Extending the length of a wood beam is a common challenge in construction and woodworking projects, often requiring careful planning and the right techniques to ensure structural integrity. Whether you’re working on a home renovation, building a deck, or crafting custom furniture, there are several methods to achieve a longer beam, including splicing, joining with metal plates, or using mechanical fasteners. Each approach has its advantages and considerations, such as load-bearing capacity, aesthetics, and ease of installation. By understanding these methods and selecting the appropriate one for your specific needs, you can effectively extend a wood beam while maintaining strength and stability.

| Characteristics | Values |

|---|---|

| Methods | 1. Sistering: Attaching a new beam alongside the existing one for added length and strength. 2. Laminating: Gluing multiple shorter pieces of wood together to create a longer beam. 3. Splice Joint: Joining two beams end-to-end using a strong joint like a scarf joint or finger joint. 4. Steel Plate Connector: Using steel plates and bolts to connect two beams. |

| Materials Needed | Wood (matching species and grade), wood glue (for laminating), screws/nails, steel plates and bolts (for steel connectors), clamps, saw, drill, measuring tape, safety gear. |

| Tools Required | Saw (circular saw, table saw, or hand saw), drill, clamps, measuring tape, square, safety gear (eye protection, gloves). |

| Difficulty Level | Moderate to Difficult (depending on method chosen and skill level) |

| Cost | Varies depending on method, wood type, and materials needed. Sistering and laminating are generally more cost-effective than steel connectors. |

| Strength | Varies depending on method and execution. Properly done, sistering and laminating can provide significant strength. Steel connectors offer high strength but require precise installation. |

| Aesthetic Impact | Sistering and steel connectors may be visible, while laminating can be less noticeable if done well. |

| Time Required | Varies depending on method and project size. Laminating requires drying time for glue, while sistering and steel connectors can be faster. |

| Safety Considerations | Always wear safety gear. Ensure proper structural support during construction. Consult a professional if unsure about load-bearing capacity. |

| Code Compliance | Check local building codes for regulations regarding beam modifications and structural integrity. |

Explore related products

What You'll Learn

Joining Beams with Splices

Wood beams, while robust, often fall short in length for larger projects. Joining beams with splices offers a practical solution, extending their reach without compromising structural integrity. This method involves connecting two or more beams end-to-end using a splice, a joint designed to transfer load seamlessly. Splices can be crafted from wood, steel, or a combination of materials, each offering unique advantages depending on the application. For instance, a steel splice plate provides superior strength, while a wooden scarf joint blends aesthetically with the beam.

To execute a splice joint effectively, precision is paramount. Begin by ensuring the ends of the beams are square and smooth, as any irregularities can weaken the connection. For a wooden scarf joint, overlap the beams by at least 12 inches, with a bevel angle of 1:5 (vertical to horizontal) to maximize surface area for gluing and fastening. Use high-strength wood glue and galvanized screws or bolts spaced no more than 6 inches apart to secure the joint. Pre-drilling holes prevents splitting, especially in hardwoods. For steel splice plates, align the plates centrally over the joint and secure with through-bolts, ensuring the bolts are tightened to the manufacturer’s torque specifications.

While splices are effective, they introduce potential failure points if not executed correctly. Overloading the joint or using inadequate fasteners can lead to shear or tensile failure. To mitigate this, calculate the load-bearing capacity of the splice based on the beam’s dimensions and material properties. For example, a 4x6 Douglas fir beam spliced with a 1/4-inch steel plate can support up to 2,500 pounds in tension, provided the bolts are spaced appropriately. Always consult structural engineering guidelines or a professional to ensure compliance with safety standards.

Aesthetic considerations also play a role in splice design. Exposed splices, such as those in timber framing, benefit from careful craftsmanship to maintain visual appeal. Sanding the joint smooth and using wood filler to conceal gaps can create a seamless appearance. For hidden splices, such as those in flooring or ceiling beams, prioritize functionality over form, focusing on strength and stability. Regardless of the application, regular inspection of spliced joints is essential to identify signs of wear or stress, ensuring long-term durability.

In summary, joining beams with splices is a versatile and effective method for extending wood beams. By selecting the appropriate splice type, ensuring precise craftsmanship, and adhering to structural guidelines, you can achieve a joint that is both strong and reliable. Whether for a rustic timber frame or a modern structural project, splices offer a practical solution to the challenge of limited beam length. With careful planning and execution, this technique transforms two shorter beams into one continuous, load-bearing element.

