When planning to buy wood for open shelving, it's essential to consider both functionality and aesthetics. Start by determining the type of wood that suits your project, such as pine for a rustic look, oak for durability, or plywood for a modern finish. Measure the space accurately to calculate the required amount of wood, ensuring you account for shelf depth, length, and the number of brackets or supports needed. Check the wood’s quality for straightness, knots, and warping to avoid structural issues. Consider the finish—whether you’ll stain, paint, or seal the wood—and choose a grade that aligns with your budget and desired appearance. Finally, source your wood from reputable suppliers, whether local lumberyards or online retailers, and inquire about sustainability certifications if eco-friendliness is a priority. Proper planning and selection will ensure your open shelving is both functional and visually appealing.

| Characteristics | Values |

|---|---|

| Wood Type | Pine, Poplar, Oak, Maple, Birch, Plywood, MDF (Medium-Density Fiberboard) |

| Grade | Select, #1 Common, #2 Common (for solid wood); A-C grades (for plywood) |

| Thickness | 3/4" (19mm) is standard for shelving, but can range from 1/2" to 1 1/4" depending on span and load |

| Width | 1x8, 1x10, 1x12 (nominal dimensions) are common; actual widths are slightly smaller (e.g., 1x8 is 3/4" x 7 1/4") |

| Length | Standard lengths: 6', 8', 10', 12', 14', 16' (custom lengths may be available) |

| Finish | Unfinished (for custom staining/painting), pre-finished (for convenience), or raw (for natural look) |

| Edge Profile | Square, rounded, bullnose, ogee (affects aesthetics and safety) |

| Moisture Content | 6-8% for indoor use (prevents warping and cracking) |

| Sustainability | Look for FSC (Forest Stewardship Council) certification or reclaimed wood options |

| Cost | Varies widely: Pine ($10-20/board), Oak ($30-50/board), Plywood ($20-40/sheet), MDF ($15-30/sheet) |

| Weight Capacity | Depends on wood type, thickness, and span; consult span tables or a professional for specific needs |

| Installation Method | Bracket-mounted, floating (with hidden supports), or wall-cleated |

| Maintenance | Regular dusting, occasional resealing (for natural finishes), and prompt cleaning of spills |

| Common Retailers | Home Depot, Lowe's, Menards, local lumberyards, online suppliers (e.g., Woodworkers Source) |

| Tools Needed | Tape measure, level, stud finder, drill, screwdriver, saw (circular or miter), sandpaper |

| Safety Considerations | Secure shelves properly to avoid tipping; use appropriate fasteners (e.g., wood screws, wall anchors) |

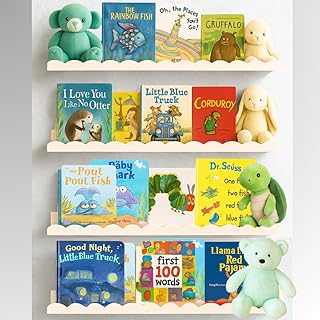

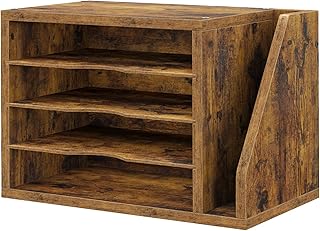

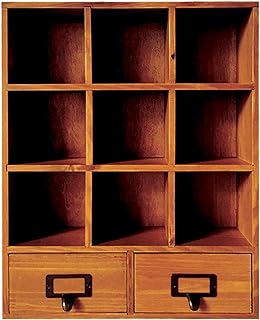

Explore related products

$26.99 $29.99

What You'll Learn

- Types of Wood: Hardwood vs. softwood, grain patterns, durability, and cost differences for shelving

- Sourcing Wood: Local suppliers, reclaimed wood, big-box stores, and online marketplaces for quality options

- Measuring Needs: Calculate shelf dimensions, thickness, and quantity based on space and weight requirements

- Finishing Options: Stains, sealants, paints, and natural finishes to enhance wood appearance and longevity

- Budgeting Tips: Compare prices, consider alternatives, and factor in tools and installation costs

Types of Wood: Hardwood vs. softwood, grain patterns, durability, and cost differences for shelving

Choosing between hardwood and softwood for open shelving hinges on balancing aesthetics, durability, and budget. Hardwoods, derived from deciduous trees, are denser and more durable, making them ideal for high-traffic areas or heavy items. Softwoods, from coniferous trees, are lighter and easier to work with but less resistant to wear. For shelving, hardwoods like oak or maple offer longevity, while softwoods like pine or cedar provide a cost-effective, rustic charm.

