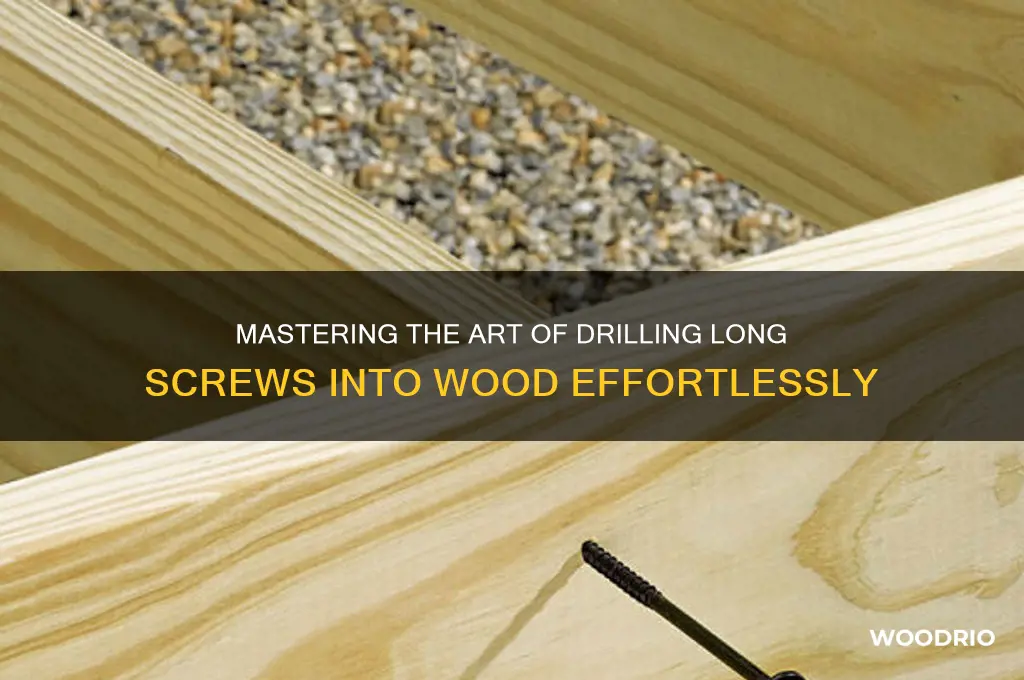

Drilling long screws into wood requires careful preparation and technique to ensure a secure hold without damaging the material. Begin by selecting the appropriate screw length and gauge for your project, ensuring it matches the wood thickness and intended load. Pre-drilling pilot holes is essential, especially for hardwoods, to prevent splitting; use a drill bit slightly smaller than the screw’s shaft diameter and slightly shorter than the screw’s length to account for threading. For deeper screws, consider using a countersink bit to create a clean recess for the screw head. Always align the screw straight to avoid bending or breaking it, and apply steady pressure while driving it in. Using a power drill with a clutch setting can help prevent over-tightening, preserving the wood’s integrity and ensuring a professional finish.

| Characteristics | Values |

|---|---|

| Drill Bit Type | Use a pilot hole drill bit (e.g., spade bit, Forstner bit, or auger bit) that matches the screw diameter. For long screws, consider a longer drill bit or extension. |

| Pilot Hole Depth | Drill a pilot hole at least 2/3 the length of the screw to prevent splitting the wood. For hardwoods, drill a deeper pilot hole. |

| Pilot Hole Diameter | The pilot hole diameter should be slightly smaller than the screw's root diameter (not including threads). Use a drill bit size chart for reference. |

| Drilling Technique | Start with a smaller pilot hole and gradually increase the size. Use slow speed and moderate pressure to avoid overheating or damaging the wood. |

| Screw Type | Choose coarse-threaded screws for softwoods and fine-threaded screws for hardwoods. Use self-tapping screws or pre-drill for harder woods. |

| Screw Length | Select a screw length that is at least 2/3 the thickness of the wood being fastened, plus the thickness of the material being attached. |

| Clamping | Clamp the wood pieces together to ensure proper alignment and prevent shifting during drilling and screwing. |

| Pre-drilling Hardwoods | Always pre-drill pilot holes in hardwoods to prevent splitting. Use a backing board behind the wood to reduce blowout. |

