Oak wood is a highly sought-after material known for its durability, strength, and aesthetic appeal, making it a popular choice for furniture, flooring, cabinetry, and construction. The cost of oak wood can vary significantly depending on factors such as the type of oak (e.g., red oak, white oak), grade, thickness, and whether it is purchased as lumber, planks, or finished products. On average, oak lumber can range from $5 to $20 per board foot, with premium or specialty oak commanding higher prices. Additionally, market demand, geographic location, and seasonal availability can influence pricing. For those considering oak wood for a project, it’s essential to research local suppliers, compare prices, and factor in additional costs like milling or finishing to get an accurate estimate.

Explore related products

What You'll Learn

Oak Wood Pricing Factors

Oak wood prices fluctuate based on a complex interplay of factors, making it essential to understand what drives costs before making a purchase. The primary determinant is the type of oak, with white oak generally commanding a higher price than red oak due to its superior rot resistance and aesthetic appeal. For instance, white oak can range from $5 to $15 per board foot, while red oak typically falls between $3 and $10 per board foot. However, these prices are not set in stone and can vary widely depending on additional factors.

Grade and quality significantly influence oak wood pricing. Select and quarter-sawn grades, prized for their uniformity and tight grain patterns, are more expensive than lower grades like No. 1 Common or No. 2 Common, which may contain knots or other imperfections. For example, a select grade white oak board might cost $12 per board foot, whereas a No. 2 Common grade could be as low as $6 per board foot. Buyers should assess their project needs carefully—higher grades are ideal for visible surfaces, while lower grades suffice for structural or hidden applications.

Geographic location plays a surprising role in oak wood costs. Proximity to oak-rich regions, such as the Eastern United States, can reduce prices due to lower transportation expenses. Conversely, areas with limited local supply may see prices inflated by shipping costs. For instance, oak wood in Pennsylvania might be 20-30% cheaper than in the Pacific Northwest. To mitigate this, consider sourcing from local mills or suppliers, or factor in shipping costs when budgeting for your project.

Market demand and availability also shape oak wood pricing. Seasonal fluctuations, such as increased demand during spring construction months, can drive prices up. Additionally, environmental regulations or disease outbreaks affecting oak forests can limit supply, further inflating costs. For example, the emerald ash borer crisis has indirectly impacted oak prices as buyers shift to oak as an alternative. Staying informed about market trends and purchasing during off-peak seasons can help secure better deals.

Finally, processing and finishing add layers to oak wood pricing. Rough-sawn lumber is the most affordable option, but planed, kiln-dried, or pre-finished oak boards can double or triple the cost. For instance, a rough-sawn oak board at $5 per board foot might jump to $15 per board foot after kiln-drying and planing. If you have the tools and expertise, opting for rough lumber and handling finishing yourself can yield significant savings. However, for precision and convenience, pre-processed options may be worth the investment.

Top Retailers to Buy Traeger Wood Pellets for Your Grill

You may want to see also

Explore related products

Cost by Oak Wood Type

Oak wood, a staple in construction and craftsmanship, varies significantly in price depending on its type. White oak, prized for its durability and water resistance, typically costs between $5 to $10 per board foot, making it ideal for outdoor projects like decking or boatbuilding. Red oak, slightly less dense but equally versatile, averages $4 to $8 per board foot, often chosen for indoor furniture and flooring. These price differences reflect not only the wood’s properties but also its availability and demand in the market.

For those seeking rarity, quarter-sawn oak commands a premium, often doubling the price of plain-sawn varieties. This specialized cutting method enhances stability and creates a distinctive grain pattern, favored in high-end furniture and cabinetry. Expect to pay $10 to $15 per board foot for quarter-sawn white oak, while red oak in this cut may range from $8 to $12. If you’re working on a budget but still want the oak aesthetic, consider using oak plywood, which starts at $20 to $40 per sheet, depending on thickness and grade.

