Creating a long shelf out of wood is a practical and rewarding DIY project that can enhance any space, whether it’s for storage, display, or decoration. To begin, you’ll need to select the right type of wood, such as pine or oak, depending on your budget and desired durability. Measure and mark the wood to your desired length, ensuring it fits the intended space. Next, cut the wood using a saw, sand the edges for a smooth finish, and decide on the mounting method—whether it’s brackets, floating supports, or wall-mounted anchors. Finally, stain or paint the shelf to match your decor, and securely attach it to the wall, ensuring it’s level and sturdy. With careful planning and attention to detail, you can craft a functional and stylish long shelf tailored to your needs.

| Characteristics | Values |

|---|---|

| Materials Needed | Wood boards (length & thickness as desired), wood screws, wood glue, brackets (optional), sandpaper, stain or paint (optional), measuring tape, saw, drill, screwdriver, level |

| Wood Type | Pine, oak, plywood, MDF (Medium-Density Fiberboard) are common choices. Consider cost, durability, and aesthetics. |

| Shelf Length | Determine desired length based on space and needs. Common lengths: 6ft, 8ft, 10ft. |

| Shelf Depth | 10-12 inches is standard for most shelves. Deeper shelves (14-18 inches) are suitable for larger items. |

| Shelf Thickness | 3/4 inch to 1.5 inches depending on wood type and shelf length. Thicker wood provides more strength. |

| Bracket Spacing | Brackets should be spaced every 16-24 inches for adequate support. |

| Assembly Method | 1. Wall-Mounted: Secure brackets to wall studs, then attach shelf to brackets. 2. Floating: Use hidden brackets or cleats for a seamless look. 3. Freestanding: Build a frame with legs for a standalone shelf. |

| Finishing | Sand shelves smooth, apply stain or paint if desired, and seal with a protective coat. |

| Weight Capacity | Depends on wood type, thickness, bracket strength, and wall mounting. Consult manufacturer specifications for brackets and follow proper installation guidelines. |

| Tools Required | Measuring tape, saw (circular saw or hand saw), drill, screwdriver, level, sandpaper, paintbrush or roller (if finishing). |

| Skill Level | Beginner to intermediate depending on chosen assembly method and complexity. |

| Safety Considerations | Wear safety glasses and ear protection when using power tools. Ensure proper ventilation when sanding and finishing. Follow all tool instructions carefully. |

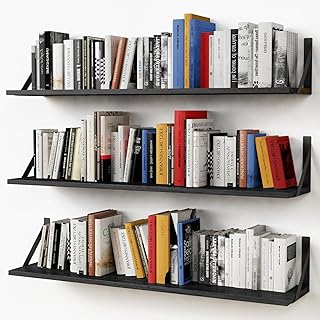

Explore related products

$21.56 $24.99

What You'll Learn

Choosing the Right Wood Type

Wood selection is the backbone of any shelving project, especially for long spans where structural integrity and aesthetics must align. Hardwoods like oak, maple, or walnut offer durability and a premium look but come with higher costs and weight considerations. Softwoods such as pine or fir are budget-friendly and easier to work with, though they may dent or warp under heavy loads. For a balance, plywood or MDF provides stability and affordability, though it lacks the natural grain appeal of solid wood. The choice hinges on your project’s demands: weight capacity, visual style, and budget.

Consider the shelf’s purpose before committing to a wood type. Books or heavy decor require denser hardwoods or reinforced softwoods to prevent sagging. Light items like plants or trinkets allow for more flexibility in material choice. Humidity-prone areas, such as bathrooms or kitchens, demand moisture-resistant options like teak or treated plywood to avoid warping. Always factor in the wood’s grain direction: aligning it vertically enhances strength, while horizontal placement may prioritize appearance.

The finish and texture of the wood also play a critical role in the shelf’s final look. Rough-sawn lumber offers a rustic charm but requires sanding for smooth edges. Pre-sanded or planed wood saves time but may lack character. Staining or painting can unify mismatched wood types or highlight natural grain patterns. For a minimalist design, birch plywood with a clear coat showcases its layered aesthetic. Conversely, reclaimed wood adds warmth and history but may require extra prep work to ensure stability.

Cost and availability are practical constraints that shape your wood choice. Local lumberyards often stock common softwoods and plywood at lower prices, while exotic hardwoods may require specialty suppliers and higher budgets. Dimensional lumber (e.g., 1x12s or 2x4s) is readily available in standard lengths, making it ideal for long shelves. For custom lengths or thicknesses, ordering from a mill may be necessary but adds time and expense. Always measure twice and plan cuts efficiently to minimize waste and maximize material use.

Finally, sustainability should guide your wood selection in an eco-conscious era. FSC-certified wood ensures responsible forestry practices, while reclaimed or recycled wood reduces environmental impact. Bamboo, though technically a grass, offers a renewable alternative with strength comparable to hardwoods. Avoid woods treated with harmful chemicals, especially for indoor projects. By prioritizing sustainability, you create a shelf that’s not only functional but also ethically sound.

