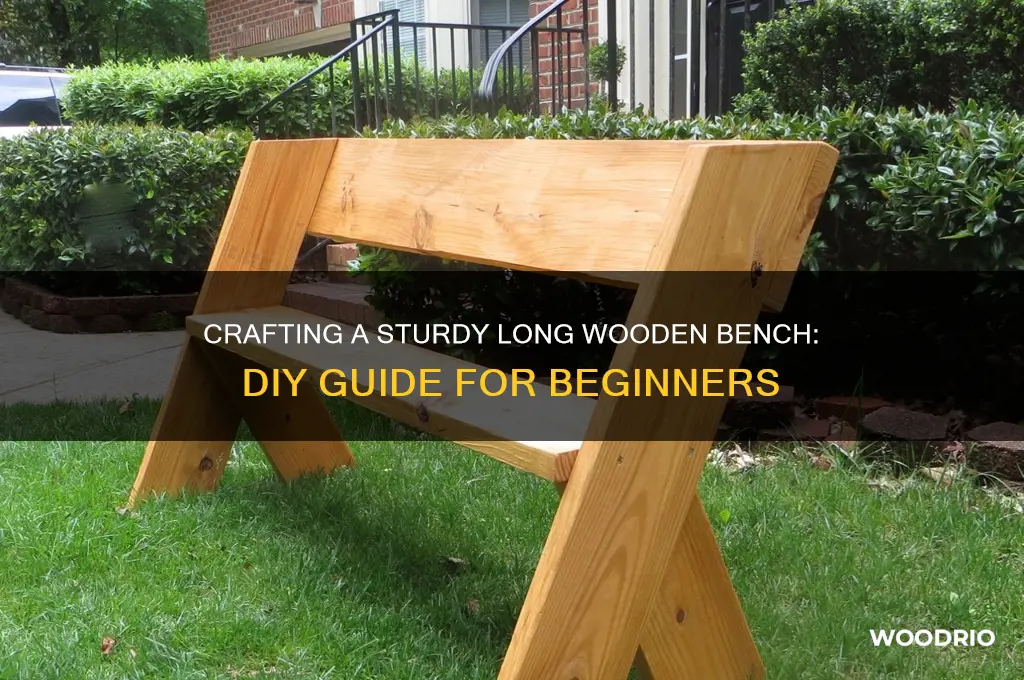

Creating a long wooden bench is a rewarding DIY project that combines functionality with craftsmanship, offering a durable and aesthetically pleasing addition to any outdoor or indoor space. To begin, selecting the right type of wood, such as cedar or teak, ensures longevity and resistance to weather conditions. The process involves measuring and cutting the wood to precise dimensions, assembling the frame using sturdy joints and screws, and sanding the surfaces for a smooth finish. Adding a protective sealant or stain enhances the wood’s natural beauty while safeguarding it from wear and tear. With careful planning, basic carpentry tools, and attention to detail, anyone can craft a long wooden bench that serves as both a practical seating solution and a handmade centerpiece.

| Characteristics | Values |

|---|---|

| Materials Needed | Wood planks (e.g., cedar, pine, or oak), wood screws, wood glue, sandpaper, stain or paint (optional), sealant |

| Tools Required | Circular saw or table saw, drill, screwdriver, measuring tape, square, clamp, sander |

| Bench Length | Typically 6–8 feet (1.8–2.4 meters), customizable |

| Bench Width | 12–18 inches (30–45 cm) for seating comfort |

| Bench Height | 18–20 inches (45–50 cm) for standard seating |

| Wood Thickness | 1.5–2 inches (3.8–5 cm) for durability |

| Design Style | Traditional, modern, rustic, or custom |

| Joinery Methods | Butt joints, miter joints, or dovetail joints (advanced) |

| Finishing Options | Sanding, staining, painting, or sealing for weather resistance |

| Assembly Time | 4–8 hours depending on skill level |

| Cost Estimate | $50–$200 depending on materials and tools |

| Difficulty Level | Intermediate (basic woodworking skills required) |

| Maintenance | Periodic sanding, resealing, or repainting for outdoor benches |

| Safety Tips | Wear safety goggles, gloves, and ear protection; work in a well-ventilated area |

| Customization | Add armrests, backrests, or decorative elements |

| Sustainability | Use reclaimed or sustainably sourced wood |

Explore related products

What You'll Learn

- Gather Materials and Tools: Essential supplies like wood, screws, saw, drill, and measuring tape

