Bending a long piece of wood is a valuable skill in woodworking and crafting, allowing artisans to create curved shapes for furniture, boat building, or decorative elements. The process involves careful preparation, including selecting the right type of wood, such as green or steamed wood, which is more pliable. Techniques like kerfing, laminating, or using a bending form are commonly employed, depending on the desired curve and the wood's thickness. Proper moisture control and gradual application of force are essential to prevent cracking or splitting, ensuring the wood retains its integrity and shape after bending. With the right tools and techniques, bending wood opens up a world of creative possibilities for both beginners and experienced craftsmen.

| Characteristics | Values |

|---|---|

| Method | Steaming, Kerfing, Laminating, Bent Lamination, Heat Bending (with a heat gun or oven) |

| Wood Type | Green wood (freshly cut), thin strips, flexible species (e.g., oak, ash, cherry, walnut) |

| Tools Required | Steam box, bending forms, clamps, heat gun, oven, saw, chisels, glue |

| Preparation | Soak wood in water (for steaming), cut kerfs (for kerfing), glue thin strips (for lamination) |

| Bending Process | Apply heat or steam to soften wood fibers, gradually bend around a form, secure with clamps |

| Cooling/Drying | Allow wood to cool and dry completely while clamped to retain shape |

| Safety | Wear protective gear (gloves, goggles), ensure proper ventilation when steaming or heating |

| Applications | Furniture making, boat building, musical instruments, decorative pieces |

| Difficulty | Moderate to high, depending on method and wood type |

| Cost | Varies; steaming and kerfing are cost-effective, while laminating may require more materials |

| Time | Hours to days, depending on method and drying time |

| Strength | Bended wood retains strength if properly dried and cured |

| Aesthetic | Creates smooth, curved shapes with natural wood grain patterns |

Explore related products

What You'll Learn

Selecting the Right Wood Type

Wood species vary dramatically in their bending potential, a characteristic rooted in their cellular structure and moisture response. Dense hardwoods like oak or maple, prized for strength, resist bending due to their rigid fibers. Conversely, softwoods like pine or cedar, with looser grain patterns, offer more flexibility but may lack durability for certain applications. Tropical woods such as rattan or bamboo excel in bendability due to their natural growth patterns, making them ideal for curved furniture or architectural elements. Understanding these inherent properties is the first step in selecting wood that will cooperate with your bending technique rather than fight it.

The key to successful wood bending lies in the material’s ability to absorb moisture without splintering. Wood with tight, even grain—such as cherry, walnut, or steamed beech—tends to bend uniformly when properly prepared. Steaming, a common method for softening wood fibers, works best on species with low resin content, as resins can impede moisture penetration. For instance, white oak, despite its hardness, bends well when steamed due to its porous structure. In contrast, woods like teak or mahogany, though beautiful, may crack under pressure due to their density and oil content. Always cross-reference the wood’s moisture compatibility with your chosen bending method to avoid costly mistakes.

If you’re working on a project requiring sharp curves or intricate shapes, consider wood thickness and grain orientation. Thinner strips of wood, regardless of species, bend more easily than thicker pieces. For example, ¼-inch thick strips of ash or hickory can be coaxed into tight radii with minimal force, while 1-inch boards of the same wood may require prolonged steaming and significant mechanical pressure. Additionally, bending wood along the grain (tangential bending) is far more forgiving than bending across it (radial bending). Selecting wood with straight, consistent grain reduces the risk of splitting, ensuring a smoother final product.

For beginners, start with readily bendable woods like white oak, ash, or elm, which offer a balance of flexibility and strength. Avoid exotic or highly figured woods until you’ve mastered the technique, as their unpredictable grain patterns can lead to frustration. If sustainability is a priority, look for fast-growing species like poplar or basswood, which bend adequately when green (freshly cut) and are eco-friendly choices. Always source wood from reputable suppliers to ensure it’s properly dried and free of defects that could compromise bending performance.

Finally, consider the end-use of your bent wood piece when selecting the species. Structural applications, such as boat frames or chair legs, demand woods with high strength-to-weight ratios, like hickory or oak. Decorative elements, however, might prioritize aesthetic qualities over durability, making softer woods like cedar or pine acceptable choices. By aligning wood selection with both bending feasibility and functional requirements, you’ll achieve results that are not only visually striking but also structurally sound.

