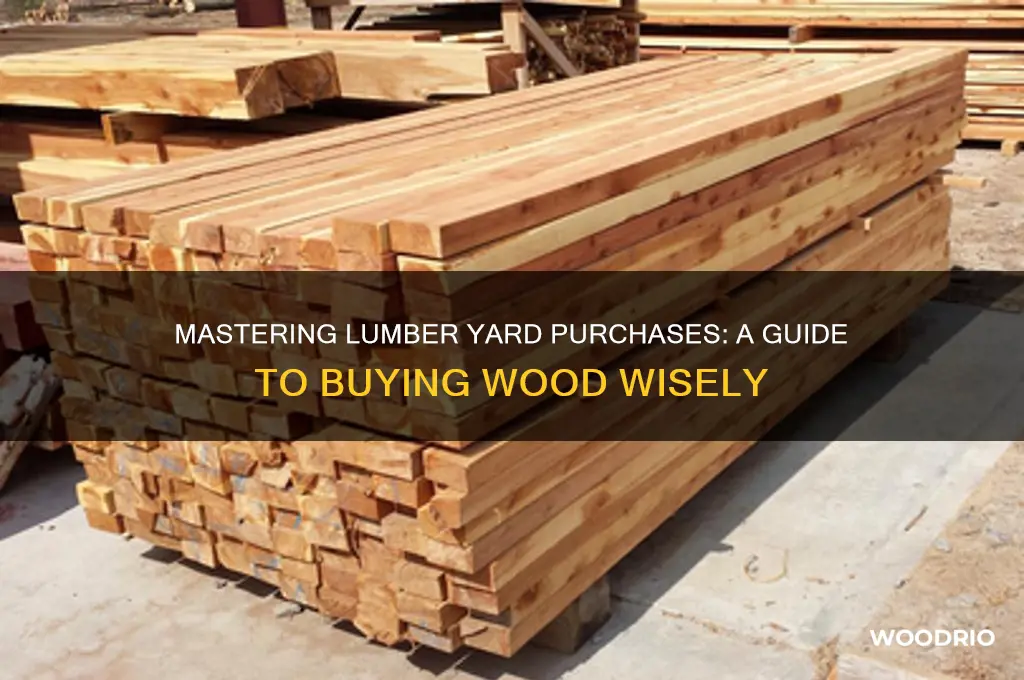

Buying wood at a lumber yard can be an efficient and cost-effective way to source materials for your projects, whether you're a professional builder or a DIY enthusiast. To start, research local lumber yards to find one with a good reputation and a wide selection of wood types, grades, and sizes. When visiting, come prepared with a detailed list of your project requirements, including dimensions, quantities, and preferred wood species. Familiarize yourself with the different grades of lumber, such as select, #1 common, or construction grade, to ensure you choose the right quality for your needs. Don’t hesitate to ask the staff for advice—they can guide you on the best options and may even offer tips on working with specific types of wood. Finally, inquire about delivery or cutting services, as many lumber yards provide these for an additional fee, saving you time and effort.

| Characteristics | Values |

|---|---|

| Research Lumber Yards | Locate nearby lumber yards, check reviews, and verify they have the type of wood you need. |

| Know Wood Types | Familiarize yourself with wood species (e.g., pine, oak, maple) and their uses (e.g., hardwood for furniture, softwood for framing). |

| Understand Grades | Learn wood grading systems (e.g., Select, #1 Common, #2 Common) to assess quality and price. |

| Measure Accurately | Calculate the exact amount of wood needed (length, width, thickness) to avoid waste. |

| Check Moisture Content | Ensure wood moisture levels match your project needs (e.g., kiln-dried for indoor use). |

| Inspect for Defects | Look for knots, warping, cracks, or splits that may affect usability. |

| Ask About Pricing | Inquire about pricing per board foot (BDFT) or linear foot, and check for bulk discounts. |

