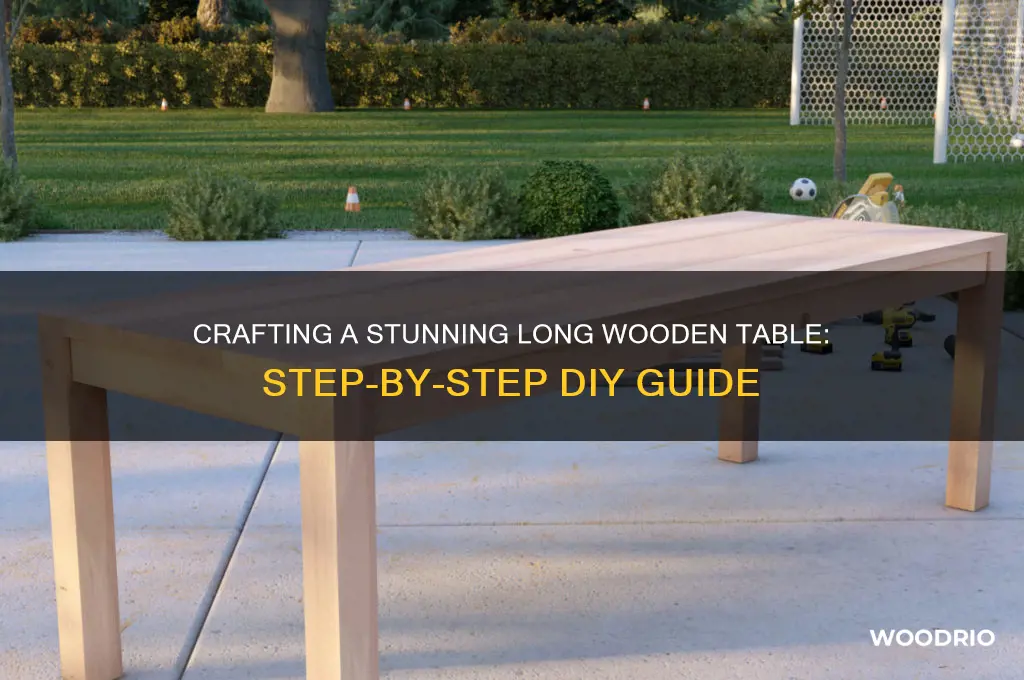

Creating a long wooden table is a rewarding DIY project that combines craftsmanship with functionality, resulting in a centerpiece that can enhance any space. To begin, you’ll need to select the right type of wood, such as hardwoods like oak or maple for durability, and plan the dimensions based on your intended use. The process involves cutting and assembling the tabletop, crafting sturdy legs or a base, and ensuring proper joinery techniques like dovetails or mortise-and-tenon joints for stability. Sanding, staining, and sealing the wood are essential steps to achieve a smooth finish and protect the table from wear and tear. With careful planning, precision, and attention to detail, you can create a long-lasting wooden table that showcases both your skills and personal style.

| Characteristics | Values |

|---|---|

| Materials Needed | Wood planks (e.g., pine, oak, or maple), screws, wood glue, sandpaper |

| Tools Required | Table saw, drill, screwdriver, clamps, measuring tape, sander |

| Table Dimensions | Length: 6-10 feet, Width: 2-3 feet, Height: 28-30 inches (standard) |

| Wood Thickness | 1-2 inches for tabletop, 2-3 inches for legs |

| Joinery Techniques | Pocket holes, mortise and tenon, or Kreg jig for stability |

| Finishing Options | Stain, paint, varnish, or polyurethane for protection and aesthetics |

| Assembly Steps | 1. Cut wood to size, 2. Assemble frame, 3. Attach legs, 4. Secure tabletop |

| Estimated Time | 1-2 days depending on skill level and complexity |

| Cost Range | $100-$500 depending on wood type and tools |

| Maintenance Tips | Regularly clean, reapply finish every 1-2 years, avoid harsh chemicals |

| Design Variations | Live edge, farmhouse, modern, or rustic styles |

| Weight Capacity | 200-500 lbs depending on construction and materials |

| Safety Precautions | Wear safety goggles, gloves, and ear protection; work in a ventilated area |

| Skill Level Required | Intermediate to advanced woodworking skills |

Explore related products

$173.53 $209.99

$72.28 $89.99

$65.74

What You'll Learn

- Choosing the Right Wood: Select durable, high-quality wood like oak, maple, or pine for longevity