Wood Pellets vs. Propane: Comparing Fuel Longevity for Grilling

You may want to see also

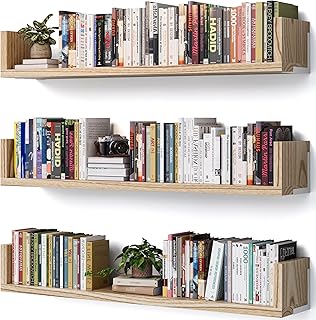

Explore related products

Measuring and Cutting Wood Pieces

Precision in measurement is the cornerstone of any woodworking project, especially when crafting a long shelf. A single miscalculation can lead to uneven weight distribution, compromising both aesthetics and functionality. Begin by determining the desired length of your shelf, typically ranging from 4 to 8 feet for standard applications. Use a tape measure to mark the exact dimensions on your chosen wood plank, ensuring the lines are straight and clear. For added accuracy, double-check measurements by referencing from both ends of the board, minimizing the risk of errors that compound over longer spans.

Once measurements are finalized, the cutting process demands both skill and the right tools. A circular saw or table saw is ideal for straight, clean cuts, particularly for hardwoods like oak or maple. For softer woods such as pine, a jigsaw or hand saw may suffice, though precision is harder to maintain. Always align the blade with your marked line, securing the wood firmly to prevent slipping. Wear safety gear, including goggles and gloves, and maintain a steady hand to avoid splintering or jagged edges. Remember, cutting too much wood is irreversible, so err on the side of caution and trim incrementally if necessary.

While cutting, consider the shelf’s structural integrity. Longer shelves benefit from additional support, such as brackets or hidden braces, which require precise notches or grooves in the wood. Use a router or chisel to create these features, ensuring they align perfectly with your mounting hardware. For floating shelves, accuracy in cutting the mounting cleat or hidden brackets is critical, as even a millimeter of misalignment can render the shelf unstable. Practice on scrap wood to refine your technique before committing to the final piece.

Finally, post-cutting refinement is essential for a professional finish. Sand the edges to remove burrs and splinters, starting with coarse-grit sandpaper (80-120) and progressing to finer grits (220+) for smoothness. Inspect the cut ends for tear-out or unevenness, addressing any imperfections before assembly. If your design includes multiple pieces, such as a top shelf and underside support, ensure all cuts are consistent in length and angle. This attention to detail not only enhances durability but also elevates the overall appearance of your long wooden shelf.

Chris Wood and Melissa Benoist: A Timeline of Their Marriage

You may want to see also

Explore related products

Assembling the Shelf Frame

The backbone of any long wooden shelf is its frame, a critical structure that determines not only the shelf's strength but also its longevity. Assembling the frame requires precision, as even minor misalignments can lead to a wobbly or unstable final product. Begin by selecting the appropriate wood for the frame—typically a hardwood like oak or maple for durability, or pine for a more budget-friendly option. Cut the wood to the desired lengths for the sides, top, and bottom of the frame, ensuring each piece is square and true. Use a miter saw or circular saw for straight cuts, and double-check measurements before making any final cuts to avoid costly mistakes.

Once the pieces are cut, the next step is joining them securely. A popular method is the butt joint, reinforced with wood glue and screws for added strength. Pre-drill holes to prevent the wood from splitting, especially if using hardwood. For a more refined look, consider using pocket hole joinery, which hides the screws and creates a cleaner appearance. If you're aiming for a minimalist design, metal brackets can be used to connect the frame pieces, though this may compromise the shelf's overall aesthetic. Regardless of the method, ensure each joint is clamped tightly while the glue dries to maintain alignment.

While assembling, consider the shelf's intended use. A long shelf designed to hold heavy items, such as books or plants, requires additional support. Incorporate a center support beam or use thicker wood for the frame to distribute weight evenly. For added stability, attach the frame directly to a wall stud if the shelf is wall-mounted. If the shelf is freestanding, ensure the base is wide enough to prevent tipping, and consider adding adjustable feet to level the shelf on uneven floors.

One often-overlooked aspect of frame assembly is sanding. Before joining the pieces, sand each edge to ensure a smooth fit and remove any rough spots that could weaken the joint. After assembly, sand the entire frame again to prepare it for finishing. This step not only enhances the shelf's appearance but also ensures that stains or paints adhere properly. Use progressively finer grits of sandpaper, finishing with a 220-grit for a professional touch.

Finally, test the frame’s integrity before proceeding to the next steps. Stand it upright and check for any wobbling or gaps in the joints. If issues arise, disassemble the frame, reassess the joints, and reattach them with additional glue or screws as needed. A sturdy frame is the foundation of a reliable shelf, and taking the time to ensure its stability now will save you from potential headaches later. With the frame assembled and secure, you're ready to add shelving boards, apply finishes, and transform this skeletal structure into a functional and stylish long wooden shelf.