Vinegar on Wood Decks: Optimal Soak Time for Effective Cleaning

You may want to see also

Explore related products

Using Metal Plates for Extension

Metal plates offer a robust solution for extending wood beams, particularly in structural applications where strength and durability are paramount. By splicing two beams together with a metal plate, you can effectively double the length while maintaining—or even enhancing—the load-bearing capacity. This method is commonly used in construction and renovation projects where existing beams fall short of required spans. The key lies in selecting the right type of plate: steel is ideal for its high tensile strength, while galvanized options provide added corrosion resistance in moisture-prone environments. Properly executed, this technique not only extends the beam but also reinforces its structural integrity.

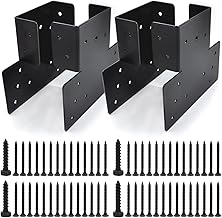

To implement this method, begin by measuring and cutting the wood beams to the desired lengths, ensuring clean, straight cuts for optimal alignment. Position the beams end-to-end, leaving a small gap to accommodate the metal plate. The plate should be sized to span the joint, typically extending 6 to 12 inches on each side of the splice, depending on the beam’s load requirements. Secure the plate using high-strength bolts or screws, pre-drilling holes to prevent wood splitting. For added stability, consider using multiple plates along the joint or incorporating a staggered bolt pattern to distribute stress evenly. Always follow local building codes and consult structural guidelines to ensure compliance.

While metal plates provide a reliable solution, their effectiveness hinges on precise installation. Misalignment or inadequate fastening can compromise the joint, leading to structural failure under load. To mitigate risks, use a level and clamps to align the beams before securing the plate. Additionally, apply a waterproof sealant around the joint to prevent moisture infiltration, which can cause wood rot or rust over time. For heavy-duty applications, such as supporting floors or roofs, consult a structural engineer to verify the design and ensure it meets safety standards.

Comparatively, metal plate extensions offer advantages over alternative methods like scarfing or sistering. Scarfing, though traditional, requires skilled craftsmanship and may weaken the beam if not executed perfectly. Sistering, which involves attaching a new beam alongside the existing one, can be space-consuming and less aesthetically pleasing. Metal plates, on the other hand, provide a seamless, low-profile solution that preserves the beam’s original appearance while delivering superior strength. This makes them particularly suitable for projects where both functionality and aesthetics are critical.

In conclusion, using metal plates to extend wood beams is a practical, efficient, and structurally sound approach. By combining the natural warmth of wood with the strength of steel, this method bridges the gap between traditional craftsmanship and modern engineering. Whether for residential renovations or commercial construction, it offers a versatile solution that stands the test of time. With careful planning and execution, metal plate extensions can transform limited beams into robust structural elements capable of meeting demanding project requirements.

Growing Basal Wood: Understanding the Timeframe for Optimal Growth

You may want to see also

Explore related products

Finger Jointing Techniques

Finger jointing is a precise method for extending wood beams by seamlessly joining shorter pieces into longer, structurally sound units. This technique relies on interlocking finger-shaped cuts, maximizing glue surface area and creating a bond stronger than the wood itself. Unlike simple butt joints, finger joints distribute stress evenly, reducing the risk of failure under load. Commonly used in cabinetry and construction, this method ensures both aesthetic appeal and durability, making it ideal for applications where longer spans are required without sacrificing strength.

To execute finger jointing, begin by selecting straight-grained, defect-free wood pieces of equal thickness. Use a table saw with a dado blade or a dedicated finger jointing router bit to create the interlocking profiles. For optimal results, ensure the fingers are consistent in width and depth, typically ranging from 1/4 to 1/2 inch, depending on the wood species and intended load. Apply a high-quality wood glue to the joint surfaces, clamping the pieces together until the glue cures fully. Proper alignment is critical; misalignment can weaken the joint or create visible gaps.

One of the key advantages of finger jointing is its efficiency in utilizing shorter, often less expensive wood pieces. This reduces waste and lowers material costs compared to sourcing longer, single-piece beams. However, the technique demands precision and practice. Beginners should start with softer woods like pine to refine their technique before moving to harder species like oak or maple. Additionally, pre-drilling pilot holes for clamping can prevent wood splitting, especially in brittle or dense materials.

While finger jointing excels in strength and appearance, it’s not without limitations. The joint’s integrity depends heavily on glue quality and application—epoxy or polyurethane adhesives are recommended for high-stress applications. Environmental factors, such as moisture exposure, can also impact longevity, so sealing the joint with a waterproof finish is advisable for outdoor use. Despite these considerations, when executed correctly, finger jointing remains a superior method for extending wood beams, blending craftsmanship with functionality.