- Measuring and Cutting: Accurately measure and cut planks to desired table length and width

- Assembling the Frame: Join legs and supports using screws, brackets, or dowels for stability

- Sanding and Finishing: Sand surfaces smooth, apply stain or paint, and seal with polyurethane

- Adding Final Touches: Attach tabletop to frame, check for level, and secure all components tightly

Choosing the Right Wood: Select durable, high-quality wood like oak, maple, or pine for longevity

The foundation of any long wooden table lies in the wood itself. While aesthetics play a role, prioritizing durability ensures your creation withstands years of use. Oak, maple, and pine stand out as top choices, each offering unique characteristics. Oak, renowned for its strength and resistance to wear, boasts a prominent grain pattern that adds visual depth. Maple, equally robust, presents a finer grain and lighter hue, making it ideal for modern or minimalist designs. Pine, a more affordable option, offers a rustic charm but requires careful sealing to prevent scratches and dents.

Understanding the specific demands of your table's intended use is crucial. A dining table subjected to daily meals and gatherings demands the resilience of oak or maple. A decorative console table might allow for the budget-friendly charm of pine, provided it's properly protected.

Selecting the right wood goes beyond species. Consider the grade and cut. Higher grades, free from knots and imperfections, ensure structural integrity and a refined appearance. Quarter-sawn or rift-sawn cuts, while more expensive, minimize warping and cracking over time, crucial for long tabletops.

Flat-sawn lumber, more affordable, showcases a distinctive grain pattern but may be more prone to movement.

Don't underestimate the power of finishing. A high-quality finish acts as a protective shield, enhancing durability and highlighting the wood's natural beauty. For high-traffic areas, opt for a durable polyurethane finish. For a more natural look, consider oil-based finishes like tung oil or linseed oil, which penetrate the wood, providing protection while allowing the grain to shine through. Remember, proper maintenance is key. Regular cleaning and reapplication of finish will ensure your long wooden table remains a stunning centerpiece for generations.

Wood Glue Shelf Life: Storage Tips for Maximum Adhesive Longevity

You may want to see also

Explore related products

$159.99 $179.99

Measuring and Cutting: Accurately measure and cut planks to desired table length and width

Precision in measurement is the cornerstone of any woodworking project, especially when crafting a long wooden table. A discrepancy of even a millimeter can lead to misaligned joints, uneven surfaces, or structural instability. Begin by determining the exact dimensions of your table—length, width, and thickness—based on your design and space requirements. Use a tape measure or a steel rule for accuracy, and double-check your measurements to avoid costly mistakes. Mark the cutting lines clearly with a straight edge and a pencil, ensuring the lines are sharp and visible.

Once measurements are finalized, selecting the right cutting tool is crucial. A circular saw or table saw is ideal for straight cuts, while a miter saw can handle angled or crosscuts if your design requires them. For finer adjustments or intricate cuts, a jigsaw or hand saw may be necessary. Always ensure your blade is sharp and appropriate for cutting wood to achieve clean edges. Secure the plank firmly in place using clamps or a vice to prevent movement during cutting, which can lead to inaccuracies or accidents.

Safety should never be compromised during the cutting process. Wear protective gear, including safety glasses, ear protection, and a dust mask, to guard against flying debris and wood dust. Keep your hands clear of the blade path and use push sticks or a featherboard when cutting narrow pieces. Maintain a steady pace and avoid forcing the tool through the wood, as this can cause binding or kickback. Remember, a rushed cut is often an inaccurate or dangerous one.