Optimal Drying Time for Wood Post-Stripping: A Comprehensive Guide

You may want to see also

Explore related products

Sanding and Finishing Techniques

Sanding is the unsung hero of woodworking, transforming rough lumber into a smooth, touchable surface. Begin with coarse-grit sandpaper (80–120 grit) to remove mill marks, splinters, and imperfections. Work progressively through medium (150–180 grit) and fine (220+ grit) grits, always sanding in the direction of the wood grain. For long shelves, use a sanding block or power sander to maintain consistency, especially across wide spans where hand-sanding can leave uneven patches. Skip this step, and your finish will highlight every flaw instead of enhancing the wood’s natural beauty.

The finish you choose isn’t just about looks—it’s about protection. Polyurethane, for instance, offers durability and water resistance, ideal for shelves in high-moisture areas like kitchens or bathrooms. Tung oil or Danish oil penetrates the wood, enhancing its grain while providing a matte, natural finish. For a modern, sleek look, consider a clear epoxy resin, though it requires precise application to avoid drips. Apply finishes in thin, even coats, allowing ample drying time between layers. A rushed finish will bubble, peel, or streak, undoing hours of careful sanding.

One overlooked detail in finishing is edge treatment. Long shelves often have exposed ends, which can absorb moisture or splinter if left untreated. Seal end grains with a wood sealer or multiple coats of your chosen finish, as these areas absorb more liquid than face grains. For a decorative touch, chamfer or round the edges before sanding—this not only looks refined but also prevents snagging on clothing or skin. Ignore the edges, and your shelf will age prematurely, regardless of how flawless the top surface appears.

Troubleshooting is part of the process. If your finish feels rough after drying, it’s likely due to dust contamination—wipe the surface with a tack cloth before each coat to prevent particles from bonding to the wood. Orange peel texture? That’s a sign of over-spraying or improper thinning of paint or stain. To fix, lightly sand the affected area with high-grit paper and reapply the finish. Always test your technique on a scrap piece of wood first—this small step saves time and materials, ensuring your long shelf looks professional from every angle.

Wood Frog Eggs Hatching Timeline: A Detailed Developmental Journey

You may want to see also

Explore related products

Mounting the Shelf Securely

A long wooden shelf, while aesthetically pleasing, demands robust mounting to ensure it can bear weight without sagging or detaching from the wall. The key lies in understanding the interplay between wall type, bracket strength, and weight distribution. Drywall, for instance, requires anchors rated for the shelf's anticipated load, while concrete or brick walls necessitate masonry bits and specialized anchors. Always err on the side of caution, choosing brackets and fasteners with a weight capacity exceeding your shelf's maximum load by at least 25%.

Consider the shelf's length and intended use when selecting mounting hardware. For spans exceeding 6 feet, incorporate additional supports beyond the traditional end brackets. Adjustable brackets allow for fine-tuning levelness during installation, while concealed brackets offer a sleek, minimalist aesthetic. Remember, the mounting system should complement the shelf's design without compromising structural integrity.

The mounting process itself demands precision and patience. Begin by locating wall studs using a stud finder, marking their positions with a pencil. If studs aren't aligned with your desired bracket placement, employ heavy-duty wall anchors rated for the shelf's weight. Pre-drill holes slightly smaller than your screw diameter to prevent wood splitting. When attaching brackets, ensure they're level both horizontally and vertically, using a spirit level as your guide.

Don't underestimate the importance of proper weight distribution. Avoid placing excessively heavy objects on the shelf's ends, as this can cause undue stress on the mounting points. Distribute weight evenly across the shelf's length, utilizing bookends or decorative items to prevent items from shifting and creating uneven pressure points.

Finally, periodically inspect your mounted shelf for signs of wear or loosening. Tighten screws as needed, and address any cracks or warping in the wood promptly. By combining careful planning, appropriate hardware selection, and meticulous installation, you can ensure your long wooden shelf remains securely mounted, providing both functionality and visual appeal for years to come.

Wooden Ships' Lifespan: Durability and Maintenance Secrets Revealed

You may want to see also

Frequently asked questions

For a long shelf, hardwoods like oak, maple, or birch are ideal due to their strength and durability. Plywood or pine can also be used for lighter applications, but ensure proper support to prevent sagging.

To prevent sagging, use thicker wood (at least 1-inch thick), add brackets or supports every 2-3 feet, or incorporate a steel rod or cable underneath the shelf for added reinforcement.

Essential tools include a circular saw or table saw for cutting, a drill for assembling, a sander for smoothing edges, a tape measure for accuracy, and a level for proper installation. Clamps are also helpful for holding pieces in place during assembly.