| Lubrication | Apply a small amount of beeswax or drilling lubricant to the screw threads to reduce friction and heat buildup. |

| Driving Technique | Use a power drill or impact driver with a screw-driving bit. Drive the screw at a slow, controlled speed to avoid stripping the threads or breaking the screw. |

| Wood Grain Direction | Drill and drive screws parallel to the wood grain to minimize splitting. For cross-grain applications, use shorter screws or reinforce with additional fasteners. |

| Wood Moisture Content | Ensure the wood is properly dried to prevent shrinkage and screw loosening over time. |

| Countersinking | Use a countersink bit to create a recessed hole for the screw head, ensuring a flush finish. |

| Finishing | Fill any visible screw holes with wood filler or plugs for a seamless appearance. Sand and finish the wood as desired. |

| Safety Precautions | Wear safety glasses, ear protection, and a dust mask. Secure the workpiece and maintain a firm grip on the drill to prevent accidents. |

Explore related products

What You'll Learn

- Pre-Drilling Pilot Holes: Use a drill bit slightly smaller than screw diameter to prevent wood splitting

- Choosing the Right Screw: Select screws with coarse threads for wood; match length to material thickness

- Using a Clutch Drill: Set clutch to low torque to avoid over-tightening and damaging the wood

- Aligning the Screw: Hold screw straight with a magnetic bit or manual guidance for accurate placement

- Applying Even Pressure: Drill steadily, applying consistent pressure to ensure the screw seats properly without stripping

Pre-Drilling Pilot Holes: Use a drill bit slightly smaller than screw diameter to prevent wood splitting

Drilling long screws into wood without pre-drilling pilot holes is a recipe for split timber, especially in hardwoods or near the end grain. The force required to drive a screw through dense material can cause the wood fibers to separate, compromising the joint's strength and appearance. Pre-drilling pilot holes alleviates this pressure by creating a guided path for the screw, reducing the risk of cracks and ensuring a cleaner, more professional finish.

To execute this technique effectively, select a drill bit that is slightly smaller in diameter than the screw’s shaft—not the threaded portion. For example, if using a #10 screw (approximately 3/16 inch in diameter), opt for a 1/8-inch drill bit. This size discrepancy allows the threads to grip the wood securely without overstressing the material. Mark the screw’s entry point with a pencil or awl to ensure accuracy, then drill the pilot hole to a depth equal to the screw’s length minus the thickness of the material being fastened. This prevents the screw from breaking through the opposite side prematurely.

While pre-drilling is essential for hardwoods like oak or maple, it’s also beneficial for softer woods when using long screws. Softwoods, such as pine, can still split under the pressure of deep screw penetration, particularly near knots or the end grain. For added protection, consider using a countersink bit to create a beveled hole for the screw head, ensuring it sits flush with the wood surface. This two-step process—pilot hole and countersink—is especially useful for visible joints where aesthetics matter.

One common mistake is skipping pilot holes when using self-tapping screws, assuming they eliminate the need for pre-drilling. While self-tapping screws are designed to create their own threads, they still exert significant force on the wood, particularly with longer lengths. Pre-drilling remains a best practice to preserve the wood’s integrity and ensure the screw seats properly. For outdoor projects, this step is non-negotiable, as wood expands and contracts with moisture changes, increasing the likelihood of splitting without pilot holes.

In summary, pre-drilling pilot holes is a simple yet critical step when driving long screws into wood. By using a drill bit slightly smaller than the screw’s diameter, you minimize the risk of splitting, enhance joint strength, and achieve a polished result. Whether working with hardwood or softwood, this technique ensures your project stands the test of time, both structurally and visually.

Durability of Wooden Homes: Lifespan, Maintenance, and Longevity Explained

You may want to see also

Explore related products

Choosing the Right Screw: Select screws with coarse threads for wood; match length to material thickness

Screws aren't one-size-fits-all, especially when working with wood. The key to a strong, lasting joint lies in choosing the right screw for the job. Coarse-threaded screws are your best bet for wood. Unlike fine-threaded screws designed for metal, coarse threads provide better grip and holding power in the fibrous structure of wood. Imagine trying to anchor a bookshelf with screws that barely bite into the wood – disaster waiting to happen.

