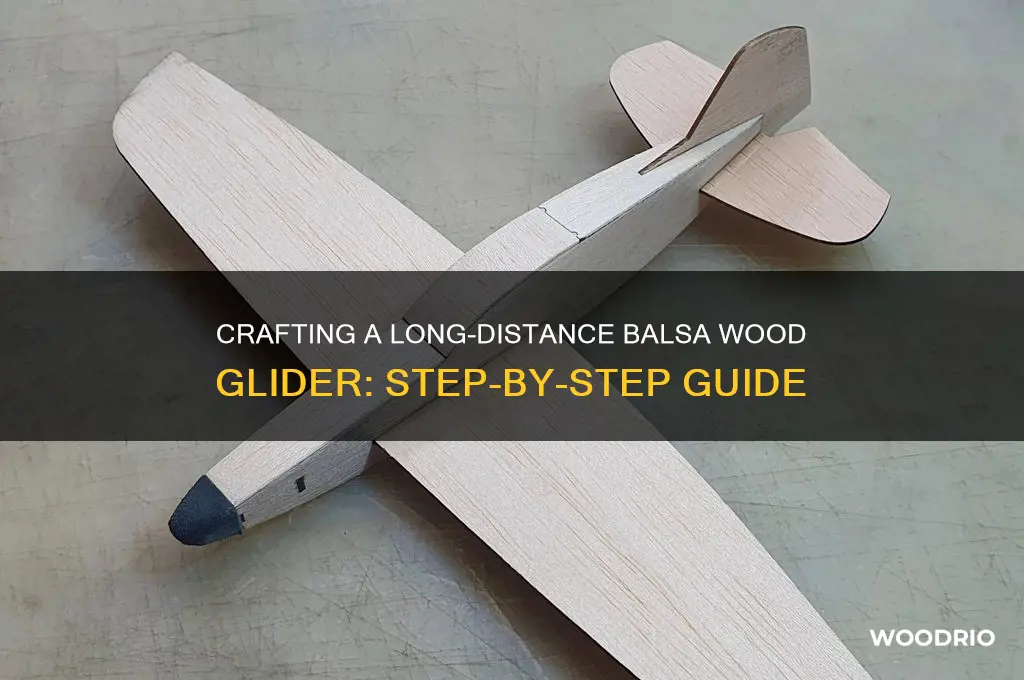

Building a long-distance balsa wood glider is an engaging project that combines craftsmanship, aerodynamics, and creativity. Balsa wood, prized for its lightweight yet durable properties, serves as the ideal material for constructing a glider capable of achieving impressive flight distances. The process involves careful planning, precise cutting, and thoughtful assembly to optimize the glider’s design for stability and efficiency. By focusing on wing shape, weight distribution, and balance, enthusiasts can create a model that glides smoothly and travels far with minimal effort. Whether for competition, hobby, or educational purposes, crafting a balsa wood glider offers a rewarding experience that blends science and artistry.

| Characteristics | Values |

|---|---|

| Material | Balsa wood (lightweight, high strength-to-weight ratio) |

| Wingspan | 12-24 inches (30-60 cm) for optimal lift and stability |

| Wing Shape | Tapered or rectangular with slight dihedral (upward angle) for stability |

| Fuselage Length | 12-18 inches (30-45 cm) for balanced weight distribution |

| Tail Design | Horizontal stabilizer with vertical fin for directional control |

| Center of Gravity (CG) | 1-2 inches (2.5-5 cm) behind the leading edge of the wing |

| Weight | 0.5-1 ounce (15-30 grams) for maximum glide efficiency |

| Airfoil | Flat or slightly curved bottom with curved top for lift |

| Wing Loading | Low (less than 5 grams/sq inch) for extended flight time |

| Launch Method | Hand-launched with a smooth, level throw at a slight upward angle |

| Glide Ratio | 10:1 to 15:1 (distance traveled to altitude lost) |

| Construction Tools | Hobby knife, sandpaper, ruler, glue (CA or wood glue) |

| Reinforcements | Carbon fiber or lightweight wire for added strength |

| Surface Finish | Smooth, lightweight coating (e.g., thin tissue paper or spray paint) |

| Balancing | Adjust weight distribution by adding small weights near the nose or tail |

| Testing | Iterate design based on flight performance (adjust CG, wing angle, etc.) |

Explore related products

What You'll Learn

- Materials Needed: Balsa wood, sandpaper, glue, ruler, knife, and lightweight coating for durability

- Design Basics: Choose a glider design, consider wing shape, tail size, and weight distribution

