Creating long trapezoids out of wood is a practical and rewarding woodworking project that combines precision and creativity. To begin, select a suitable type of wood, such as pine or oak, ensuring it is straight-grained and free of defects. Measure and mark the dimensions of the trapezoid on the wood, focusing on the lengths of the parallel sides and the angles of the non-parallel sides. Use a table saw or circular saw to cut the wood to the desired lengths, and a miter saw or hand saw to achieve the precise angles. Sand the edges to smooth any rough surfaces and ensure clean, accurate joints. Assemble the pieces using wood glue and clamps, or reinforce with screws or dowels for added stability. Finally, sand the entire trapezoid to achieve a uniform finish and apply a coat of stain or sealant to protect the wood and enhance its appearance. With careful planning and attention to detail, you can craft a durable and visually appealing long trapezoid for various applications, such as furniture, decor, or structural elements.

| Characteristics | Values |

|---|---|

| Materials Needed | Wood planks (length and thickness as per trapezoid size), saw, measuring tape, pencil, sandpaper, wood glue, clamps, screws/nails, drill, safety gear (glasses, gloves) |

| Tools Required | Table saw or circular saw, miter saw (optional), clamps, drill, screwdriver, sandpaper (various grits), measuring tape, pencil, safety gear |

| Wood Type | Pine, oak, plywood, MDF (choose based on project needs and budget) |

| Trapezoid Dimensions | Length (long base), short base length, height (distance between parallel sides), thickness (wood plank thickness) |

| Cutting Technique | Measure and mark trapezoid dimensions on wood. Use a table saw or circular saw to cut long sides at an angle. Ensure parallel sides are straight and perpendicular to height. |

| Assembly Method | 1. Cut four trapezoid pieces (two for each long side). 2. Sand edges and surfaces. 3. Apply wood glue to edges and clamp together. 4. Reinforce joints with screws or nails. |

| Finishing | Sand entire trapezoid smoothly. Apply stain, paint, or sealant as desired. Allow to dry completely before use. |

| Safety Precautions | Wear safety glasses and gloves. Ensure proper ventilation when using power tools and finishes. Follow tool instructions carefully. |

| Applications | Furniture making (tables, shelves), decorative elements, DIY projects, woodworking crafts |

| Difficulty Level | Intermediate (requires precise measuring and cutting skills) |

| Time Required | 2-4 hours (depending on trapezoid size and finishing complexity) |

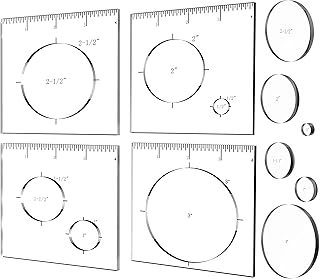

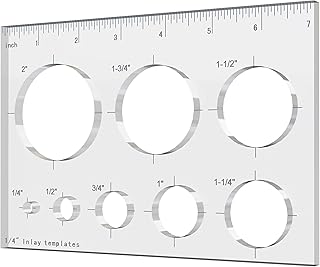

Explore related products

What You'll Learn

Measure and Mark Wood

Precision in measurement is the cornerstone of crafting long trapezoids from wood, ensuring not only structural integrity but also aesthetic appeal. Begin by determining the dimensions of your trapezoid: the lengths of the parallel sides (bases) and the height. For instance, if you aim for a trapezoid with a longer base of 48 inches, a shorter base of 36 inches, and a height of 12 inches, these measurements will dictate your cutting and marking process. Use a tape measure to record these dimensions accurately, as even a slight deviation can distort the trapezoid’s shape.

Once dimensions are finalized, transfer them onto the wood. Start by marking the longer base along the edge of your wooden board. A straightedge or carpenter’s square ensures a clean, straight line. From the endpoints of this base, measure and mark the height (12 inches in our example) perpendicular to the base. Repeat this process for the shorter base, ensuring it is parallel to the longer one. Connect the endpoints of the bases with straight lines to outline the trapezoid. Double-check alignment using a square to confirm the sides are perfectly vertical.

Marking the wood is not just about lines; it’s about visualizing the final cut. Use a pencil for clarity, and consider adding arrows or labels to indicate which lines are the bases and height. For longer trapezoids, where wood grain direction matters, ensure the grain runs parallel to the bases to minimize warping. If using multiple boards to achieve the desired length, mark each piece individually, accounting for any joints or overlaps in your design.

Caution is key during this stage. Inaccurate markings can lead to wasted material and time. Always measure twice before committing to a mark. For trapezoids longer than 4 feet, consider using a chalk line for straight, consistent lines across the wood’s length. Additionally, if your trapezoid requires precise angles or additional features, such as tapered sides, use a protractor or angle finder to ensure accuracy.

