Creating a long wooden pipe can be a rewarding DIY project, combining craftsmanship with practicality. To begin, select a suitable type of wood, such as hardwoods like oak or maple, which offer durability and strength. Start by cutting the wood into manageable sections, ensuring they are straight and free of defects. Hollow out the center of each piece using a drill press or a Forstner bit, maintaining a consistent diameter throughout. Sand the interior and exterior surfaces to achieve a smooth finish, and then join the sections together using wood glue or dowels for added stability. Finally, seal the pipe with a food-safe finish to protect the wood and ensure longevity, especially if it will be used for functional purposes like water transport or decorative applications.

| Characteristics | Values |

|---|---|

| Materials Needed | Wood (preferably hardwood like oak, maple, or walnut), wood glue, sandpaper, drill, saw, measuring tape, clamps, sealant (optional) |

| Tools Required | Drill with Forstner bits or hole saw, table saw or hand saw, sander or sandpaper, clamps, measuring tools |

| Wood Selection | Choose straight-grained, dry hardwood with minimal knots for strength and durability |

| Pipe Diameter | Depends on intended use; common sizes range from 1" to 4" |

| Pipe Length | Can be made as long as needed by joining multiple wood sections |

| Joining Method | Use wood glue and dowels, or threaded connectors for modular designs |

| Sealing | Apply food-safe sealant or oil (e.g., tung oil) for water pipes or decorative purposes |

| Sanding | Sand interior and exterior surfaces to ensure smooth flow and prevent splinters |

| Drilling Technique | Use Forstner bits or hole saws to create consistent, clean holes through the wood |

| Strengthening | Reinforce joints with dowels or metal brackets for added stability |

| Finishing | Apply stain or varnish for aesthetic appeal and protection against moisture |

| Safety Considerations | Wear safety goggles, dust mask, and ear protection during cutting and drilling |

| Applications | Decorative, plumbing (non-potable water), air ventilation, or DIY projects |

| Maintenance | Regularly inspect for cracks or leaks, reapply sealant as needed |

| Cost | Varies based on wood type and tools; generally cost-effective compared to metal pipes |

| Time Required | 2-4 hours for a single section, longer for complex or longer pipes |

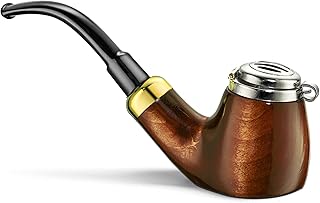

Explore related products

What You'll Learn

Selecting suitable wood type for durability and ease of shaping

Choosing the right wood for a long pipe is a balance between durability and workability. Hardwoods like oak or maple offer exceptional strength and resistance to wear, but their density can make them challenging to shape without specialized tools. Softwoods such as pine or cedar are easier to carve and drill, yet they may lack the longevity required for a functional pipe, especially if exposed to moisture or frequent use. The ideal candidate strikes a middle ground, combining moderate hardness with ease of manipulation.

Consider the grain pattern and moisture content of the wood, as these factors directly impact both shaping and durability. Straight-grained woods like ash or hickory are less prone to splitting during drilling or carving, making them excellent choices for beginners. Avoid woods with irregular grain or high resin content, as they can clog tools and complicate the shaping process. Air-dried or kiln-dried wood with a moisture content below 12% is preferable, as it minimizes warping and cracking once the pipe is in use.

For those prioritizing ease of shaping, basswood or butternut are standout options. Basswood’s fine, even texture allows for smooth cuts and detailed work, while butternut’s softness makes it forgiving for hand tools. However, neither is as durable as hardwoods, so they’re best suited for decorative or lightly used pipes. If durability is non-negotiable, teak or black walnut offer superior resistance to decay and wear, though their hardness demands sharp, high-quality tools and patience during shaping.

A practical approach is to test small samples of different woods before committing to a full-scale project. Experiment with drilling, sanding, and bending techniques to gauge how each wood responds. For instance, try creating a short pipe segment from cherry and another from mahogany to compare their workability and finish. This hands-on evaluation will reveal which wood aligns best with your skill level and the pipe’s intended use.

Finally, consider the finish and maintenance requirements of the wood. Dense, naturally oily woods like cocobolo or ebony require minimal sealing but may be expensive and difficult to source. Lighter woods like birch or poplar benefit from multiple coats of a waterproof sealant to enhance durability. Regardless of the choice, regular maintenance—such as reapplying oil or wax—will extend the pipe’s lifespan and preserve its appearance. Selecting the right wood is not just about the present task but also about ensuring the pipe remains functional and attractive for years to come.

Wood Mulch Decomposition Timeline: Factors Affecting Breakdown and Nutrient Release

You may want to see also

Explore related products

Measuring and marking wood to ensure precise pipe dimensions

Precision in measurement is the cornerstone of crafting a long wooden pipe that not only looks professional but functions flawlessly. Even a millimeter off can disrupt alignment, impede airflow, or compromise structural integrity. Begin by determining the desired internal diameter (ID) and external diameter (OD) of your pipe, factoring in wall thickness for strength and material removal during hollowing. For example, a 2-inch ID with a 1/4-inch wall thickness would require a starting blank with a 2.5-inch diameter. Use calipers for accuracy, as they provide measurements to the nearest hundredth of an inch, ensuring your dimensions are spot-on.