- Cutting & Shaping: Measure and cut balsa wood pieces precisely, sand edges for smoothness

- Assembly Steps: Glue components together, ensure alignment, let dry completely before handling

- Balancing & Testing: Adjust weight distribution, test glide, tweak for stability and distance

Materials Needed: Balsa wood, sandpaper, glue, ruler, knife, and lightweight coating for durability

Balsa wood is the backbone of your long-distance glider, prized for its exceptional strength-to-weight ratio. Select sheets with a thickness between 1/16" and 1/8" (1.5mm to 3mm) for the wings and fuselage. Thinner balsa (1/32") can be used for lightweight ribs or stabilizers. Avoid knots or warping, as imperfections will compromise aerodynamics. While balsa is the star, consider supplementing with basswood for areas needing extra rigidity, like the leading edge of the wings.

Sandpaper is your sculptor, transforming rough cuts into aerodynamic precision. Start with coarse grit (120-150) to remove excess material and shape the basic form. Progress to finer grits (220-400) for smoothing surfaces, ensuring a seamless finish that reduces drag. Pay special attention to the wingtips and trailing edges, where even minor imperfections can disrupt airflow. A well-sanded glider will slice through the air with minimal resistance.

Glue is the silent hero binding your glider together, but not all adhesives are created equal. Cyanoacrylate (super glue) dries fast but can be brittle; use it sparingly for small joints. White or yellow wood glue offers stronger, more flexible bonds, ideal for larger surfaces. Apply glue thinly to avoid adding unnecessary weight, and clamp joints firmly for 30 minutes to ensure a secure hold. Test joints before flight—a weak bond will fail mid-air.

A ruler and knife are your precision tools, dictating the glider’s performance. Measure twice, cut once—accuracy in wing span, chord, and dihedral angle is critical. Use a sharp hobby knife for clean cuts, and consider a metal ruler as a straightedge for consistency. For intricate cuts, like airfoil profiles, a scalpel or razor saw provides better control. Mistakes here are costly; a misaligned wing will send your glider tumbling.

A lightweight coating seals your glider against moisture and minor impacts without adding bulk. Spray-on polyurethane or clear acrylic provides durability while maintaining flexibility. Apply thin coats, allowing each layer to dry completely before sanding lightly (400-grit) to preserve smoothness. Avoid heavy varnishes or paints, as they can double the weight, negating balsa’s advantage. A well-coated glider will withstand crashes and weather, extending its flying life.

Durability of Wooden Dishes: Lifespan and Care Tips Revealed

You may want to see also

Explore related products

Design Basics: Choose a glider design, consider wing shape, tail size, and weight distribution

The foundation of a long-distance balsa wood glider lies in its design, a blueprint that dictates performance. Among the myriad designs, the flying wing and conventional tailless configurations stand out for their efficiency. The flying wing, devoid of a fuselage, minimizes drag but demands precise weight distribution. Conversely, the conventional tailless design offers stability with a distinct wing and tail, though it may sacrifice some glide distance. Choosing between these designs hinges on your priority: maximal distance or ease of control.

Wing shape is the next critical factor, acting as the glider’s engine in the absence of propulsion. A high-aspect-ratio wing (long and narrow) provides superior lift-to-drag ratios, ideal for long-distance flights. For instance, a wing with a 10:1 aspect ratio (span to chord) will outperform a shorter, stubbier wing by reducing induced drag. However, such wings are less maneuverable and require careful balancing. A tapered wing, where the chord decreases toward the tips, further enhances efficiency by reducing tip drag. Experiment with dihedral angles (wing tilt) to improve stability without compromising glide performance.

Tail size and shape are often overlooked but play a pivotal role in stability and control. A large tail increases stability but adds weight and drag, while a small tail reduces drag but demands precision in placement and alignment. The T-tail design, where the horizontal stabilizer sits atop the vertical fin, minimizes interference drag and is favored in high-performance gliders. Ensure the tail’s center of gravity is slightly behind the wing’s to maintain longitudinal stability. A rule of thumb: the tail’s area should be 20-30% of the wing’s area for optimal balance.

Weight distribution is the silent architect of a glider’s success. The center of gravity (CG) should align with the wing’s aerodynamic center, typically located 25-30% of the mean aerodynamic chord back from the leading edge. Use ballast, such as small weights or strategically placed balsa, to fine-tune the CG. A forward CG enhances stability but reduces glide distance, while a rearward CG increases maneuverability at the risk of instability. Test iterations by shifting the CG in 1-2 mm increments to find the sweet spot.

