Drilling a long hole in wood requires careful planning and the right tools to ensure precision and avoid damaging the material. To begin, select a drill bit that matches the diameter of the hole you need, opting for a longer bit or an extension if the depth exceeds standard lengths. Secure the wood firmly in place using clamps or a vise to prevent movement during drilling. Start by marking the entry and exit points with a pencil and center punch to guide the bit. Use a pilot hole at the starting point to reduce the risk of splitting, especially in hardwoods. Drill slowly and steadily, applying consistent pressure and periodically retracting the bit to clear wood chips. For through-holes, consider supporting the exit side with a sacrificial board to prevent tear-out. Always wear safety gear, including eye protection, and ensure your workspace is well-ventilated. With the right technique and precautions, drilling a long hole in wood can be accomplished efficiently and cleanly.

| Characteristics | Values |

|---|---|

| Drill Bit Type | Spade bit, Forstner bit, or auger bit (depending on hole diameter and depth) |

| Pilot Hole | Recommended for holes longer than 3 inches to guide the bit and prevent wandering |

| Drill Speed | Slow to moderate speed (500-1500 RPM) to avoid overheating and burning the wood |

| Drill Pressure | Consistent, moderate pressure to maintain control and prevent bit binding |

| Lubrication | Wax, soap, or specialized drill lubricants to reduce friction and heat buildup |

| Backing Board | Use a sacrificial board behind the workpiece to prevent tear-out on the exit side |

| Clamping | Secure the workpiece firmly to prevent movement during drilling |

| Marking | Accurately mark the hole's starting point and path using a straight edge or guide |

| Drill Depth Stops | Use depth stops or tape on the bit to control hole depth |

| Cooling Breaks | Pause periodically for long holes to allow the bit to cool down |

| Bit Sharpening | Ensure the drill bit is sharp to improve cutting efficiency and reduce effort |

| Alignment Tools | Use a drill guide or jig for straight and accurate hole alignment |

| Wood Grain Consideration | Drill with the grain when possible to reduce splintering and tear-out |

| Hole Diameter | Choose a bit size appropriate for the intended application (e.g., wiring, dowels) |

| Safety Gear | Wear safety glasses and ear protection during drilling |

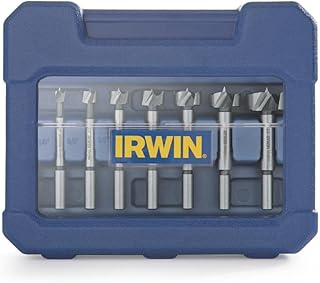

Explore related products

$14.79 $18.98

$15.29 $18.99

What You'll Learn

Choose the Right Drill Bit

Drilling a long hole in wood requires precision and the right tools, starting with the drill bit. The first step is to select a bit designed for wood, typically identified by its brad point or auger design. Brad point bits, with their sharp, centered point and cutting spurs, ensure accurate hole placement and clean edges, making them ideal for long holes. Auger bits, on the other hand, excel at removing wood chips efficiently, reducing friction and heat buildup during extended drilling. Both types are available in lengths up to 18 inches, but for holes deeper than 6 inches, an extension or a specialized long-reach bit may be necessary.

The diameter of the bit is equally critical. For structural applications, such as running wiring or piping, a 1-inch or larger bit is common. However, smaller diameters (e.g., ¼-inch to ½-inch) are often used for pilot holes or decorative purposes. When drilling long holes, consider using a stepped approach: start with a smaller bit to guide the path, then gradually increase the size to reduce splintering and maintain control. This method also minimizes the risk of the bit binding, which can cause the wood to crack or the drill to overheat.

Material quality plays a significant role in bit performance. High-speed steel (HSS) bits are affordable and suitable for occasional use, but they dull quickly under prolonged friction. For longer holes or repeated drilling, carbide-tipped bits offer superior durability and heat resistance. Cobalt bits, while more expensive, provide a balance between cost and longevity, making them a practical choice for intermediate projects. Always ensure the bit is sharp; a dull edge increases drilling time and the likelihood of errors.

Drilling technique complements bit selection. Use a drill press for maximum control, especially when accuracy is critical. If a handheld drill is necessary, secure the wood in a vise and maintain steady pressure without forcing the bit. Periodically retract the bit to clear wood chips, which accumulate faster in longer holes. For holes deeper than 12 inches, consider using a lubricant like beeswax or a specialized drilling fluid to reduce friction and extend bit life.

Finally, safety should never be overlooked. Long bits are prone to bending or breaking under excessive force, so let the tool do the work without applying undue pressure. Wear safety goggles to protect against flying debris, and ensure the workspace is well-lit and free of obstructions. By pairing the right bit with careful technique, drilling long holes in wood becomes a manageable task rather than a daunting challenge.

