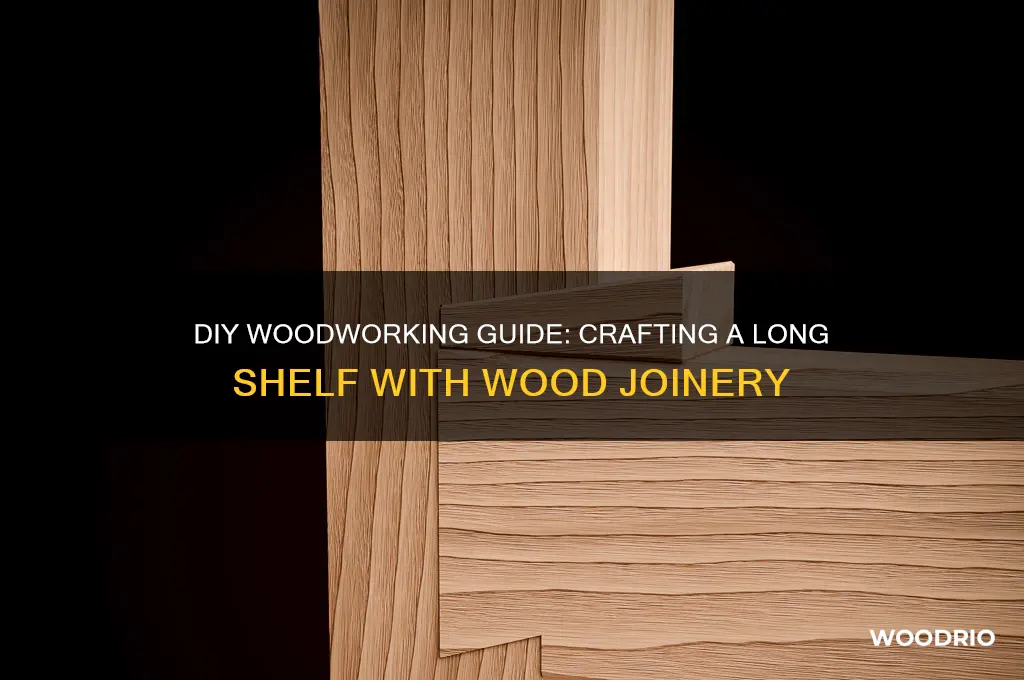

Creating a long shelf out of wood joinery is a rewarding woodworking project that combines functionality with craftsmanship. By using traditional joinery techniques, such as dovetail, mortise and tenon, or box joints, you can ensure a sturdy and durable structure that avoids the need for visible hardware. The process involves carefully selecting the right type of wood, planning the dimensions, and meticulously cutting and fitting the joints to achieve a seamless and professional finish. Whether for a home office, living room, or garage, a long wooden shelf not only provides ample storage but also adds a touch of elegance and warmth to any space. With the right tools, patience, and attention to detail, even beginners can master the art of wood joinery to create a piece that stands the test of time.

| Characteristics | Values |

|---|---|

| Materials Needed | Wood boards (length and width as desired), wood glue, screws, brackets, sandpaper, wood finish (optional) |

| Tools Required | Tape measure, saw, drill, screwdriver, clamp, sander |

| Wood Type | Pine, oak, maple, or plywood (based on preference and budget) |

| Joint Types | Butt joint, miter joint, dovetail joint, or biscuit joint |

| Shelf Length | Customizable (common lengths: 6-10 feet) |

| Shelf Depth | 10-16 inches (standard) |

| Weight Capacity | Depends on wood type, joint strength, and bracket support (typically 20-50 lbs per foot) |

| Finishing Options | Stain, paint, varnish, or sealant |

| Assembly Time | 2-4 hours (excluding drying time for glue/finish) |

| Skill Level | Intermediate (basic woodworking skills required) |

| Cost Estimate | $50-$200 (depending on materials and tools) |

| Maintenance | Regular dusting, reapplication of finish every 1-2 years |

| Safety Tips | Wear safety goggles, gloves, and a dust mask; work in a well-ventilated area |

| Additional Tips | Pre-drill holes to prevent wood splitting; use a level to ensure shelf is straight |

Explore related products

What You'll Learn

Choosing the Right Wood Type

The wood you choose for your long shelf will determine its strength, durability, and aesthetic appeal. Hardwoods like oak, maple, or walnut offer exceptional strength and a refined look, making them ideal for shelves supporting heavy items or those in high-visibility areas. Softer woods like pine or cedar are more affordable and easier to work with, but may dent or scratch more easily under heavy use. Consider the shelf's intended purpose and location when weighing these trade-offs.

For a truly unique and eye-catching shelf, explore the world of exotic hardwoods. Species like teak, mahogany, or zebrawood boast stunning grain patterns and rich colors, adding a touch of luxury to any space. However, these woods often come with a higher price tag and may require specialized tools and techniques for proper joining. If sustainability is a priority, look for certified sustainable sources or consider reclaimed wood, which offers a rustic charm and reduces environmental impact.