Grain patterns play a pivotal role in the visual appeal of your shelves. Hardwoods often feature tight, intricate grains that add sophistication, while softwoods showcase wider, more open patterns for a casual, natural look. Consider the room’s style: a modern kitchen might benefit from the sleek grain of walnut, whereas a farmhouse-style pantry could be enhanced by the knotty texture of pine. Stain or finish can amplify these patterns, so test samples to ensure the final look aligns with your vision.

Durability is a critical factor, especially for shelves bearing heavy loads or exposed to moisture. Hardwoods resist scratches, dents, and warping better than softwoods, making them superior for long-term use. However, softwoods treated with sealants or varnishes can perform adequately in drier environments. For example, teak or mahogany shelves in a living room will outlast pine shelves in the same space, but pine can suffice if properly maintained and used for lighter items.

Cost differences between hardwood and softwood are significant and should align with your project scope. Softwoods are generally 30–50% cheaper than hardwoods, making them a budget-friendly option for large or temporary installations. Hardwoods, while pricier, offer a premium finish and longevity that can justify the investment. For instance, a 4x8 sheet of pine plywood might cost $20–$30, whereas oak plywood could range from $60–$100. Prioritize your needs: if durability and appearance are paramount, hardwoods are worth the expense; if cost is the primary concern, softwoods can deliver satisfactory results with careful selection and care.

Finally, sustainability and availability should factor into your decision. Hardwoods, often sourced from slower-growing trees, may have environmental implications unless certified by organizations like the FSC. Softwoods, typically from faster-growing species, are more readily available and renewable. Local sourcing can reduce costs and environmental impact, so check regional suppliers for both hardwood and softwood options. By weighing these factors, you can select the wood type that best meets your shelving needs while aligning with your values and budget.

Discover the Best Sources to Buy Authentic Brazilian Wood Today

You may want to see also

Explore related products

$178.49 $254.99

$23.99 $25.99

Sourcing Wood: Local suppliers, reclaimed wood, big-box stores, and online marketplaces for quality options

Local suppliers often offer the freshest cuts and most personalized service, making them an ideal starting point for sourcing wood for open shelving. Visit nearby lumberyards or woodworking shops to inspect the wood firsthand, ensuring it meets your grain, color, and durability requirements. Many local suppliers specialize in regional hardwoods like oak, maple, or walnut, which can add a distinctive, place-based character to your shelves. Ask about moisture content—ideally between 6-8% for indoor use—to avoid warping. Building a relationship with a local expert can also provide tailored advice on milling, finishing, or custom cuts, turning a transaction into a collaborative project.

Reclaimed wood introduces a layer of history and sustainability to open shelving, but sourcing it requires patience and discernment. Salvage yards, deconstruction companies, and specialty reclaimed wood dealers are prime hunting grounds. Inspect boards for signs of rot, insect damage, or excessive wear, and inquire about their origin—barn beams, factory floors, or wine barrels each carry unique textures and stories. Reclaimed wood is typically denser and more stable due to decades of seasoning, but it may require additional cleaning, planing, or sealing. Factor in the cost of preparation, as this option can be pricier upfront but offers unmatched character and eco-friendliness.

Big-box stores like Home Depot or Lowe’s provide convenience and consistency, ideal for straightforward projects or tight timelines. Their pre-cut boards, often in pine, poplar, or birch, are readily available in standard dimensions (e.g., 1x8s or 1x10s) and finishes. However, quality can vary, and the selection leans toward softer woods or engineered options like plywood or MDF. For open shelving, prioritize hardwoods or premium grades if available, and consider purchasing slightly longer or wider pieces to allow for trimming imperfections. While less personalized, these stores often offer bulk discounts or delivery, making them practical for larger installations.

Online marketplaces such as Etsy, eBay, or specialty wood retailers expand your options exponentially but demand careful vetting. Look for sellers with detailed photos, clear descriptions of species, grade, and dimensions, and transparent shipping policies—oversized freight can add significant costs. Exotic woods like teak, mahogany, or live-edge slabs are more accessible online but verify sustainability certifications (e.g., FSC) to avoid unethical sourcing. Reviews are critical here; prioritize sellers with a track record of delivering undamaged, accurately described products. For custom orders, communicate specific requirements (e.g., flatness, grain orientation) upfront to avoid mismatches.

