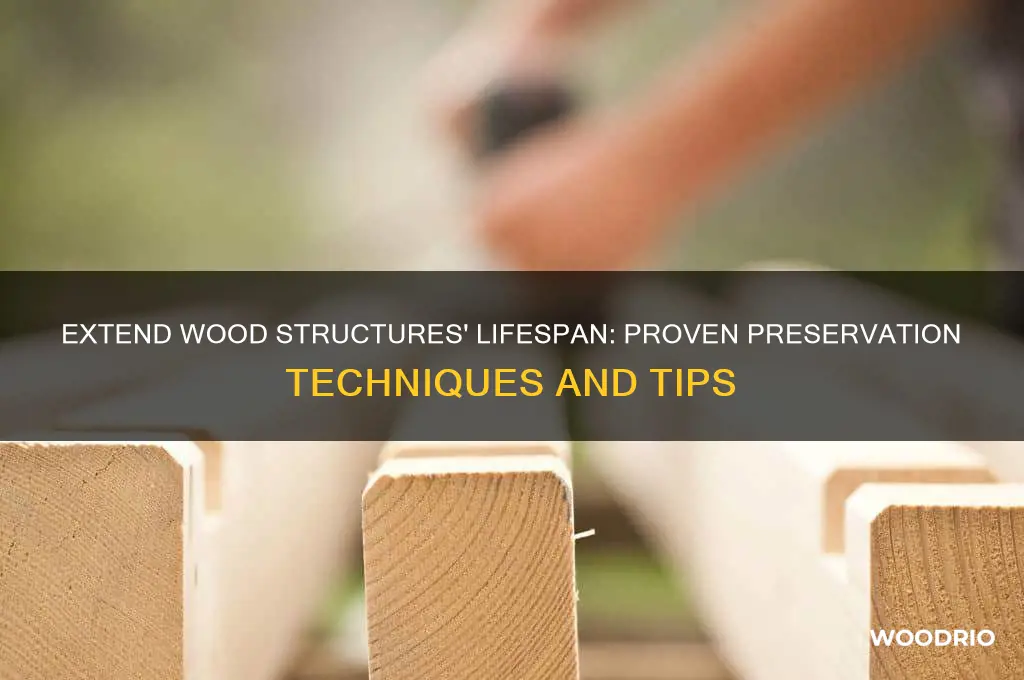

Preserving wood structures to ensure their longevity requires a combination of proper material selection, protective treatments, and regular maintenance. Choosing naturally durable wood species like cedar or redwood can provide inherent resistance to decay and insects. Applying high-quality sealants, stains, or paints creates a barrier against moisture, UV rays, and pests, while periodic inspections and repairs address minor issues before they escalate. Additionally, ensuring proper ventilation and drainage around the structure prevents water accumulation, a primary cause of rot. By integrating these strategies, wood structures can withstand environmental stressors and remain functional and aesthetically pleasing for decades.

| Characteristics | Values |

|---|---|

| Proper Wood Selection | Choose naturally durable wood species (e.g., cedar, redwood, cypress) or pressure-treated wood for resistance to decay and insects. |

| Moisture Control | Ensure proper drainage, use waterproof sealants, and maintain a moisture content below 19% to prevent rot and mold. |

| Regular Maintenance | Inspect and repair structures annually, reapply finishes, and address any damage promptly. |

| Protective Finishes | Apply stains, sealers, or paints to protect wood from UV rays, moisture, and pests. Reapply every 2-3 years. |

| Elevated Foundations | Use concrete piers, posts, or gravel pads to keep wood structures off the ground, reducing contact with moisture and soil-dwelling pests. |

| Ventilation | Design structures with adequate airflow to prevent moisture buildup, especially in enclosed spaces like sheds or decks. |

| Termite Protection | Use termite-resistant materials, apply termite barriers, and schedule regular inspections in high-risk areas. |