After cutting, inspect each plank for accuracy using a square to ensure the edges are straight and the corners are at precise right angles. Sand any rough edges or splintered areas with medium-grit sandpaper to create a smooth, professional finish. If your design includes multiple planks joined together, dry-fit them to verify alignment and make adjustments as needed. This step is essential for ensuring the final assembly will be seamless and structurally sound.

Finally, consider the wood’s natural characteristics when measuring and cutting. Account for the direction of the grain to avoid splitting or weakening the material. If using reclaimed or uneven planks, plan your cuts to maximize stability and aesthetics. By combining meticulous measurement, the right tools, and attention to detail, you’ll lay a solid foundation for a long wooden table that’s both functional and visually striking.

Mineral Oil Soaking Time for Wood: A Complete Guide

You may want to see also

Explore related products

$129.99 $179.99

Assembling the Frame: Join legs and supports using screws, brackets, or dowels for stability

The foundation of any sturdy wooden table lies in its frame, and the method you choose to join the legs and supports will significantly impact its durability. Screws, brackets, and dowels each offer distinct advantages, but the choice depends on your skill level, tools available, and desired aesthetic. Screws provide a straightforward, adjustable solution, ideal for beginners. Brackets, often metal, add industrial strength and a modern touch, though they may detract from a purely wooden look. Dowels, on the other hand, create a seamless, traditional joint but require precision and woodworking expertise.

Consider the table’s intended use when selecting your joining method. For a dining table that will bear heavy loads and frequent movement, screws or brackets offer superior stability. Dowels, while elegant, may loosen over time under such stress unless executed with meticulous care. If you’re crafting a decorative or occasional-use table, dowels can be a beautiful choice, showcasing craftsmanship. Always pre-drill holes for screws to prevent wood splitting, and ensure brackets are securely fastened to avoid wobbling.

A practical tip for beginners is to dry-fit the frame before committing to any permanent joints. This allows you to check alignment and make adjustments without the hassle of disassembling glued or screwed pieces. If using dowels, invest in a doweling jig to ensure accurate hole placement. For brackets, measure twice to ensure they’re level and centered, as misalignment can compromise the table’s balance. Remember, the goal is not just to join the pieces but to create a unified structure that can withstand years of use.

Comparing the three methods, screws are the most forgiving and versatile, making them a go-to for DIY enthusiasts. Brackets, while robust, can be overkill for lighter tables and may require additional finishing to blend with the wood. Dowels, though time-consuming, offer a timeless, invisible joint that elevates the table’s craftsmanship. Whichever method you choose, prioritize stability over speed—a wobbly table is a frustrating outcome that can often be traced back to rushed or poorly executed joints.

In conclusion, assembling the frame is a critical step that demands attention to detail and thoughtful material selection. By carefully joining legs and supports with screws, brackets, or dowels, you ensure not only the table’s stability but also its longevity. Take the time to plan, measure, and test your joints, and you’ll end up with a piece that’s as functional as it is beautiful. After all, a well-built frame is the backbone of any great wooden table.

Wood Glue Drying Time: Factors Affecting Cure Speed and Strength

You may want to see also

Explore related products

Sanding and Finishing: Sand surfaces smooth, apply stain or paint, and seal with polyurethane

Sanding is the unsung hero of woodworking, transforming rough, splintered surfaces into smooth canvases ready for finishing. Begin with a coarse-grit sandpaper, such as 80 or 120 grit, to remove imperfections and level the wood’s surface. Progress to finer grits—220, then 320—to achieve a silky-smooth finish. Always sand in the direction of the grain to avoid scratches that will mar the final look. For long wooden tables, use a random orbital sander for efficiency, especially on large, flat surfaces, but switch to hand sanding for edges, corners, and intricate details. Dust is your enemy here; wipe the surface with a tack cloth between grits to ensure no particles interfere with the next sanding stage.