Each sourcing option carries trade-offs: local suppliers offer expertise but may limit variety, reclaimed wood prioritizes character but demands scrutiny, big-box stores provide convenience but sacrifice uniqueness, and online marketplaces broaden horizons but require diligence. The ideal choice depends on your project’s priorities—whether it’s supporting local artisans, embracing sustainability, meeting deadlines, or achieving a specific aesthetic. Combining sources, such as pairing reclaimed brackets with big-box planks, can also balance cost, character, and practicality. Ultimately, the wood you choose becomes the backbone of your shelving, so invest time in sourcing it thoughtfully.

Best Places to Purchase Butternut Wood for Carving Projects

You may want to see also

Explore related products

Measuring Needs: Calculate shelf dimensions, thickness, and quantity based on space and weight requirements

Before heading to the lumberyard, grab your tape measure and notepad. Accurate measurements are the backbone of a successful open shelving project. Start by determining the available wall space, noting height, width, and depth. Consider the purpose of your shelves—will they display lightweight decor or hold heavy cookbooks? This dictates the necessary thickness and length of your wooden boards. For instance, a standard shelf depth ranges from 10 to 12 inches for everyday items, while deeper shelves (14–16 inches) accommodate larger objects.

Weight capacity is a critical factor often overlooked. A shelf’s thickness directly impacts its strength; 3/4-inch plywood or solid wood is ideal for most residential uses, while heavier loads may require 1-inch or thicker material. Calculate the total weight your shelves will bear and distribute it evenly. For example, if you plan to store 100 pounds of items, divide this across multiple shelves to avoid overloading a single board. Use online weight calculators or consult a hardware specialist for precise recommendations.

Quantity planning goes hand in hand with measurements. Measure the vertical spacing between shelves, typically 12–15 inches apart, to ensure items fit comfortably. Factor in the number of brackets or supports needed—each shelf typically requires two to four brackets, depending on length and weight. For a 6-foot shelf, three brackets spaced evenly provide optimal stability. Always purchase extra wood for cutting mistakes or future adjustments.

Finally, consider the aesthetic impact of your measurements. Shelves that are too long may overwhelm a small space, while overly thick boards can appear bulky. Strike a balance between functionality and design by sketching a rough layout or using online shelving planners. Remember, precise measurements not only ensure structural integrity but also elevate the overall look of your open shelving project.

Buying Fake Wood Brown Gable Accents: A Comprehensive Guide

You may want to see also

Explore related products

$44.99 $49.99

Finishing Options: Stains, sealants, paints, and natural finishes to enhance wood appearance and longevity

Wood finishing is a critical step in open shelving projects, as it not only enhances the aesthetic appeal but also protects the material from wear, moisture, and UV damage. Stains, sealants, paints, and natural finishes each offer distinct benefits, and the choice depends on the desired look, durability requirements, and maintenance preferences. For instance, a clear sealant like polyurethane preserves the wood’s natural grain while adding a protective layer, making it ideal for rustic or minimalist designs. Conversely, paint provides a uniform, opaque finish that can hide imperfections and complement modern or bold interiors. Understanding these options ensures the wood not only looks great but also stands the test of time.

Stains are a popular choice for open shelving because they penetrate the wood, enhancing its natural color and grain without obscuring it. Water-based stains dry quickly and are low in volatile organic compounds (VOCs), making them eco-friendly and safe for indoor use. Oil-based stains, while slower to dry, offer deeper penetration and richer color. When applying stain, start with a light coat, allow it to dry, and then assess if additional layers are needed. Always sand between coats with 220-grit sandpaper for a smooth finish. For a more dramatic effect, consider layering stains or using a glaze to add depth and dimension.

Sealants are essential for protecting wood from moisture, heat, and scratches, especially in high-traffic areas like kitchens. Polyurethane is a versatile option available in gloss, semi-gloss, and satin finishes, with satin being the most popular for its subtle sheen. For a more natural look, consider a penetrating oil sealant like tung or linseed oil, which hardens within the wood fibers. Apply sealants in thin, even coats using a foam brush or sprayer, allowing each layer to dry completely before sanding lightly with 320-grit sandpaper. Multiple thin coats provide better protection than a single thick one, reducing the risk of drips or bubbles.

Paint offers endless customization for open shelving, from matte finishes that create a sleek, contemporary look to chalk paint that adds a vintage, distressed charm. When painting wood, prime the surface first to ensure adhesion and prevent tannins from bleeding through. Use a high-quality brush or roller to achieve a smooth finish, and consider sanding between coats with 220-grit sandpaper for added durability. For a two-tone effect, pair painted shelves with stained brackets or edges to highlight the wood’s natural beauty. Keep in mind that paint requires periodic touch-ups, especially in areas prone to wear.