In conclusion, measuring and marking wood for long trapezoids demands attention to detail and methodical planning. By meticulously transferring dimensions onto the wood and employing tools like squares and chalk lines, you lay the foundation for a successful project. This step, though seemingly simple, is where the trapezoid’s form takes shape, setting the stage for cutting, assembling, and finishing. Master this phase, and the rest of the process becomes significantly more manageable.

Wood Shrimp Lifespan: Understanding Their Survival in Captivity and the Wild

You may want to see also

Explore related products

Cut Trapezoid Sides Precisely

Precision is paramount when cutting trapezoid sides from wood, as even a millimeter's deviation can disrupt the shape's integrity. Begin by marking your wood with exact measurements, ensuring the parallel sides (bases) are accurately aligned. Use a straightedge and a sharp pencil to draw clear, visible lines. For longer trapezoids, consider using a chalk line or laser guide to maintain straightness over the extended length. Always double-check your measurements before making the first cut—a small error at this stage compounds with each subsequent step.

The choice of cutting tool significantly impacts precision. A table saw or track saw paired with a fine-toothed blade is ideal for clean, straight cuts. If using a circular saw, attach a guide rail to minimize wandering. For hand tools like a jigsaw, clamp a straightedge to the wood as a guide. Regardless of the tool, ensure the blade is sharp and the wood is securely clamped to prevent shifting. Cutting slowly and steadily reduces the risk of splintering or veering off the marked line.

Angle accuracy is critical for trapezoids, especially when the non-parallel sides (legs) are slanted. Use a bevel gauge to transfer the desired angle from your plan to the wood. If your trapezoid requires a specific slope, calculate the angle using the arctangent function (angle = arctan(rise/run)). For example, a 2-inch rise over a 12-inch run yields a 9.46-degree angle. Mark this angle precisely and test it with a speed square before cutting.

Post-cutting refinement ensures each side meets specifications. Sand the edges lightly to remove burrs and smooth imperfections, but avoid over-sanding, which can alter dimensions. Use a straightedge to verify flatness and a protractor or angle finder to confirm angles. If joining multiple trapezoids, dry-fit the pieces to ensure alignment before final assembly. This meticulous approach guarantees each trapezoid side is not just cut, but crafted with precision.

Understanding Wood Mold Growth: Factors Affecting Timeframe and Prevention

You may want to see also

Explore related products

Sand Edges Smoothly

Rough edges on wooden trapezoids aren't just unsightly; they're a safety hazard. Splinters, catches, and jagged surfaces can ruin the tactile experience and even cause injury. Sanding those edges smoothly is the transformative step that elevates your trapezoid from rough-hewn to refined.

Think of it as the difference between a hastily carved stick and a polished wand.

The Gritty Details: A Step-by-Step Guide

Start with a medium-grit sandpaper, around 120-150 grit. This initial pass removes the bulk of the roughness left by sawing or cutting. Follow the natural grain of the wood, sanding in the direction of the fibers. Avoid applying excessive pressure; let the sandpaper do the work. Gradually work your way up to finer grits (220, 320, even 400) for a progressively smoother finish. Each grit level refines the surface further, creating a silky-smooth edge.

Beyond the Basics: Techniques for Precision

For long trapezoids, consider using a sanding block to maintain consistent pressure and avoid rounding corners unintentionally. Pay special attention to the corners and intersections, where sanding can be trickier. Fold your sandpaper into a tight point for better control in these areas. If your trapezoid has intricate details or curves, switch to a sanding sponge or a flexible sanding pad for better maneuverability.

Pro Tip: Dip your sandpaper in water periodically to prevent clogging, especially when working with softer woods.

The Finishing Touch: Polishing for Perfection

Once you've achieved a smooth surface with your highest grit sandpaper, it's time to polish. A simple cloth dampened with mineral spirits or a wood polish can bring out the natural beauty of the grain. For a truly professional finish, consider applying a thin coat of wax or oil, buffing it to a gentle sheen. This not only enhances the aesthetic appeal but also protects the wood from moisture and wear.

Safety First: Sanding with Care

Always wear a dust mask when sanding to protect your lungs from wood particles. Work in a well-ventilated area, and consider using a dust collector or shop vacuum to minimize airborne dust. Be mindful of your hands and fingers, keeping them clear of the sanding surface. Finally, dispose of used sandpaper responsibly, as the sharp edges can be hazardous.

