Laying wood for a longer deck requires careful planning and execution to ensure durability, stability, and aesthetic appeal. Begin by selecting high-quality, weather-resistant wood such as cedar, redwood, or pressure-treated lumber, which can withstand outdoor conditions. Prepare the ground by leveling the area and installing a sturdy foundation, typically using concrete footings or pier blocks to support the deck’s frame. Measure and mark the layout to ensure straight lines and proper spacing, then build the frame with joists spaced no more than 16 inches apart to provide adequate support for the longer span. Secure the decking boards perpendicular to the joists, starting from one end and using corrosion-resistant screws or nails to prevent warping or shifting. Leave a small gap between boards for water drainage and expansion, and pre-drill holes to avoid splitting the wood. Finally, sand rough edges and apply a protective sealant or stain to enhance longevity and maintain the deck’s appearance. Following these steps will result in a strong, visually appealing, and long-lasting wooden deck.

Explore related products

$43.95

What You'll Learn

- Choose the right wood type for durability and weather resistance

- Prepare the deck foundation with proper support and spacing

- Use corrosion-resistant screws or nails for secure fastening

- Apply sealant or stain to protect wood from elements

- Ensure consistent spacing between boards for expansion and drainage

Choose the right wood type for durability and weather resistance

Selecting the right wood type is the cornerstone of building a deck that withstands the test of time and elements. Hardwoods like Ipe, Cumaru, and Tigerwood are premium choices due to their natural resistance to rot, insects, and UV damage. These dense tropical woods have a Janka hardness rating exceeding 3,000 lbf, making them significantly more durable than softwoods like cedar or pine. While the upfront cost is higher—often $5 to $20 per square foot compared to $1 to $4 for pressure-treated pine—their lifespan of 40+ years with minimal maintenance justifies the investment. For those prioritizing longevity over budget, hardwoods are unparalleled.

If hardwoods are beyond your budget, pressure-treated lumber offers a cost-effective alternative with proper preparation. Look for wood treated with ACQ (alkaline copper quaternary) or CA-B (copper azole), which are less corrosive to fasteners than older CCA (chromated copper arsenate) treatments. Ensure the wood is rated for ground contact to maximize resistance to moisture and decay. After installation, apply a semi-transparent stain with UV inhibitors annually to protect against fading and warping. While its lifespan of 15–20 years is shorter than hardwood, diligent maintenance can extend its usability.

For a middle-ground option, consider naturally rot-resistant softwoods like cedar or redwood. These woods contain tannins and oils that deter pests and decay without chemical treatment. Cedar, with a Janka rating of 900 lbf, is lightweight and easy to work with, while redwood (1,200 lbf) offers richer color variations. Both require sealing every 1–2 years to maintain their appearance and structural integrity. At $3 to $7 per square foot, they balance affordability and durability, making them ideal for moderate climates with less extreme weather fluctuations.

When weighing your options, factor in your local climate and maintenance commitment. In humid or coastal areas, hardwoods or pressure-treated lumber are superior due to their moisture resistance. In drier regions, cedar or redwood may suffice with regular sealing. Always source wood certified by the Forest Stewardship Council (FSC) to ensure sustainability. Pair your wood choice with corrosion-resistant fasteners like stainless steel or hot-dipped galvanized screws to prevent premature failure. The right wood type, combined with thoughtful installation and care, ensures your deck remains a durable outdoor sanctuary for decades.

Trex vs. Wood: Which Material Offers Superior Longevity for Decks?

You may want to see also

Explore related products

Prepare the deck foundation with proper support and spacing

A solid foundation is the backbone of any deck, especially one designed for longevity. Proper support and spacing are critical to prevent sagging, warping, and premature deterioration. Begin by assessing the soil type and local building codes to determine the necessary depth and size of footings. For most residential decks, footings should extend below the frost line, typically 36 to 48 inches deep, to prevent shifting during freeze-thaw cycles. Use concrete forms and rebar to create sturdy footings, ensuring they are level and plumb before pouring concrete.

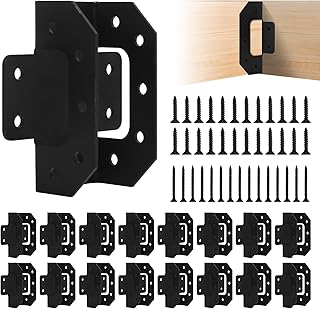

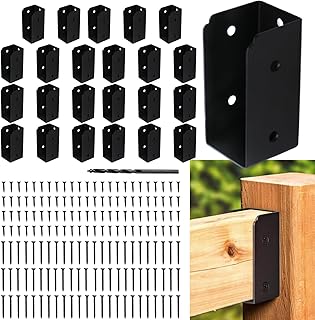

Once the footings are set, the next step is to install beams and joists with precise spacing. Beams, typically made of pressure-treated lumber, should span the length of the deck and rest securely on the footings. Joists, which run perpendicular to the beams, must be spaced according to the type of decking material used. For standard 2x6 decking boards, joists should be no more than 16 inches on center. For 5/4 decking, reduce this to 12 inches on center to prevent sagging. Use galvanized joist hangers to secure joists to beams, ensuring a strong, stable framework.

