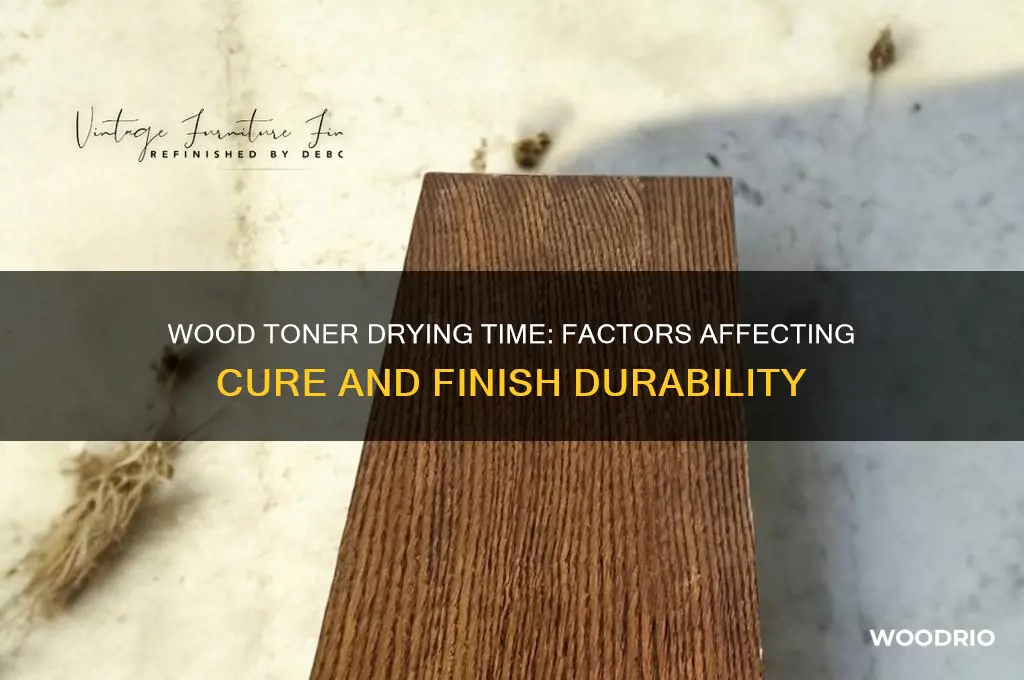

Wood toner is a popular finishing product used to enhance the color and appearance of wood surfaces, but one common question among users is how long it takes for wood toner to dry. The drying time can vary depending on several factors, including the type of toner, the humidity and temperature of the environment, and the thickness of the application. Generally, water-based wood toners dry faster, often within 1 to 2 hours, while oil-based toners may take 4 to 6 hours or longer. Proper ventilation and optimal conditions—such as moderate temperatures and low humidity—can significantly speed up the drying process. It’s essential to follow the manufacturer’s instructions and allow sufficient drying time before applying additional coats or using the treated surface to ensure the best results.

| Characteristics | Values |

|---|---|

| Drying Time (General) | 2 to 4 hours for surface dry, 24 hours for full cure |

| Factors Affecting Drying Time | Humidity, temperature, wood type, application thickness |

| Optimal Drying Conditions | Low humidity (below 50%), temperatures between 70°F and 80°F (21°C to 27°C) |

| Surface Dry Time | 2 to 4 hours |

| Full Cure Time | 24 hours |

| Recoat Time | 2 to 4 hours (if additional coats are needed) |

| Wood Type Impact | Softwoods dry faster than hardwoods |

| Application Method | Spraying or wiping can affect drying time |

| Manufacturer Recommendations | Always follow product-specific instructions for accurate drying times |

| Ventilation Requirement | Good ventilation speeds up drying and reduces fumes |

| Accelerating Drying | Use fans or heaters (if safe) to reduce drying time |

Explore related products

What You'll Learn

- Factors Affecting Drying Time: Humidity, temperature, wood type, and toner brand influence drying speed

- Average Drying Times: Most wood toners dry within 2-4 hours under ideal conditions

