Wood shrinkage is a natural process influenced by changes in moisture content and environmental conditions, and understanding how long it takes for wood to shrink is essential for woodworking, construction, and furniture making. The duration of wood shrinkage varies depending on factors such as wood species, initial moisture content, humidity levels, and temperature. Generally, wood can begin to shrink within days or weeks when exposed to drier conditions, but significant shrinkage may take several months or even years to stabilize, especially in thicker or denser pieces. Hardwoods like oak and maple tend to shrink more slowly compared to softwoods like pine, which can shrink more rapidly. Proper acclimatization and moisture control are crucial to minimizing shrinkage and ensuring the longevity of wood products.

| Characteristics | Values |

|---|---|

| Time for Wood to Shrink | Varies based on wood type, moisture content, and environmental conditions |

| Initial Shrinkage (Green Wood) | Begins immediately after cutting and can take weeks to months |

| Air-Drying Time | 1-2 years for most hardwoods, depending on thickness and climate |

| Kiln-Drying Time | 2-14 days, depending on wood type and desired moisture level |

| Equilibrium Moisture Content (EMC) | Reached in 6-12 months for air-dried wood, faster with kiln-drying |

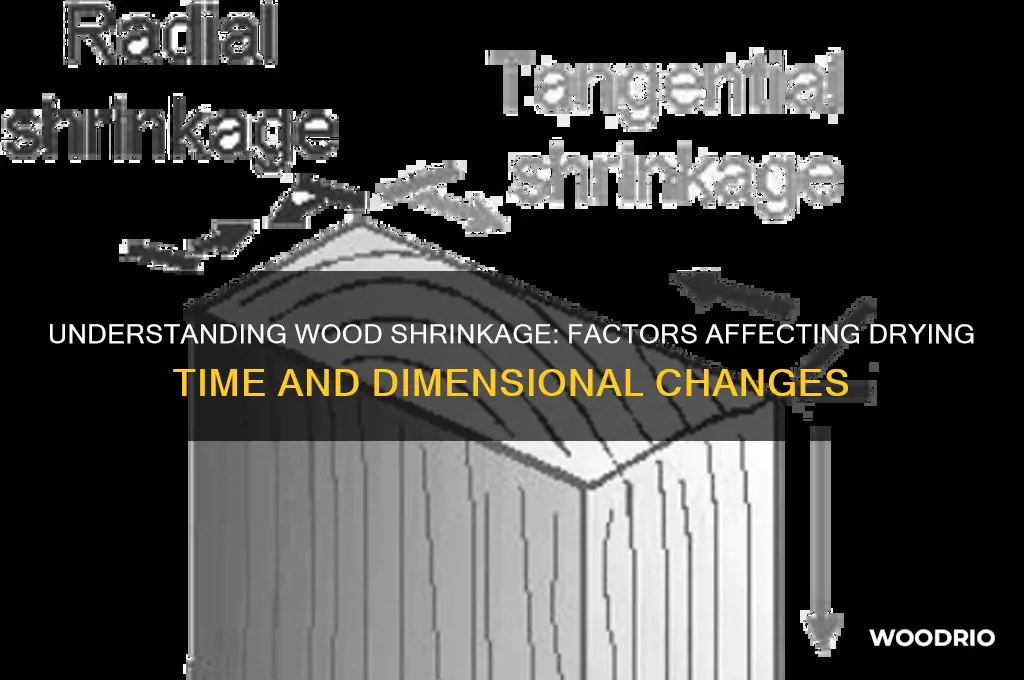

| Shrinkage Rate | 4-10% tangential, 2-6% radial, depending on wood species |

| Factors Affecting Shrinkage | Humidity, temperature, wood density, grain orientation |

| Stability After Shrinkage | Achieved once wood reaches EMC with its environment |

| Seasoning Time for Stability | 6-12 months for air-dried wood, immediate for kiln-dried wood |

| Long-Term Shrinkage | Minimal after reaching EMC, unless environmental conditions change |

Explore related products

What You'll Learn

Factors Affecting Shrinkage Rate

Wood shrinkage is a complex process influenced by multiple variables, each playing a unique role in determining how quickly and to what extent wood contracts. Understanding these factors is crucial for anyone working with wood, from carpenters to hobbyists, as it directly impacts the durability and stability of wooden structures and objects. The rate at which wood shrinks is not uniform; it varies significantly based on the wood's species, moisture content, and environmental conditions. For instance, softwoods like pine tend to shrink more rapidly than hardwoods such as oak, primarily due to differences in cellular structure and density. This variation highlights the importance of selecting the right type of wood for specific applications to minimize unwanted shrinkage.