- Measure and Cut Wood: Plan dimensions, mark cuts, and use a saw for precision

- Assemble Bench Frame: Join legs and supports using screws and wood glue securely

- Attach Bench Seat: Secure planks to the frame, ensuring even spacing and alignment

- Sand and Finish: Smooth surfaces, apply stain or paint, and seal for durability

Gather Materials and Tools: Essential supplies like wood, screws, saw, drill, and measuring tape

Selecting the right wood is the cornerstone of your bench’s durability and aesthetic. Opt for hardwoods like oak, maple, or teak for outdoor benches, as they resist warping and decay. For indoor benches, softer woods like pine or cedar are cost-effective but require protective finishes. Consider reclaimed wood for a rustic look, but inspect it for cracks or rot. Measure the bench’s dimensions—a standard long bench is 6 to 8 feet—and calculate the total wood needed, including planks for the seat, legs, and supports. Always add 10% extra for cuts and mistakes.

Tools are your silent partners in this project, and their quality directly impacts efficiency and precision. A circular saw or table saw is ideal for straight cuts, while a jigsaw handles curves if your design demands them. A cordless drill with a driver bit set simplifies screw insertion, but pre-drilling holes prevents wood splitting. Measuring tape and a carpenter’s square ensure accuracy, while a clamp holds pieces steady during assembly. Sandpaper (80 to 220 grit) smooths edges, and a wood finish (polyurethane, stain, or varnish) protects the surface.

Screws and fasteners are the unsung heroes of structural integrity. Use galvanized or stainless steel screws for outdoor benches to prevent rust. For indoor benches, standard wood screws suffice. Length matters: screws should penetrate at least 1.5 inches into each piece of wood for a secure hold. Consider countersinking screws for a flush finish, and use wood glue in joints for added strength. Keep a variety of screw sizes on hand—common lengths range from 1.25 to 2.5 inches—to accommodate different wood thicknesses.

Efficiency in gathering materials hinges on planning and sourcing. Create a detailed shopping list to avoid multiple trips to the hardware store. Compare prices online versus local suppliers, and check for bulk discounts on screws or wood. If cutting wood intimidates you, many stores offer cutting services for a small fee. Borrow or rent tools if buying isn’t feasible, but ensure they’re in good condition. Finally, organize your workspace: lay out materials and tools within arm’s reach to streamline the build process.

A common pitfall is underestimating the importance of quality materials and tools. Skimping on wood or using dull blades can lead to uneven cuts or weak joints. Similarly, rushing measurements often results in misaligned pieces. Take your time, double-check dimensions, and test-fit components before securing them. Remember, the goal isn’t just to build a bench but to create a sturdy, long-lasting piece that withstands use and time. Invest in the right supplies, and the craftsmanship will follow.

Polycrylic Drying Time on Wood: A Comprehensive Guide for Beginners

You may want to see also

Explore related products

Measure and Cut Wood: Plan dimensions, mark cuts, and use a saw for precision

The foundation of any sturdy wooden bench lies in precise measurements and clean cuts. Before you even pick up a saw, dedicate time to planning your bench's dimensions. Consider the intended use: will it accommodate two people comfortably, or is it a grand statement piece for a sprawling garden? A standard bench height ranges from 18 to 20 inches, with a depth of 15 to 18 inches. Length is more flexible, but aim for at least 48 inches for a two-seater. Sketch your design, factoring in leg placement, seat slat width, and any decorative elements. This blueprint will be your roadmap for the cutting phase.

For example, a 6-foot bench might require two 6-foot 2x4s for the sides, four 18-inch 2x4s for the legs, and eight 1x4s cut to 6 feet for the seat slats.

Once your dimensions are finalized, transfer them onto your lumber with a sharp pencil and a straightedge. Accuracy is paramount; a millimeter off here can compound into a noticeable gap later. Use a carpenter's square to ensure perpendicular lines, especially when marking leg notches or seat slat placements. Consider using a marking gauge for consistent lines along the wood's length. Remember, it's easier to remove more wood later than to add back what's been cut. When in doubt, err on the side of caution and mark slightly longer than your measurement.