In practice, start with a conventional tailless design featuring a high-aspect-ratio, tapered wing for beginners. Use lightweight 1/16” balsa for the wing spars and 1/32” sheeting for the tail. Position the CG at 27% of the wing chord and verify alignment with a balancing test. For advanced builders, experiment with a flying wing design, incorporating a swept-back leading edge to delay stall. Regardless of design, prioritize symmetry and minimalism—every gram and millimeter counts in the pursuit of distance.

Perfect Wood-Fired Turkey: Optimal Cooking Time & Tips for Juicy Results

You may want to see also

Explore related products

Cutting & Shaping: Measure and cut balsa wood pieces precisely, sand edges for smoothness

Precision in cutting and shaping balsa wood is the cornerstone of a glider’s aerodynamic efficiency. A single misplaced cut or rough edge can disrupt airflow, reducing flight distance significantly. Begin by selecting high-quality balsa wood sheets, typically 1/16 to 1/8 inch thick, depending on the glider’s design. Use a sharp hobby knife or scalpel for clean cuts, ensuring the blade is perpendicular to the wood surface to avoid splintering. Measure twice, cut once—this adage holds especially true here, as balsa’s lightweight nature makes it unforgiving to errors.

Once measured, secure the wood firmly against a straightedge or cutting mat to maintain accuracy. For complex shapes, such as tapered wings or a streamlined fuselage, consider using templates made from cardstock or thin plywood. These templates act as guides, ensuring consistency across multiple pieces. When cutting curves, work slowly and apply gentle pressure to prevent tearing. Remember, balsa wood is deceptively strong yet fragile; treat it with respect, and it will reward you with a glider that slices through the air effortlessly.

Sanding is where your glider transitions from a rough prototype to a refined machine. Start with medium-grit sandpaper (150–220 grit) to remove burrs and sharp edges, then progress to fine-grit (320–400 grit) for a smooth finish. Pay special attention to leading edges, such as the wingtips and nose, as these areas have the most significant impact on aerodynamics. Use a sanding block for flat surfaces and wrap sandpaper around a dowel for curved sections. The goal is to create a surface so smooth that your finger glides over it without catching—a tactile test that ensures optimal performance.

A common mistake is rushing the sanding process, leaving micro-imperfections that compromise flight. Take your time, and periodically check your work under bright light to spot uneven areas. For an extra edge, apply a light coat of wood sealer or thin varnish after sanding, which reduces drag by minimizing surface friction. However, avoid over-application, as added weight can negate the benefits of balsa’s lightness.

In essence, cutting and shaping balsa wood is a blend of art and science. It demands patience, precision, and an eye for detail. By mastering these steps, you’ll not only create a glider capable of long-distance flight but also develop skills transferable to more complex woodworking projects. The satisfaction of launching a perfectly crafted glider and watching it soar is a testament to the care invested in this phase of construction.

Birch Wood Durability: Lifespan, Maintenance, and Longevity Explained

You may want to see also

Explore related products

Assembly Steps: Glue components together, ensure alignment, let dry completely before handling

Precision in assembly is the linchpin of a glider’s aerodynamic efficiency. Begin by applying a thin, even layer of lightweight wood glue (such as Titebond II) to the mating surfaces of balsa components—wings, fuselage, and tail sections. Use a small brush or applicator to avoid excess glue, which adds unnecessary weight and compromises structural integrity. Press the pieces together firmly, ensuring joints are flush and aligned according to your design blueprint. Misalignment at this stage, even by a millimeter, can introduce drag or instability during flight, drastically reducing glide distance.

Alignment is not just about visual symmetry; it’s about functional harmony. Use a straightedge or ruler to verify that wings are level and perpendicular to the fuselage. For the tail assembly, double-check that the vertical and horizontal stabilizers are aligned with the fuselage’s centerline. A misaligned tail can cause yaw or pitch oscillations, sabotaging the glider’s ability to maintain a straight, efficient trajectory. Consider using clamps or rubber bands to hold components in place while the glue sets, but avoid over-tightening to prevent warping the delicate balsa wood.

Drying time is a non-negotiable step often rushed by impatient builders. Balsa wood glue typically requires 30 minutes to an hour to set, but full curing can take up to 24 hours, depending on humidity and temperature. Handle the glider minimally during this period, and avoid testing its flight capabilities until the glue is completely dry. Premature handling risks joint failure, undoing hours of meticulous work. Place the glider in a stable, dust-free environment to dry, as particles settling on wet glue can disrupt surface smoothness, affecting aerodynamics.