Once dimensions are finalized, marking the wood becomes a meticulous art. Secure the wood in a vise or clamp to prevent shifting, which can introduce errors. Use a sharp pencil and a straightedge to draw precise lines along the length and circumference of the blank. For circular markings, a compass or a makeshift guide (like a string with a pencil tied to it) can help maintain consistency. When marking the centerline for drilling, double-check alignment by measuring from opposite edges to ensure symmetry. A single misaligned mark can lead to uneven hollowing or a crooked pipe, so take your time and verify each line before proceeding.

The process of marking also involves planning for material removal and tool paths. If using a lathe, mark the areas where the tool rest will travel to avoid cutting too deep or leaving uneven surfaces. For hand-hollowing methods, like auger bits or Forstner drills, mark incremental depths to avoid over-drilling. For instance, if hollowing a 24-inch pipe, mark every 6 inches to create controlled sections, reducing the risk of splitting the wood. This staged approach not only ensures precision but also allows for adjustments if the wood begins to warp or crack under stress.

Finally, consider the wood’s natural characteristics when measuring and marking. Grain direction, knots, and moisture content can affect both the ease of cutting and the final dimensions. Always measure and mark with the grain direction in mind, as cutting across the grain can lead to splintering or uneven surfaces. If working with green wood, account for shrinkage during drying by adding a slight margin to your measurements. For example, a 10% increase in diameter can compensate for drying, ensuring the final pipe retains its intended dimensions. By integrating these specifics into your marking process, you’ll achieve a wooden pipe that’s not just long, but also precise and durable.

Mastering Smoke Time: How Long Do Wood Chips Last?

You may want to see also

Explore related products

Drilling and hollowing techniques for creating the pipe interior

Creating a long wooden pipe requires precision in drilling and hollowing to ensure a smooth, functional interior. The first step is selecting the right tools: a high-speed drill with a long, thin bit (such as a Forstner or spade bit) is ideal for initial boreholes. For larger pipes, a hole saw can expedite the process, but it’s crucial to match the bit diameter to the desired pipe interior size. Always secure the wood in a vise or clamp to prevent slipping, as the force required for drilling can be substantial. Start drilling slowly to maintain control and reduce the risk of splintering the wood grain.

Once the initial hole is drilled, hollowing the interior to the desired thickness becomes the next challenge. A common technique is using a reamer or an auger bit to gradually widen the hole. For more intricate or curved pipes, a hollow auger or a specialized pipe-making tool like a calabash scraper can be employed. Hand tools such as files or rasps are useful for refining the interior, but they require patience and precision to avoid uneven walls. Electric tools like a Dremel with a cylindrical burr attachment can speed up this process, but caution must be taken to avoid overheating the wood, which can cause cracking or discoloration.

The choice of wood significantly impacts the drilling and hollowing process. Hardwoods like maple or oak are durable but require sharper tools and more force to penetrate. Softer woods like pine or cedar are easier to work with but may splinter more easily if not handled carefully. Regardless of the wood type, always drill with the grain to minimize resistance and achieve a cleaner finish. Applying a small amount of lubricant, such as beeswax or drilling oil, can reduce friction and prolong tool life, especially when working with denser materials.

Safety is paramount when hollowing a wooden pipe. Always wear safety goggles and a dust mask, as drilling generates fine wood particles that can irritate the eyes and lungs. Ensure proper ventilation in your workspace to avoid inhaling dust. When using power tools, maintain a firm grip and avoid loose clothing or jewelry that could get caught in the machinery. For longer pipes, consider working in sections to manage the length and maintain control, rather than attempting to drill the entire length in one pass.

Finally, finishing the interior is as important as the drilling process. Sanding the interior walls with progressively finer grits (starting from 120 to 400 grit) ensures a smooth surface that won’t impede airflow. A flexible sanding tool or a long, thin sanding stick can reach deep into the pipe. Applying a food-safe sealant or natural oil, such as tung oil, can protect the wood and enhance its appearance without compromising functionality. Test the pipe for airflow and make any necessary adjustments before final assembly, ensuring a seamless and enjoyable end product.

Durability of Wood Frame Homes in Coastal Florida's Harsh Climate

You may want to see also

Explore related products

Sanding and smoothing wood to achieve a seamless finish

Wood, with its natural grain and texture, is a beautiful material, but achieving a seamless finish on a long wooden pipe requires meticulous sanding. The process begins with understanding the grain direction, as sanding against it can lead to scratches and an uneven surface. Always sand with the grain, starting with a coarse grit (80-120) to remove imperfections and rough spots. This initial step is crucial for leveling the surface and preparing it for finer grits. Use a sanding block or wrap sandpaper around a flat, sturdy object to maintain even pressure and avoid rounding over edges unintentionally.