When comparing domestic versus imported oak, the cost disparity becomes more pronounced. American white oak remains the most accessible and affordable option, while European oak, known for its tighter grain and richer color, can cost 20-30% more. For exotic varieties like Japanese or Mongolian oak, prices can soar to $20 or more per board foot due to limited supply and higher import costs. Always verify the source and sustainability certifications to ensure ethical purchasing.

To maximize value, consider the project’s requirements before selecting an oak type. For structural applications, white oak’s strength justifies its higher cost, while red oak’s affordability makes it suitable for decorative pieces. If grain appearance is crucial, invest in quarter-sawn or rift-sawn cuts despite their premium. Additionally, buying in bulk or during seasonal sales can reduce costs by 10-15%. Always factor in finishing expenses, as some oak types require more treatment to achieve the desired look.

Finally, reclaimed oak offers an eco-friendly alternative, though prices vary widely based on age and condition. A century-old barn beam, for instance, might cost $15 to $25 per board foot, reflecting its historical value and unique character. While reclaimed wood is pricier upfront, its durability and sustainability often outweigh the initial investment. Whether you prioritize cost, aesthetics, or environmental impact, understanding oak wood types ensures you make an informed decision tailored to your needs.

Where to Buy Curved Wood for Unique DIY Projects

You may want to see also

Explore related products

$11.5 $13.95

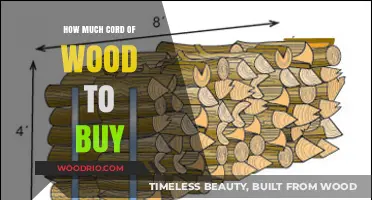

Buying Oak Wood in Bulk

Oak wood, prized for its durability, aesthetic appeal, and versatility, is a staple in construction, furniture making, and flooring. When purchasing oak wood in bulk, understanding the factors that influence cost is essential. Prices vary widely based on grade, type (red oak vs. white oak), and regional availability. For instance, high-grade white oak can cost between $5 to $12 per board foot, while red oak typically ranges from $3 to $8 per board foot. Bulk purchases often come with discounts, but transportation and storage costs must also be factored in.

To maximize savings when buying oak wood in bulk, start by assessing your project needs. Calculate the total volume required, accounting for waste and additional pieces. Next, research suppliers in your area and compare prices, ensuring they offer bulk discounts. Some suppliers may require a minimum order, often starting at 1,000 board feet, to qualify for reduced rates. Additionally, consider purchasing during off-peak seasons, such as winter, when demand is lower and prices may be more competitive.

One critical aspect of bulk oak wood purchases is quality inspection. Unlike smaller orders, bulk shipments can sometimes include inconsistent grades or damaged pieces. Request samples or inspect the wood before finalizing the purchase. Look for signs of warping, cracks, or insect damage. If possible, opt for suppliers who provide kiln-dried wood, as this reduces moisture content and minimizes the risk of warping during storage or use.

Storage is another key consideration when buying oak wood in bulk. Proper storage ensures the wood remains in optimal condition until it’s ready for use. Store the wood in a dry, well-ventilated area, preferably under cover to protect it from rain and direct sunlight. Stack the wood on stickers (small pieces of wood) to allow air circulation and prevent moisture buildup. For long-term storage, consider investing in a weatherproof shed or using tarps to shield the wood from the elements.

Finally, explore alternative sourcing options to reduce costs. Reclaimed oak wood, salvaged from old buildings or barns, can be a cost-effective and eco-friendly choice. While prices vary, reclaimed oak often falls within the $4 to $10 per board foot range. Another option is purchasing directly from sawmills, which may offer lower prices than retailers. However, sawmill purchases often require larger minimum orders and may not include additional services like kiln drying or planing. By weighing these factors, you can make an informed decision that balances cost, quality, and practicality when buying oak wood in bulk.

Discover the Best Sources to Buy Authentic Brazilian Wood Today

You may want to see also

Explore related products

Local vs. Imported Oak Prices

Oak wood prices vary significantly depending on whether you opt for locally sourced or imported varieties. Local oak, often harvested from nearby forests or mills, typically ranges from $3 to $8 per board foot for common species like red or white oak. This price reflects lower transportation costs and supports regional economies. Imported oak, on the other hand, can cost $10 to $20 per board foot or more, especially for high-demand European or Asian varieties like English brown oak or Japanese evergreen oak. The higher cost accounts for international shipping, tariffs, and the exclusivity of certain species.