While spacing is crucial for structural integrity, it also impacts the deck’s appearance and functionality. Consistent spacing between boards allows for proper water drainage and prevents pooling, which can lead to rot and mold. Aim for a 1/8-inch gap between boards to accommodate expansion and contraction due to temperature changes. Use a consistent method, such as spacer clips or a small piece of wood, to maintain uniformity. For longer decks, consider incorporating expansion joints every 20 feet to allow the structure to move without cracking.

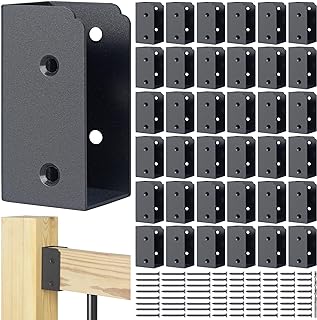

One often-overlooked aspect of foundation preparation is the use of proper hardware and materials. Galvanized or stainless steel fasteners are essential to prevent corrosion, especially in humid or coastal environments. Additionally, using a moisture barrier, such as a layer of gravel or geotextile fabric, beneath the deck can protect the foundation from water damage. For added stability, consider installing diagonal bracing or cross-bracing in larger decks to distribute weight more evenly.

In conclusion, preparing the deck foundation with proper support and spacing is a meticulous process that requires careful planning and execution. By adhering to structural guidelines, using high-quality materials, and incorporating practical techniques, you can ensure a deck that not only looks great but stands the test of time. Skimping on this step may save time initially but will inevitably lead to costly repairs or replacements down the line. Invest in a strong foundation, and your longer deck will reward you with years of enjoyment.

Crafting a Wooden Wheel: Time and Techniques Explained

You may want to see also

Explore related products

Use corrosion-resistant screws or nails for secure fastening

Corrosion-resistant fasteners are the unsung heroes of a long-lasting deck. Exposure to moisture, temperature fluctuations, and UV rays can cause standard screws or nails to rust, compromising the structural integrity of your deck over time. Stainless steel, galvanized, or polymer-coated fasteners are your best bet to combat this. Stainless steel offers superior corrosion resistance but can be more expensive, while galvanized fasteners provide a cost-effective alternative with good durability. Polymer-coated screws combine corrosion resistance with ease of installation, making them a popular choice for DIY enthusiasts.

Selecting the right type of corrosion-resistant fastener depends on your deck’s environment. For coastal areas with high salt exposure, stainless steel is non-negotiable. In humid climates, galvanized or polymer-coated screws will suffice but ensure the coating is thick enough to withstand prolonged moisture. For arid regions, any corrosion-resistant option will work, though stainless steel’s longevity justifies its higher cost. Always check the manufacturer’s specifications to ensure compatibility with your wood type and environmental conditions.

Proper installation techniques maximize the effectiveness of corrosion-resistant fasteners. Pre-drilling holes reduces wood splitting and ensures a snug fit, especially with hardwoods like ipe or cumaru. Use a drill bit slightly smaller than the screw’s diameter for optimal results. When driving screws, avoid over-tightening, as this can strip the wood or damage the fastener’s coating. For nails, use a nail gun with adjustable force settings to prevent bending or surface damage. Regularly inspect your deck for loose or protruding fasteners and replace them promptly to maintain structural stability.

While corrosion-resistant fasteners are an investment, they pay dividends in longevity and safety. Rusted fasteners not only weaken the deck but can also create hazards like splinters or tripping risks. By prioritizing quality materials and proper installation, you ensure your deck remains secure and aesthetically pleasing for years. Think of it as preventive maintenance—a small upfront cost to avoid costly repairs or replacements down the line.

Finally, consider the environmental impact of your choice. Stainless steel is highly recyclable, making it a sustainable option for eco-conscious builders. Galvanized fasteners, while durable, contain zinc coatings that can leach into soil over time. Polymer-coated screws offer a middle ground, combining durability with minimal environmental footprint. By choosing wisely, you not only protect your deck but also contribute to a greener building practice.

Wood Ear Mushrooms: Fridge Storage Lifespan and Freshness Tips

You may want to see also

Explore related products

Apply sealant or stain to protect wood from elements

Wood, despite its natural beauty and durability, is inherently vulnerable to the elements. Sunlight, rain, snow, and temperature fluctuations can cause warping, cracking, and fading over time. Applying a sealant or stain is not just a cosmetic choice; it’s a critical step in preserving the structural integrity and appearance of your deck. Without this protective layer, even the highest-quality wood will deteriorate prematurely, leading to costly repairs or replacements.