A helpful tip: clamp a stop block to your saw fence at the desired cut length. This ensures consistent, repeatable cuts, especially when dealing with multiple pieces of the same size.

Choosing the right saw is crucial for achieving clean, precise cuts. A circular saw is versatile and powerful, ideal for ripping long boards to width and making crosscuts. For finer work, like notching legs or creating decorative profiles, a jigsaw or handsaw offers more control. Always prioritize safety: wear eye protection, secure your workpiece firmly, and let the saw do the work without forcing it. Remember, a sharp blade is a safer blade, as it reduces the risk of kickback and produces cleaner cuts.

After each cut, inspect the piece for squareness and accuracy. Use a speed square to check right angles, and a tape measure to verify lengths. If adjustments are needed, make them incrementally, removing small amounts of material until the piece fits perfectly. This iterative process ensures a professional-looking final product. Remember, the time invested in meticulous measuring and cutting will be rewarded with a bench that's not only beautiful but also structurally sound.

Polyurethane Wood Rust-Oleum Drying Time: A Comprehensive Guide

You may want to see also

Explore related products

Assemble Bench Frame: Join legs and supports using screws and wood glue securely

The bench frame is the backbone of your project, and its strength depends on the precision of your joinery. Begin by laying out the legs and supports on a flat surface, ensuring they align perfectly with your design plans. Use a square to verify that each joint is at a 90-degree angle, as even a slight misalignment can compromise stability. Pre-drilling pilot holes is essential to prevent wood splitting, especially when working with hardwoods like oak or maple. For a 2x4 frame, a 1/8-inch drill bit works well, followed by 2.5-inch screws for robust connections.

Wood glue acts as the invisible bond that reinforces screw joints, distributing stress evenly across the connection. Apply a generous bead of waterproof wood glue to each mating surface, ensuring it covers the entire contact area but doesn’t ooze excessively. Use clamps to hold the pieces together while the glue sets, typically for 24 hours. If your bench will be exposed to outdoor elements, opt for a glue rated for exterior use, such as Titebond III, which resists moisture and temperature fluctuations.

While screws provide immediate strength, their effectiveness diminishes if over-tightened or misaligned. To avoid this, tighten screws incrementally, alternating between opposite sides of the joint to maintain even pressure. For added durability, consider using galvanized or stainless steel screws, which resist rust and corrosion. If your bench is longer than 6 feet, incorporate additional supports or braces to prevent sagging under weight.

A common mistake is neglecting to reinforce corner joints, which bear the most stress. To address this, add corner brackets or metal plates for extra stability. These can be concealed within the frame or left exposed for an industrial aesthetic. Test the frame’s rigidity by applying pressure to the legs and supports before attaching the seat. If any wobble is detected, recheck screw tightness and glue application, ensuring no gaps exist between joints.

In conclusion, assembling a bench frame requires attention to detail and a combination of mechanical and adhesive techniques. By pre-drilling, using quality screws and glue, and reinforcing critical points, you’ll create a sturdy foundation capable of supporting years of use. This step, though labor-intensive, is pivotal in ensuring your long wooden bench is both functional and safe.

Ideal Wooden Fence Post Length for Corner Posts: A Comprehensive Guide

You may want to see also

Explore related products

Attach Bench Seat: Secure planks to the frame, ensuring even spacing and alignment

Attaching the bench seat is a pivotal step that bridges functionality and aesthetics. The planks must be secured firmly to the frame, ensuring they can withstand daily use while maintaining a polished appearance. Even spacing and precise alignment are non-negotiable—misaligned planks can detract from the bench’s visual appeal and compromise structural integrity. Begin by laying the planks atop the frame, using a tape measure to confirm equal gaps between each board, typically ¼ to ½ inch for drainage and expansion. Mark these positions lightly with a pencil to guide screw placement.