One of the most critical factors affecting shrinkage rate is the initial moisture content of the wood. Freshly cut wood, often referred to as green wood, contains a high percentage of moisture, which can be as much as 50% or more of its weight. As this moisture evaporates, the wood cells contract, leading to shrinkage. To mitigate excessive shrinkage, wood is often kiln-dried to reduce its moisture content to a more stable level, typically between 6% and 12%, depending on the intended use and local climate conditions. For example, wood used in outdoor furniture should be dried to a lower moisture content to withstand varying humidity levels without significant warping or cracking.

Environmental conditions, particularly humidity and temperature, also play a pivotal role in the shrinkage process. Wood is hygroscopic, meaning it absorbs and releases moisture in response to changes in its surroundings. In dry environments, wood loses moisture more quickly, accelerating shrinkage, while in humid conditions, it may absorb moisture and expand. Temperature fluctuations can exacerbate these effects, as warmer air holds more moisture, potentially slowing shrinkage in heated indoor spaces. To control shrinkage, it’s advisable to acclimate wood to its final environment for at least one to two weeks before use, allowing it to reach equilibrium moisture content (EMC) and stabilize its dimensions.

Another often-overlooked factor is the direction of wood grain, which significantly influences how wood shrinks. Wood shrinks more across the grain (tangentially and radially) than along the grain (longitudinally). Tangential shrinkage, which occurs perpendicular to the growth rings, is typically greater than radial shrinkage, which occurs along the radius of the tree trunk. This anisotropy means that wood pieces with different grain orientations will shrink at varying rates, potentially leading to distortion or joint failure in woodworking projects. Craftspeople can minimize this risk by aligning grain directions strategically and using techniques like quarter-sawing or rift-sawing to produce more stable lumber.

Finally, the thickness and size of the wood piece directly impact the time it takes for shrinkage to occur. Thicker boards take longer to dry and shrink because moisture must travel farther to escape, whereas thinner pieces dry and stabilize more quickly. For example, a 4/4 (1-inch thick) board may take several weeks to months to reach EMC, while a 8/4 (2-inch thick) board could require twice as long. This principle underscores the importance of planning ahead and allowing sufficient drying time, especially for larger projects. By considering these factors—wood species, moisture content, environmental conditions, grain direction, and piece size—craftspeople can better predict and manage wood shrinkage, ensuring the longevity and quality of their work.

Heat-Treated Wood Durability: Longevity and Outdoor Performance Explained

You may want to see also

Explore related products

Wood Species and Shrinkage Time

Wood shrinkage is not a one-size-fits-all process; the time it takes for wood to shrink varies significantly depending on the species. For instance, dense hardwoods like oak and maple can take several months to years to fully stabilize, whereas softer woods like pine may shrink more rapidly, often within weeks to months. This disparity is primarily due to differences in cellular structure and moisture content. Understanding these variations is crucial for anyone working with wood, whether in construction, furniture making, or crafting.

Consider the example of teak, a tropical hardwood prized for its durability. Teak has a naturally high oil content, which slows down the moisture evaporation process, resulting in a shrinkage period that can extend over several years. In contrast, balsa wood, known for its lightweight properties, dries and shrinks much faster due to its loose, porous structure. This highlights the importance of selecting the right wood species for your project based on its intended use and environmental conditions. For instance, if you’re building outdoor furniture, a slow-shrinking wood like teak would be more suitable than a fast-shrinking species like balsa.

To minimize shrinkage-related issues, follow these practical steps: first, acclimate the wood to its intended environment for at least 2–4 weeks before use. This allows it to adjust to the ambient humidity and temperature, reducing the risk of warping or cracking. Second, seal the wood with a moisture-resistant finish to slow down the drying process. For example, applying a coat of polyurethane can help stabilize softer woods like cedar. Lastly, store wood in a controlled environment—ideally at 40–60% humidity and 60–80°F—to prevent rapid moisture loss.

