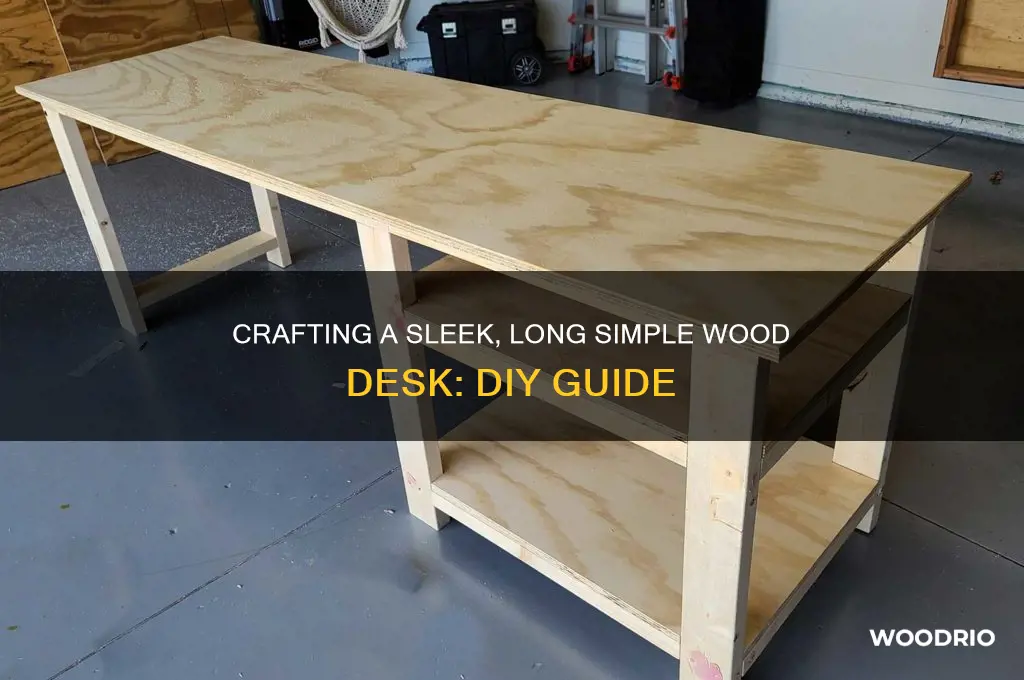

Creating a long, simple wood desk is a rewarding DIY project that combines functionality with a minimalist aesthetic. To begin, gather essential materials such as solid wood planks (e.g., pine or oak) for the desktop and legs, screws, wood glue, and basic tools like a saw, drill, and sander. Start by measuring and cutting the wood to your desired dimensions, ensuring the desktop is long enough for your needs and the legs are sturdy and level. Assemble the frame using screws and wood glue for added stability, then attach the tabletop securely. Sand all surfaces to achieve a smooth finish, and consider applying a stain or sealant to protect the wood and enhance its natural beauty. With careful planning and attention to detail, you can craft a durable, stylish desk tailored to your space and preferences.

| Characteristics | Values |

|---|---|

| Desk Length | 6-8 feet (adjustable based on need) |

| Desk Width | 24-30 inches (standard depth) |

| Desk Height | 28-30 inches (ergonomic standard) |

| Wood Type | Pine, oak, or plywood (cost-effective and durable) |

| Thickness | 1-1.5 inches (for tabletop and shelves) |

| Legs | 4x4 or 2x4 wooden posts, metal legs, or pre-made desk legs |

| Leg Height | 28-30 inches (to achieve desired desk height) |

| Joinery Methods | Pocket holes, screws, wood glue, or brackets |

| Finish | Stain, paint, or sealant (polyurethane for protection) |

| Tools Required | Table saw, drill, screwdriver, sander, measuring tape, clamp |

| Assembly Time | 4-8 hours (depending on skill level) |

| Cost Estimate | $50-$200 (depending on wood type and finish) |

| Design Features | Minimalist, straight edges, optional shelves or drawers |

| Weight Capacity | 100-200 lbs (depending on construction and materials) |

| Customization | Adjustable length, added storage, cable management |

| Difficulty Level | Beginner to intermediate DIY |

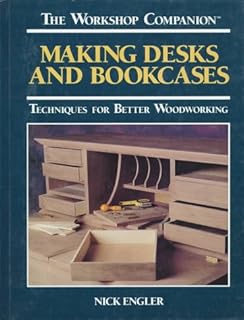

Explore related products

What You'll Learn

- Gather Materials and Tools: Essential supplies like wood, screws, saw, drill, and measuring tape