When working with wood, always prioritize safety. Wear protective gear, including safety glasses, ear protection, and a dust mask, especially when cutting or sanding. Ensure your workspace is well-ventilated, and follow proper handling procedures for adhesives and finishes. If you're new to woodworking, start with a simpler project to hone your skills before tackling a long shelf.

The joining method you choose will also influence your wood selection. For example, dovetail or mortise-and-tenon joints require hardwoods with tight grain patterns to ensure a strong, durable connection. Softer woods may be more suitable for simpler butt joints or bracket-supported shelves. Consider the complexity of the joinery and your skill level when making your wood choice.

Ultimately, the right wood type for your long shelf depends on a balance of factors: strength, appearance, cost, and workability. By carefully considering these elements and selecting a wood that aligns with your project's unique requirements, you'll create a shelf that's not only functional but also a beautiful addition to your space. Remember, the wood is the foundation of your project, so choose wisely and enjoy the process of bringing your vision to life.

How Long Does Wood Take to Rot from Water Exposure?

You may want to see also

Explore related products

Measuring and Cutting Wood Pieces

Accurate measurement is the cornerstone of any woodworking project, especially when crafting a long shelf. A single miscalculation can lead to uneven joints, unstable structures, or wasted materials. Begin by determining the desired length of your shelf, factoring in overhang if you plan to mount it on brackets. Use a tape measure to mark the dimensions on your wood, ensuring the lines are straight and clear. For precision, double-check measurements against your project plan before making any cuts. Remember, the adage “measure twice, cut once” is not just a saying—it’s a safeguard against costly mistakes.

Once measurements are finalized, the cutting process demands both skill and the right tools. A circular saw or table saw is ideal for straight, long cuts, while a miter saw can handle precise angles if your design includes them. Secure the wood firmly to prevent slipping, which can lead to inaccurate cuts or injuries. When cutting, maintain a steady hand and follow the marked lines closely. For thicker or harder wood, reduce the blade’s speed to avoid burning or splintering the material. Always prioritize safety by wearing protective gear, including goggles and gloves, and ensuring your workspace is free of obstructions.

While cutting, consider the grain direction of the wood, as it affects both aesthetics and structural integrity. For a long shelf, align the grain parallel to the length of the board to minimize warping over time. If joining multiple pieces, ensure the grain patterns match for a cohesive look. Additionally, account for the width of your joints when measuring and cutting. For example, if using a butt joint with a 1/8-inch gap for glue, adjust your cuts accordingly to maintain the overall shelf length.

After cutting, inspect each piece for accuracy and smoothness. Use a sanding block or orbital sander to refine edges, removing any splinters or rough spots that could affect assembly. If your shelf requires notches or holes for mounting hardware, mark and cut these features now, ensuring they align with your wall studs or bracket positions. A well-measured and cleanly cut foundation sets the stage for a sturdy, professional-looking shelf that will stand the test of time.

Rubber vs. Wood Mulch: Which Lasts Longer in Your Garden?

You may want to see also

Explore related products

Joining Techniques: Dovetail vs. Butt Joints

Dovetail joints have long been celebrated for their strength and durability, often used in high-quality furniture like drawers and cabinets. This interlocking technique involves trapezoidal pins and tails that resist pulling apart, making it ideal for long shelves where structural integrity is paramount. Unlike butt joints, which simply abut two pieces of wood, dovetails distribute weight more evenly, reducing the risk of separation over time. However, they require precision and skill, often necessitating specialized tools like a dovetail saw and chisels. For a long shelf, dovetail joints at the corners or seams can ensure longevity, especially if the shelf will bear heavy loads or experience frequent use.

Butt joints, in contrast, are the simplest and most straightforward method for joining wood pieces. They involve aligning the ends of two boards and securing them with screws, nails, or adhesive. While butt joints are quick to execute and require minimal tools, they lack the inherent strength of dovetail joints. To reinforce a butt joint for a long shelf, consider adding biscuits, splines, or metal brackets for added stability. This technique is best suited for lighter-duty applications or when aesthetics are less critical, as the joint can be less visually appealing without additional finishing.

When deciding between dovetail and butt joints for a long shelf, consider the intended use and your skill level. Dovetail joints are superior in strength but demand time and precision, making them a better choice for experienced woodworkers or projects requiring maximum durability. Butt joints, while weaker, are beginner-friendly and can be adequately reinforced for moderate loads. For a long shelf spanning multiple boards, combining both techniques—using dovetails at critical stress points and butt joints elsewhere—can balance strength and efficiency.

Practical tips for execution include using a dovetail jig for consistent results if you’re not confident in hand-cutting. For butt joints, pre-drilling holes prevents wood splitting, and applying a quality wood glue enhances bonding. Regardless of the method, ensure the wood is properly aligned and clamped during assembly to avoid gaps or misalignment. Finishing touches, such as sanding and staining, can also improve the joint’s appearance and longevity.

In conclusion, the choice between dovetail and butt joints hinges on your project’s demands and your woodworking expertise. Dovetails offer unmatched strength but require meticulous craftsmanship, while butt joints provide simplicity with the option for reinforcement. By understanding these trade-offs, you can select the best technique to create a long shelf that is both functional and durable.

