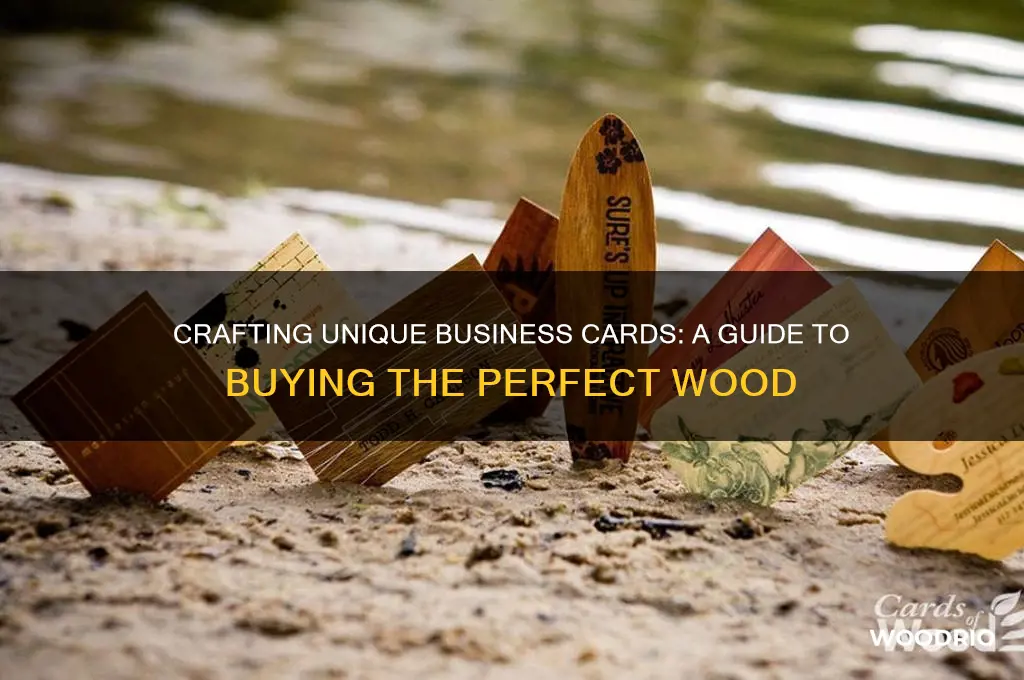

When venturing into the unique and eco-friendly realm of creating wooden business cards, the first step is to carefully select the type of wood that aligns with your brand’s aesthetic and durability needs. Common choices include maple, cherry, or walnut, each offering distinct grains and textures. Sourcing wood from reputable suppliers ensures quality and sustainability, often requiring thin sheets or veneers that can be easily laser-cut or engraved. Consider factors like thickness (typically 0.5mm to 1.5mm) and finish, as these will impact both the card’s functionality and the engraving process. Additionally, purchasing in bulk can reduce costs, making it a viable option for businesses looking to stand out with a premium, tactile alternative to traditional paper cards.

| Characteristics | Values |

|---|---|

| Material | Wood (e.g., birch, cherry, walnut, maple, bamboo) |

| Thickness | Typically 0.5mm to 1.5mm (0.02" to 0.06") |

| Size | Standard business card size: 89mm x 51mm (3.5" x 2") |

| Finish | Natural, stained, varnished, or laser-engraved |

| Engraving Options | Laser engraving for logos, text, and designs |

| Sustainability | Look for sustainably sourced or reclaimed wood |

| Quantity | Available in small batches (e.g., 50-500 cards) |

| Cost | $1–$5 per card, depending on wood type and customization |

| Durability | More durable than paper but susceptible to moisture |

| Vendors | Specialty wood product suppliers, Etsy, or custom manufacturers |

| Customization | Personalized designs, shapes, and edge finishes |

| Lead Time | 1–3 weeks, depending on complexity and vendor |

| Shipping | Additional cost; varies by vendor and location |

| Eco-Friendly Packaging | Some vendors offer recyclable or biodegradable packaging |

| Maintenance | Avoid prolonged exposure to water; occasional polishing recommended |

| Unique Features | Natural grain patterns make each card one-of-a-kind |

Explore related products

What You'll Learn

- Choose Wood Type: Select hardwoods like cherry, walnut, or maple for durability and aesthetic appeal

