When embarking on a shelving project, selecting the right wood is crucial for both functionality and aesthetics. Begin by determining the type of wood that best suits your needs, considering factors such as durability, grain pattern, and budget. Common options include pine for affordability, oak for strength, or plywood for versatility. Measure the dimensions of your shelves to calculate the required amount of wood, ensuring you account for any additional cuts or supports. Visit local hardware stores, lumberyards, or online retailers to compare prices and quality, and don’t hesitate to ask for advice on the best materials for your specific project. Finally, inspect the wood for defects like knots, warping, or cracks to ensure a sturdy and visually appealing final product.

| Characteristics | Values |

|---|---|

| Wood Type | Pine, Oak, Maple, Birch, Plywood, MDF, Particle Board |

| Thickness | ¾ inch (18mm) is standard for shelves; adjust based on weight and span |

| Width | Common widths: 1x8, 1x10, 1x12 inches; custom cuts available |

| Length | Standard lengths: 6, 8, 10, 12 feet; custom lengths can be ordered |

| Finish | Raw, stained, painted, or sealed; choose based on aesthetics and durability |

| Grade | Select (highest quality), #1 Common, #2 Common; higher grades have fewer knots and defects |

| Cost | Varies by type: Pine ($10-20/board), Oak ($20-40/board), Plywood ($20-50/sheet) |

| Weight Capacity | Solid wood > Plywood > MDF/Particle Board; consider shelf supports and brackets |

| Moisture Resistance | Treated or sealed wood for humid areas; avoid untreated wood in bathrooms/kitchens |

| Sustainability | Look for FSC-certified wood or reclaimed options for eco-friendly choices |

| Ease of Cutting | Pine and MDF are easy to cut; hardwoods like Oak require sharper tools |

| Availability | Home improvement stores (Home Depot, Lowe's), local lumberyards, online retailers |

| Installation | Pre-drilled holes for screws, brackets, or floating shelf kits recommended |

| Maintenance | Regular dusting; reapply sealant or paint as needed for longevity |

Explore related products

What You'll Learn

- Types of Wood: Hardwood vs. softwood, plywood, MDF, particle board, and solid wood options

- Wood Grades: Select, common, or utility grades and their impact on cost and appearance

- Sizing & Thickness: Measuring shelf dimensions, standard wood thicknesses, and cutting requirements

- Finishing Options: Stain, paint, varnish, or sealant choices for durability and aesthetics

- Where to Buy: Local lumberyards, hardware stores, online retailers, and reclaimed wood sources?

Types of Wood: Hardwood vs. softwood, plywood, MDF, particle board, and solid wood options