Wood Duck Egg Hatching Timeline: Incubation Period Explained

You may want to see also

Explore related products

Assemble with Wood Glue

Wood glue is the unsung hero of woodworking, especially when crafting long trapezoids. Its strength lies in creating invisible bonds that maintain the integrity of the wood’s natural appearance. Unlike mechanical fasteners, wood glue distributes stress evenly across joints, reducing the risk of splitting or warping in long, slender pieces. For trapezoidal shapes, where precision is key, this adhesive ensures seams remain tight and flush, preserving the geometric accuracy of your project.

Applying wood glue effectively requires a light touch and strategic planning. Start by dry-fitting your trapezoid pieces to ensure alignment. Then, apply a thin, even coat of glue to both mating surfaces using a small brush or roller. Aim for a dosage of approximately 1/16 inch thickness—enough to bond without excess squeeze-out. Clamping is critical here: use bar clamps or quick grips to hold the pieces together, ensuring even pressure along the entire joint. Allow the glue to cure for at least 24 hours, depending on humidity and temperature, to achieve maximum strength.

While wood glue is versatile, it’s not without limitations. Avoid using it in areas exposed to extreme moisture or heat, as this can compromise its adhesive properties. For long trapezoids, consider reinforcing joints with splines or biscuits if the wood grain doesn’t provide sufficient surface area for gluing. Additionally, always sand the wood before gluing to remove any oils or residues that could hinder adhesion. A well-prepared surface is half the battle in achieving a seamless bond.

The beauty of wood glue lies in its simplicity and reliability. It’s an affordable, accessible solution for hobbyists and professionals alike, offering a bond that’s often stronger than the wood itself. When crafting long trapezoids, think of glue as the invisible thread stitching your project together. With careful application and proper clamping, it transforms individual pieces into a cohesive, durable structure. Master this technique, and you’ll unlock endless possibilities in woodworking.

Optimal Wood Clamping Time for Glued Joints: A Comprehensive Guide

You may want to see also

Explore related products

Reinforce Joints with Brackets

Wooden trapezoids, especially long ones, face inherent structural challenges due to their angled sides and potential for joint stress. Brackets emerge as a simple yet effective solution to fortify these vulnerable points. By strategically placing metal or wooden brackets at the corners and along the joints, you create a rigid framework that distributes weight and resists warping. This method is particularly crucial for longer trapezoids, where the leverage on the joints increases exponentially with length.

Opt for brackets made from galvanized steel or corrosion-resistant materials, especially if your trapezoid will be exposed to moisture.

The placement of brackets is as critical as their material. Position them at every corner joint, ensuring they span the entire width of the connecting pieces. For longer trapezoids exceeding 4 feet in length, consider adding intermediate brackets along the sides, spaced no more than 24 inches apart. This prevents the wood from bowing under its own weight or external pressure. When attaching brackets, use screws rather than nails. Screws provide superior holding power and allow for easier adjustments if needed. Pre-drill pilot holes to prevent wood splitting, especially when working with hardwoods.

A common mistake is underestimating the number of brackets required. Remember, the goal is to create a robust internal skeleton. Don't skimp on brackets, as their absence will compromise the structural integrity of your trapezoid.

While brackets primarily serve a functional purpose, they can also be incorporated into the design aesthetic. Choose brackets with decorative elements or paint them to match the wood finish. For a more rustic look, consider using wooden brackets crafted from contrasting wood species. This approach adds visual interest while maintaining structural soundness.

Imagine a long trapezoid serving as a unique garden trellis. Strategically placed brackets not only ensure its stability against climbing plants but can also be painted in vibrant colors, transforming them into eye-catching design elements.

By incorporating brackets into your wooden trapezoid construction, you're not just reinforcing joints; you're investing in longevity and durability. This simple yet effective technique allows you to create structures that are both functional and aesthetically pleasing, capable of withstanding the test of time and the elements. Remember, the key lies in choosing the right materials, ensuring proper placement, and embracing the potential for both strength and style.

Mastering the Art of Joining Long Wooden Dowels End to End

You may want to see also

Frequently asked questions

Essential tools include a table saw or circular saw for cutting, a miter saw for precise angles, a tape measure, a pencil, a square, sandpaper, and clamps to hold the wood securely during cutting.

Determine the lengths of the parallel sides (bases) and the height of the trapezoid. Use a tape measure and square to mark the dimensions on the wood. Connect the marks to outline the trapezoid shape before cutting.

Choose straight-grained, stable wood like pine, oak, or plywood, depending on the project’s needs. Avoid warped or uneven boards to ensure accurate cuts and a clean finish.

Use a miter saw set to the correct angle for the trapezoid’s sides. Double-check measurements and use a square to verify alignment before cutting. Sand the edges afterward for smoothness.