- Determine Thickness: Opt for 1-2mm thickness to ensure cards are sturdy yet pocket-friendly

- Sourcing Wood: Buy from local suppliers or online stores specializing in thin wood sheets

- Cutting Tools: Use laser cutters or precision saws for clean, accurate business card dimensions

- Finishing Techniques: Sand, seal, or engrave wood for a professional, polished final look

Choose Wood Type: Select hardwoods like cherry, walnut, or maple for durability and aesthetic appeal

Selecting the right wood type is the cornerstone of crafting business cards that stand out and endure. Hardwoods like cherry, walnut, and maple are not just materials; they are investments in quality. Cherry wood, with its warm, reddish hue, ages beautifully, developing a richer patina over time. Walnut offers a darker, more sophisticated tone, ideal for making a bold statement. Maple, known for its light color and fine grain, provides a clean, modern aesthetic. Each of these woods brings a unique character to your business card, ensuring it’s not just a piece of contact information but a memorable keepsake.

When choosing between these hardwoods, consider the practical aspects of durability. Cherry and walnut are both dense and resistant to wear, making them excellent choices for items that will be handled frequently. Maple, while slightly softer, still offers robust durability and is particularly suited for laser engraving due to its consistent grain. For business cards, thickness matters—aim for a wood veneer or thin sheet (around 1-2mm) to maintain flexibility while ensuring the card remains sturdy. Thicker pieces, though more durable, can be cumbersome and less practical for everyday use.

Aesthetic appeal is where these hardwoods truly shine. Cherry’s natural warmth pairs well with minimalist designs, while walnut’s deep tones complement metallic accents or bold typography. Maple’s neutral palette serves as a blank canvas, allowing vibrant colors or intricate patterns to pop. To enhance the wood’s natural beauty, consider finishing techniques like oiling or waxing, which protect the surface while highlighting the grain. Avoid heavy varnishes, as they can obscure the wood’s texture and detract from its organic charm.

Cost and availability are practical factors to weigh. Cherry and maple are generally more affordable and widely available, making them accessible options for larger orders. Walnut, with its premium look and feel, comes at a higher price point but can justify the expense for high-end or luxury branding. If sustainability is a priority, opt for FSC-certified wood or reclaimed sources, ensuring your business cards align with eco-conscious values.

In conclusion, choosing the right hardwood for your business cards is a balance of aesthetics, durability, and practicality. Cherry, walnut, and maple each offer distinct advantages, from their unique visual appeal to their ability to withstand daily use. By selecting the wood type thoughtfully, you can create business cards that not only leave a lasting impression but also reflect the quality and values of your brand.

Best Places to Buy Rough Sawn Wood for Your Next Project

You may want to see also

Explore related products

$10.99 $13.99

Determine Thickness: Opt for 1-2mm thickness to ensure cards are sturdy yet pocket-friendly

Choosing the right thickness for wooden business cards is a delicate balance between durability and practicality. A thickness of 1-2mm strikes this balance perfectly. At 1mm, the card is thin enough to slip into a wallet or cardholder without bulking it up, yet thick enough to avoid feeling flimsy. At 2mm, it gains a substantial, premium feel that communicates quality and craftsmanship. Anything thinner risks bending or breaking, while anything thicker becomes cumbersome and less pocket-friendly.

Consider the end-user experience when selecting thickness. A 1mm card is ideal for professionals who frequently exchange cards and need them to be lightweight and easy to carry. For luxury brands or high-end clients, a 2mm card conveys a sense of exclusivity and robustness. However, ensure the thickness aligns with the card’s design—intricate engravings or cutouts may require slightly thicker wood to maintain structural integrity.

