Creating a long thin slot in wood requires precision and the right tools. Whether you're working on a woodworking project like a cabinet, a box, or a decorative piece, the process involves careful planning and execution. Start by marking the exact location and dimensions of the slot on the wood using a ruler and pencil. A router fitted with a straight bit is often the best tool for this task, as it allows for clean, accurate cuts. Alternatively, a table saw with a dado blade can be used for thicker materials. Always ensure the wood is securely clamped to prevent movement, and work gradually, making multiple shallow passes to avoid tear-out or splintering. Safety is paramount, so wear protective gear and follow proper techniques to achieve a professional finish.

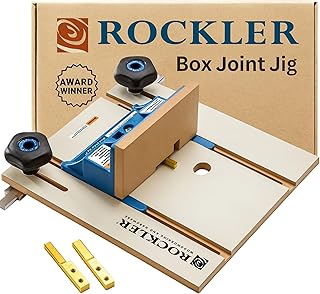

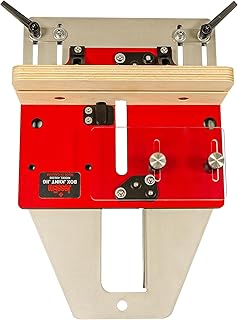

Explore related products

What You'll Learn

- Using a Router: Guide a router with a straight bit along a clamped guide board for precision

- Jigsaw Technique: Clamp a straightedge to the wood and follow it with a jigsaw for control

- Table Saw Method: Use a table saw with a featherboard to ensure a straight, thin cut safely

- Hand Saw and Chisel: Mark the slot, cut with a fine handsaw, and clean edges with a chisel

- Laminate Trimmer: Employ a laminate trimmer with a guide for detailed, thin slots in wood

Using a Router: Guide a router with a straight bit along a clamped guide board for precision

A router, when paired with a straight bit and a clamped guide board, becomes an indispensable tool for creating long, thin slots in wood with precision. This method is particularly effective for projects requiring consistent depth and straight edges, such as cabinetmaking or creating grooves for joinery. The guide board acts as a physical reference, ensuring the router follows a straight path without deviation, even over extended lengths.

To begin, select a straight bit that matches the desired width of your slot. A 1/4-inch or 1/2-inch bit is commonly used for thin slots, but the size depends on your project’s requirements. Secure the workpiece firmly to your workbench using clamps, ensuring it doesn’t shift during routing. Next, prepare the guide board—a straight, sturdy piece of wood or aluminum that’s longer than the slot you intend to cut. Align the guide board parallel to the edge of your workpiece and clamp it in place, leaving enough space for the router base to ride along its edge.

The key to precision lies in the setup. Position the router so its baseplate rests against the guide board, with the bit just above the workpiece. Start the router and gently lower the bit into the wood, allowing the guide board to steer the tool in a straight line. Move the router at a steady pace, letting the guide board maintain alignment. For deeper slots, make multiple passes, lowering the bit incrementally (about 1/8 inch per pass) to prevent tear-out or excessive strain on the router.

One critical caution is to avoid forcing the router or rushing the process. Let the tool’s speed and the guide board’s stability do the work. Always wear safety gear, including eye protection and earplugs, as routers generate dust and noise. Additionally, ensure the guide board is securely clamped and free of defects, as any wobble or misalignment will transfer to the cut.

In conclusion, using a router with a straight bit and a clamped guide board is a reliable technique for achieving long, thin slots with professional accuracy. While it requires careful setup and attention to detail, the results are well worth the effort, offering clean, consistent cuts that enhance the quality of your woodworking projects. This method is especially valuable for craftsmen seeking precision in joinery or decorative elements.

Air Drying Elm Wood: Understanding the Timeframe for Optimal Results

You may want to see also

Explore related products

Jigsaw Technique: Clamp a straightedge to the wood and follow it with a jigsaw for control

Creating a long, thin slot in wood demands precision, and the jigsaw technique paired with a straightedge is a reliable method to achieve this. By clamping a straightedge to the wood, you establish a stable guide for your jigsaw, minimizing the risk of deviation. This approach is particularly effective for slots requiring consistent width and straightness, such as those for inlays or mechanical components. The straightedge acts as a physical barrier, ensuring the jigsaw blade follows a predetermined path without wandering.

