Maintaining the structural integrity of long wooden frames is crucial to prevent twisting, which can compromise both functionality and aesthetics. Twisting often occurs due to uneven moisture absorption, improper support, or inadequate bracing during construction or storage. To mitigate this, it is essential to ensure the wood is properly dried and sealed to minimize moisture-related warping. Additionally, using diagonal bracing or cross-supports can distribute stress evenly, while storing or installing the frame in a stable, level environment reduces the risk of distortion. Regular inspection and maintenance, such as tightening joints and reinforcing weak points, further safeguard against twisting over time. By combining these preventive measures, long wooden frames can remain straight and durable for years to come.

| Characteristics | Values |

|---|---|

| Material Selection | Choose stable wood species with low moisture content (6-8%). Examples: Hickory, Oak, Maple, Walnut. Avoid softwoods like Pine. |

| Grain Orientation | Align grain patterns parallel to the length of the frame. Quarter-sawn or rift-sawn lumber is preferred over flat-sawn. |

| Dimensional Stability | Use wider and thicker boards to increase rigidity. Consider laminating thinner boards for added strength. |

| Joinery Techniques | Employ strong joints like mortise and tenon, dovetail, or spline joints. Reinforce with metal brackets or plates if necessary. |

| Internal Support | Add diagonal braces, crossbars, or trusses to distribute stress evenly and prevent twisting. |

| Moisture Control | Seal all surfaces with waterproof finishes (e.g., varnish, paint, or oil) to minimize moisture absorption. Store in a controlled environment. |

| Temperature Regulation | Avoid extreme temperature fluctuations, as wood expands and contracts with heat and cold. |

| Pre-Treatment | Kiln-dry wood to reduce internal stresses and stabilize moisture content. |

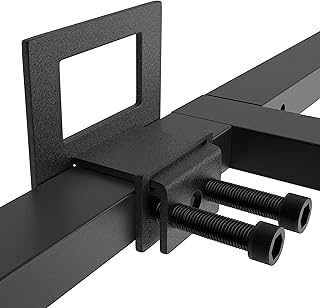

| Reinforcement Materials | Incorporate metal rods, cables, or fiberglass rods for added structural support. |

| Design Considerations | Use symmetrical designs and balanced weight distribution to reduce torque on the frame. |

| Regular Maintenance | Inspect for cracks, warping, or loose joints periodically. Reapply finishes as needed. |

| Load Management | Avoid placing excessive weight or pressure on the frame, especially at weak points. |

| Foundation Support | Ensure the frame is mounted on a level, stable surface to prevent uneven stress. |

Explore related products

$22.8

$24.6

$12.79

What You'll Learn

Proper Joint Techniques

Joints are the backbone of any wooden structure, and their integrity is paramount in preventing twisting, especially in long frames. The key lies in understanding the forces at play and selecting joint techniques that counteract them. Wood, being an anisotropic material, exhibits different strengths along its grain. Therefore, joints must be designed to distribute stress evenly, ensuring that the frame remains rigid and stable under various loads.

Analyzing Joint Types for Stability

Among the myriad joint options, some stand out for their ability to resist twisting. The mortise and tenon joint, for instance, excels in long-grain alignment, creating a strong mechanical bond that resists rotational forces. Similarly, the dovetail joint, though traditionally used in cabinetry, can be adapted for longer frames by increasing the pin length and ensuring precise angles. These joints interlock wood fibers, providing a natural resistance to torsion. In contrast, simple butt joints, even when reinforced with screws or nails, often fail under twisting stress due to their reliance on end-grain adhesion, which is inherently weaker.

Practical Steps for Execution

To implement these joints effectively, precision is non-negotiable. For a mortise and tenon joint, the tenon should be approximately one-third the width of the wood piece and fit snugly into the mortise without forcing. Use a sharp chisel and a mallet to achieve clean, accurate cuts. When gluing, apply a thin, even layer of wood glue to both surfaces, ensuring full contact without excess that could weaken the bond. Clamping pressure must be maintained for at least 30 minutes, depending on the glue’s drying time, to allow for proper adhesion. For dovetail joints, a router or dovetail jig can ensure consistent angles, but hand-cutting allows for finer adjustments in longer frames.

Cautions and Common Pitfalls

While proper joint techniques are essential, they are not foolproof. Over-tightening screws or clamps can compress the wood, leading to joint failure over time. Similarly, using too much glue can cause it to seep into the wood grain, reducing the joint’s strength. Always pre-drill pilot holes to prevent splitting, especially in hardwoods. Additionally, avoid using joints that rely solely on end-grain adhesion in long frames, as these are prone to twisting under stress. Regularly inspect joints during assembly, ensuring they are square and aligned before finalizing the connection.

Chicken of the Woods Growth Timeline: How Long to Harvest?