From a production standpoint, 1-2mm thickness is practical for laser cutting and engraving, as it minimizes material waste while ensuring precision. Thicker wood can be more challenging to work with and may increase production costs. Additionally, thinner wood is easier to source in various types, such as cherry, walnut, or bamboo, allowing for greater customization in texture and color.

A practical tip: test the thickness by holding a sample card alongside a standard paper business card. Notice how it feels in your hand and how it fits in a wallet. If it bends easily or feels too heavy, adjust accordingly. Remember, the goal is to create a card that stands out for its uniqueness, not its inconvenience.

In conclusion, opting for a 1-2mm thickness ensures your wooden business cards are both functional and impressive. This range provides the ideal blend of sturdiness and portability, making your cards memorable without being burdensome. By prioritizing thickness, you elevate the tactile experience of your brand, leaving a lasting impression on anyone who receives it.

Buying Just the Head of Callaway Rogue Fairway Wood: Is It Possible?

You may want to see also

Explore related products

Sourcing Wood: Buy from local suppliers or online stores specializing in thin wood sheets

Local suppliers offer a tactile, hands-on approach to sourcing wood for business cards. Visiting a sawmill or woodworking specialty store allows you to inspect the grain, texture, and thickness of thin wood sheets firsthand. This is crucial when aiming for a specific aesthetic, as digital images often fail to capture the nuances of natural wood. Ask about locally sourced options to reduce your carbon footprint and support regional businesses. Many local suppliers also offer custom cutting services, ensuring the wood sheets are precisely the size needed for your business cards, minimizing waste.

Online stores specializing in thin wood sheets provide a vast selection of species, finishes, and thicknesses, often catering to niche preferences. Websites like WoodSlabs.com or ExoticLumberCo.com offer detailed product descriptions, including moisture content and recommended uses, which is essential for ensuring the wood’s durability in a business card format. Look for vendors that provide sample packs, allowing you to test different woods before committing to a larger order. Be mindful of shipping costs and lead times, as these can vary significantly depending on the supplier’s location and the quantity ordered.

Comparing local and online sourcing reveals trade-offs. Local suppliers often charge higher prices due to smaller-scale operations but offer immediate availability and personalized service. Online stores, while potentially more affordable, may require longer lead times and lack the ability to inspect the wood before purchase. For small-scale projects like business cards, consider starting with a local supplier for a few sheets to ensure quality, then scaling up with an online order if needed. Always verify the supplier’s reputation through reviews or testimonials to avoid subpar materials.

When selecting wood, prioritize species known for their workability and durability in thin formats, such as birch, cherry, or walnut. Thicknesses between 1/32” and 1/16” are ideal for business cards, balancing flexibility and sturdiness. Avoid exotic woods unless they’re sustainably sourced, as many are endangered. If opting for online purchases, inquire about finishing options—some suppliers offer pre-sanded or sealed sheets, saving time in the production process. Regardless of the source, always acclimate the wood to your workspace’s humidity for at least 48 hours to prevent warping.

Best Places to Buy Wood for Laser Cutting Projects

You may want to see also

Explore related products

Cutting Tools: Use laser cutters or precision saws for clean, accurate business card dimensions

Achieving precise dimensions is critical when crafting wooden business cards, as even a millimeter’s deviation can compromise their professionalism. Laser cutters and precision saws are the go-to tools for this task, each offering distinct advantages depending on your needs. Laser cutters excel in producing intricate designs with razor-sharp edges, ideal for cards featuring detailed logos or patterns. Precision saws, on the other hand, are more accessible and cost-effective for simpler designs, provided you have a steady hand and a sharp blade.

To use a laser cutter, start by preparing a digital file of your design in vector format, ensuring all dimensions match the standard business card size of 3.5 x 2 inches. Secure the wood sheet firmly on the laser bed to prevent shifting during cutting. Adjust the laser settings based on the wood’s thickness—typically, softer woods like balsa require lower power, while hardwoods like walnut demand higher intensity. Always test on a scrap piece first to fine-tune speed and power settings. Safety is paramount; wear protective eyewear and ensure proper ventilation to avoid inhaling fumes.