To execute this technique, begin by marking the slot’s starting and ending points on the wood. Position a metal or aluminum straightedge along the line, ensuring it extends beyond the cut area for added stability. Secure the straightedge firmly with clamps, using at least two to prevent shifting during cutting. Select a jigsaw blade designed for fine cuts, such as a narrow, high-tooth-count blade, to reduce splintering and ensure a clean edge. Align the jigsaw blade against the straightedge and begin cutting at a moderate speed, allowing the blade to follow the guide without forcing it.

One critical aspect of this method is maintaining consistent pressure and speed. Applying too much force can cause the blade to bind or the straightedge to shift, while moving too quickly increases the risk of inaccuracy. For longer slots, pause periodically to reassess alignment and ensure the straightedge remains securely clamped. If the slot exceeds the length of your straightedge, reposition it along the marked line, overlapping the previous cut slightly to maintain continuity.

While the jigsaw technique with a straightedge is versatile, it’s not without limitations. For slots narrower than 1/8 inch, a router with a guide bushing may yield better results due to the jigsaw’s blade width. Additionally, softer woods like pine or cedar may chip along the cut edge, requiring sanding or a zero-clearance backing to minimize tear-out. Despite these considerations, this method remains a practical choice for most woodworking projects, balancing precision with accessibility for both beginners and experienced craftsmen.

Wood Glue Shelf Life: Storage Tips for Maximum Adhesive Longevity

You may want to see also

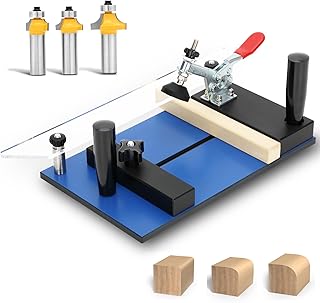

Explore related products

$29.99 $39.99

Table Saw Method: Use a table saw with a featherboard to ensure a straight, thin cut safely

A table saw, when paired with a featherboard, becomes a precision tool for creating long, thin slots in wood. The key lies in the featherboard's ability to apply consistent pressure, keeping the workpiece firmly against the fence and preventing kickback. This method is ideal for projects requiring clean, straight slots, such as cabinetry or jig-making, where accuracy is paramount.

Setting Up for Success: Begin by adjusting your table saw's blade height to match the desired slot depth. A thin-kerf blade, around 0.090 inches, is recommended for minimizing material removal and reducing the risk of tear-out. Position the fence to determine the slot's width, ensuring it’s parallel to the blade. Attach a featherboard to the fence, tightening it just enough to hold the wood securely without causing binding. For added safety, use a push stick or push block to maintain control of the workpiece as it nears the blade.

Executing the Cut: With the setup complete, feed the wood into the blade at a steady pace, allowing the featherboard to guide it along the fence. For longer slots, consider making multiple passes, lowering the blade slightly each time to achieve the desired depth gradually. This reduces strain on the blade and minimizes the risk of burning or chipping the wood. Always keep your hands clear of the blade and maintain focus on the cut to ensure a straight, clean result.

Cautions and Considerations: While the table saw method is efficient, it demands respect for safety. Always wear eye protection and avoid loose clothing or jewelry that could catch on the machinery. Be mindful of wood grain direction to prevent splintering, especially when working with hardwoods. If the slot requires precision alignment, mark the cut line beforehand and use a zero-clearance insert to reduce tear-out.

Exploring Muir Woods: Tour Duration and What to Expect

You may want to see also

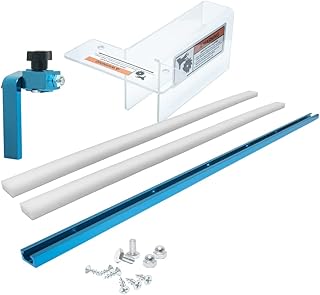

Explore related products

$43.68

Hand Saw and Chisel: Mark the slot, cut with a fine handsaw, and clean edges with a chisel

Creating a long, thin slot in wood using a hand saw and chisel is a precise and traditional method that combines control with craftsmanship. Begin by marking the slot’s dimensions directly onto the wood with a sharp pencil and a straightedge. Accuracy here is critical—even a slight deviation can compromise the final result. Use a ruler or a marking gauge to ensure the lines are straight and consistent, especially if the slot spans a significant length. For added precision, consider scoring the lines lightly with a utility knife to guide your cuts.

Once marked, position a fine-toothed handsaw at the starting point of the slot. A dovetail saw or a backsaw is ideal due to their thin blades and fine teeth, which minimize tear-out and allow for cleaner cuts. Hold the saw at a 90-degree angle to the wood and follow the marked line carefully. Apply gentle, even pressure, letting the saw do the work. For longer slots, pause periodically to check alignment and adjust as needed. Aim to cut about three-quarters of the way through the wood’s thickness to avoid splitting the backside.