| Bring Proper Tools | Carry a tape measure, pencil, and paper for notes; some yards may allow you to mark wood. |

| Transportation | Plan how to transport the wood (e.g., truck, trailer) and bring tie-downs or straps. |

| Payment Methods | Confirm accepted payment methods (cash, card, etc.) before purchasing. |

| Ask for Assistance | Don’t hesitate to ask staff for help in selecting or loading wood. |

| Check Return Policy | Understand the yard’s policy on returns or exchanges in case of mistakes. |

| Sustainability | Consider purchasing FSC-certified or sustainably sourced wood if available. |

| Seasonal Buying | Be aware of seasonal price fluctuations and plan purchases accordingly. |

| Custom Cuts | Some yards offer cutting services; inquire about fees and capabilities. |

| Storage Tips | Ask for advice on storing wood properly to prevent warping or damage. |

Explore related products

What You'll Learn

- Identify Wood Types: Learn hardwoods, softwoods, and their uses for your project

- Understand Grades: Know wood quality grades (Select, #1 Common, etc.) for best fit

- Measure Accurately: Calculate dimensions to avoid waste and extra costs

- Check Moisture Content: Ensure wood is properly dried to prevent warping

- Inspect for Defects: Look for knots, cracks, or twists before buying

Identify Wood Types: Learn hardwoods, softwoods, and their uses for your project

Understanding the difference between hardwoods and softwoods is crucial when selecting wood for your project. Hardwoods, derived from deciduous trees like oak, maple, and cherry, are generally denser and more durable, making them ideal for furniture, flooring, and cabinetry. Softwoods, sourced from coniferous trees such as pine, cedar, and spruce, are lighter and easier to work with, often used for framing, trim, and outdoor projects. Knowing these distinctions ensures you choose the right material for both function and aesthetics.

For instance, if you’re building a dining table, hardwoods like walnut or mahogany offer a rich, polished look and can withstand heavy use. Conversely, a backyard deck might benefit from softwoods like cedar, which naturally resists rot and insects. Always consider the project’s environment—indoor or outdoor—and the level of wear it will endure. Hardwoods are typically more expensive, so weigh the cost against the longevity and appearance you desire.

When identifying wood types at a lumber yard, examine the grain patterns and color. Hardwoods often have intricate, varied grains, while softwoods tend to have simpler, straighter patterns. Ask the staff for samples or guidance if you’re unsure. Pro tip: Bring a small magnet—it won’t stick to most softwoods due to their lower density, but it can adhere to denser hardwoods, though this isn’t foolproof.

Another practical tip is to consider the wood’s workability. Softwoods are easier to cut, nail, and shape, making them beginner-friendly. Hardwoods, while more challenging to work with, offer superior strength and finish. If you’re new to woodworking, start with softwoods for practice projects before tackling hardwoods. Always use sharp tools to avoid splintering, especially with harder species.

Finally, think about sustainability. Some hardwoods, like teak or rosewood, are endangered, so opt for certified sustainable options or reclaimed wood when possible. Softwoods like pine are often more readily available and renewable. By choosing responsibly, you support both your project and the environment. Identifying the right wood type isn’t just about aesthetics—it’s about matching the material to your project’s needs and values.

Where to Buy Bulk Pine Wood Fence Pickets for Your Project

You may want to see also

Explore related products

Understand Grades: Know wood quality grades (Select, #1 Common, etc.) for best fit

Wood grades are not just labels—they are a language that communicates quality, appearance, and intended use. Understanding this language ensures you select the right wood for your project, balancing cost and performance. Grades like Select, #1 Common, and Utility are not arbitrary; they reflect specific criteria such as knot size, grain pattern, and surface defects. For instance, Select grade wood is nearly flawless, ideal for fine furniture, while Utility grade, with its larger knots and imperfections, suits structural applications where aesthetics are secondary.

