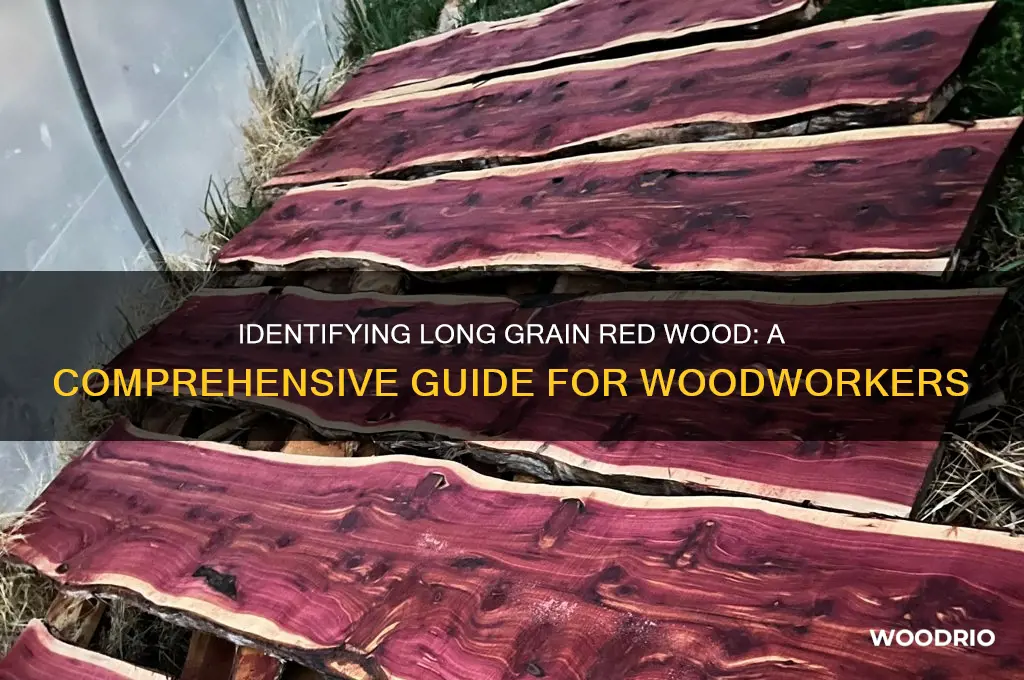

Identifying long grain red wood requires a keen eye for detail and an understanding of its distinctive characteristics. This type of wood is prized for its rich, reddish-brown hue and straight, uniform grain patterns that run parallel to the wood’s length. To spot it, look for a fine, even texture with minimal knots or imperfections, which enhances its smooth appearance. Long grain red wood often exhibits a subtle luster when polished, further highlighting its natural beauty. Additionally, its durability and resistance to warping make it a popular choice for furniture, flooring, and decorative elements. By examining these visual and tactile qualities, one can confidently distinguish long grain red wood from other varieties.

Explore related products

$19.95

What You'll Learn

- Examine Grain Pattern: Look for parallel, elongated lines running lengthwise, characteristic of long grain

- Check Color Consistency: Ensure uniform reddish-brown hue without unnatural variations or patches

- Assess Texture: Feel for smooth, fine texture along the grain, typical of long grain wood

- Measure Density: Test weight; long grain red wood is denser and heavier than short grain

- Inspect Knots: Minimal knots and defects indicate higher quality long grain wood

Examine Grain Pattern: Look for parallel, elongated lines running lengthwise, characteristic of long grain

The grain pattern is the fingerprint of wood, revealing its growth history and structural properties. In long grain red wood, this pattern manifests as parallel, elongated lines that run lengthwise along the surface. These lines are not merely decorative; they are a testament to the wood’s strength and stability, making them a critical identifier for craftsmen and enthusiasts alike. When examining a piece of wood, start by observing the directionality of these lines. Unlike cross-grain or end-grain patterns, long grain lines are consistent and uninterrupted, creating a visually cohesive flow that mirrors the tree’s natural growth.