The method of attachment depends on the bench’s design and intended use. For outdoor benches, stainless steel or galvanized screws are essential to prevent rust. Pre-drilling pilot holes is critical, especially in hardwoods like teak or oak, to avoid splitting. Drive screws at a slight downward angle through the planks and into the frame’s supports, ensuring each plank is flush with its neighbors. A clamp can hold planks in place temporarily, guaranteeing alignment while fastening. Avoid over-tightening screws, as this can warp the wood or strip threads.

A comparative analysis reveals that using pocket hole joinery or brackets can enhance durability but adds complexity. Pocket holes, drilled at a 15-degree angle, hide screws for a cleaner look, ideal for indoor benches. Brackets, while bulkier, distribute weight more evenly, making them suitable for heavy-use public spaces. However, both methods require additional tools and time, so weigh the trade-offs based on your skill level and the bench’s purpose.

Finally, a descriptive tip: envision the bench in its final setting. If it’s a garden bench, consider how sunlight and rain will affect the wood. For indoor benches, think about how the grain patterns of the planks align to create a cohesive design. After securing the planks, sand any rough edges and apply a finish—polyurethane for indoor benches or a weather-resistant sealant for outdoor use. This not only protects the wood but also highlights its natural beauty, ensuring your bench is both sturdy and stunning.

Durability of Wood Bowls: Lifespan, Care, and Longevity Tips

You may want to see also

Explore related products

$49.99 $57.44

Sand and Finish: Smooth surfaces, apply stain or paint, and seal for durability

The final touch in crafting a long wooden bench lies in the sanding and finishing process, which transforms raw wood into a refined, durable piece. Begin with sanding, a step that not only smooths the surface but also prepares the wood to absorb finishes evenly. Start with a coarse-grit sandpaper, such as 80-grit, to remove any rough spots, splinters, or imperfections. Gradually move to finer grits—120, 180, and finally 220-grit—to achieve a silky-smooth texture. Always sand in the direction of the wood grain to avoid scratches and ensure a uniform finish.

Once sanding is complete, the wood is ready for its finish. The choice between stain and paint depends on your aesthetic preference and the bench’s intended use. Stain enhances the natural beauty of the wood, allowing its grain and texture to shine through, while paint offers a more uniform, customizable look. For stains, apply a thin, even coat with a brush or cloth, wiping away excess to prevent pooling. Allow it to dry according to the manufacturer’s instructions, typically 2–4 hours, before applying a second coat if desired. Paint, on the other hand, requires priming for better adhesion, especially on dense woods like oak or maple. Use a high-quality exterior paint for outdoor benches, applying two thin coats to ensure coverage and longevity.

Sealing is the critical final step that protects your bench from moisture, UV rays, and wear. For stained benches, a clear wood sealer or polyurethane provides a protective barrier while preserving the wood’s natural appearance. Apply it with a brush or sprayer in thin, even layers, allowing each coat to dry fully before adding the next. Painted benches benefit from a topcoat of exterior-grade varnish or polycrylic, which adds durability without altering the color. Regardless of the finish, ensure proper ventilation during application and allow ample curing time—typically 24–48 hours—before using the bench.

A practical tip for achieving a professional finish is to test your chosen stain, paint, or sealer on a scrap piece of the same wood species. This allows you to gauge the final color and ensure compatibility with your bench. Additionally, consider the bench’s environment: outdoor benches require finishes rated for exterior use, while indoor benches can use less heavy-duty options. By investing time in sanding, finishing, and sealing, you not only enhance the bench’s appearance but also extend its lifespan, ensuring it remains a functional and beautiful piece for years to come.

Durability of Permanent Wood Foundations: Lifespan and Maintenance Tips

You may want to see also

Frequently asked questions

Hardwoods like oak, maple, or teak are ideal for durability and strength, but cedar or pine are good budget-friendly options if treated for outdoor use.

Essential tools include a circular saw or table saw, drill, screwdriver, measuring tape, clamps, sandpaper, and a square for accurate cuts and assembly.

Use sturdy joinery techniques like mortise and tenon or screws with wood glue, ensure legs are evenly spaced, and check for levelness during assembly with a spirit level.

Apply a weather-resistant sealant, exterior varnish, or teak oil to protect against moisture, UV rays, and wear. Reapply annually for outdoor benches.

Shape the seat slightly concave, round the edges of the slats, and ensure proper spacing between slats for airflow and comfort.