To decode grades effectively, start by identifying your project’s requirements. If you’re crafting a dining table, Select or #1 Common grades offer minimal defects and consistent color, ensuring a polished finish. For framing or outdoor structures, #2 Common or Utility grades provide strength at a lower cost, as their imperfections are hidden or irrelevant. Pro tip: Inspect boards individually, as even within a grade, variation exists. A #1 Common board might still have a minor defect that could affect your design, so always examine before purchasing.

Grades also correlate with price, making them a critical factor in budgeting. Select grade wood can cost 2–3 times more than Utility grade due to its superior appearance and tighter quality control. However, overpaying for a higher grade than necessary wastes money. For example, using Select grade for a shed’s interior walls is unnecessary when #2 Common would suffice. Conversely, skimping on grade for visible elements like cabinetry can compromise the final look.

A practical approach is to prioritize grades based on wood exposure and function. For hidden structural elements, opt for lower grades like Utility or Stud. For semi-exposed areas, such as shelving, #2 Common strikes a balance between cost and appearance. Visible surfaces, like trim or furniture, demand higher grades like Select or #1 Common. Always cross-reference grade standards with your project’s demands to avoid mismatches.

Finally, remember that grades are not universal across species. A #1 Common pine board differs from a #1 Common oak board in terms of defects and appearance due to species-specific characteristics. Research or consult with lumber yard staff to understand how grades apply to the wood species you’re buying. This knowledge ensures you’re not just buying wood—you’re investing in the right wood for your needs.

Best Places to Buy High-Quality Wood Veneer Sheets Online & Locally

You may want to see also

Explore related products

Measure Accurately: Calculate dimensions to avoid waste and extra costs

Accurate measurement is the cornerstone of efficient wood purchasing. Before stepping into a lumber yard, know the exact dimensions required for your project. This isn’t just about length and width—consider thickness, grain direction, and any necessary allowances for cuts or joints. A miscalculation of even a quarter-inch can render a board unusable, turning a cost-saving trip into an expensive lesson. Use a tape measure and double-check your numbers; digital tools like laser measurers can provide precision but aren’t always necessary for straightforward projects.

Let’s break it down into actionable steps. First, sketch your project to scale, labeling each piece with its dimensions. Next, account for waste by adding 10–15% to your total wood length. For example, if your project requires 50 linear feet of 2x4s, purchase 55–57.5 feet. This buffer covers mistakes, warped boards, or unexpected design changes. Finally, convert your measurements to the lumber yard’s standard units—typically linear feet for boards and square feet for plywood. Knowing these conversions prevents over-ordering and ensures you’re charged fairly.

Consider the financial impact of imprecise measurements. Buying a 12-foot board when you only need 10 feet wastes 20% of the material. Multiply that by multiple boards, and the cost adds up quickly. For instance, if a 12-foot 2x4 costs $8, wasting 2 feet per board on a 10-board project costs you $16—money that could’ve been saved with careful planning. Conversely, underestimating leaves you scrambling for additional trips, potentially incurring fuel costs or delaying your project.

A comparative analysis reveals that professionals often use software like SketchUp or even Excel to calculate material needs, but DIYers can achieve similar results with pen and paper. The key is consistency: use the same unit of measurement throughout your calculations and stick to it when shopping. For complex projects, break down each component separately—e.g., calculate framing, shelving, and trim as distinct categories. This modular approach reduces errors and makes it easier to adjust quantities if needed.

Finally, a practical tip: always measure twice, cut once, but *plan* three times. Review your measurements at three stages: initial design, material list creation, and just before purchasing. This redundancy catches errors early and ensures your trip to the lumber yard is efficient and cost-effective. Remember, the goal isn’t just to buy wood—it’s to buy the *right* wood, in the right amounts, for the right price. Precision pays off, both in your wallet and in the success of your project.