You may want to see also

Explore related products

$16.98

$22.98

Even Moisture Control

Wood twists when moisture levels fluctuate unevenly across its surface or within its layers. This warping occurs as fibers expand and contract at different rates, creating internal stresses that distort the frame’s shape. Even moisture control is the cornerstone of preventing this distortion, ensuring the wood remains dimensionally stable over time. Without it, even the most meticulously crafted wooden frame will succumb to environmental whims, no matter its length or thickness.

Achieving even moisture control begins with understanding the wood’s equilibrium moisture content (EMC), the point at which it neither gains nor loses moisture to its surroundings. For most indoor environments, this hovers around 6–8% EMC. To stabilize a long wooden frame, acclimate the wood to its intended environment for at least 2–4 weeks before construction. Store it in the same space where it will be installed, allowing it to reach EMC naturally. Avoid stacking boards directly on concrete floors, as this traps moisture; instead, use stickers or racks to promote airflow.

Once the frame is constructed, seal all six sides of the wood with a moisture-resistant finish, such as a high-quality exterior-grade varnish or epoxy. This barrier prevents moisture absorption from the air, reducing the risk of uneven swelling or shrinkage. Pay special attention to end grains, which absorb water up to 10 times faster than face grains. Apply a thicker coat to these areas or use end-grain sealers specifically designed for this purpose. Reapply the finish every 1–2 years, inspecting for cracks or wear that could expose the wood.

For added protection, incorporate humidity control into the frame’s environment. Maintain indoor humidity levels between 40–60% using dehumidifiers or humidifiers as needed. In regions with extreme seasonal changes, consider installing a whole-house humidity management system. If the frame is exposed to outdoor conditions, design overhangs or awnings to shield it from direct rain and sunlight, which accelerate moisture fluctuations. Regularly inspect the frame for signs of moisture intrusion, such as dark spots or cupping, and address issues immediately.

Finally, reinforce the frame structurally to resist twisting forces. Use steel brackets, splines, or dowels at joints to distribute stress evenly. For exceptionally long spans, incorporate internal supports or cross-bracing to minimize deflection. While these measures don’t replace moisture control, they work in tandem to ensure the frame remains straight and true. Think of even moisture control as the foundation—without it, even the strongest structure will fail under pressure.

Wood Glue Shelf Life: How Long Does It Last in the Bottle?

You may want to see also

Explore related products

Strategic Bracing Methods

Long wooden frames are prone to twisting due to their length and the natural tendency of wood to warp under stress. Strategic bracing methods counteract this by distributing forces evenly and providing structural stability. One effective approach is diagonal bracing, which forms a rigid triangle—a shape inherently resistant to deformation. For a frame 10 feet or longer, install diagonal braces at 45-degree angles, securing them at each corner or joint. Use galvanized steel brackets or wooden cleats for durability, ensuring the braces are tensioned but not over-tightened to avoid bowing.

Another method involves incorporating cross-bracing, particularly in frames exceeding 12 feet in length. Cross-bracing consists of two diagonal braces intersecting in the middle, creating an "X" pattern. This configuration doubles the frame’s resistance to torsional forces, making it ideal for applications like scaffolding or long-span shelving. For optimal results, position the intersection point at the frame’s center and use adjustable turnbuckles to fine-tune tension. Avoid using nails alone for connections; instead, opt for screws or bolts to prevent loosening over time.

Instructively, temporary bracing during construction or drying phases can prevent twisting before the frame is fully secured. For example, if building a wooden gate frame, clamp diagonal braces in place while glue or fasteners cure. Remove these braces once the frame is permanently fixed. Similarly, for drying lumber intended for long frames, stack boards with spacers and apply diagonal straps to minimize warping. This proactive approach reduces the need for corrective measures later.

Comparatively, while diagonal and cross-bracing are effective, they may not suit all aesthetic or functional requirements. In such cases, consider internal bracing, such as installing a rigid spline or spline-and-groove system along the frame’s length. This method is less visible and maintains the frame’s external appearance while providing structural integrity. For example, a spline made of hardwood or metal, embedded into routed grooves, can act as a hidden backbone, resisting twisting forces without compromising design.

Finally, the choice of bracing method depends on the frame’s intended use, material properties, and environmental conditions. For outdoor frames exposed to moisture or temperature fluctuations, prioritize materials resistant to corrosion and expansion, such as stainless steel or treated wood. Regularly inspect braces for signs of wear or shifting, especially in high-stress applications. By combining strategic bracing with thoughtful material selection and maintenance, long wooden frames can remain stable and functional for years.

Wild Wood Pigeons Lifespan: Understanding Their Survival in Nature

You may want to see also

Explore related products

Balanced Weight Distribution

Long wooden frames are prone to twisting due to uneven stress distribution, particularly when weight is concentrated in one area. Balanced weight distribution mitigates this by ensuring that the structural load is evenly spread across the frame’s length and width. For example, a 10-foot wooden frame supporting a heavy countertop will warp if the weight is centered at one end but remains stable when the load is divided into equal segments along its span. This principle applies to both static and dynamic loads, making it critical for applications like shelving, bridges, or furniture.