The process begins with selecting the right product. Sealants primarily act as a barrier against moisture, while stains penetrate the wood to enhance color and provide moderate protection. For maximum longevity, opt for a semi-transparent or solid stain with built-in UV protection and water repellency. Brands like Cabot, Behr, and Olympic offer formulations specifically designed for decks, often with warranties ranging from 3 to 8 years. Before application, ensure the wood is clean, dry, and free of old finishes—pressure washing and sanding are essential preparatory steps.

Application technique matters as much as the product itself. Use a synthetic brush, roller, or sprayer, depending on the deck size and wood texture. Apply the sealant or stain in thin, even coats, following the wood grain. Avoid over-application, as this can lead to peeling or an uneven finish. For larger decks, work in small sections to maintain a wet edge, preventing lap marks. Allow each coat to dry completely (typically 24–48 hours) before applying a second coat, especially in humid climates.

Timing and maintenance are equally crucial. Apply sealant or stain during mild, dry weather, ideally when temperatures are between 50°F and 90°F. Reapply every 2–3 years, or as soon as water no longer beads on the surface. Regularly inspect the deck for signs of wear, such as splintering or discoloration, and address these issues promptly. While the initial application may seem labor-intensive, the long-term benefits—extended lifespan, reduced maintenance, and preserved aesthetics—far outweigh the effort.

In comparison to untreated wood, sealed or stained decks exhibit significantly slower degradation. For instance, cedar decks without protection may gray within a year and crack within five, whereas treated cedar can retain its color and structural integrity for over a decade. This stark difference underscores the importance of this step in the deck-building process. By investing time and resources into proper sealing or staining, you ensure your deck remains a functional and attractive outdoor space for years to come.

How to Safely Haul One Cord of Wood in a Long Bed Truck

You may want to see also

Explore related products

Ensure consistent spacing between boards for expansion and drainage

Wood expands and contracts with changes in moisture and temperature, a natural process that can wreak havoc on a deck if not accommodated. This movement, often underestimated, can cause boards to warp, cup, or even split if they're laid too tightly together. Ensuring consistent spacing between boards isn't just about aesthetics; it's a critical step in preserving the structural integrity and longevity of your deck.

To achieve this, start by selecting the appropriate gap size. A common rule of thumb is to leave a 1/8-inch to 1/4-inch space between boards. This range allows for adequate expansion while maintaining a visually pleasing, uniform look. Use spacers—small pieces of wood or specialized tools—to maintain consistency as you lay each board. For example, a 3/16-inch-thick hardwood strip works perfectly for this purpose, ensuring precision without adding bulk.

While spacing is essential for wood movement, it also serves another critical function: drainage. Water trapped between boards can lead to rot, mold, and decay, significantly shortening the lifespan of your deck. Proper spacing allows rainwater and morning dew to drain freely, preventing moisture buildup. Consider the climate in your area; in regions with heavy rainfall, slightly wider gaps (closer to 1/4 inch) may be beneficial to enhance water runoff.

One common mistake is neglecting to account for board width variations. Even within the same batch, wood planks can differ slightly in size. Measure each board before installation and adjust your spacing accordingly. If you’re using pre-grooved decking, ensure the grooves align properly to maintain consistent gaps. For a more polished look, use a rubber mallet to gently tap boards into place, avoiding damage while achieving tight, even spacing.

Finally, don’t overlook the importance of end-to-end spacing. While side-to-side gaps are crucial, leaving a 1/8-inch space between the ends of boards allows for longitudinal expansion. This is particularly important for longer decks, where wood movement is more pronounced. By addressing both dimensions, you create a deck that not only looks professional but also stands the test of time, resisting the elements with grace and durability.

Mastering Wood Aging: Optimal Time for Perfect Patina and Durability

You may want to see also

Frequently asked questions

Lay the wood boards perpendicular to the joists for maximum support and stability. This ensures the boards are properly supported along their length, preventing sagging or bending over time.

Leave a 1/8-inch to 1/4-inch gap between boards to allow for expansion and contraction due to moisture and temperature changes. This spacing also helps with water drainage.

Use corrosion-resistant screws rather than nails for better holding power and longevity. Screws provide a stronger connection and are less likely to loosen over time, especially in longer deck applications.

Use a chalk line to mark straight lines along the joists as a guide. Additionally, pre-drill holes and use a string line to keep boards aligned as you work across the deck.

Choose pressure-treated lumber, cedar, or composite decking for longer decks. These materials are resistant to rot, insects, and weathering, ensuring a longer lifespan with minimal maintenance.