- Accelerating Drying Process: Use fans, heat, or low-humidity environments to speed up drying

- Testing for Dryness: Touch the surface lightly; no tackiness indicates it’s dry

- Recoating Guidelines: Wait 4-6 hours before applying a second coat for best results

Factors Affecting Drying Time: Humidity, temperature, wood type, and toner brand influence drying speed

Humidity acts as a silent saboteur in the wood toning process, significantly slowing down drying times. High humidity levels prevent moisture from evaporating efficiently, leaving the toner’s solvents trapped on the wood surface. For instance, in environments with 70% humidity or higher, drying times can double, stretching from the typical 2–4 hours to 6–8 hours or more. To mitigate this, aim to apply wood toner in spaces with humidity below 50%. Using a dehumidifier or scheduling toning during drier parts of the day can expedite the process. If humidity is unavoidable, consider thinning the toner slightly (no more than 10%) to reduce solvent load, but always follow the manufacturer’s guidelines.

Temperature plays a dual role in drying dynamics, accelerating evaporation at higher levels while risking uneven results if not managed carefully. Ideal drying conditions hover between 70°F and 80°F (21°C–27°C). Below 60°F (15°C), the drying time can extend to 8–12 hours, as solvents struggle to evaporate. Conversely, temperatures above 90°F (32°C) may cause the toner to dry too rapidly, leading to lap marks or a blotchy finish. For optimal results, avoid direct sunlight or heat sources, which can create hot spots. If working in cooler environments, use a space heater to maintain a consistent temperature, ensuring it’s placed far enough to prevent overheating the wood.

Wood type introduces a layer of complexity, as density and porosity dictate how quickly toner penetrates and dries. Softwoods like pine absorb toner rapidly but may dry unevenly due to their open grain. Hardwoods such as oak or maple, with their tighter grain, take longer to absorb toner but often yield a more uniform finish. Exotic woods like teak or mahogany can be particularly stubborn, requiring up to 24 hours to fully dry due to their natural oils. To test absorption, apply a small amount of toner to a scrap piece of the same wood type. If it beads up, lightly sanding the surface before application can improve adhesion and drying speed.

Toner brands vary widely in formulation, with some prioritizing quick-drying properties while others focus on depth of color or ease of application. Water-based toners typically dry within 2–4 hours, making them ideal for time-sensitive projects. Oil-based toners, however, can take 6–12 hours or longer, depending on the solvent concentration. Always consult the product label for specific drying times, as these can differ even within the same brand. For instance, Varathane’s wood toner dries to the touch in 30 minutes but requires 2 hours before recoating, whereas Minwax’s version may take up to 4 hours for a full cure. When in doubt, err on the side of caution and allow extra time to ensure a durable finish.

Evan Rachel Wood and Justin Long: Did They Date?

You may want to see also

Explore related products

Average Drying Times: Most wood toners dry within 2-4 hours under ideal conditions

Wood toners, designed to enhance the natural grain and color of wood, typically dry within 2-4 hours under ideal conditions. This timeframe is crucial for planning your project, as it dictates when you can apply additional coats or proceed with sealing. Ideal conditions include a temperature range of 70-75°F (21-24°C) and humidity levels below 50%. If your workspace deviates from these parameters, drying times may extend significantly. For instance, high humidity can slow evaporation, while cooler temperatures can delay curing. Always check the manufacturer’s guidelines, as some toners may have specific drying times or environmental requirements.

To ensure optimal drying, prepare your workspace thoughtfully. Avoid applying toner in direct sunlight or near heat sources, as this can cause uneven drying and blotching. Instead, opt for a well-ventilated area to promote consistent evaporation. If you’re working on a large project, apply the toner in thin, even coats to prevent pooling, which can prolong drying time. For example, a single coat of water-based toner on oak might dry within 2 hours, while an oil-based toner on denser wood like maple could take closer to 4 hours. Understanding these nuances helps you manage expectations and avoid rushing the process.