Natural finishes, such as wax or oil, are ideal for those seeking an organic, chemical-free option. Beeswax or carnauba wax provides a soft, matte finish and repels moisture, though it requires reapplication every 6–12 months. Danish or teak oil enhances the wood’s color while providing moderate protection, making it suitable for low-moisture environments. Apply natural finishes with a clean cloth, rubbing the product into the wood in the direction of the grain. While these finishes may not offer the same durability as sealants or paint, they are easy to maintain and allow the wood’s character to shine through. Choose the finish that aligns with both the desired aesthetic and the shelf’s functional demands.

Buying Wood Doors with Frame: A Comprehensive Guide for Homeowners

You may want to see also

Explore related products

Budgeting Tips: Compare prices, consider alternatives, and factor in tools and installation costs

Before diving into your open shelving project, pause to compare wood prices across suppliers. A quick survey of local hardware stores, online retailers, and specialty lumberyards reveals significant price disparities. For instance, a 4x8 sheet of birch plywood might cost $40 at a big-box store but only $30 at a local sawmill. Use price comparison tools like CamelCamelCamel for online purchases or call around for bulk discounts. Pro tip: Ask suppliers about off-cuts or slightly damaged pieces, which can be 30-50% cheaper and perfect for smaller shelving projects.

Alternatives to traditional hardwoods can slash costs without compromising aesthetics. Instead of pricey oak or walnut, consider pine, poplar, or MDF (medium-density fiberboard) for a budget-friendly option. Pine, for example, is often half the price of oak but stains beautifully to mimic higher-end woods. For a modern look, try painted MDF shelves, which cost as little as $15 per sheet. Another creative alternative is reclaimed wood from salvage yards, which adds character and reduces environmental impact, though prices vary widely based on availability.

Tools and installation costs are often overlooked but can double your budget if not planned carefully. A basic shelving project requires a circular saw ($50-$150), drill ($30-$100), and sander ($20-$80), totaling $100-$330 for DIYers. Renting tools from hardware stores can save money, with daily rates typically 10-20% of the purchase price. If hiring a professional, expect to pay $50-$100 per hour for installation, adding $200-$500 to your total. To cut costs, opt for pre-cut wood or simpler designs that require fewer tools and less labor.

Factor in hidden expenses to avoid mid-project financial surprises. Sandpaper, wood glue, screws, and finishing products like stain or sealant can add $30-$100 to your budget. If your shelves require wall anchors or additional support, budget an extra $20-$50 for hardware. For painted shelves, include primer and paint costs, which range from $20-$60 per gallon. Always add a 10-15% buffer to your total estimate to cover unexpected expenses, ensuring your project stays on track financially.

Strategic planning can maximize your budget without sacrificing quality. Buy wood in bulk to secure discounts, and consider timing your purchase during seasonal sales (e.g., Black Friday or spring home improvement events). If your project allows, opt for thinner wood (e.g., ¾-inch instead of 1-inch) to reduce material costs. Finally, prioritize functionality over trends—a simple, well-built shelf using affordable materials will outlast a flashy design that breaks the bank. With careful comparison and creative alternatives, open shelving can be both stylish and budget-friendly.

Discover the Best Places to Buy High-Quality Wood for Your Projects

You may want to see also

Frequently asked questions

The best wood for open shelving depends on your budget, style, and durability needs. Popular options include pine (affordable and easy to work with), oak (durable and classic), maple (smooth and modern), and walnut (premium and rich in color). For a budget-friendly choice, pine or poplar works well, while hardwoods like oak or walnut offer long-lasting quality.

The thickness of the wood depends on the shelf size and weight it will support. For standard open shelving (10–12 inches deep), ¾-inch thick wood is common and provides sufficient strength. For longer or heavier-duty shelves, consider 1-inch or 1¼-inch thick wood to prevent sagging. Always ensure the wood is sturdy enough for your intended use.

You can buy wood from home improvement stores (e.g., Home Depot, Lowe’s), local lumberyards, or online retailers like Woodcraft or eBay. When choosing boards, look for straight, flat, and knot-free wood for a clean finish. Check for warping or cracks, and opt for pre-sanded or smooth boards to save time on preparation. If staining or painting, select wood with a consistent grain pattern.