As you progress, gradually increase the grit size (150-220, then 320-400) to refine the surface. Each grit should remove the scratches left by the previous one, bringing the wood closer to a smooth finish. For long pipes, consider using a power sander for larger areas, but switch to hand sanding for curved or intricate sections to maintain control. Pay special attention to joints and transitions, as these areas often require extra care to blend seamlessly. A well-sanded surface should feel uniformly smooth to the touch, with no visible scratches or rough patches.

One often-overlooked aspect of sanding is dust management. Wood dust can clog sandpaper and compromise the finish, so regularly clean the surface with a tack cloth or a damp rag. Additionally, wearing a dust mask is essential to protect your lungs during this process. For a truly seamless finish, finish with an ultra-fine grit (600-800) or even a sanding sponge, which conforms to the wood’s contours. This final step ensures the wood is ready for staining, sealing, or polishing, enhancing its natural beauty without imperfections.

The art of sanding lies in patience and attention to detail. Rushing through grits or skipping steps will result in a subpar finish. For example, if you notice a persistent rough spot, resist the urge to apply more pressure; instead, revert to a slightly coarser grit and work the area systematically. Similarly, when sanding curved surfaces, use flexible sandpaper or a sanding sponge to maintain contact with the wood’s shape. The goal is not just smoothness but consistency across the entire pipe, ensuring a professional-quality result.

Finally, consider the environment in which you’re sanding. Humidity can affect wood, causing it to expand or contract, so work in a controlled, dry space. After sanding, inspect the pipe under different lighting angles to catch any missed spots or imperfections. A seamless finish is not just about touch—it’s about visual perfection. With the right tools, technique, and mindset, sanding transforms a rough wooden pipe into a polished masterpiece, ready to impress both in function and form.

Hardwood vs. Softwood: Which Furniture Material Offers Greater Durability?

You may want to see also

Explore related products

Sealing and finishing methods to protect the wooden pipe

Wooden pipes, while aesthetically pleasing and functional, are inherently vulnerable to moisture, temperature fluctuations, and wear. Sealing and finishing are not optional steps—they are critical to preserving the pipe’s integrity and longevity. Without proper protection, wood can warp, crack, or rot, rendering your creation unusable. The goal is to create a barrier that repels water, resists abrasion, and enhances the wood’s natural beauty. This requires a strategic combination of sealing and finishing techniques tailored to the pipe’s intended use and environment.

Step 1: Choose the Right Sealant

For internal surfaces of the pipe, food-safe sealants like tung oil or boiled linseed oil are ideal, especially if the pipe will carry liquids. Apply 2–3 thin coats, allowing each to dry fully (typically 24 hours) before sanding lightly with 220-grit sandpaper. For external surfaces, marine-grade epoxy or polyurethane provides superior moisture resistance. Epoxy, in particular, penetrates the wood grain, hardening it against impact and water. Mix epoxy in small batches, following the manufacturer’s ratio (e.g., 1:1 or 2:1), and apply with a brush or cloth, ensuring even coverage.

Cautions and Considerations

Avoid oil-based finishes if the pipe will be exposed to high temperatures, as they can degrade or smoke. Similarly, water-based sealants may raise the wood grain, requiring additional sanding. Always test your chosen sealant on a scrap piece of wood to ensure compatibility with the species and grain pattern. Work in a well-ventilated area, especially when using epoxy or polyurethane, as fumes can be hazardous. Wear gloves to prevent skin irritation.

Finishing for Durability and Aesthetics

After sealing, apply a topcoat finish to enhance durability and appearance. Polyurethane is a popular choice for its hardness and UV resistance, but it can yellow over time. For a more natural look, consider shellac or wax, though these offer less protection against moisture. Apply finishes in thin, even coats, sanding lightly between layers with 320-grit sandpaper. For a matte finish, add a flattening agent to the final coat. Allow the pipe to cure for at least 72 hours before use, as incomplete curing can lead to tackiness or damage.

Maintenance Tips for Longevity

Even with proper sealing and finishing, wooden pipes require periodic maintenance. Reapply oil-based sealants annually, especially in humid environments. Inspect the pipe regularly for signs of wear, such as cracks or peeling finish, and address issues promptly. Store the pipe in a dry, temperature-controlled space to minimize stress on the wood. With care, a well-sealed and finished wooden pipe can last for decades, combining functionality with timeless craftsmanship.

How Long Was Grey Lost in the Woods: Unraveling the Mystery

You may want to see also

Frequently asked questions

Hardwoods like oak, maple, or walnut are ideal due to their durability and resistance to splitting. Avoid softwoods like pine, as they may not hold up well over time.

Sand the interior of the pipe thoroughly to create a smooth surface, then apply a food-safe sealant or beeswax to seal any gaps. Test for leaks by submerging the pipe in water and checking for bubbles.

Essential tools include a drill with a hole saw or Forstner bit, sandpaper, a lathe (optional for shaping), a saw for cutting the wood to length, and clamps for stability during assembly.

Use wooden dowels or threaded rods with epoxy for a secure joint. Ensure the ends are smooth and evenly cut for a tight fit, and sand the connection points after assembly for a seamless finish.