A practical tip for ensuring alignment during drying is to create a simple jig from foam board or cardboard. Cut slots or notches that correspond to the glider’s components, providing a cradle that holds everything in place while the glue cures. This method is particularly useful for complex designs with multiple joints. Additionally, mark alignment points with a pencil before gluing to serve as a visual guide during assembly. These small precautions transform a fragile collection of balsa pieces into a cohesive, high-performance glider.

The final takeaway is that patience and precision in assembly are as critical as the design itself. Rushing the gluing process or neglecting alignment checks will undermine even the most sophisticated glider blueprint. By treating each joint with care, verifying alignment at every step, and allowing ample drying time, you ensure that the glider’s structure is robust and aerodynamically sound. This foundation is what enables the glider to cut through air efficiently, maximizing distance and performance in flight.

How Long Does Flavored Wood Last? A Comprehensive Guide

You may want to see also

Explore related products

Balancing & Testing: Adjust weight distribution, test glide, tweak for stability and distance

A well-balanced glider is the key to achieving maximum distance and stability in flight. The center of gravity (CG) is the point where the glider's weight is evenly distributed, allowing it to maintain a level flight path. To find the optimal CG, start by placing a temporary mark at the midpoint of the glider's fuselage, then adjust the weight distribution by moving small weights (e.g., paper clips or modeling clay) forward or backward in 1-centimeter increments. A general rule of thumb is to position the CG approximately 25-30% of the wing's chord length from the leading edge, but this may vary depending on the glider's design and weight.

Testing the glider's performance is a crucial step in refining its balance and stability. Begin by launching the glider at a consistent angle (around 10-15 degrees) and observing its flight path. A stable glider should maintain a straight, level trajectory without nosing up or down. If the glider stalls or dives, adjust the CG by moving the weights accordingly. For example, if the nose drops, move the weights forward to shift the CG slightly ahead. Conversely, if the glider climbs excessively, move the weights rearward to bring the CG back. Repeat this process until the glider exhibits a smooth, stable glide.

One effective method for tweaking stability and distance is to incorporate a dihedral angle – the upward angle of the wings from the root to the tip. A dihedral angle of 3-5 degrees can improve lateral stability, reducing the likelihood of rolling or tipping during flight. However, excessive dihedral can increase drag, negatively impacting distance. Experiment with different dihedral angles by bending the wing tips gently and testing the glider's performance. Additionally, consider adjusting the tailplane's angle of incidence (the angle between the tailplane and the fuselage) to fine-tune pitch stability. A slightly positive angle (around 1-2 degrees) can help maintain a level flight path.

As you refine the glider's balance and stability, keep in mind that small adjustments can have a significant impact on performance. For instance, adding a 1-gram weight to the nose can alter the CG by several millimeters, affecting the glider's flight characteristics. To ensure consistent results, maintain a systematic approach to testing: launch the glider from the same height and angle each time, and observe its performance in similar environmental conditions (e.g., minimal wind). By carefully analyzing the glider's behavior and making incremental adjustments, you can optimize its weight distribution, stability, and distance.

In the final stages of balancing and testing, focus on fine-tuning the glider for maximum distance. This may involve slightly shifting the CG forward to promote a gentle descent, allowing the glider to maintain altitude for longer periods. Experiment with different launch techniques, such as a flat or arched throw, to identify the most effective method for your glider. Remember that the goal is not only to achieve stability but also to minimize drag and maximize lift, enabling the glider to soar effortlessly through the air. With patience, persistence, and a keen eye for detail, you can transform your balsa wood glider into a high-performance, long-distance flying machine.

Durability of Wooden Condos: Lifespan and Maintenance Tips Revealed

You may want to see also

Frequently asked questions

You will need balsa wood sheets (lightweight and flexible), a hobby knife, sandpaper, wood glue, a ruler, a pencil, and optionally a lightweight tissue paper or covering film for added durability.

Design the wings with a high aspect ratio (long and narrow) to reduce drag. Use a dihedral angle (upward V-shape) for stability, and ensure the airfoil is thin and symmetrical for efficient lift.

Balance the glider by placing the center of gravity (CG) slightly forward of the wing's center. Test by balancing it on a finger or a straight edge, adjusting weight distribution or trimming the tail until it sits level.

Minimize excess material by carefully sanding edges and using thin balsa sheets. Avoid over-gluing, and consider hollowing out non-critical areas. Use lightweight tissue or film for covering instead of heavy materials.

Launch the glider at a slight upward angle (10-15 degrees) with a smooth, consistent throw. Ensure the glider is trimmed for straight flight, and avoid windy conditions to maintain control and stability.