and grit, but it typically takes 15–30 minutes for a small area (e.g., 1x1 meter) with a heavy-duty belt sander.

Yes, but it’s labor-intensive and time-consuming. Expect it to take several hours to a full day for a small surface, depending on the wood hardness and your effort.

Wood hardness, sander type, grit size, surface area, and operator skill all impact the time required.

Yes, a planer is significantly faster and more efficient for removing material, often completing the task in minutes compared to sanding.

Use a powerful belt sander, start with coarse grit (e.g., 40-60), work in consistent passes, and ensure the wood is securely clamped to avoid wasted effort.