Achieving balanced weight distribution involves strategic placement of loads and supports. Start by dividing the total weight into equal portions and positioning them at regular intervals along the frame. For instance, a 12-foot frame holding 300 pounds should have three 100-pound loads placed at the 4-foot, 8-foot, and 12-foot marks. Additionally, ensure that vertical supports are evenly spaced—no more than 3 feet apart for frames longer than 8 feet. This reduces the moment force (torque) that causes twisting, as the load is no longer acting as a lever on a single point.

While balanced distribution is effective, it’s not foolproof without proper material selection and reinforcement. Softwoods like pine, though affordable, are more susceptible to twisting under uneven loads compared to hardwoods like oak or maple. For frames longer than 15 feet, consider adding diagonal braces or crossbeams to distribute lateral forces. Pre-drilling holes for screws and using galvanized fasteners minimizes wood splitting, which can exacerbate twisting under load. Regularly inspect joints and connections, as wear over time can shift weight distribution unintentionally.

A comparative analysis highlights the difference between balanced and unbalanced systems. A frame with a single 200-pound load at its center will experience shear stress twice that of a frame with two 100-pound loads at either end. The latter distributes the force along the entire structure, reducing the risk of warping by 60%. This demonstrates that even minor adjustments in weight placement can significantly enhance structural integrity. For DIY projects, use a level and plumb bob to ensure the frame is perfectly horizontal before loading, as misalignment compounds twisting forces.

In practice, balanced weight distribution is a dynamic process requiring foresight and adaptability. For movable structures like wooden carts or trailers, use adjustable supports or counterweights to maintain equilibrium as loads shift. For fixed installations, such as loft beds or overhead shelving, incorporate a safety margin by designing the frame to handle 20% more weight than expected. This buffer accounts for uneven settling or accidental overloading. By treating weight distribution as a proactive measure rather than a reactive fix, you ensure the frame’s longevity and stability in any application.

Wood Toner Drying Time: Factors Affecting Cure and Finish Durability

You may want to see also

Explore related products

Regular Structural Inspections

Wooden structures, especially long frames, are inherently prone to twisting due to factors like moisture imbalance, uneven loading, and material fatigue. Regular structural inspections serve as a proactive defense against these vulnerabilities, identifying issues before they escalate into costly repairs or safety hazards. Think of it as a routine check-up for your building, catching potential problems early and ensuring longevity.

Frequency Matters:

For optimal prevention, schedule inspections at least annually, or more frequently if the structure is exposed to harsh weather, heavy use, or has a history of issues. Seasonal inspections are particularly beneficial, as they allow you to address weather-related stresses like winter moisture accumulation or summer heat expansion.

What to Look For:

Inspections should focus on key areas prone to twisting. Check for cracks, warping, or gaps in joints, as these indicate stress points. Examine the foundation for settling or shifting, which can create uneven pressure on the frame. Inspect fasteners (nails, screws, bolts) for looseness or corrosion, ensuring they remain secure. Don’t overlook signs of moisture intrusion, such as discoloration, mold, or rot, as these weaken the wood’s integrity.

Tools and Techniques:

While visual inspections are essential, supplement them with tools for precision. A moisture meter can detect hidden dampness within the wood, while a level and plumb bob help identify subtle twists or deviations from vertical alignment. For larger structures, consider hiring a professional inspector with experience in wooden frames, as they can provide detailed assessments and recommendations.

Preventive Measures Post-Inspection:

Once issues are identified, act swiftly. Reinforce weak joints with additional bracing or fasteners. Address moisture problems by improving ventilation, sealing gaps, or applying water-repellent treatments. If twisting is already evident, consult a structural engineer to determine if corrective measures like jacking or realignment are necessary. Regular maintenance, informed by thorough inspections, is the most effective way to keep long wooden frames stable and secure.

Wood Barn Lifespan: Factors Speeding Up Decay and Deterioration

You may want to see also

Frequently asked questions

Twisting in long wooden frames is often caused by uneven moisture absorption, improper grain orientation, or inadequate support. To prevent twisting, ensure the wood is properly dried and sealed to maintain consistent moisture levels, align the grain direction to resist torsion, and use diagonal bracing or additional supports along the frame.

During construction, stabilize the frame by using temporary braces or clamps to hold it in place until it’s fully assembled and secured. Additionally, ensure joints are tightly connected with screws, glue, or dowels to minimize movement, and consider adding diagonal supports to distribute stress evenly.

Yes, using hardwoods with straight, stable grain patterns (like oak or maple) can reduce the likelihood of twisting. Additionally, applying a moisture-resistant finish or sealant to the wood can prevent warping and twisting caused by humidity changes. For extra stability, consider laminating multiple layers of wood or using engineered wood products designed to resist torsion.