To effectively examine the grain pattern, ensure the wood is well-lit and free from dust or debris that could obscure details. Use a magnifying glass if necessary to inspect finer lines, especially in denser red wood varieties. Run your hand along the surface to feel the texture of the grain; long grain wood typically feels smoother in the direction of the lines and slightly rougher against them. This tactile approach complements visual inspection, providing a more comprehensive understanding of the wood’s structure. For beginners, practice on samples of known long grain red wood to train your eye and touch.

One practical tip is to compare the grain pattern to natural phenomena for easier recognition. Think of the lines as rivers flowing in the same direction, each one distinct yet part of a larger system. This analogy helps in distinguishing long grain from other patterns, such as the swirling, chaotic appearance of burl wood or the short, segmented lines of end grain. Additionally, note the spacing between the lines; in long grain red wood, this spacing is generally consistent, reflecting uniform growth conditions. Irregular spacing may indicate stress or environmental changes during the tree’s life, which could affect the wood’s quality.

While examining the grain pattern is essential, it’s equally important to consider the wood’s color and texture in conjunction with the grain. Long grain red wood often exhibits a rich, reddish-brown hue that deepens with age, but the grain lines themselves may appear slightly lighter or darker depending on the species. For instance, Sapele and Mahogany, both prized red woods, have distinct grain patterns that can help differentiate between them. Sapele’s grain is finer and more uniform, while Mahogany’s is coarser with occasional ribbon-like stripes. Understanding these nuances enhances your ability to identify long grain red wood accurately.

Finally, remember that the grain pattern is not just a visual identifier but also an indicator of the wood’s working properties. Long grain red wood is prized for its ease of cutting and shaping along the grain, making it ideal for furniture, flooring, and musical instruments. However, cutting across the grain can lead to splintering or uneven surfaces, so always align your tools with the grain direction. By mastering the art of examining grain patterns, you not only ensure the authenticity of the wood but also optimize its use in your projects, combining craftsmanship with respect for the material’s natural beauty.

Surviving The Long Dark: Essential Wood Gathering Tips and Strategies

You may want to see also

Explore related products

Check Color Consistency: Ensure uniform reddish-brown hue without unnatural variations or patches

The eye is naturally drawn to anomalies, and in the case of long grain red wood, color consistency is a critical marker of quality. A uniform reddish-brown hue signals maturity and even growth conditions, while unnatural variations or patches can indicate defects like mineral staining, fungal discoloration, or uneven exposure to light. To assess this, examine the wood under natural daylight, rotating it to catch different angles. Use a magnifying glass if necessary to spot subtle inconsistencies that might escape the naked eye.

Instructively, begin by dividing the wood surface into quadrants for systematic inspection. Compare each section side-by-side, noting any deviations in tone or saturation. For larger pieces, step back to view the wood from a distance, as some variations may only become apparent when seen as a whole. If working with multiple planks, lay them adjacent to ensure consistency across the batch. A useful tip: photograph the wood and review the image on a screen, as digital representation can highlight discrepancies not immediately visible in person.

Persuasively, consider the long-term implications of overlooking color inconsistencies. While minor variations might seem trivial, they can detract from the wood’s aesthetic appeal, particularly in high-end furniture or flooring. Unnatural patches may also indicate underlying structural issues, such as rot or insect damage, which compromise durability. Investing time in this step not only ensures visual harmony but also safeguards against potential defects that could manifest later.

Comparatively, contrast long grain red wood with species like cherry or mahogany, which are prized for their ability to darken uniformly over time. Red wood, however, is more prone to uneven coloration due to its denser grain structure and higher tannin content. Unlike softer woods, where variations might be sanded out, red wood’s inconsistencies are often permanent, making initial inspection crucial. This distinction underscores why color consistency is a non-negotiable criterion for this specific wood type.

