Making a wood leg that is too short longer can be achieved through several practical methods, depending on the desired aesthetic and structural integrity. One common approach is to add an extension piece, such as a wooden block or dowel, securely attached to the existing leg using wood glue and screws or dowels for reinforcement. Alternatively, a decorative collar or spacer made of wood or metal can be inserted between the leg and the furniture piece, blending seamlessly with the design. For a more discreet solution, a wooden shim or veneer can be applied to the bottom of the leg, ensuring it matches the surrounding material. Each method requires careful measurement, sanding, and finishing to maintain consistency in appearance and stability. Always consider the load-bearing capacity and overall balance of the furniture when extending the leg to ensure safety and functionality.

Explore related products

What You'll Learn

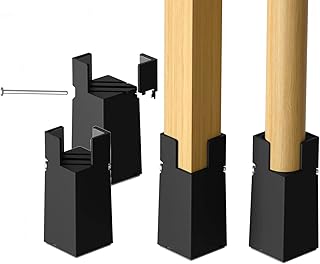

- Adding Wooden Extensions: Attach pre-cut wooden blocks or dowels to extend leg length securely

- Using Adjustable Feet: Install screw-in or bolt-on feet for customizable height adjustments

- Tapered Wood Inserts: Insert tapered wooden pieces into leg cavities for seamless extension

- Metal or Plastic Caps: Add height with durable metal or plastic caps on leg ends

- Layered Wood Stacks: Glue or screw additional wood layers to the bottom of the leg

Adding Wooden Extensions: Attach pre-cut wooden blocks or dowels to extend leg length securely

Extending a wooden leg that's too short can be achieved with precision and simplicity by attaching pre-cut wooden blocks or dowels. This method is particularly effective for furniture pieces where the leg’s structural integrity must remain uncompromised. Begin by selecting a block or dowel that matches the leg’s wood type and grain pattern for seamless integration. Measure the required extension length, ensuring accuracy to avoid uneven alignment. Sand the top of the leg and the bottom of the extension to create a smooth, even surface for adhesion. Use a high-strength wood adhesive, applying a thin, even layer to both mating surfaces. For added security, drill pilot holes through the extension and into the leg, then secure with screws appropriate for the wood density. Allow the adhesive to cure fully before applying weight, typically 24 hours for most wood glues.

While this method is straightforward, its success hinges on attention to detail. A mismatch in wood type or grain can detract from the piece’s aesthetic appeal, so sourcing materials from the same supplier or batch is advisable. For legs under heavy load, such as table or chair legs, reinforce the joint by adding wooden dowels or biscuits before gluing. This distributes stress more evenly, reducing the risk of failure. If the leg has a decorative profile, shape the extension to match using a router or chisel before attachment. Always test the extension’s stability by applying gradual pressure before full use.

Comparatively, this approach offers a balance of durability and aesthetics that temporary fixes like stacking blocks or using adjustable feet cannot match. Unlike metal or plastic extensions, wooden blocks maintain the piece’s natural look and feel. However, it requires more skill and time than quick-fix solutions, making it ideal for long-term repairs or custom furniture projects. For antique or high-value pieces, consult a professional to ensure the extension aligns with conservation standards.

In practice, this technique is versatile across various applications. For example, extending the legs of a mid-century dining table by 2 inches involves cutting a 2-inch hardwood block, staining it to match, and securing it with adhesive and 1.5-inch wood screws. For a child’s chair, softer pine dowels can be used, sanded smooth to prevent splinters. Always consider the leg’s diameter when selecting extensions—a block or dowel should be at least 75% of the original leg’s width for stability. With proper execution, wooden extensions not only correct height discrepancies but also enhance the piece’s structural integrity.

Extending Wood Beams: Simple Techniques to Increase Length and Strength

You may want to see also

Explore related products

Using Adjustable Feet: Install screw-in or bolt-on feet for customizable height adjustments

Adjustable feet offer a practical and elegant solution for extending the height of wooden legs, blending functionality with aesthetics. Available in screw-in or bolt-on varieties, these feet are designed to thread or attach securely to the bottom of the leg, providing a customizable lift. Typically made from materials like metal, plastic, or rubber, they come in various styles to match the furniture’s design while ensuring stability. This method is particularly useful for tables, chairs, or cabinets that require precise leveling or additional height without compromising the original structure.