| UV Protection | Use UV-resistant finishes or shade structures to minimize sun damage and fading. |

| Proper Construction Techniques | Use corrosion-resistant fasteners, avoid trapping water with design flaws, and ensure tight joints. |

| Environmental Considerations | Avoid placing structures in areas prone to standing water, high humidity, or heavy vegetation. |

| Fire Resistance | Apply fire-retardant treatments, especially in wildfire-prone areas, to enhance safety and longevity. |

| Pest Management | Regularly inspect for and treat infestations of insects or rodents that can damage wood. |

| Temperature Regulation | Avoid extreme temperature fluctuations by using breathable finishes and proper insulation in enclosed structures. |

| Cleaning | Regularly clean surfaces to remove dirt, debris, and organic matter that can retain moisture and promote decay. |

| Structural Support | Ensure proper load-bearing capacity and reinforce structures as needed to prevent sagging or collapse. |

Explore related products

What You'll Learn

- Proper Wood Selection: Choose durable, rot-resistant species like cedar or teak for longevity

- Sealants and Finishes: Apply waterproof sealants or oils to protect against moisture and UV damage

- Regular Maintenance: Inspect and repair cracks, splinters, or damage promptly to prevent deterioration

- Elevated Foundations: Keep structures off the ground using concrete or metal bases to avoid rot

- Pest Prevention: Use treatments or barriers to protect wood from termites, beetles, and fungi

Proper Wood Selection: Choose durable, rot-resistant species like cedar or teak for longevity

The lifespan of a wood structure hinges on the species you choose. Opting for naturally durable, rot-resistant woods like cedar or teak is the first line of defense against decay. These species contain natural oils and resins that repel moisture, insects, and fungal growth, significantly reducing the need for frequent treatments and repairs. While initial costs may be higher, the long-term savings in maintenance and replacement make them a wise investment.

Consider the environment where your structure will reside. Cedar, with its rich reddish-brown hue, thrives in outdoor settings due to its resistance to warping and cracking. Teak, prized for its golden-brown patina, excels in humid or wet conditions, making it ideal for decks, docks, or outdoor furniture. Both woods age gracefully, developing a silver-gray tone if left untreated, or maintaining their original color with periodic sealing.

Not all wood species are created equal. Softwoods like pine or spruce, while affordable, lack the natural defenses of cedar or teak and require frequent chemical treatments to withstand the elements. In contrast, hardwoods like oak or maple, though durable, are more prone to moisture absorption and may warp or split over time. By selecting cedar or teak, you bypass these vulnerabilities, ensuring your structure remains structurally sound and aesthetically pleasing for decades.

For optimal results, pair proper wood selection with good construction practices. Use stainless steel or galvanized fasteners to prevent corrosion, which can weaken joints and accelerate decay. Ensure adequate ventilation and drainage to minimize moisture accumulation, and apply a high-quality sealant every 2–3 years to enhance protection. With these measures, your cedar or teak structure will not only endure but also retain its beauty, becoming a lasting testament to thoughtful craftsmanship.

Wood Durability Inside: Factors Affecting Longevity and Preservation Tips

You may want to see also

Explore related products

$23.7 $24.95

Sealants and Finishes: Apply waterproof sealants or oils to protect against moisture and UV damage

Wood, a timeless and versatile material, is inherently susceptible to the elements. Moisture and ultraviolet (UV) radiation are its primary adversaries, causing warping, cracking, and fading over time. To combat these forces, waterproof sealants and oils emerge as essential tools in the wood preservation arsenal. These protective coatings act as a barrier, repelling water and shielding the wood from the sun's damaging rays.

Unlike paints, which form a film on the surface, sealants and oils penetrate the wood fibers, providing protection from within. This allows the wood's natural beauty to shine through while ensuring its longevity.