Descriptively, imagine the ideal piece of long grain red wood: a rich, velvety hue that flows seamlessly from one end to the other, like a sunset captured in timber. The absence of blotches or streaks creates a sense of depth and warmth, enhancing its natural beauty. Achieving this uniformity requires not just keen observation but also an understanding of the wood’s origins. For instance, wood sourced from older, slower-growing trees tends to exhibit more consistent coloration than younger, rapidly grown specimens.

Conclusively, mastering the art of checking color consistency is both a science and a skill. It demands attention to detail, the right tools, and a nuanced understanding of the wood’s characteristics. By ensuring a uniform reddish-brown hue without unnatural variations, you not only preserve the wood’s aesthetic value but also its structural integrity. This step, though time-consuming, is indispensable for anyone working with long grain red wood, whether for craftsmanship or appraisal.

Durability of Wood Section Paths: Lifespan and Maintenance Tips

You may want to see also

Explore related products

$4.98

Assess Texture: Feel for smooth, fine texture along the grain, typical of long grain wood

The texture of wood is a tactile fingerprint, revealing its character and quality. When identifying long grain red wood, your fingers become as important as your eyes. Run your hand along the surface, following the direction of the grain. You’re searching for a smoothness that feels almost polished, a fine texture that distinguishes long grain wood from its coarser counterparts. This isn’t about rough edges or splintery surfaces; it’s about a refined, linear feel that speaks to the wood’s tight grain structure.

To assess texture effectively, start by cleaning the wood surface of any dust or debris. Use your dominant hand to glide along the grain, applying gentle pressure to detect subtle variations. Compare the texture to other wood samples if possible—long grain red wood typically lacks the pronounced ridges or uneven patterns found in open-grained varieties. For beginners, practice on known samples to train your sense of touch. Over time, you’ll develop an intuitive understanding of what “smooth and fine” truly means in this context.

A practical tip: use the back of your hand for a broader assessment, then switch to your fingertips for detailed scrutiny. The back of your hand is more sensitive to overall smoothness, while your fingertips can detect finer inconsistencies. If the wood feels uniformly smooth and almost silky along the grain, you’re likely dealing with long grain red wood. However, be cautious—some treated or sanded woods can mimic this texture, so always cross-reference with other identification methods.

The science behind this texture lies in the wood’s growth pattern. Long grain red wood, often sourced from slower-growing trees, develops tighter, more compact grain lines. This density translates to a smoother surface, even when unfinished. In contrast, faster-growing woods tend to have looser grains, resulting in a rougher texture. By focusing on texture, you’re not just feeling the wood—you’re interpreting its history and structure.

Finally, remember that texture assessment is a skill honed through repetition. Keep a reference sample of confirmed long grain red wood for comparison. Over time, you’ll be able to identify it with confidence, even in dim lighting or without visual cues. This tactile approach isn’t just a step in identification—it’s a way to connect with the material, understanding its essence beyond what meets the eye.

Understanding the Timeframe for Waterlogging Wood: A Comprehensive Guide

You may want to see also

Explore related products

$1.77

Measure Density: Test weight; long grain red wood is denser and heavier than short grain

One of the most tangible ways to distinguish long grain red wood from its short grain counterpart is by assessing its density through a simple weight test. Long grain red wood, due to its tighter grain structure and more compact cellular arrangement, is inherently denser and heavier. This characteristic is not just a theoretical distinction but a practical one that can be verified with a hands-on approach. By comparing the weight of two similarly sized pieces—one long grain and one short grain—you can immediately notice the difference. This method is particularly useful in situations where visual inspection alone may not suffice, such as when dealing with unfinished or unlabeled wood pieces.

To perform this test effectively, start by selecting two wood samples of identical dimensions, ensuring they are free from moisture or other contaminants that could skew the results. A piece measuring approximately 12 inches in length, 4 inches in width, and 1 inch in thickness is ideal for this purpose. Weigh each sample using a precise digital scale capable of measuring in grams or ounces. Long grain red wood will typically register a higher weight due to its denser composition. For instance, a long grain sample might weigh around 500 grams, while a short grain piece of the same size could weigh closer to 450 grams. This 10% weight difference is a reliable indicator of the wood’s grain orientation.