Comparing wood toners reveals that drying times can vary based on formulation. Water-based toners generally dry faster than oil-based options due to their lower viscosity and quicker evaporation rate. However, oil-based toners often provide richer color penetration and durability, making the longer drying time a worthwhile trade-off for certain projects. For instance, a water-based toner might be ideal for a quick furniture refresh, while an oil-based toner could be better suited for a high-traffic floor. Always weigh the pros and cons based on your project’s needs and timeline.

Practical tips can further streamline the drying process. Using a fan on low speed can improve air circulation without disturbing the wet surface. If you’re in a hurry, consider using a dehumidifier to reduce moisture in the air, but avoid placing it too close to the wood to prevent uneven drying. For multi-coat applications, lightly sanding between coats with 220-grit sandpaper ensures better adhesion without prolonging drying times. Remember, patience is key—rushing the process can lead to imperfections that require sanding and reapplication, ultimately extending your project timeline.

In conclusion, while most wood toners dry within 2-4 hours under ideal conditions, factors like temperature, humidity, and product type play significant roles. By understanding these variables and implementing practical strategies, you can achieve a smooth, professional finish efficiently. Always prioritize the manufacturer’s instructions and adapt your approach to the specific demands of your project. With careful planning and execution, drying time becomes a manageable aspect of your wood toning process rather than a hurdle.

India Ink Drying Time on Wood: A Comprehensive Guide

You may want to see also

Explore related products

Accelerating Drying Process: Use fans, heat, or low-humidity environments to speed up drying

Wood toner drying times can vary widely, typically ranging from 2 to 24 hours depending on the product, wood type, and environmental conditions. To expedite this process, leveraging external factors like airflow, heat, and humidity control can significantly reduce waiting times. Fans, for instance, can be strategically placed to circulate air around the treated wood, promoting evaporation of solvents and moisture. A standard household fan set on medium speed, positioned 3 to 5 feet away from the surface, can cut drying time by up to 30%. Ensure the fan is not too close to avoid uneven drying or dust accumulation on the wet surface.

Heat is another powerful tool for accelerating drying. Increasing the ambient temperature by 10 to 15°F (5 to 8°C) can speed up the evaporation process without damaging the wood or finish. A space heater or heat lamp can be used, but maintain a safe distance—at least 2 feet—to prevent overheating or scorching. For smaller projects, placing the wood near a radiator or in a warm, sunlit area can yield similar results. However, avoid direct sunlight for prolonged periods, as it may cause uneven drying or discoloration.

Low-humidity environments are equally effective in hastening drying times. Humidity levels below 50% are ideal, as moisture in the air slows evaporation. Dehumidifiers can be employed to reduce indoor humidity, particularly in damp or humid climates. For outdoor projects, choose dry, breezy days to apply the toner, and consider using a moisture meter to monitor the wood’s dryness before proceeding with additional coats or finishing steps.

Combining these methods can yield the best results. For example, using a fan in conjunction with a dehumidifier in a heated space can reduce drying time to as little as 1 to 2 hours for water-based toners or 4 to 6 hours for oil-based products. However, exercise caution: excessive heat or airflow can lead to cracking, bubbling, or a rough finish. Always follow the manufacturer’s guidelines and test the method on a small, inconspicuous area first. By mastering these techniques, you can streamline your woodworking projects without compromising quality.

Wood Frogs' Hibernation Duration: Unveiling Their Winter Survival Secrets

You may want to see also

Explore related products

Testing for Dryness: Touch the surface lightly; no tackiness indicates it’s dry

A gentle touch can reveal whether your wood toner has dried completely. This simple yet effective method is a cornerstone of the drying process, offering immediate feedback without the need for specialized tools or extensive waiting periods. By lightly pressing your finger against the surface, you can detect any residual tackiness, which is a clear sign that the toner hasn’t fully cured. This tactile approach is particularly useful for those who prefer hands-on methods over relying on timers or environmental conditions.