Resanding Wet Wood: Optimal Timing for Smooth, Flawless Results

You may want to see also

Explore related products

Preparing Wood for Bending

Wood bending is both art and science, requiring careful preparation to ensure the material cooperates rather than cracks. The first critical step is selecting the right wood species. Hardwoods like oak or maple are notoriously difficult to bend due to their density, while softwoods such as pine or cedar lack the necessary strength for structural applications. Instead, opt for woods like white oak, ash, or walnut, which strike a balance between flexibility and durability. For smaller projects, consider steam-bending-friendly species like cherry or birch, which respond well to moisture and heat.

Once the wood is chosen, moisture content becomes the next focal point. Dry wood is brittle and prone to splitting, while overly wet wood loses its structural integrity. Aim for a moisture content of 12–15%, which can be measured using a moisture meter. If the wood is too dry, soak it in water or apply a damp cloth for several hours, ensuring even absorption. Conversely, if it’s too wet, air-dry it gradually to avoid warping. This step is non-negotiable for steam bending, where precise moisture levels are essential for success.

The thickness and width of the wood also play a pivotal role in its bendability. Thinner strips bend more easily than thicker ones, so plane or resaw the wood to the desired thickness, typically 1/4 to 1/2 inch for most projects. Wider pieces can be bent along their length but require more force and heat. For complex curves, consider laminating thinner strips together, a technique often used in furniture making. Always sand the wood smooth before bending to prevent stress concentrations that could lead to cracks.

Finally, consider the grain orientation, a factor often overlooked by beginners. Wood bends most easily along the grain, so align the piece accordingly. If bending around a form, ensure the grain runs parallel to the curve for maximum flexibility. Cross-grain bending is possible but requires extreme care and often results in weaker joints. For added insurance, apply a compressive force along the grain using clamps or weights before applying heat or steam. This pre-stressing technique reduces the risk of splitting and ensures a smoother bend.

In summary, preparing wood for bending is a meticulous process that demands attention to species selection, moisture control, dimensional adjustments, and grain orientation. Each step builds on the last, creating a foundation for successful bending. Whether crafting a chair leg or a boat hull, the right preparation transforms rigid wood into a pliable material, opening up a world of creative possibilities.