Once the wood is flawlessly smooth, the choice between stain and paint becomes a defining moment in your table’s character. Stain enhances the natural beauty of the wood, highlighting its grain and texture, while paint offers a blank canvas for bold colors or distressed finishes. If staining, test the color on a scrap piece of the same wood species to ensure it matches your vision. Apply the stain with a brush or cloth in thin, even coats, wiping off excess to avoid blotching. Paint, on the other hand, requires a primer coat to ensure adhesion and opacity, followed by 2–3 thin layers of your chosen color. Allow ample drying time between coats—typically 2–4 hours for stain and 4–6 hours for paint—to prevent drips and ensure a professional finish.

Polyurethane is the armor that protects your hard work, sealing the wood against moisture, heat, and everyday wear. Choose between oil-based polyurethane for a warm, amber tone or water-based for a clear, non-yellowing finish. Apply it with a high-quality brush or foam applicator in thin, even strokes, following the direction of the wood grain. Two to three coats are standard, with sanding between coats using 320-grit sandpaper to ensure a smooth, glass-like surface. Be mindful of temperature and humidity during application—ideally, work in a well-ventilated area with moderate conditions to prevent bubbling or uneven drying. Patience is key; allow 24–48 hours of curing time before placing heavy objects on the table.

The devil is in the details when it comes to finishing a long wooden table. For example, if your table has a live edge or natural curves, consider using a flexible sanding sponge to maintain the wood’s organic shape. When applying polyurethane, work quickly but methodically to avoid lap marks, and always keep a wet edge by overlapping each stroke slightly. If you’re aiming for a distressed look, sand through the paint in high-wear areas after the final coat of polyurethane for a weathered effect. Finally, remember that finishing is as much art as science—small imperfections can add character, but consistency in application will elevate your table from handmade to heirloom quality.

Composite Decking vs. Wood: Lifespan Comparison and Durability Insights

You may want to see also

Explore related products

Adding Final Touches: Attach tabletop to frame, check for level, and secure all components tightly

Attaching the tabletop to the frame is the moment your wooden table transforms from a collection of parts into a functional piece of furniture. This critical step demands precision and care. Begin by aligning the tabletop carefully, ensuring the overhang is consistent on all sides. Use clamps to hold it in place temporarily, allowing you to step back and verify alignment from multiple angles. Once satisfied, secure the tabletop using screws driven through pre-drilled pilot holes to prevent splitting the wood. Opt for countersunk screws for a flush finish, or use pocket holes for a cleaner appearance.

Leveling the table is not just about aesthetics—it’s about stability and functionality. Place a spirit level on the tabletop in multiple directions to check for evenness. If adjustments are needed, shim the legs or slightly adjust the frame joints. Remember, a table that rocks is not only annoying but also prone to wear and tear over time. Fine-tune until the bubble rests perfectly in the center, ensuring your table sits flat on any surface.

Securing all components tightly is the final safeguard against future issues. Double-check every joint, bracket, and fastener to ensure nothing is loose. Use wood glue in critical joints for added strength, but avoid over-application to prevent squeeze-out. For metal brackets or hardware, tighten bolts with a torque wrench to the manufacturer’s specifications. This step is particularly crucial for long tables, as their length can amplify stress on connections.

A practical tip: before finalizing assembly, dry-fit all components to identify potential issues. This trial run allows you to make adjustments without the permanence of glue or screws. Additionally, consider adding felt pads to the bottom of the legs to protect your floor and provide a final touch of professionalism.

In conclusion, the final touches are where craftsmanship meets functionality. By meticulously attaching the tabletop, ensuring levelness, and securing every component, you not only create a sturdy table but also a piece that stands the test of time. These steps, though seemingly minor, are the difference between a makeshift structure and a polished, enduring masterpiece.

Wood Frog Eggs Hatching Timeline: A Detailed Developmental Journey

You may want to see also

Frequently asked questions

Hardwoods like oak, maple, or walnut are ideal for durability and aesthetics, but pine or cedar are budget-friendly alternatives.

Essential tools include a circular saw or table saw, drill, clamps, sander, and a tape measure for precise cuts and assembly.

Use sturdy legs or a base, reinforce joints with wood glue and screws, and check for levelness during assembly with a spirit level.

Apply a polyurethane, varnish, or tung oil finish to protect the wood from moisture and wear while enhancing its natural beauty.