Coarse threads act like tiny wedges, distributing the load and preventing the wood from splitting.

Length matters just as much as thread type. A screw too short won't provide enough bite, while one too long risks poking through the other side or weakening the material. As a general rule, the screw should penetrate the second piece of wood by at least half its diameter. For example, a 3-inch screw joining two 1-inch thick boards should extend at least 1.5 inches into the second board.

Don't be afraid to experiment with different screw lengths and types for specific projects. For softer woods like pine, shorter screws with wider threads might suffice. Harder woods like oak demand longer screws with more aggressive threads. Remember, the goal is to create a secure joint that can withstand the intended stress.

When in doubt, consult a screw size chart or seek advice from a hardware store professional.

Satin Wood Finish Curing Time: A Comprehensive Guide to Drying

You may want to see also

Explore related products

Using a Clutch Drill: Set clutch to low torque to avoid over-tightening and damaging the wood

Drilling long screws into wood requires precision to avoid splitting the material or stripping the screw threads. One effective tool for this task is a clutch drill, which allows you to control the torque applied during the process. By setting the clutch to a low torque, you can prevent over-tightening, a common issue that can compromise the integrity of both the screw and the wood. This method is particularly useful when working with softer woods or delicate projects where precision is paramount.

To begin, familiarize yourself with the clutch settings on your drill. Most clutch drills have a numbered dial, typically ranging from 1 to 20, where lower numbers indicate lower torque. For drilling long screws into wood, start by setting the clutch to a low value, such as 3 or 4. This setting ensures that the drill stops applying force once the screw reaches the desired depth, reducing the risk of over-tightening. Always test the clutch setting on a scrap piece of wood to ensure it provides the right balance of force without causing damage.

The technique you use while drilling is equally important. Hold the drill firmly but avoid applying excessive pressure, as the clutch is designed to do the work for you. Begin by positioning the screw tip on the marked spot and apply gentle, steady pressure to start the drilling process. Once the screw is partially inserted, the clutch will engage, allowing the drill to drive the screw in without forcing it. This approach not only protects the wood but also ensures the screw is securely fastened without being over-tightened.

A common mistake when using a clutch drill is ignoring the wood’s grain direction. Always align the screw with the grain to minimize the risk of splitting. If you’re working with hardwoods or thicker pieces, consider pre-drilling a pilot hole to guide the screw and further reduce stress on the wood fibers. Combining a pilot hole with a low torque clutch setting creates a fail-safe method for driving long screws into wood with professional results.

In conclusion, using a clutch drill with a low torque setting is a smart strategy for drilling long screws into wood. It balances efficiency with protection, ensuring your project remains intact and visually appealing. By understanding your tool, testing settings, and employing proper technique, you can achieve strong, damage-free connections every time. This method is especially valuable for DIY enthusiasts and professionals alike, offering a reliable solution for a common woodworking challenge.

Crafting a Solid Wood Gaming Table: Timeframe and Tips

You may want to see also

Explore related products

Aligning the Screw: Hold screw straight with a magnetic bit or manual guidance for accurate placement

Precision in screw alignment is non-negotiable when driving long screws into wood, as even a slight deviation can compromise structural integrity or aesthetics. A magnetic bit emerges as a game-changer here, its embedded magnet gripping the screw securely, ensuring it remains perpendicular to the wood surface. This tool is particularly invaluable for overhead or hard-to-reach areas where manual control is challenging. For instance, when fastening a wooden beam to a ceiling joist, a magnetic bit prevents the screw from wobbling or falling, allowing for seamless, one-handed operation.

While magnetic bits offer convenience, manual guidance provides tactile control, ideal for delicate or high-stakes projects. To align a screw manually, place its tip at the pre-drilled hole and apply gentle pressure while turning the screwdriver. Maintain a steady hand, ensuring the screw’s axis remains aligned with the hole’s center. This method is especially useful for fine woodworking, where precision outweighs speed. For example, when securing a cabinet hinge, manual alignment ensures the screw doesn’t skew, preserving the hinge’s functionality and the wood’s finish.