Choosing the right sealant or oil depends on the wood type, its intended use, and the desired aesthetic. For exterior structures like decks and fences, opt for marine-grade sealants with high UV resistance and water repellency. These products often contain additives like mildewcides and fungicides to prevent mold and mildew growth. For interior woodwork, such as furniture and cabinetry, consider natural oils like linseed or tung oil. These penetrate deeply, enhancing the wood's grain and providing a warm, natural finish. Application is key to maximizing protection. Ensure the wood surface is clean, dry, and free of any previous finishes. Apply the sealant or oil generously, following the manufacturer's instructions regarding drying times and number of coats.

Regular reapplication, typically every 1-3 years depending on exposure, is crucial for maintaining optimal protection.

While sealants and oils offer significant protection, they are not invincible. Extreme weather conditions and heavy foot traffic can accelerate wear and tear. Regular inspections and prompt touch-ups are essential for addressing any vulnerabilities. By incorporating waterproof sealants and oils into your wood care routine, you can significantly extend the lifespan of your wooden structures, ensuring they remain beautiful and functional for years to come.

Joe Smith's Mysterious Journey: How Long Was He in the Woods?

You may want to see also

Explore related products

Regular Maintenance: Inspect and repair cracks, splinters, or damage promptly to prevent deterioration

Wood, like any organic material, is susceptible to the ravages of time and environment. Left unchecked, small imperfections—cracks, splinters, or surface damage—can become gateways for moisture, pests, and rot. Regular maintenance isn’t just about aesthetics; it’s a proactive defense against structural compromise. A bi-annual inspection schedule, ideally in spring and fall, allows you to catch issues before they escalate. Use a bright flashlight and a magnifying glass to scrutinize joints, corners, and areas prone to moisture accumulation, such as near gutters or ground contact points.

Once identified, damage demands immediate action. Splinters, for instance, should be sanded smooth with 120-grit sandpaper, followed by a coat of exterior-grade wood sealant to prevent moisture penetration. Cracks wider than 1/8 inch require filling with epoxy wood filler, a material that hardens to match the structural integrity of the surrounding wood. For deeper structural damage, such as rot, remove the affected area with a chisel, treat the exposed wood with a borate-based preservative, and replace with pressure-treated lumber. Always wear gloves and a mask during repairs to avoid exposure to wood dust and chemicals.

Comparing neglect to diligence underscores the value of regular maintenance. A deck left unrepaired for a year may require $1,500 in professional restoration due to rot and warping, whereas biannual inspections and minor fixes cost less than $100 in materials. Similarly, a fence post with untreated cracks can fail within two years, while a repaired and sealed post can last a decade. The financial and time savings are clear, but the longevity of the structure is the ultimate reward.

Persuasively, consider the analogy of a car: you wouldn’t ignore an oil leak until the engine seizes. Wood structures require the same preventative mindset. By treating maintenance as non-negotiable, you’re not just preserving wood—you’re safeguarding the safety and functionality of your outdoor spaces. Make it a habit, and your wood structures will defy the odds, standing resilient against time and elements.

Wood Chip Mulch Breakdown: Understanding Decomposition Time and Factors

You may want to see also

Explore related products

Elevated Foundations: Keep structures off the ground using concrete or metal bases to avoid rot

Wood, a timeless building material, is inherently susceptible to moisture-induced decay. Ground contact accelerates this process, as soil retains moisture and harbors fungi that feast on cellulose. Elevated foundations, constructed from durable materials like concrete or metal, create a critical barrier between wood and the earth, significantly extending the lifespan of structures.

Imagine a wooden deck, its planks slowly succumbing to rot where they meet the damp soil. Now picture the same deck supported by concrete piers, elevated inches above the ground. The difference is stark: the elevated deck remains dry, resisting rot and insect damage for decades longer.

Implementing elevated foundations requires careful planning. Begin by assessing soil conditions and local building codes. For lighter structures like sheds or playhouses, precast concrete piers offer a cost-effective solution. Heavier structures, such as cabins or garages, demand poured concrete footings, ensuring stability and weight distribution. Metal bases, while more expensive, provide superior corrosion resistance in coastal areas or regions with high humidity.