Air Drying Wood Slabs: Optimal Time for Perfect Results

You may want to see also

Explore related products

Mark and Align the Hole Accurately

Precision in marking and aligning a hole in wood is the linchpin of a successful drilling operation, especially when dealing with longer holes where even a minor misalignment can compound into a significant error. Begin by identifying the exact center point of the hole using a sharp pencil and a ruler or square. For through-holes, align the mark on both faces of the wood to ensure the drill bit enters and exits precisely where intended. This dual-marking technique eliminates guesswork and provides a visual guide for maintaining alignment throughout the drilling process.

Consider the grain direction when marking your hole, as drilling perpendicular to the grain minimizes splintering and ensures cleaner edges. If the hole must align with existing features, such as joints or edges, use a combination square or straightedge to extend reference lines across the workpiece. For larger projects, a laser guide or plumb bob can help transfer measurements from a blueprint or template onto the wood surface. Always double-check measurements with a tape measure or caliper to avoid errors that become irreversible once drilling begins.

Alignment tools like drill guides or jigs are indispensable for maintaining accuracy, particularly for longer holes where the drill bit’s tendency to wander increases. A drill press, when available, offers superior control compared to handheld drills, as its fixed axis ensures the bit remains perpendicular to the wood surface. If using a handheld drill, attach a guide sleeve or fence to the bit to stabilize its path. For angled holes, a tilt guide or adjustable jig can help maintain the desired angle consistently, reducing the risk of deviation.

One often-overlooked technique is the use of sacrificial boards or backing material to prevent blowout on the exit side of the hole. Place a piece of scrap wood behind the workpiece to support the fibers as the bit breaks through, minimizing splintering and ensuring a clean exit. Additionally, applying masking tape over the marked area can sharpen the visibility of your pencil lines and reduce tear-out caused by the drill bit’s edges. These small preparations can dramatically improve the accuracy and finish of the hole.

Finally, test your alignment with a pilot hole or smaller bit before committing to the full-size drill. This preliminary step allows you to assess the accuracy of your markings and make adjustments without damaging the wood. If misalignment occurs, fill the pilot hole with wood putty or glue, realign your marks, and attempt again. Patience and methodical preparation in the marking and alignment phase are the cornerstones of drilling long holes that meet both functional and aesthetic standards.

Heart Wood Pellets Lifespan: Durability, Storage Tips, and Longevity Explained

You may want to see also

Explore related products

Use a Pilot Hole Technique

Drilling a long hole in wood without splitting or damaging the material requires precision and the right technique. One of the most effective methods to achieve this is by using a pilot hole technique. This approach involves creating a smaller, preliminary hole that guides the larger drill bit, reducing the risk of wood splitting and ensuring a cleaner, more accurate result.

Steps to Master the Pilot Hole Technique

Begin by selecting a drill bit that is significantly smaller than your final hole size—typically 1/3 to 1/2 the diameter of the larger bit. For example, if you’re drilling a 1-inch hole, start with a 1/4-inch or 3/8-inch bit. Mark the center of your drilling location with a sharp pencil or awl to ensure accuracy. Secure the wood firmly in place using clamps or a vise to prevent movement during drilling. Drill the pilot hole at a steady pace, maintaining consistent pressure. This initial hole acts as a guide, reducing friction and resistance when you switch to the larger bit.

Cautions and Practical Tips

While the pilot hole technique is straightforward, there are a few pitfalls to avoid. First, ensure the wood is free of knots or weak spots, as these areas are prone to splitting even with a pilot hole. If drilling through hardwoods like oak or maple, consider using a lubricant such as beeswax or drilling fluid to minimize heat buildup and friction. For longer holes, periodically withdraw the bit to clear wood chips, which can clog the hole and cause binding. Finally, always wear safety gear, including eye protection and gloves, to guard against flying debris.

Comparative Advantage Over Direct Drilling

Compared to drilling directly with a large bit, the pilot hole technique offers several advantages. It significantly reduces the torque required, making it easier to control the drill, especially for handheld operations. This method also minimizes the risk of the wood cracking or splintering, which is particularly important when working with delicate or expensive materials. Additionally, the pilot hole ensures that the larger bit follows a straight path, improving accuracy and reducing the likelihood of wandering or misalignment.

The pilot hole technique is a simple yet powerful method for drilling long holes in wood with precision and confidence. By investing a few extra minutes to create a preliminary hole, you can achieve professional-quality results while protecting your material from damage. Whether you’re a seasoned woodworker or a DIY enthusiast, mastering this technique will elevate your craftsmanship and expand your project capabilities.