A Comprehensive Guide to Buying High-Quality Teak Wood

You may want to see also

Explore related products

Check Moisture Content: Ensure wood is properly dried to prevent warping

Wood with high moisture content is a ticking time bomb for your project. As it dries, it warps, cracks, and shrinks, undoing hours of careful craftsmanship. This is why checking moisture content is a critical step when buying wood at a lumber yard.

Imagine spending a weekend building a beautiful bookshelf, only to find the shelves bowing under the weight of your favorite novels a few months later. This scenario is all too common when wood hasn't been properly dried.

The ideal moisture content for indoor woodworking projects is between 6% and 8%. Wood at this level is considered "kiln-dried" and is significantly less prone to warping. Lumber yards often have moisture meters available for customer use. These handheld devices are simple to operate: just press the pins into the wood and get an instant reading. If the meter isn't readily available, ask a staff member for assistance.

Don't be afraid to test multiple boards, especially if you're buying a large quantity. Moisture content can vary even within the same stack.

While kiln-dried wood is the gold standard, air-dried wood can also be suitable, but it requires more scrutiny. Air-dried wood has been naturally dried outdoors, a process that takes significantly longer than kiln drying. Look for signs of proper air drying: evenly colored wood with no signs of mold or mildew. Even then, it's wise to use a moisture meter to confirm the moisture content is within the desired range.

Remember, preventing warping is far easier than fixing it later. Taking the time to check moisture content at the lumber yard is a small investment that pays off in the long run, ensuring your woodworking projects stand the test of time.

Best Places to Buy Pressure Treated Wood for Your Projects

You may want to see also

Explore related products

$9.94 $21.99

$25.88 $27.62

Inspect for Defects: Look for knots, cracks, or twists before buying

Wood, though naturally beautiful, is inherently flawed. Knots, cracks, and twists are the battle scars of a tree’s life, and they can compromise the strength, stability, and appearance of your project. Before committing to a purchase, inspect each board meticulously. Run your hands along the surface, feeling for raised knots or depressions that indicate cracks. Sight down the length of the board to check for twists or warping. A few minor imperfections might be acceptable depending on your project, but structural pieces like beams or load-bearing supports demand near-flawless wood.

Think of it as a medical exam for your lumber. Just as a doctor checks for signs of illness, you’re assessing the wood’s fitness for its intended purpose. A knot might add character to a rustic shelf, but it could be a weak point in a chair leg. A hairline crack might be invisible to the casual eye, but it could expand under stress, leading to failure.

Inspection isn’t just about aesthetics; it’s about safety and longevity. A twisted board will never sit flush, leading to uneven joints and compromised stability. A cracked board, even if glued, will always be weaker than a solid one. Don’t be afraid to reject boards with significant defects, even if they’re cheaper. The cost of replacing a failed piece later will far outweigh the initial savings.

Here’s a practical tip: Bring a straightedge (a long, flat tool like a level or a ruler) to the lumber yard. Lay it across the width of the board at several points to check for twists. If there’s a noticeable gap between the straightedge and the wood, that board is warped and should be avoided. For cracks, tap the board gently with a knuckle. A hollow sound indicates a void or crack within the wood.

Choosing the Right Wood: A Buyer's Guide for Quality and Value

You may want to see also

Frequently asked questions

Before visiting, know the type of wood you need (e.g., hardwood, softwood, or engineered wood), the dimensions required (length, width, thickness), and the quantity. Also, consider the wood’s intended use (indoor, outdoor, structural, or decorative) to ensure you choose the right grade and species.

Bring a tape measure and a list of your project’s dimensions. Inspect the wood for defects like knots, warping, or cracks. Stack boards flat to check for straightness, and ask staff for assistance if needed. Most lumber yards have pre-cut sizes, but some may offer custom cutting services.

Buy in bulk if possible, as many yards offer discounts for larger quantities. Look for "seconds" or slightly damaged pieces at a lower price if imperfections won’t affect your project. Also, compare prices between different species—some less common woods may be more affordable and still suit your needs.