Installing adjustable feet is a straightforward process that requires minimal tools and expertise. Begin by selecting feet with threads or mounting hardware compatible with the leg’s diameter and material. For screw-in feet, drill a pilot hole into the bottom of the leg if necessary, then thread the foot in by hand or with a wrench until it reaches the desired height. Bolt-on feet, on the other hand, attach via screws or bolts through pre-drilled holes, offering a more permanent but equally adjustable solution. Ensure the leg is clean and free of debris for a secure fit, and test the stability before fully tightening the components.

One of the standout advantages of adjustable feet is their versatility. Unlike permanent extensions, they allow for fine-tuning the height in increments, often as small as 1/8 inch, depending on the model. This precision is invaluable for uneven floors or when aligning furniture with other pieces. Additionally, many adjustable feet feature non-slip bases, reducing the risk of scratches or movement on hard surfaces. For outdoor furniture, opt for weather-resistant materials like stainless steel or galvanized metal to prevent rust and ensure longevity.

While adjustable feet are a convenient solution, there are a few considerations to keep in mind. Over-tightening can strip the threads or damage the wood, so use moderate force and consider applying thread locker for added security. For heavier furniture, choose feet with higher weight capacities, typically ranging from 50 to 500 pounds per foot. Lastly, while adjustable feet are discreet, they may slightly alter the furniture’s appearance, so select a finish that complements the existing design. With proper installation and care, adjustable feet provide a durable, adaptable fix for legs that are too short.

Pinewood Derby Race Duration: Understanding the Time It Takes

You may want to see also

Explore related products

Tapered Wood Inserts: Insert tapered wooden pieces into leg cavities for seamless extension

Tapered wood inserts offer a discreet and elegant solution for extending wooden legs that have fallen short over time or were initially miscalculated. By crafting a piece of wood that tapers in diameter from one end to the other, you can insert it into the existing leg cavity, effectively lengthening the leg without compromising its structural integrity or aesthetic appeal. This method is particularly effective for furniture with turned or cylindrical legs, where the insert can be seamlessly integrated to match the original design.

To begin, measure the diameter of the leg at both the top and bottom of the cavity where the insert will sit. Use these measurements to create a tapered blank from a matching wood species. For example, if the leg’s top diameter is 2 inches and the bottom is 1.5 inches, the insert should taper smoothly between these dimensions. A bandsaw or spindle sander can be used to shape the taper, ensuring a precise fit. Sand the insert thoroughly to remove any tool marks and achieve a smooth transition between the original leg and the extension.

One of the key advantages of tapered wood inserts is their ability to maintain the leg’s original profile. Unlike external extensions, which can disrupt the furniture’s silhouette, tapered inserts are hidden within the leg itself. To enhance the seamless appearance, apply a finish to the insert that matches the existing piece. If the furniture has a stained or painted finish, apply the same treatment to the insert before installation. For a more durable bond, use a two-part epoxy adhesive to secure the insert in place, ensuring it aligns perfectly with the leg’s axis.

While this method is highly effective, it requires careful planning and precision. Mismatched tapers or improper alignment can result in visible gaps or uneven surfaces. Always test the fit of the insert before applying adhesive, making minor adjustments as needed. Additionally, consider the weight-bearing capacity of the extended leg, especially for furniture like tables or chairs. Reinforcing the joint with a dowel or screw can provide added stability, particularly in high-stress applications.

In conclusion, tapered wood inserts are a sophisticated solution for lengthening wooden legs, blending functionality with craftsmanship. By focusing on precision and attention to detail, you can achieve a result that not only extends the leg but also preserves the furniture’s original beauty. Whether restoring an heirloom piece or correcting a DIY mistake, this technique offers a professional and lasting fix.

Deer Antler Sheds: Lifespan and Decay in Woodland Environments

You may want to see also

Explore related products

Metal or Plastic Caps: Add height with durable metal or plastic caps on leg ends

One straightforward solution to lengthen a wooden leg that’s too short is to attach metal or plastic caps to its ends. These caps, often used in furniture design, serve both functional and aesthetic purposes. Available in various heights, typically ranging from 1 to 4 inches, they can be selected to match the exact additional length needed. Metal caps offer a sleek, industrial look and are highly durable, while plastic caps are lightweight and budget-friendly, often coming in colors that can blend seamlessly with the wood. Installation is simple: ensure the leg end is clean and flat, then secure the cap using adhesive or screws, depending on the design.