Masterbuilt Electric Smoker: Optimal Wood Chip Soaking Time Guide

You may want to see also

Explore related products

Apply Consistent Drilling Pressure

Drilling a long hole in wood requires more than just a steady hand; it demands consistent pressure to maintain control and precision. Applying even force ensures the bit advances smoothly without binding or overheating, which can lead to splintered wood or a broken tool. Start by setting the drill at a low to medium speed—around 500 to 1,000 RPM—to reduce the risk of burning the wood. Gradually increase pressure as the bit penetrates, but avoid forcing it. Think of it as a partnership between the tool and the material, where balance is key.

Consider the analogy of driving a nail: too much force can bend it, while too little leaves it sticking out. Similarly, inconsistent pressure while drilling can cause the bit to wander or create an uneven hole. For longer holes, where the bit’s depth exceeds 3 inches, use a drill press if available. This tool naturally maintains consistent pressure and alignment, minimizing human error. If a handheld drill is your only option, brace your non-drilling hand against a stable surface to steady the tool and apply pressure uniformly.

A practical tip for maintaining pressure is to mark the bit with tape at the desired depth. This visual cue helps you monitor progress and adjust force accordingly. For example, if you’re drilling a 6-inch hole, mark the bit at 2-inch intervals. As you reach each mark, lighten the pressure slightly to allow the bit to clear wood chips, then resume steady force. This technique prevents clogging, which can stall the bit and damage the wood.

Caution is essential when drilling through dense hardwoods like oak or maple, as these materials resist penetration and can blunt the bit quickly. In such cases, reduce pressure slightly and let the tool work at its own pace. Conversely, softer woods like pine may tempt you to apply more force, but this can lead to tear-out at the exit point. Always prioritize consistency over speed, regardless of the wood type.

In conclusion, consistent drilling pressure is the linchpin of creating clean, accurate long holes in wood. It’s a skill honed through practice, but simple techniques—like using a drill press, marking the bit, and adjusting force based on wood density—can yield professional results. Remember, the goal isn’t to rush but to maintain control, ensuring the tool and material work in harmony.

Perfect Air Fryer Time for Roger Wood Sausage: A Guide

You may want to see also

Explore related products

Support Wood to Prevent Splinters

Drilling long holes in wood often leads to splintering, especially when the bit exits the material. This occurs because the wood fibers, no longer supported, tear and fracture under pressure. To mitigate this, supporting the wood becomes critical. Place a sacrificial board—a scrap piece of plywood or hardwood—directly beneath the exit point. This backing absorbs the force, keeping the fibers intact as the bit breaks through. Without this simple step, even the sharpest bit will leave unsightly splinters, compromising both appearance and structural integrity.

Consider the analogy of punching through paper versus punching through cardboard. The paper tears because it lacks rigidity, while the cardboard resists due to its layered structure. Wood behaves similarly when drilling. By adding a sacrificial board, you mimic the cardboard’s stability, allowing the bit to exit cleanly. For best results, ensure the backing board is at least ½ inch thick and securely clamped to the workpiece. Thinner boards may warp or crack under pressure, defeating their purpose.

While backing boards are effective, they’re not the only method. Another approach involves using a drill press with a fence or guide. This setup ensures the bit remains perpendicular to the wood, reducing lateral stress that causes splintering. However, this method requires precision and additional tools, making it less accessible for casual woodworkers. For handheld drills, the backing board remains the most practical solution, combining simplicity with reliability.

A lesser-known technique involves applying masking tape or painter’s tape to the exit point. While not as robust as a backing board, the tape can help hold fibers together momentarily as the bit exits. This method is best for shallow holes or softer woods, where splintering is minimal. For deeper holes or hardwoods, tape alone is insufficient. Combine it with a backing board for added protection, especially when drilling through dense species like oak or maple.

In conclusion, supporting wood to prevent splinters is a matter of understanding material behavior and applying practical solutions. Whether using a backing board, tape, or a drill press guide, the goal is to maintain fiber integrity during drilling. Each method has its merits, but the backing board stands out for its versatility and effectiveness. By incorporating this simple technique, woodworkers can achieve clean, professional results without the frustration of splintered exits.

Understanding the Petrification Process: How Long Does Wood Turn to Stone?

You may want to see also

Frequently asked questions

For drilling long holes in wood, use an auger bit or a spur point bit. Auger bits are ideal for deep holes as they have a spiral design that efficiently removes wood chips, while spur point bits are great for precision and cleaner entry points.

To ensure a straight hole, start by marking the center point with a sharp awl or center punch. Use a drill guide or fence to keep the drill bit aligned. Begin drilling at a slow speed and apply steady pressure without forcing the bit.

To prevent splitting, use a backer board behind the wood to provide support as the bit exits. Drill at a slower speed and use a sharp bit to reduce friction. For hardwoods or near the edges, pre-drill a pilot hole with a smaller bit before using the larger one.