Seasoning Wood Indoors: Understanding the Timeframe for Optimal Results

You may want to see also

Explore related products

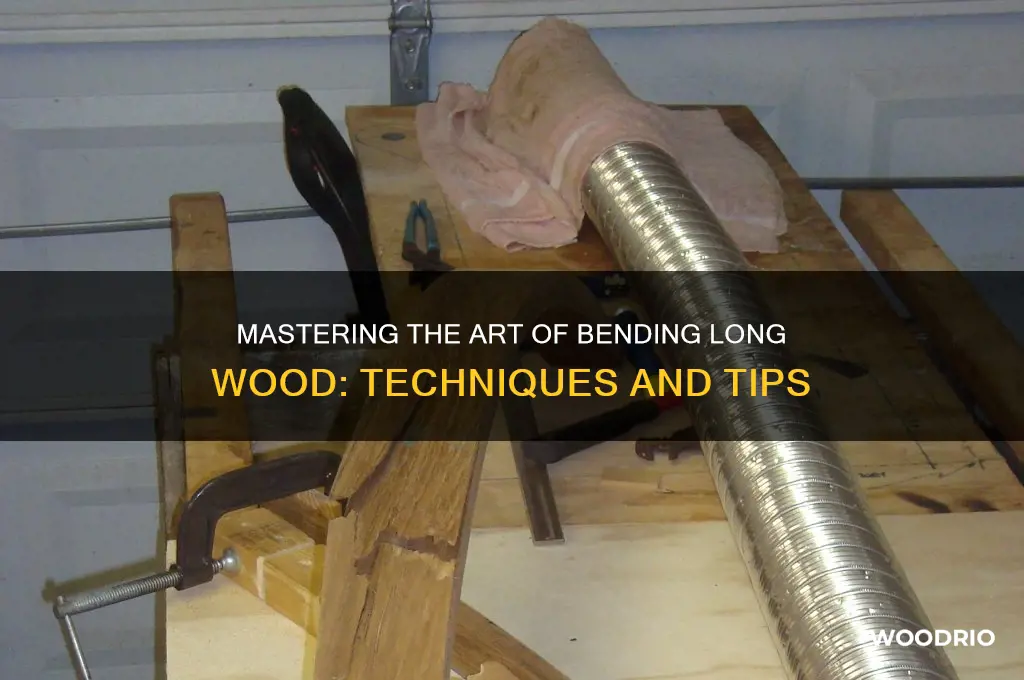

Steam Bending Techniques

Steam bending is a traditional woodworking technique that allows artisans to shape wood into curved forms by making it more pliable through the application of heat and moisture. This method has been used for centuries to create everything from furniture and boat parts to musical instruments. The process involves exposing the wood to steam, which softens the lignin—a natural polymer in wood—allowing it to bend without breaking. Unlike dry bending, which is limited to thinner or greener wood, steam bending can handle thicker, drier pieces, making it a versatile choice for complex projects.

To begin steam bending, you’ll need a steam box, which can be homemade or purchased. The steam box should be long enough to accommodate the wood piece and sealed to retain heat and moisture. For optimal results, the wood should be heated to a temperature of 180–212°F (82–100°C) for 30 minutes to 2 hours, depending on its thickness. Hardwoods like oak or maple typically require longer steaming times compared to softer woods like pine or cedar. Always use a thermometer to monitor the temperature and ensure even heating. Once the wood is sufficiently steamed, it becomes flexible and can be bent around a form or mold.

One critical aspect of steam bending is timing. After removing the wood from the steam box, you have a limited window—usually 1–2 minutes—to bend it before it begins to cool and harden. Work quickly but carefully, as the wood can still crack if forced too abruptly. Clamps or weights can be used to hold the wood in place as it cools, ensuring it retains the desired shape. It’s also essential to apply pressure evenly to avoid stress points that could weaken the final piece.

While steam bending is effective, it’s not without challenges. Oversteaming can cause the wood to become too soft, leading to deformation or collapse, while understeaming may result in cracks. Additionally, not all wood species are suitable for steam bending; dense, brittle woods like walnut or cherry are less forgiving than more flexible options like ash or birch. Experimenting with scrap pieces before committing to your project can help you understand the wood’s behavior and refine your technique.

In conclusion, steam bending is a powerful technique for creating elegant, curved wooden structures. With the right tools, careful monitoring, and practice, even beginners can achieve professional results. Whether you’re crafting a chair leg or a boat hull, mastering steam bending opens up a world of creative possibilities in woodworking. Just remember: precision, timing, and patience are key to success.

Wood Ear Mushrooms: Fridge Storage Lifespan and Freshness Tips

You may want to see also

Explore related products

Using Kerf Cuts for Flexibility

Kerf cuts, a technique borrowed from woodworking and metalworking, involve making a series of parallel cuts along the length of a material to allow it to bend. When applied to wood, these cuts act as hinges, enabling a rigid piece to flex without breaking. The key lies in the spacing and depth of the cuts: too close, and the wood weakens; too far apart, and it resists bending. For a 1-inch thick piece of hardwood, cuts spaced 1/8 to 3/16 inch apart are ideal, while softer woods may require slightly wider intervals. This method is particularly useful for creating curves in long pieces, such as for furniture legs, boat ribs, or decorative panels.

To execute kerf cuts effectively, precision is paramount. Use a table saw or a circular saw with a guide to ensure straight, evenly spaced cuts. Begin by marking the lines where the cuts will be made, ensuring they run parallel to the grain to maintain structural integrity. The depth of each cut should be approximately 75% of the wood’s thickness, leaving enough material to hold the piece together while allowing flexibility. For longer bends, consider making the cuts on the tension side of the curve, as this reduces the risk of splitting. Always test the bend on a scrap piece first to fine-tune the spacing and depth.

One of the advantages of kerf cuts is their versatility. Unlike steaming or laminating, this technique requires minimal specialized equipment and can be applied to a wide range of wood types and thicknesses. It’s also reversible: if the bend isn’t perfect, the wood can often be straightened and recut. However, the technique has limitations. Kerf cuts weaken the wood, making it unsuitable for load-bearing applications. Additionally, the exposed cut edges may require finishing to prevent splintering or moisture absorption. For best results, apply a flexible wood glue or epoxy to the cuts before bending to enhance durability.