When choosing between metal and plastic, consider the environment where the furniture will be used. Metal caps are ideal for high-traffic areas or outdoor furniture due to their resistance to wear and corrosion, especially if made from stainless steel or coated with a protective finish. Plastic caps, on the other hand, are better suited for indoor use or lighter applications, as they may degrade under prolonged exposure to sunlight or heavy loads. Both options are widely available at hardware stores or online, with prices ranging from $2 to $10 per cap, depending on material and size.

A key advantage of using caps is their reversibility. Unlike cutting or altering the wooden leg itself, adding caps allows for easy removal or replacement if the height needs to be adjusted later. This makes them a versatile solution for renters or those who prefer non-permanent modifications. To ensure stability, select caps with a wide base or anti-slip features, especially for furniture like tables or chairs that bear significant weight. For a polished finish, choose caps with a threaded insert or pre-drilled holes for secure attachment.

While metal and plastic caps are effective, they do alter the furniture’s appearance. To minimize visual impact, opt for caps that match the leg’s diameter and color as closely as possible. For wooden legs, consider staining or painting plastic caps to blend in. Metal caps, particularly in brass or chrome, can add a decorative touch if the style complements the piece. Always test the stability of the furniture after installation, ensuring the caps are firmly attached and the added height doesn’t compromise balance. With careful selection and proper installation, these caps provide a practical, durable solution for lengthening wooden legs.

Power Washing Wooden Homes: Durability and Maintenance Tips for Longevity

You may want to see also

Explore related products

Layered Wood Stacks: Glue or screw additional wood layers to the bottom of the leg

One effective method to lengthen a wood leg that’s too short is by creating layered wood stacks. This technique involves gluing or screwing additional wood layers to the bottom of the leg, adding height while maintaining structural integrity. The key to success lies in selecting wood that matches the leg’s grain, color, and density to ensure a seamless integration. For example, if the leg is made of oak, use oak layers to avoid visual or structural discrepancies. This approach is particularly useful for furniture pieces where precision and aesthetics are critical.

When opting for glue, choose a high-strength wood adhesive like epoxy or polyurethane glue, which provides a durable bond even under weight-bearing stress. Apply the glue evenly to the mating surfaces, clamp the layers together, and allow at least 24 hours for curing. For added stability, reinforce the joint with screws. Use 1¼-inch wood screws, pre-drilling pilot holes to prevent splitting. Space the screws evenly around the perimeter, ensuring they penetrate both layers securely. This dual approach—gluing and screwing—maximizes strength and longevity.

A comparative analysis reveals that gluing offers a cleaner, more discreet finish, ideal for visible furniture legs. Screwing, while leaving visible hardware, provides immediate strength and is better suited for hidden or less prominent areas. For example, a dining table leg might benefit from glued layers for aesthetics, while a bed frame leg could tolerate screws for practicality. The choice depends on the leg’s visibility and the desired balance between appearance and expediency.

Practical tips include sanding the joint between layers to create a smooth transition and staining or painting the added wood to match the original leg. If the leg has a tapered design, cut the additional layers to match the taper angle for a cohesive look. Always test the leg’s stability after modification by applying weight gradually. This method is cost-effective, requiring minimal materials, and can be completed in a few hours, making it accessible for DIY enthusiasts and professionals alike.

The History and Evolution of the Wood Boss: A Timeline

You may want to see also

Frequently asked questions

Yes, you can extend a wood leg by adding a wooden extension piece, using a dowel or block, or attaching a decorative footer to increase its height.

You’ll need basic tools like a saw, drill, sandpaper, wood glue, clamps, and possibly screws or dowels, depending on the method you choose.

Sand the extension piece to match the leg’s texture, then stain or paint it to blend seamlessly. Finish with a matching sealant for consistency.

Yes, by using a dowel or spline joint and carefully aligning the grain, you can create a nearly invisible connection with proper sanding and finishing.

![4 Pcs Adjustable Height Furniture Support Legs [with Screws] 3.15-4.72 inch, Metal Heavy Duty Furniture Replacement Legs for Chair/Bed/Sofa/Cabinet/Couch/Dresser/Bed/Table (Black)](https://m.media-amazon.com/images/I/61YoSOf22HL._AC_UL320_.jpg)