- Measure and Cut Wood: Plan desk dimensions, mark wood, and cut pieces accurately

- Assemble Desk Frame: Join legs and supports using screws and brackets for stability

- Attach Tabletop: Secure the wooden tabletop to the frame with screws or glue

- Sand and Finish: Smooth edges, sand surfaces, and apply stain or sealant for durability

Gather Materials and Tools: Essential supplies like wood, screws, saw, drill, and measuring tape

Selecting the right wood is the cornerstone of your desk project. For a long, simple desk, opt for hardwoods like oak, maple, or birch for durability, or pine for a budget-friendly option. Consider the desk’s length—a 6-foot desk typically requires two 8-foot 2x4s for the frame and a ¾-inch plywood sheet for the tabletop. Ensure the wood is straight and free of knots to avoid structural issues. If sustainability is a priority, look for FSC-certified or reclaimed wood.

Tools are your project’s backbone, and precision matters. A circular saw or table saw is ideal for cutting wood to size, while a drill with a screwdriver bit ensures screws are driven cleanly. For accuracy, a measuring tape and carpenter’s square are indispensable—measure twice, cut once. Sandpaper (120-grit for smoothing, 220-grit for finishing) will refine edges and surfaces. If you lack a saw, hardware stores often offer cutting services for a small fee, saving time and ensuring straight cuts.

Fasteners like screws are critical for assembly. Use 2.5-inch wood screws for joining the frame and 1.25-inch screws for attaching the tabletop. Galvanized or stainless steel screws resist rust, especially if the desk will be in a humid environment. Pre-drilling holes prevents wood splitting—a small step that avoids costly mistakes. Keep a variety of screw lengths on hand to accommodate different joints, and consider using wood glue for added stability in key connections.

Organization streamlines the build process. Lay out all materials and tools before starting to avoid mid-project interruptions. Label cut pieces with their intended location (e.g., “left leg,” “top rail”) to prevent confusion. A workbench or clear floor space is essential for assembly, and a clamp set will hold pieces steady while drilling or screwing. If working solo, a sawhorse or temporary support can act as an extra pair of hands during assembly.

Finally, safety is non-negotiable. Wear safety glasses and ear protection when cutting or drilling. Keep a first-aid kit nearby, and ensure proper ventilation if using stains or sealants. For power tools, unplug them when not in use, and never force a cut—let the tool do the work. A well-prepared workspace not only speeds up the project but also reduces the risk of accidents, ensuring your desk-building experience is as smooth as the finished product.

Treated Wood Lifespan: Factors Affecting Rot and Decay Resistance

You may want to see also

Explore related products

Measure and Cut Wood: Plan desk dimensions, mark wood, and cut pieces accurately

The foundation of any woodworking project lies in precise measurements and cuts. For a long, simple wood desk, this step is critical to ensure stability, functionality, and aesthetic appeal. Begin by determining the desk’s dimensions based on your space and needs. A standard desk height is 29–30 inches, with a depth of 20–30 inches and a length tailored to your room—common choices range from 48 to 72 inches. Sketch these measurements on paper, noting the number of pieces required: legs, tabletop, supports, and any additional features like drawers or shelves. Accuracy here prevents costly mistakes and ensures all components fit seamlessly.

Once dimensions are finalized, transfer them onto your wood. Use a straightedge and pencil to mark lines clearly, double-checking measurements with a tape measure or ruler. For straight cuts, a circular saw or table saw is ideal, while a jigsaw works for curved edges. Always prioritize safety: wear goggles, secure the wood firmly, and follow the saw’s cutting line precisely. If cutting large sheets, such as plywood for the tabletop, enlist a helper to prevent warping or splintering. Sand the edges immediately after cutting to smooth rough surfaces and ensure a professional finish.