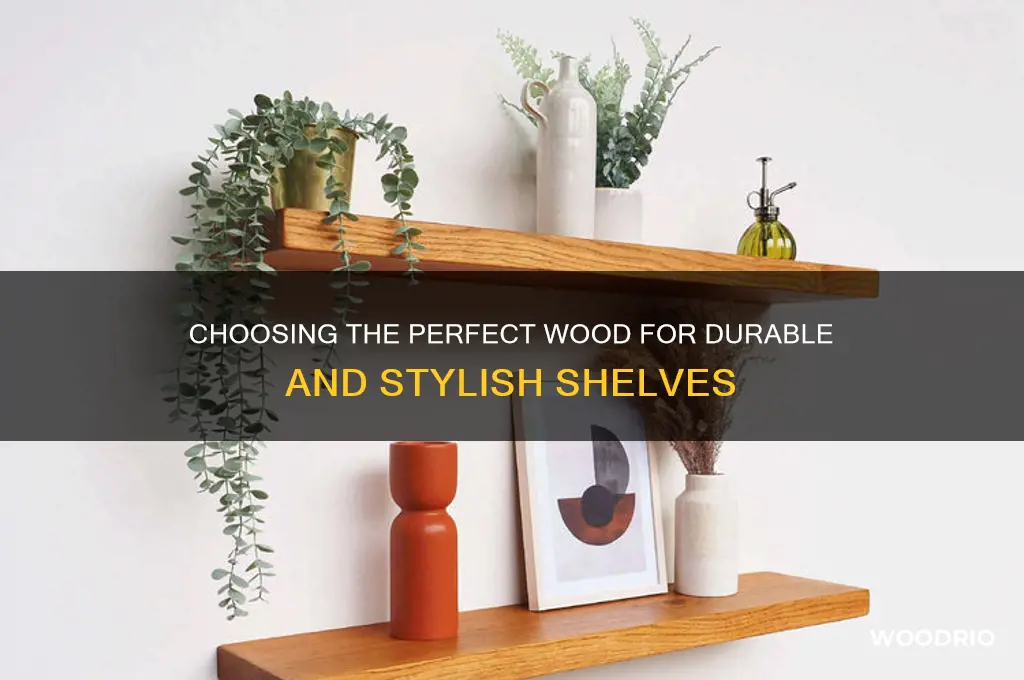

Choosing the right wood for your shelves begins with understanding the fundamental difference between hardwood and softwood. Hardwoods, like oak, maple, and cherry, come from deciduous trees and are denser, more durable, and often more expensive. They’re ideal for high-traffic areas or shelves that need to bear heavy loads. Softwoods, such as pine and cedar, come from coniferous trees and are lighter, easier to work with, and more budget-friendly. While softwoods are less dense, they’re perfect for decorative shelves or areas with minimal stress. The choice depends on your project’s demands and your budget.

If you’re looking for versatility and affordability, plywood is a strong contender. Made by gluing thin layers of wood veneer together, plywood offers stability and resists warping better than solid wood. It’s available in various thicknesses, with ¾-inch being a common choice for sturdy shelving. For a smoother finish, opt for plywood with a higher grade on the face side. However, keep in mind that plywood edges may need edging tape or trim to look polished. It’s a practical option for DIYers who want a balance of strength and cost.

Medium-density fiberboard (MDF) and particle board are engineered wood products often used for shelving, but they come with trade-offs. MDF is made from fine wood fibers and resin, creating a smooth, uniform surface ideal for painting. It’s lightweight and affordable but prone to swelling when exposed to moisture, making it unsuitable for humid areas like bathrooms. Particle board, composed of wood chips and resin, is even cheaper but less durable. Both are best for lightweight shelves or projects where aesthetics are prioritized over strength.

For a premium, timeless look, solid wood shelves are unmatched. Whether it’s walnut, mahogany, or reclaimed barnwood, solid wood brings natural beauty and character to any space. However, it’s the most expensive option and requires careful maintenance to prevent warping or cracking. Solid wood is best for statement pieces or areas where durability and aesthetics are equally important. If you’re willing to invest time and money, solid wood shelves can last a lifetime and become a focal point of your room.

In summary, the type of wood you choose for your shelves should align with your project’s functional and aesthetic needs. Hardwoods and solid wood offer durability and beauty but come at a higher cost, while softwoods and engineered options like plywood, MDF, and particle board provide affordability and ease of use. Consider the shelf’s location, weight-bearing requirements, and desired finish to make an informed decision. With the right wood, your shelves will not only be functional but also enhance the overall design of your space.

Bulk Wood Buying Guide: Cost-Effective Strategies for Large Purchases

You may want to see also

Explore related products

$89.22 $94.66

Wood Grades: Select, common, or utility grades and their impact on cost and appearance

Wood grades are the unsung heroes of shelf-building, quietly dictating both your budget and the final aesthetic. At the top tier, Select grade wood is the crème de la crème, boasting minimal knots, uniform color, and a smooth, flawless surface. Think of it as the hardwood equivalent of a luxury car—pristine but pricey. For shelves in high-visibility areas like living rooms or offices, Select grade ensures a polished, professional look. However, this premium appearance comes at a cost, often 20–30% higher than lower grades. If your shelves will be prominently displayed and you’re aiming for a seamless finish, the investment might be justified.

One step down, Common grade wood strikes a balance between affordability and appearance. It allows for small knots, slight color variations, and minor imperfections, making it a practical choice for most shelving projects. For example, if you’re building pantry shelves or a garage storage unit, Common grade offers durability without breaking the bank. Its character adds a rustic charm, especially when paired with a clear finish that highlights the wood’s natural texture. While it’s not as flawless as Select grade, it’s often half the price, making it a smart compromise for functional yet attractive shelves.