Comparing kerf cuts to other bending methods highlights their unique benefits. Steaming, while effective, is time-consuming and requires specific conditions, whereas laminating involves gluing multiple thin layers, which can be labor-intensive. Kerf cuts offer a middle ground, providing flexibility without the need for heat or adhesives. They are particularly advantageous for projects requiring tight curves or intricate shapes. For instance, a kerf-cut wooden lampshade can achieve a smooth, organic form that would be difficult to replicate with other techniques. The trade-off is the visible pattern of cuts, which some may see as a design flaw but others embrace as a distinctive feature.

In practice, kerf cuts are a go-to solution for hobbyists and professionals alike. A common application is in crafting wooden bowls or vases, where a flat piece of wood is transformed into a three-dimensional form. To achieve a smooth bend, clamp the wood between two forms—one on the inside and one on the outside of the curve—and gradually tighten the clamps until the desired shape is reached. For added stability, consider reinforcing the bent piece with a flexible backing material, such as thin plywood or fabric. With careful planning and execution, kerf cuts can turn a rigid piece of wood into a gracefully curved masterpiece, blending functionality with artistic flair.

Drying Wet Wood: Optimal Air Blowing Time for Effective Results

You may want to see also

Explore related products

Applying Heat and Pressure Methods

Steam bending is one of the most traditional methods for shaping wood, leveraging moisture and heat to soften the lignin, the natural glue in wood fibers. To begin, prepare a steam box—a sealed chamber that can maintain a consistent temperature of around 180°F to 212°F (82°C to 100°C). The wood should be steamed for approximately 30 minutes per inch of thickness, ensuring the heat penetrates evenly. Once pliable, quickly transfer the wood to a bending form, clamping it securely to maintain the desired shape as it cools. This method is ideal for creating smooth, tight curves, such as those in chair legs or musical instruments, but requires careful timing to avoid over-steaming, which can weaken the wood.

For those without access to a steam box, a simpler alternative is the hot pipe method, which applies localized heat and pressure. Heat a metal pipe or rod to around 350°F (177°C) using a propane torch or heat gun, ensuring the temperature is consistent along the length. Place the wood piece over the heated pipe, allowing the heat to soften the fibers. Gradually apply pressure by bending the wood around the pipe, using clamps or weights to hold it in place as it cools. This technique is best suited for thinner wood strips and shallow bends, as excessive heat can scorch or warp the material. Always wear heat-resistant gloves and work in a well-ventilated area to avoid burns or fumes.

A more controlled approach involves using a strip-building technique with heat and pressure, often employed in boatbuilding or furniture making. Thin strips of wood are heated in a bending iron or on a hot plate until they become flexible, typically at temperatures between 300°F and 350°F (149°C to 177°C). Each strip is then glued edge-to-edge onto a form, creating a laminated structure that conforms to the desired curve. This method allows for precise control over the bend radius and is particularly effective for large, compound curves. However, it requires patience and attention to detail, as improper gluing or overheating can compromise the integrity of the final piece.

While heat and pressure methods are effective, they come with inherent risks that demand caution. Overheating can cause the wood to crack, split, or lose structural strength, while uneven application of heat or pressure may result in warping or distortion. Always test the bending process on scrap wood to calibrate temperature and timing. Additionally, consider the wood species, as some, like oak or maple, respond better to heat than others, such as pine or cedar. By understanding these nuances, craftsmen can harness the power of heat and pressure to transform rigid wood into elegant, curved forms that defy its natural straight-grained structure.

PVA Glue Drying Time on Wood: Quick Tips for Perfect Results

You may want to see also

Frequently asked questions

You’ll need a bending form or jig, clamps, a heat source (like a heat gun or steam box for larger pieces), a moisture source (if steaming), and safety gear like gloves and goggles.

Ensure the wood is properly prepared by soaking or steaming it to make it pliable. Work slowly and apply even pressure, avoiding sharp bends or excessive force.

Yes, for thinner or more flexible woods, you can use a cold bending method with a form and clamps. However, heat or steam is recommended for thicker or harder woods to prevent cracking.