Comparing the two methods reveals their complementary strengths. Magnetic bits excel in efficiency and consistency, reducing the risk of human error, while manual guidance offers unparalleled control for intricate tasks. A hybrid approach—starting with a magnetic bit for initial alignment and switching to manual control for final tightening—can optimize results. This strategy is particularly effective for long screws, which are prone to misalignment due to their length and torque requirements.

Practical tips enhance alignment regardless of method. Always pre-drill a pilot hole to guide the screw’s path, especially in hardwoods where resistance is higher. For magnetic bits, ensure the magnet’s strength is sufficient for the screw size; weak magnets may fail with larger screws. When guiding manually, use a screwdriver with a comfortable grip and a tip that fits the screw head precisely to minimize slippage. Finally, practice on scrap wood to refine your technique before tackling the actual project.

In conclusion, aligning long screws into wood demands a blend of tools and techniques tailored to the task. Whether leveraging the efficiency of a magnetic bit or the precision of manual guidance, the goal remains the same: achieving a straight, secure fastening that withstands time and stress. Mastery of these methods transforms a potentially frustrating task into a seamless step in any woodworking project.

Exploring Muir Woods: Walking Time and Trail Tips Revealed

You may want to see also

Explore related products

Applying Even Pressure: Drill steadily, applying consistent pressure to ensure the screw seats properly without stripping

Drilling long screws into wood demands precision, and one critical aspect often overlooked is the application of even pressure. Uneven force can lead to stripped screw heads, misaligned holes, or damaged wood fibers. To avoid these pitfalls, start by positioning the screw tip at a 90-degree angle to the wood surface. Use a drill with a clutch setting if available, as this allows you to control the torque and prevent over-tightening. Begin drilling slowly, applying steady pressure without forcing the screw. This gradual approach ensures the threads bite into the wood evenly, reducing the risk of splitting or stripping.

Consider the wood type when applying pressure. Softer woods like pine require less force compared to hardwoods like oak, which demand more consistent and deliberate pressure. For longer screws, pause intermittently to assess alignment and ensure the screw is seating straight. If resistance increases suddenly, stop and re-evaluate—forcing the drill can cause the wood to crack or the screw to break. A firm, controlled grip on the drill minimizes wobbling, which can lead to uneven pressure distribution.

A practical tip is to use a depth-stop collar or tape on the screw to mark the desired depth. This prevents over-drilling and helps maintain consistent pressure throughout the process. For screws longer than 3 inches, consider pre-drilling a pilot hole to reduce friction and ensure smoother insertion. When drilling near the wood’s edge, apply slightly less pressure to avoid splintering. Remember, the goal is not speed but precision—rushing can compromise the integrity of the joint.

Comparing manual vs. powered drilling highlights the importance of even pressure. Hand-drilling allows for finer control but requires more effort, while powered drills offer efficiency but demand vigilance to avoid over-tightening. In both cases, maintaining a steady hand and consistent force is key. Think of it as threading a needle—too much pressure bends the needle, too little fails to pierce the fabric. Similarly, balanced pressure ensures the screw seats securely without damaging the material.

In conclusion, applying even pressure is a skill that bridges technique and awareness. It’s about understanding the wood’s properties, using the right tools, and practicing patience. By drilling steadily and monitoring resistance, you’ll achieve clean, durable screw placements every time. This approach not only enhances the structural integrity of your project but also extends the lifespan of your tools and materials. Master this technique, and you’ll tackle long screws with confidence, knowing each one is seated perfectly.

Cedar Wood Chips Decomposition: Breakdown Timeline and Factors Explained

You may want to see also

Frequently asked questions

Use a pilot hole drill bit that matches the screw size, typically a tapered or spade bit for larger screws, or a standard twist bit for smaller ones.

Pre-drill a pilot hole slightly smaller than the screw diameter, especially in hardwood or near the edges, to reduce splitting.

Use a screwdriver bit designed for the screw head type (e.g., Phillips, flathead, or Torx) and ensure it fits securely to avoid stripping the screw head.

Use a drill guide or clamp to keep the drill steady, and apply consistent pressure while driving the screw to maintain alignment.

It’s not recommended, as drilling long screws directly into wood increases the risk of splitting, especially in hardwood or near the edges. Always pre-drill for best results.