Regular inspection and maintenance are crucial. Check for cracks in concrete, rust on metal bases, and signs of settling. Addressing these issues promptly prevents structural compromise and ensures the longevity of your elevated foundation system.

The benefits of elevated foundations extend beyond rot prevention. By raising structures above ground level, you improve air circulation, deterring pests and promoting faster drying after rain. This elevated position also protects against flooding and termite infestations, common threats to wood structures in contact with the ground.

Investing in elevated foundations is an investment in the future of your wood structures. By creating a physical barrier against moisture and pests, you ensure their beauty, functionality, and value for generations to come.

Measuring the Length of a Classic Wooden Toy Train Engine

You may want to see also

Explore related products

Pest Prevention: Use treatments or barriers to protect wood from termites, beetles, and fungi

Wood structures, despite their timeless appeal, are under constant siege from pests that can compromise their integrity. Termites, beetles, and fungi are relentless adversaries, capable of turning sturdy beams into brittle, hollow shells. To safeguard your investment, proactive pest prevention is non-negotiable. Chemical treatments, such as borate-based preservatives, penetrate the wood’s surface, creating a toxic barrier that repels termites and fungi. Applied at a concentration of 1–2% solution, these treatments are effective for both new and existing structures. For optimal results, ensure the wood is clean and dry before application, and allow sufficient time for absorption.

Physical barriers offer another layer of defense, particularly in high-risk environments. Stainless steel mesh, for instance, can be installed around the foundation of a structure to block termite entry points. Similarly, sand barriers, composed of particles too large for termites to navigate, disrupt their foraging paths. When constructing new wood structures, consider using naturally resistant species like cedar or redwood, which contain oils that deter beetles and fungi. However, even these woods benefit from additional treatments, as no natural resistance is foolproof.

For existing structures, regular inspections are critical. Look for mud tubes along foundations, hollow-sounding wood, or frass (insect waste) near wooden surfaces—these are telltale signs of infestation. If detected early, localized treatments like foam termiticides or fungal sprays can mitigate damage. For severe cases, professional fumigation may be necessary, though this is costly and disruptive. Prevention, therefore, is far more economical than remediation.

A comparative analysis reveals that while chemical treatments are highly effective, they may raise environmental concerns due to toxicity. Physical barriers, on the other hand, are eco-friendly but require precise installation to be effective. Combining both methods—applying borate treatments and installing mesh barriers—provides a robust, dual-layered defense. This hybrid approach not only extends the lifespan of wood structures but also minimizes the need for future interventions.

In practice, pest prevention is as much about maintenance as it is about initial treatment. Keep wood structures well-ventilated to discourage fungal growth, and promptly repair any cracks or gaps that could serve as entry points for pests. For outdoor structures, elevate wood off the ground using concrete or metal supports to reduce moisture absorption and termite access. By integrating these strategies, you transform vulnerability into resilience, ensuring your wood structures stand the test of time.

Wooden Ceiling Durability: Preventing Rust and Extending Lifespan Tips

You may want to see also

Frequently asked questions

Apply a high-quality waterproof sealant or stain to all exposed surfaces, including ends and edges. Ensure proper drainage around the structure and elevate wood off the ground using concrete or metal supports to prevent direct contact with soil.

Reapply sealant or stain every 2–3 years, depending on the product and exposure to weather. Inspect the wood annually for signs of wear, cracking, or peeling, and treat as needed to maintain protection.

Yes, use pressure-treated wood or apply insecticidal treatments specifically designed for wood preservation. Regularly inspect for signs of infestation, such as sawdust piles or holes, and address issues promptly.

Proper ventilation prevents moisture buildup, which can lead to rot and mold. Ensure wood structures, like decks or sheds, have adequate airflow by leaving gaps between boards and avoiding enclosed designs in humid areas.