With the majority of the slot cut, turn to a chisel to refine and complete the task. Select a sharp, bevel-edged chisel slightly narrower than the slot width to ensure precision. Position the chisel within the saw cut and tap it gently with a mallet to remove the remaining wood fibers. Work gradually, removing thin layers at a time to maintain control. For cleaner edges, tilt the chisel slightly inward on the final pass to create a smooth, crisp finish. This step is where the slot transitions from rough to refined.

While this method is straightforward, it demands patience and attention to detail. Common pitfalls include uneven cuts or splintering, which can be mitigated by sharpening tools regularly and working slowly. For beginners, practicing on scrap wood is highly recommended. Advanced woodworkers might experiment with varying chisel angles or saw techniques to achieve different effects. Ultimately, the hand saw and chisel approach yields a slot that is not only functional but also bears the mark of handmade precision, making it ideal for projects where craftsmanship is paramount.

Yellowjackets in the Woods: Understanding Their Seasonal Presence and Duration

You may want to see also

Explore related products

Laminate Trimmer: Employ a laminate trimmer with a guide for detailed, thin slots in wood

A laminate trimmer, often overshadowed by its bulkier cousin the router, is a precision tool ideal for creating long, thin slots in wood. Its compact size and maneuverability make it perfect for detailed work where larger tools might falter. When paired with a guide, a laminate trimmer becomes a controlled cutting machine, ensuring straight, consistent slots with minimal effort. This combination is particularly useful for projects like inlay work, creating grooves for joinery, or crafting custom wooden handles.

By leveraging the trimmer's lightweight design and the guide's stability, even intricate patterns become achievable.

To begin, select a straight or curved guide depending on your slot's desired shape. Secure the guide firmly to your workpiece using clamps or double-sided tape, ensuring it won't shift during cutting. Choose a router bit with a diameter matching your desired slot width, typically ranging from 1/8 inch to 1/4 inch for thin slots. Install the bit in your laminate trimmer, adjusting the depth stop to control the slot's depth incrementally. Start the trimmer and carefully guide it along the edge of the guide, allowing the bit to cut smoothly without forcing the tool. Multiple passes may be necessary to achieve the full depth, especially for deeper slots.

Regularly check your progress and adjust the depth stop as needed.

While the laminate trimmer and guide offer precision, caution is paramount. Always wear safety goggles and ear protection, as the trimmer's high-speed rotation can send wood chips flying. Secure your workpiece firmly to prevent kickback, and maintain a steady hand to avoid veering off the guide. For added control, consider using a push stick or featherboard to guide the trimmer along the workpiece. Remember, the goal is not speed but accuracy, so take your time and let the tool do the work.

Compared to other methods like using a jigsaw or hand saw, the laminate trimmer with a guide offers unparalleled precision and consistency. Jigsaws, while versatile, can be difficult to control for straight, thin cuts, often resulting in jagged edges. Hand saws, though traditional, require significant skill and patience to achieve clean, straight slots. The laminate trimmer, on the other hand, simplifies the process, making it accessible even to novice woodworkers. Its ability to create uniform slots with minimal setup and cleanup time makes it a valuable addition to any workshop.

In conclusion, employing a laminate trimmer with a guide is a highly effective method for creating long, thin slots in wood. Its precision, ease of use, and versatility make it a standout choice for both simple and complex projects. By following proper safety precautions and taking a methodical approach, woodworkers of all skill levels can achieve professional results. Whether you're crafting custom furniture or adding intricate details to a project, this technique ensures your slots are not only functional but also aesthetically pleasing.

Wood Piles in Salt Water: Durability and Lifespan Explained

You may want to see also

Frequently asked questions

You can use a router with a straight bit, a table saw with a dado blade, or a jigsaw with a narrow blade. For precision, a router is often the best choice.

Use a straightedge or guide clamped to the wood to guide your tool. For routers, a router table with a fence works well. Measure and mark the slot path beforehand for accuracy.

Yes, you can use a chisel and mallet to carefully carve out the slot. Start by marking the slot, then make a series of cuts along the line, removing wood gradually until the slot is complete.

Use a sharp blade or bit and cut with the grain whenever possible. Apply masking tape along the cut line or use a sacrificial backing board to reduce tear-out.