Elmer's Wood Glue Setting Time: A Quick Drying Guide

You may want to see also

Explore related products

$18.99 $19.99

$32.99

Adding Wooden Extensions

Extending a wooden beam requires careful planning and execution to maintain structural integrity. Adding wooden extensions is a practical solution when you need to increase the length of a beam without replacing it entirely. This method involves joining additional pieces of wood to the existing beam, ensuring a strong and seamless connection. The key to success lies in selecting compatible wood, using appropriate joinery techniques, and reinforcing the joint for added stability.

Selecting the Right Wood and Joinery

Begin by choosing wood that matches the species, grain pattern, and moisture content of the original beam. Mismatched wood can lead to warping or weakening over time. For joinery, a scarf joint or splice joint is commonly used. A scarf joint involves cutting complementary angled ends on both the beam and the extension, then fastening them together. Alternatively, a splice joint uses overlapping pieces secured with bolts or dowels. Both methods distribute stress evenly, but scarf joints are often preferred for their strength and aesthetic appeal. Always ensure the joint is centered along the beam’s length to avoid creating weak points.

Reinforcing the Joint for Durability

Once the joint is in place, reinforcement is crucial. Metal plates or brackets can be installed on both sides of the joint to provide additional support. For beams under heavy load, consider using steel straps or bolts to secure the extension. Epoxy resins can also be applied to the joint for added bonding strength. Ensure all hardware is corrosion-resistant, especially in outdoor applications. Proper reinforcement not only enhances durability but also ensures the extended beam meets structural requirements.

Practical Tips for a Seamless Finish

To achieve a professional finish, sand the joint area to blend the surfaces smoothly. Stain or paint the extension to match the original beam, ensuring consistency in color and texture. If the beam is visible, consider using wood filler to conceal any gaps or imperfections. Regularly inspect the joint for signs of stress or movement, especially during the first year after installation. Applying a protective sealant can prevent moisture damage and prolong the life of the extended beam.

Cautions and Considerations

While adding wooden extensions is cost-effective, it’s not suitable for all scenarios. Avoid extending beams in critical load-bearing structures without consulting a structural engineer. Overloading an extended beam can lead to failure, posing safety risks. Additionally, ensure local building codes permit such modifications. If the beam has existing damage or rot, address these issues before proceeding. Always prioritize safety and structural integrity over convenience.

From Forest to Factory: Crafting Long Wooden Planks Explained

You may want to see also

Explore related products

$22.24 $23.46

Reinforcing with Steel Rods

Steel rods offer a robust solution for extending the length of a wood beam while maintaining structural integrity. By embedding steel rods through the beam’s core, you create a composite system that leverages the tensile strength of steel and the compressive strength of wood. This method is particularly effective for spanning longer distances or supporting heavier loads than the original beam could handle alone. For instance, a 4-inch diameter steel rod can increase the beam’s load-bearing capacity by up to 40%, depending on the wood species and rod placement.

To implement this technique, begin by drilling holes through the beam’s neutral axis, ensuring they align perfectly along the beam’s length. Use a drill bit slightly larger than the rod diameter to allow for epoxy adhesion. Clean the holes thoroughly to remove debris, then apply a structural epoxy adhesive, following the manufacturer’s recommended dosage (typically 1:1 by volume). Insert the steel rods, ensuring they are straight and fully seated. For added stability, consider threading the rods and using nuts at each end to create tension, effectively pre-stressing the system.

While this method is highly effective, it requires precision and caution. Misalignment of the rods or insufficient epoxy can compromise the beam’s strength. Always use galvanized or stainless steel rods to prevent corrosion, especially in outdoor applications. Additionally, consult a structural engineer to ensure the design meets local building codes and load requirements. Compared to splicing or sistering beams, steel rod reinforcement is less invasive and preserves the beam’s aesthetic appearance, making it ideal for both functional and decorative projects.

The takeaway is clear: reinforcing wood beams with steel rods is a practical, durable solution for extending length and capacity. With careful planning and execution, this method transforms a standard wood beam into a high-performance structural element capable of meeting demanding applications. Whether for residential construction or creative woodworking, steel rod reinforcement bridges the gap between traditional materials and modern engineering needs.

How Long Does It Take for Spider Wood to Sink?

You may want to see also

Frequently asked questions

Yes, you can join two wood beams using techniques like scarfing, splicing, or using metal connectors. Ensure proper alignment and secure fastening for structural integrity.

Scarfing is a reliable method where the ends of two beams are cut at an angle and joined with adhesive and fasteners, distributing the load evenly and maintaining strength.

Yes, metal plates or brackets can be used to connect two beams, but they are best suited for non-load-bearing applications. For structural beams, consult an engineer to ensure safety.

Yes, a wooden splice or joint, such as a finger joint or lap joint, can be used. However, these methods may reduce the beam's load capacity, so professional guidance is recommended.