At the budget-friendly end, Utility grade wood is the workhorse of the bunch, prized for its affordability but not its looks. Expect larger knots, cracks, and uneven grain patterns—imperfections that are less about charm and more about utility. This grade is ideal for hidden or temporary shelves, such as those in closets, basements, or workshops. To make Utility grade more presentable, consider painting it or using it in a distressed, farmhouse-style design. While it’s the cheapest option, its rough appearance limits its use to areas where form takes a backseat to function.

Choosing the right grade depends on your project’s visibility and purpose. For instance, a bookshelf in a home office might warrant Select grade for a sleek, professional vibe, while a laundry room shelf could easily use Utility grade. Always inspect the wood before purchasing, as even within grades, quality can vary. Pro tip: If you’re mixing grades, use higher-quality wood for the visible faces and lower grades for the sides or back to save costs without sacrificing appearance. Ultimately, understanding wood grades empowers you to make informed decisions that align with both your budget and design goals.

Best Places to Buy Quality Wood for Charcuterie Boards

You may want to see also

Explore related products

Sizing & Thickness: Measuring shelf dimensions, standard wood thicknesses, and cutting requirements

Accurate measurements are the backbone of any shelving project. Start by determining the length, width, and depth of your desired shelves. Consider the space where they’ll be installed—measure wall lengths, account for obstructions, and decide on the number of shelves. For example, a standard bookshelf might require boards 36 inches long, 12 inches deep, and spaced 12 inches apart vertically. Always double-check measurements to avoid costly mistakes. Pro tip: Use a tape measure with metric and imperial markings for flexibility, especially if working with pre-cut wood sizes.

Wood thickness directly impacts shelf strength and aesthetics. Common thicknesses for shelving include ¾ inch (18 mm), 1 inch (25 mm), and 1.5 inches (38 mm). Thicker wood provides greater load-bearing capacity but can look bulky in smaller spaces. For lightweight items like books or decor, ¾-inch plywood or solid wood is sufficient. Heavier loads, such as storage bins or collectibles, require 1-inch or thicker boards. Specialty projects, like floating shelves, often use 2-inch thick wood for both strength and visual appeal. Match thickness to function and style for optimal results.

Cutting wood to size requires precision and the right tools. If you’re purchasing pre-cut wood, most hardware stores offer cutting services for a small fee—bring your measurements and confirm they’re accurate before leaving the store. For DIY cutting, a circular saw or table saw works best for straight cuts, while a jigsaw handles curved designs. Always mark cut lines with a pencil and use a straightedge for guidance. Safety first: wear eye protection, secure the wood firmly, and let the blade do the work without forcing it. Sand cut edges to smooth rough surfaces and prevent splinters.

Standard lumber dimensions can be misleading—a “1x4” board is actually ¾ inch thick and 3.5 inches wide. This discrepancy arises from drying and planing during manufacturing. When planning shelves, account for actual dimensions, not nominal sizes. For example, if you need a shelf 11 inches deep, a 1x12 board (actual width: 11.25 inches) is ideal. Understanding this difference ensures your measurements align with available materials and avoids unnecessary trimming. Always verify dimensions before purchasing to streamline your project.

Where to Find Wooden Crates in West Plains, MO: A Guide

You may want to see also

Explore related products

Finishing Options: Stain, paint, varnish, or sealant choices for durability and aesthetics

Choosing the right finish for your wood shelves is crucial for both protection and style. Stain, paint, varnish, and sealant each offer distinct advantages, but their suitability depends on your desired look, the wood type, and the shelf’s intended use. Stain penetrates the wood, enhancing its natural grain while allowing texture to show through. It’s ideal for hardwoods like oak or maple where showcasing the wood’s character is desired. For softer woods like pine, stain can highlight imperfections, so a more opaque finish might be preferable. Always test stain on a scrap piece to ensure the color matches your vision.

Paint provides a uniform, opaque finish that conceals flaws and allows for endless color customization. It’s perfect for modern or eclectic spaces where the wood’s natural grain isn’t a focal point. Latex paint is durable and easy to clean, making it suitable for high-traffic areas like kitchens or children’s rooms. For a smoother finish, sand the wood with 220-grit sandpaper before applying two thin coats of primer followed by two coats of paint. Avoid overloading the brush to prevent drips, and allow ample drying time between coats.