Consider the wood’s grain direction when marking and cutting. For structural pieces like legs, align the grain vertically to enhance strength. For the tabletop, orient the grain parallel to the longer side to minimize movement and cracking over time. If using multiple boards for the tabletop, ensure the grain patterns match for visual consistency. This attention to detail not only improves durability but also elevates the desk’s overall appearance.

Mistakes in cutting can derail a project, so take preventive measures. Dry-fit all pieces before final assembly to verify alignment and make adjustments as needed. Label each piece with its intended location to avoid confusion. If using power tools, practice on scrap wood to familiarize yourself with the equipment and cutting technique. For intricate cuts or if precision is paramount, consider using a clamp-on straightedge guide or investing in a professional cut from a hardware store. These steps, though time-consuming, save effort in the long run and guarantee a desk that’s both functional and visually striking.

Firewood Drying Time: Uncovering the Truth Behind the Process

You may want to see also

Explore related products

Assemble Desk Frame: Join legs and supports using screws and brackets for stability

The foundation of any sturdy desk lies in its frame, and assembling this structure demands precision and the right hardware. Begin by laying out your wooden legs and supports on a flat surface, ensuring they align perfectly with your desk’s dimensions. For a long desk, consider using at least four legs and two horizontal supports to distribute weight evenly. Pre-drill holes in both the legs and supports to prevent wood splitting, especially if using hardwood like oak or maple. Use 3-inch wood screws for a secure hold, and reinforce each joint with L-brackets for added stability. This combination of screws and brackets not only strengthens the frame but also ensures it can withstand daily use without wobbling.

While screws and brackets are essential, their placement is equally critical. Position the brackets at the top and bottom of each leg-support junction, ensuring they are flush with the wood surface. Tighten the screws gradually, alternating between them to maintain even pressure and avoid warping. For longer desks, consider adding a third support beam in the center to prevent sagging. This additional beam should be attached to the legs using the same screw-and-bracket method, creating a robust internal skeleton. Remember, the goal is to create a rigid frame that can support the desktop and any items placed on it without flexing or shifting.

A common mistake in desk frame assembly is underestimating the importance of alignment. Even a slight misalignment can lead to an unstable desk, especially over time as the wood settles. Use a carpenter’s square to ensure each joint is at a perfect 90-degree angle before securing it. If your desk design includes adjustable feet, attach them to the legs after the frame is assembled to compensate for uneven floors. These feet should be tightened securely but not so much that they distort the leg’s shape. Proper alignment and adjustment not only enhance stability but also contribute to the desk’s overall aesthetic appeal.

Finally, test the frame’s stability before attaching the desktop. Stand it upright and apply gentle pressure to each corner, checking for any wobble or movement. If instability is detected, revisit the joints and ensure all screws are tight and brackets are firmly attached. For added peace of mind, apply wood glue to the joints before screwing them together, though this step is optional. Once the frame passes the stability test, it’s ready for the desktop and any finishing touches. A well-assembled frame is the backbone of your desk, ensuring it remains functional and reliable for years to come.

Replacing Window Wood: Timeframe and Tips for a Smooth Repair

You may want to see also

Explore related products

Attach Tabletop: Secure the wooden tabletop to the frame with screws or glue

Attaching the tabletop is the moment your desk transforms from a skeletal frame into a functional workspace. This critical step demands precision and the right technique to ensure stability and longevity. While both screws and glue are viable options, each has its strengths and considerations.

Screws offer the advantage of adjustability and disassembly. If you anticipate moving your desk frequently or desire the ability to refinish the tabletop in the future, screws provide flexibility. Use countersunk screws to create a flush surface, and pre-drill pilot holes to prevent the wood from splitting. For a long desk, aim for a screw every 6-8 inches along the frame, ensuring even distribution of weight and minimizing the risk of warping.