Wooden Form Construction Timeline: Factors Affecting Build Duration

You may want to see also

Explore related products

Sanding and Finishing the Shelf

Sanding is the unsung hero of woodworking, transforming raw, splintered edges into smooth, inviting surfaces. Begin with a medium-grit sandpaper, like 120-grit, to remove imperfections and rough patches left by cutting or joining. Work in the direction of the wood grain to avoid scratches, and use long, even strokes. For tight corners or intricate details, switch to a sanding block or folded paper to maintain control. Once the surface feels uniformly smooth, progress to a finer grit—220 or higher—to refine the texture and prepare the wood for finishing. This step is crucial; skipping it can leave your shelf feeling unfinished, both literally and figuratively.

Finishing isn’t just about aesthetics—it’s about protection. Wood is porous and vulnerable to moisture, stains, and wear. Choose a finish based on the shelf’s purpose and location. For a natural look, opt for a clear polyurethane or Danish oil, applying thin coats with a brush or lint-free cloth. If you prefer color, consider stain, but test it on a scrap piece first to ensure the shade matches your vision. Allow each coat to dry completely, lightly sanding with 320-grit paper between applications to ensure adhesion. Two to three coats are typically sufficient, but high-traffic areas may benefit from an extra layer. Remember, patience is key—rushing the drying process can lead to uneven results.

A common mistake is overloading the brush or cloth with finish, which can cause drips, bubbles, or a tacky surface. Apply sparingly, working in the direction of the grain, and wipe off excess immediately. For added durability, especially on long shelves that span walls, consider a topcoat of wax or paste polish. This not only enhances the sheen but also provides an extra barrier against scratches and spills. If you’re aiming for a matte or satin finish, choose products labeled accordingly, as gloss levels vary widely.

Finally, don’t underestimate the power of a well-finished edge. End grains absorb finish differently than face grains, often appearing darker or more pronounced. To mitigate this, apply a pre-stain wood conditioner or seal the ends with a thin coat of finish before staining. For a seamless look, wrap the finish around the edges and underside of the shelf, ensuring every surface is protected. Once complete, step back and admire your work—a long, beautifully finished shelf that’s as functional as it is striking.

Microwaving Wet Wood Bowls: Quick Drying Tips and Safety Guide

You may want to see also

Explore related products

Mounting the Shelf Securely on the Wall

Securing a long wooden shelf to the wall requires more than just screws and hope. The key lies in understanding your wall's composition. Drywall alone cannot support significant weight, so locate the studs—the vertical framing members behind the wall. Use a stud finder or tap the wall, listening for a solid sound versus a hollow one. Mark the stud positions with a pencil, ensuring your shelf brackets align with at least two studs for maximum stability. If studs are scarce, consider using heavy-duty drywall anchors rated for the shelf's weight, though this is a less ideal solution for long, heavy shelves.

Once you’ve identified the stud locations, measure and mark the bracket positions on both the wall and the shelf. Precision is critical here; even a slight misalignment can compromise the shelf’s stability. Use a level to ensure the brackets are perfectly horizontal. Pre-drill pilot holes into the studs to prevent wood splitting, especially if using hardwood. For added strength, opt for metal brackets with a weight capacity exceeding your shelf’s load. Attach the brackets to the wall first, then position the shelf onto them, securing it with screws driven through pre-drilled holes in the shelf.

While mounting, consider the shelf’s length and potential sag. For shelves over 4 feet, incorporate additional support by installing a hidden bracket or corbel midway along the span. Alternatively, use a French cleat system, which involves a beveled strip mounted to the wall and a matching strip on the shelf, creating a locking mechanism. This method distributes weight more evenly and provides a sleek, floating appearance. Ensure the cleat is also anchored into studs for maximum security.

Finally, test the shelf’s stability before loading it with items. Apply gentle pressure to check for wobbling or shifting. If the shelf feels secure, gradually add weight, starting with lighter objects and progressing to heavier ones. Avoid overloading the shelf beyond its capacity, as this can lead to failure, regardless of how well it’s mounted. Regularly inspect the brackets and wall anchors for signs of strain or wear, tightening screws as needed to maintain long-term stability.

Treated Wood Under Deck: Lifespan, Durability, and Maintenance Tips

You may want to see also

Frequently asked questions

Essential tools include a circular saw or table saw, drill, screwdriver, clamps, measuring tape, square, sandpaper, and a wood glue applicator.

Use strong joinery techniques like dovetail, mortise and tenon, or pocket hole joints, and reinforce with wood glue and screws for added stability.

Hardwoods like oak, maple, or birch are ideal for durability, but plywood or pine can also work if properly supported and finished.

Add supports like brackets, corbels, or additional wall studs underneath the shelf, and use thicker wood or a stronger joint design.

Apply a coat of polyurethane, varnish, or paint to protect the wood from moisture, scratches, and wear, ensuring longevity and aesthetic appeal.