Varnish and sealant prioritize durability, forming a protective layer that resists moisture, scratches, and wear. Varnish is oil- or water-based and adds a glossy or satin sheen, ideal for shelves in humid environments like bathrooms or laundry rooms. Sealants, such as polyurethane, are more matte and versatile, working well on both hardwood and softwood. Apply varnish or sealant with a foam brush or sprayer for an even finish, sanding lightly between coats with 320-grit sandpaper to ensure adhesion. Two to three coats are typically sufficient for optimal protection.

The choice between these finishes often boils down to balancing aesthetics and functionality. For a rustic, natural look, stain paired with a clear sealant offers the best of both worlds. If durability is paramount, a tinted varnish can provide color while protecting against damage. Paint is the go-to for bold statements or hiding imperfections. Consider the shelf’s location and usage—high-traffic areas benefit from harder finishes like polyurethane, while decorative shelves in low-moisture zones might only need a light stain. Always follow manufacturer instructions for application and curing times to ensure longevity.

Essential Guide to Choosing and Buying the Perfect Wood Planer

You may want to see also

Explore related products

Where to Buy: Local lumberyards, hardware stores, online retailers, and reclaimed wood sources

Local lumberyards are treasure troves for shelf-building enthusiasts, offering a hands-on experience that online shopping can’t replicate. Here, you’ll find a wide variety of wood species, from oak and maple to pine and cedar, often in larger quantities and at competitive prices. Many lumberyards also provide custom cutting services, allowing you to purchase wood in the exact dimensions needed for your shelves. Pro tip: Call ahead to check availability and ask if they offer delivery or loading assistance, as lumber can be heavy and awkward to transport.

Hardware stores like Home Depot or Lowe’s are convenient one-stop shops for shelf wood, especially for beginners or small projects. These stores typically carry pre-cut boards in standard sizes, making it easy to grab what you need without fussing over measurements. Look for their in-store wood cutting services if you need precise lengths. While selection may be limited compared to lumberyards, hardware stores often have the advantage of predictable pricing and frequent sales. Keep an eye out for treated or finished wood options, which can save time on sanding and staining.

Online retailers such as Amazon, BuildDirect, or specialty wood suppliers like Woodworkers Source expand your options exponentially, offering exotic woods, rare grains, and even international species. This route is ideal for unique or high-end shelf projects, but it comes with caveats. Shipping costs can be steep for heavy items, and you won’t be able to inspect the wood for defects before purchasing. Always read reviews and check return policies. For best results, order samples first to ensure the color and quality meet your expectations.

Reclaimed wood sources, including salvage yards, antique stores, and online marketplaces like Etsy or Craigslist, are perfect for eco-conscious builders or those seeking a rustic aesthetic. Reclaimed wood often comes with character—knots, weathering, and patina—that new lumber lacks. However, sourcing it requires patience and flexibility, as availability is unpredictable. Inspect pieces carefully for rot, pests, or warping, and plan to clean and treat the wood before use. Reclaimed wood can be pricier per board foot, but its sustainability and unique charm often justify the cost.

Each buying option has its strengths: lumberyards for variety and customization, hardware stores for convenience, online retailers for specialty woods, and reclaimed sources for sustainability and character. Your choice depends on project scale, budget, and desired aesthetic. Combining sources—like buying structural wood from a lumberyard and accent pieces from a reclaimed supplier—can yield the best of both worlds. Always measure twice, plan for waste, and factor in finishing materials when budgeting. With the right wood, your shelves will be both functional and a reflection of your style.

Choosing the Perfect Wood Table: A Buyer's Guide to Quality

You may want to see also

Frequently asked questions

The best wood for shelves depends on your needs. Pine and poplar are affordable and easy to work with for DIY projects, while oak and maple offer durability and a premium look. Plywood or MDF are cost-effective options for painted shelves.

Shelf thickness depends on the span and weight it will support. For shorter spans (under 2 feet), 3/4-inch thick wood is sufficient. Longer spans (over 2 feet) may require 1-inch or thicker wood, or additional support like brackets.

You can buy wood at home improvement stores like Home Depot or Lowe’s, local lumberyards, or online retailers such as Amazon or specialty wood suppliers. Check for quality and pricing before purchasing.

Pre-cut wood is convenient and saves time, especially for beginners. If you have specific size requirements or access to cutting tools, cutting it yourself allows for customization but requires more effort and precision.