Glue, on the other hand, provides a permanent, invisible bond, ideal for a desk intended to remain stationary. Choose a high-quality wood glue designed for structural applications. Apply a generous bead of glue along the entire contact surface between the tabletop and frame, ensuring complete coverage. Use clamps to apply even pressure while the glue dries, following the manufacturer's recommended curing time.

Remember, combining screws and glue can offer the best of both worlds. A few strategically placed screws can provide immediate stability while the glue cures, resulting in a rock-solid bond.

Regardless of your chosen method, ensure the tabletop is perfectly aligned with the frame before securing it. Use a level to check for flatness and adjust as needed. A misaligned tabletop will not only look unsightly but can also compromise the desk's structural integrity. With careful planning and execution, attaching the tabletop is a satisfying step that brings your long, simple wood desk one step closer to completion.

Epoxy Wood Filler Drying Time: Factors Affecting Cure Speed

You may want to see also

Explore related products

$267.52

$63.15 $89.99

Sand and Finish: Smooth edges, sand surfaces, and apply stain or sealant for durability

Smooth edges and surfaces are the difference between a desk that feels professional and one that feels like a DIY afterthought. Sanding is the critical step that transforms raw wood into a refined piece, eliminating splinters, rough patches, and imperfections. Start with a coarse-grit sandpaper (80-120 grit) to tackle major flaws, then progress to finer grits (150-220 grit) for a silky-smooth finish. Always sand in the direction of the wood grain to avoid scratches. Pay extra attention to edges and corners, where hands and objects will make the most contact. A power sander can speed up the process, but hand-sanding gives you better control for detailed areas.

Once the wood is smooth, cleaning is non-negotiable. Wipe away dust with a tack cloth or a damp rag to ensure no particles interfere with the finish. Applying stain or sealant directly to a dusty surface will result in a flawed, uneven coat. If you’re staining, test the color on a scrap piece of wood first to ensure it matches your vision. Apply the stain with a brush or cloth in thin, even layers, allowing each coat to dry completely before adding another. For a natural look, opt for a clear sealant like polyurethane, which comes in matte, satin, or gloss finishes. Two to three coats are typically sufficient for durability, with drying times of 2-4 hours between applications.

The choice between stain and sealant depends on your aesthetic and functional goals. Stain enhances the wood’s natural grain while adding color, but it doesn’t provide the same level of protection as a sealant. Sealants, on the other hand, create a protective barrier against moisture, heat, and scratches. For a desk that will see heavy use, a combination of both is ideal: stain for beauty and sealant for longevity. Water-based finishes are low-odor and dry quickly, while oil-based options offer deeper penetration and richer color but require more ventilation and drying time.

A common mistake is rushing the finishing process. Patience is key. Allow each coat to cure fully before adding the next, and avoid using the desk for at least 24-48 hours after the final application. For added protection, consider waxing the surface after sealing. Beeswax or carnauba wax can provide a smooth, water-resistant finish and enhance the wood’s natural luster. Regular maintenance, such as wiping the desk with a soft cloth and reapplying sealant every few years, will keep it looking pristine.

In the end, sanding and finishing are where craftsmanship meets artistry. These steps elevate a simple wood desk from functional to exceptional, ensuring it not only looks good but stands the test of time. The effort invested here pays dividends in both appearance and durability, making it a cornerstone of any DIY desk project.

Durability of Early Hominid Wooden Tools: Lifespan and Preservation Insights

You may want to see also

Frequently asked questions

You’ll need wooden boards (e.g., pine, oak, or plywood) for the desktop and legs, wood screws, wood glue, sandpaper, a saw, a drill, and a measuring tape. Optionally, include stain or paint for finishing.

Measure the space where the desk will go. A standard desk height is 28–30 inches, with a depth of 24–30 inches. The length depends on your needs, but common sizes range from 48 to 72 inches.

Use L-brackets or wooden aprons for stability. Pre-drill holes to avoid splitting the wood, then secure the legs with screws. Ensure the legs are level and flush with the desktop edges.

Sand the desk thoroughly to smooth rough edges. Apply wood stain or paint for color, then seal it with polyurethane or varnish to protect against scratches and moisture. Allow ample drying time between coats.