While the weight test is straightforward, it’s important to account for variables that could affect accuracy. For example, wood moisture content can significantly impact weight, with wetter wood naturally weighing more. To ensure a fair comparison, allow both samples to acclimate to the same environmental conditions for at least 48 hours before testing. Additionally, avoid using wood that has been treated with finishes or preservatives, as these can add weight and obscure the natural density differences. If you’re working with larger pieces, consider taking multiple measurements from different sections to account for any inconsistencies in density.

The practical applications of this density test extend beyond mere identification. Carpenters and woodworkers often prefer long grain red wood for structural projects due to its superior strength and durability, which are direct results of its higher density. By mastering this weight-based method, you can make informed decisions about material selection, ensuring that your projects benefit from the unique properties of long grain wood. Whether you’re crafting furniture, building frameworks, or restoring antique pieces, this simple yet effective technique empowers you to choose the right wood for the job with confidence.

Drying Time for Pressure Treated Wood: What to Expect

You may want to see also

Explore related products

Inspect Knots: Minimal knots and defects indicate higher quality long grain wood

Knots, those circular patterns where branches once grew, are natural in wood but can compromise its integrity. In long grain red wood, their presence and size matter significantly. A single 1-inch knot in a 10-foot board might be acceptable, but multiple knots or those larger than 2 inches often signal weaker structural areas. When inspecting, run your hand along the surface to feel for raised or uneven spots, as visual inspection alone can miss subtle defects.

Analyzing knot distribution reveals more than just aesthetics. Tight, sound knots (those firmly embedded with no cracks) are less concerning than loose or cracked ones, which can allow moisture to penetrate and cause warping. For example, a board with three tight knots spaced evenly might still be suitable for furniture, while a board with one large, cracked knot near the edge should be avoided. Always prioritize pieces with minimal, well-contained knots for projects requiring durability.

Persuasively, consider the cost-benefit of choosing higher-quality wood. While knot-heavy boards may be cheaper upfront, they often require more labor to work around defects and may fail prematurely in load-bearing applications. Investing in wood with fewer knots reduces long-term maintenance and replacement costs, especially in outdoor projects like decking or fencing, where exposure to elements accelerates wear.

Comparatively, examine how different wood species handle knots. Red oak, for instance, tends to have larger, more pronounced knots than maple, making it less ideal for fine cabinetry. Long grain red wood, such as meranti or cedar, often exhibits smaller, tighter knots when sourced from mature trees. Always compare samples from the same species to ensure you’re selecting the best quality within that category.

Practically, here’s a step-by-step inspection process: First, hold the wood at eye level and scan for visible knots, noting their size and spacing. Second, tap around each knot with a mallet; a hollow sound indicates a loose knot. Third, check the end grain for knot density—a crowded pattern suggests weaker wood. Finally, reject any piece with knots near edges or corners, as these areas are prone to splitting under stress. Following these steps ensures you select long grain red wood that combines beauty with reliability.

Efficient Kiln Drying: Optimal Time for Perfectly Seasoned Wood

You may want to see also

Frequently asked questions

Long grain red wood typically features a straight, uniform grain pattern with a deep reddish-brown color. It often has a fine to medium texture and may exhibit natural luster. Look for consistent grain lines running parallel to the wood’s length.

Long grain red wood is specifically identified by its pronounced, straight grain structure, whereas other red woods like mahogany or cherry may have more interlocked or wavy grains. Additionally, long grain red wood tends to be harder and denser compared to some other red wood varieties.

A magnifying glass or wood identification guide can help you examine the grain pattern and color more closely. Testing the wood’s hardness with a scratch test or checking its weight (long grain red wood is often heavier) can also aid in identification.