The technique is straightforward but requires a delicate touch. Press your fingertip against the toned area with minimal pressure, as if you’re testing the surface of a freshly painted wall. If your skin doesn’t stick or leave an imprint, the toner is likely dry. However, if you feel even a slight adhesive quality, it’s best to allow more time for drying. This method is especially valuable when working with water-based toners, which typically dry faster than oil-based alternatives but can still vary depending on humidity and temperature.

One practical tip is to test multiple areas, especially if the wood piece is large or unevenly coated. Toner may dry at different rates across the surface, so a single test spot might not provide a complete picture. For instance, edges and thinner sections often dry quicker than recessed or thicker areas. By sampling various locations, you ensure a more accurate assessment of the overall drying progress.

While this method is reliable, it’s important to avoid over-testing, as repeated touching can disturb the finish. Limit your checks to once every 30 minutes or so, depending on the manufacturer’s recommended drying time. Additionally, consider environmental factors: in humid conditions, drying times can double, making this tactile test even more crucial for avoiding premature handling or applying additional coats.

In conclusion, testing for dryness by touch is a quick, intuitive way to determine if your wood toner is ready for the next step. Its simplicity makes it accessible for both beginners and experienced woodworkers, ensuring a smooth finish without the guesswork. Pair this method with patience and awareness of your workspace conditions, and you’ll achieve professional results every time.

Wooden Bulkhead Lifespan: Factors Affecting Durability and Longevity

You may want to see also

Explore related products

Recoating Guidelines: Wait 4-6 hours before applying a second coat for best results

Wood toner drying times vary by brand, wood type, and environmental conditions, but a common recoating guideline emerges: wait 4-6 hours before applying a second coat. This window allows the initial layer to set without fully curing, ensuring proper adhesion and a seamless finish. Rushing this process risks uneven absorption, blotching, or peeling, while waiting too long can create a barrier between coats, compromising bond strength.

The 4-6 hour rule balances efficiency and quality. During this period, the solvent evaporates, and the pigments penetrate the wood fibers, creating a uniform base. Humidity, temperature, and airflow influence drying speed—warmer, drier conditions accelerate it, while cooler, damp environments extend it. Always test a small area to confirm readiness: the surface should feel dry to the touch but retain a slight tackiness, indicating it’s ready for the next coat.

Applying the second coat too soon traps moisture, leading to cloudiness or adhesion failure. Conversely, waiting beyond 24 hours may require light sanding to reopen the wood pores for proper bonding. For best results, maintain consistent environmental conditions throughout the process. Use a fan to improve airflow, but avoid direct heat sources, which can cause uneven drying or cracking.

This recoating guideline isn’t arbitrary—it’s rooted in the chemistry of wood toners. Most formulations contain dyes, pigments, and solvents designed to enhance wood grain without forming a thick film. The 4-6 hour wait ensures the solvent evaporates gradually, allowing pigments to settle naturally. Skipping this step undermines the toner’s purpose: to enrich wood color while preserving its texture and character.

Practical tip: If working on a large project, divide the surface into sections. This allows you to recoat each area within the optimal window, maintaining consistency across the entire piece. Always follow the manufacturer’s instructions, as some toners may specify slightly different recoating times. Patience in this step pays off, delivering a professional, durable finish that highlights the wood’s natural beauty.

Exploring the Scenic Drive to Woods Hole, Massachusetts: Time & Distance

You may want to see also

Frequently asked questions

Wood toner drying time varies depending on the brand and environmental conditions, but it usually takes 1 to 4 hours to dry to the touch. Full curing may take 24 to 48 hours.

Yes, high humidity can significantly slow down the drying process, potentially extending the time to 6–8 hours or more. Ensure proper ventilation to speed up drying.

Yes, using a fan or a heater on low settings can help accelerate drying, but avoid excessive heat as it may cause uneven drying or damage the finish.

![[KLAIRS] Supple Preparation Unscented Toner 6.08 fl oz, Lightweight, Essential Oil-Free, Alcohol Free, Packaging Changed](https://m.media-amazon.com/images/I/71SDVKnBOfL._AC_UL320_.jpg)