Precision saws, such as scroll saws or table saws with fine-tooth blades, require a steady hand and careful planning. Mark the wood with a pencil and ruler, double-checking measurements before making the first cut. For straight cuts, a table saw with a crosscut sled ensures accuracy, while a scroll saw is better for curved or intricate edges. Use a blade with at least 14 teeth per inch for clean results, and apply light, consistent pressure to avoid splintering. Sand the edges afterward to smooth any rough spots.

Comparing the two, laser cutters offer unmatched precision and speed, making them ideal for bulk production or complex designs. However, they come with a higher upfront cost and require technical know-how. Precision saws are more budget-friendly and accessible but demand greater manual skill and time. For hobbyists or small-scale projects, a saw may suffice, while professionals often opt for the efficiency of a laser cutter.

Regardless of the tool chosen, consistency is key. Measure twice, cut once, and always prioritize safety. With the right equipment and technique, you’ll achieve wooden business cards that stand out for their craftsmanship and professionalism.

Choosing the Perfect Wood for Your Furniture: A Buyer's Guide

You may want to see also

Explore related products

Finishing Techniques: Sand, seal, or engrave wood for a professional, polished final look

Wooden business cards demand a finish that elevates their natural beauty while ensuring durability. Sanding is the foundational step, smoothing rough edges and surfaces to create a canvas for further refinement. Start with a coarse grit (80-120) to remove imperfections, then progress to finer grits (220-400) for a silky texture. Hand-sanding allows precision, especially for intricate designs, while power sanders expedite the process for larger batches. Always sand in the direction of the grain to avoid scratches that mar the wood’s integrity.

Sealing is where functionality meets aesthetics. A protective coat not only enhances the wood’s color and grain but also guards against moisture, stains, and wear. Choose a finish based on the desired look and card usage. For a matte, natural appearance, opt for a wax-based sealant like beeswax or carnauba wax. Polyurethane or varnish provides a glossy, durable finish ideal for high-contact cards. Apply thin, even coats with a brush or cloth, allowing ample drying time between layers. Two to three coats typically suffice, striking a balance between protection and thickness.

Engraving adds a tactile and visual dimension, transforming a simple card into a memorable keepsake. Laser engraving is precise and versatile, allowing for intricate logos, text, or patterns. For a handcrafted touch, consider hand-engraving with a woodburning tool, though this requires skill and time. Engrave before sealing to avoid damaging the protective layer. Pairing engraving with a contrasting wood stain or paint can highlight the design, though this risks obscuring the wood’s natural charm—a trade-off worth considering.

Combining these techniques requires strategic sequencing. Sand first to ensure a uniform surface, engrave next to embed designs cleanly, and seal last to lock in both the wood’s beauty and the engraved details. Each step builds on the last, culminating in a card that feels as premium as it looks. While the process demands patience and attention to detail, the result—a polished, professional wooden business card—is a testament to craftsmanship that leaves a lasting impression.

Best Places to Buy Smoking Wood for Perfect BBQ Flavor

You may want to see also

Frequently asked questions

Hardwoods like cherry, walnut, or maple are ideal due to their durability, fine grain, and aesthetic appeal. Avoid softwoods as they may splinter or warp easily.

You can purchase wood from local lumberyards, woodworking suppliers, or online platforms like Etsy, Amazon, or specialty wood vendors. Look for thin wood veneers or sheets.

Aim for wood thickness between 1/16 inch (1.5mm) and 1/8 inch (3mm) to ensure the card is sturdy yet practical for wallet use.

Yes, a laser cutter or CNC machine is recommended for precision. Alternatively, a scroll saw or band saw can be used, but finishing edges with sandpaper is essential.

Apply a thin coat of clear polyurethane, varnish, or beeswax to seal the wood. Avoid excessive moisture and reapply the finish periodically to maintain durability.