Choosing between local and imported oak requires balancing budget, quality, and sustainability. Local oak is generally more affordable and environmentally friendly due to reduced carbon footprints from shorter transportation routes. However, imported oak often boasts unique grain patterns, colors, or densities that local varieties may lack, making it ideal for high-end furniture or specialty projects. For instance, European white oak is prized for its straight grain and light color, while American white oak is slightly darker and more readily available.

To make an informed decision, consider the project’s scale and purpose. For large-scale construction or flooring, local oak’s cost-effectiveness and availability make it a practical choice. Imported oak is better suited for smaller, detail-oriented projects like cabinetry or decorative panels, where its distinctive qualities justify the expense. Additionally, research suppliers thoroughly—some local mills offer premium grades at competitive prices, while certain importers specialize in sustainably sourced exotic oak, bridging the price gap.

A practical tip: request samples or visit showrooms to compare local and imported oak side by side. This allows you to assess differences in texture, durability, and aesthetics firsthand. Also, factor in finishing costs—imported oak may require specialized treatments to preserve its unique characteristics, adding to the overall expense. By weighing these considerations, you can select the oak that best aligns with your project’s needs and budget.

Cost of Wood Tile: Pricing Guide for Your Flooring Project

You may want to see also

Explore related products

Oak Wood Price per Board Foot

Oak wood prices per board foot vary widely based on factors like species, grade, and market demand. For instance, red oak typically ranges from $4 to $8 per board foot, while white oak, prized for its durability and aesthetic appeal, can cost between $6 and $12 per board foot. Quarter-sawn oak, known for its distinctive grain pattern, often commands a premium, pushing prices to $10 to $15 per board foot or higher. These figures reflect domestic U.S. prices and can fluctuate with supply chain disruptions or seasonal demand.

When budgeting for oak wood, consider the grade of the lumber. Select and #1 Common grades, which have fewer defects and more uniform color, are more expensive than #2 Common or #3 Common grades, which may include knots or other imperfections. For example, #1 Common red oak might cost $7 per board foot, while #2 Common could be $5 per board foot. If your project allows for character marks, opting for a lower grade can significantly reduce costs without compromising structural integrity.

Another critical factor is the thickness and width of the board. Standard dimensions like 4/4 (1-inch thick) or 8/4 (2-inch thick) are common, but thicker or wider boards are often priced higher due to increased milling costs and waste. For instance, a 4/4 board of white oak might be $8 per board foot, while an 8/4 board could jump to $12 per board foot. Always verify the dimensions and pricing structure with your supplier to avoid surprises.

To get the best value, compare prices from local lumberyards, online retailers, and specialty hardwood suppliers. Buying in bulk can sometimes yield discounts, but ensure you have storage space to prevent warping or damage. Additionally, consider reclaimed oak, which can cost $8 to $15 per board foot but offers sustainability benefits and unique character. Always factor in shipping or delivery costs, as these can add 10-20% to your total expense, especially for heavy or long-distance orders.

Finally, plan for waste in your project calculations. Milling, cutting, and finishing can result in 10-20% material loss, so purchasing 10-20% more than your initial estimate is prudent. For example, if your project requires 50 board feet, buy 55 to 60 board feet to account for imperfections or mistakes. This approach ensures you have enough material to complete the job without additional purchases, which can be costly and time-consuming.

Smart Tips for Buying High-Quality Wood Furniture That Lasts

You may want to see also

Frequently asked questions

The cost of oak wood varies depending on the type (red oak, white oak, etc.), quality, and location, but it typically ranges from $5 to $15 per board foot.

Factors include the type of oak, grade (select, #1 common, etc.), thickness, availability, and market demand. Custom milling or specialty cuts may also increase the price.

Yes, white oak is generally more expensive than red oak due to its durability, water resistance, and higher demand in construction and furniture making. White oak can cost 10-20% more than red oak.