A comparative analysis reveals that shrinkage time is also influenced by the wood’s initial moisture content. Freshly cut green wood, which can have a moisture content of 50–100%, will shrink more dramatically than kiln-dried wood, which typically has a moisture content of 6–8%. For example, a 1-inch thick board of green oak might shrink up to 1/16 inch in width, while the same board kiln-dried would shrink less than 1/32 inch. This underscores the need to consider both species and moisture content when estimating shrinkage time.

In conclusion, the shrinkage time of wood is a species-specific trait that requires careful consideration. By understanding the unique properties of different woods and taking proactive measures, you can mitigate the effects of shrinkage and ensure the longevity of your projects. Whether you’re a professional carpenter or a DIY enthusiast, this knowledge will empower you to make informed decisions and achieve better results.

Solar Kiln Wood Drying Time: Factors Affecting Efficiency and Duration

You may want to see also

Explore related products

Moisture Content Impact

Wood shrinkage is fundamentally a response to moisture content changes, making this factor the linchpin in predicting how long the process takes. Freshly cut timber, often called "green wood," can contain moisture levels exceeding 100% of its dry weight. As this moisture evaporates, the wood contracts, with the rate and extent of shrinkage directly tied to the initial and final moisture content. For instance, wood drying from 20% to 12% moisture content will shrink more rapidly than wood moving from 12% to 8%, as the material is more responsive to larger moisture gradients. Understanding this relationship allows craftsmen to estimate shrinkage timelines based on specific moisture reduction targets.

To mitigate excessive or uneven shrinkage, controlling moisture content during drying is critical. Air-drying wood typically reduces moisture levels at a rate of 4% to 10% per month, depending on humidity, temperature, and airflow. Kiln-drying accelerates this process, achieving similar reductions in days rather than months, but improper kiln settings can lead to case hardening—a condition where the outer layers dry too quickly, trapping moisture inside. This internal moisture can prolong shrinkage over weeks or even months after the wood appears dry. Monitoring moisture content with a pin-style or pinless meter ensures the wood stabilizes at the desired level, minimizing future movement.

The impact of moisture content on shrinkage varies by wood species, with hygroscopic woods like oak and maple being more sensitive than denser species like teak or mahogany. For example, oak can shrink up to 7.4% tangentially and 3.5% radially as it dries from green to 6% moisture content, while teak may only shrink 4.1% and 2.0%, respectively. This species-specific response underscores the need for tailored drying strategies. Softwoods, such as pine, generally shrink less overall but are more prone to warping if moisture loss is uneven. Selecting the right species for a project and understanding its moisture-shrinkage profile can prevent costly mistakes.

Practical tips for managing moisture content include acclimating wood to its final environment before use. For indoor projects, store lumber in the space where it will be installed for 2–4 weeks to equilibrate with ambient humidity, typically around 6–8% moisture content. For outdoor applications, allow wood to reach an equilibrium moisture content (EMC) of 12–14%, reflecting average outdoor conditions. Applying sealants or finishes after acclimation can slow moisture exchange, reducing long-term shrinkage. Regularly inspecting wood for signs of moisture regain, such as cupping or crowning, ensures the material remains stable over its lifespan.

In summary, moisture content dictates the pace and magnitude of wood shrinkage, influenced by species, drying methods, and environmental conditions. By measuring moisture levels, controlling drying rates, and accounting for species-specific responses, craftsmen can predict and manage shrinkage effectively. Whether air-drying, kiln-drying, or acclimating wood, precision in moisture management transforms an unpredictable process into a calculable science, ensuring wood performs as intended in its final application.

Dremel Wood Blade Lifespan: Factors Affecting Durability and Longevity

You may want to see also

Explore related products

Environmental Conditions Role

Wood shrinkage is a natural process influenced heavily by environmental conditions, particularly humidity and temperature. When wood is exposed to dry air, it releases moisture, causing its cells to contract and the material to shrink. This process is not instantaneous; it occurs gradually over weeks, months, or even years, depending on the severity of the environmental changes. For instance, a piece of wood moved from a humid environment (80% relative humidity) to a dry one (30% relative humidity) can lose up to 5% of its moisture content within the first month, with further shrinkage tapering off over time. Understanding this dynamic is crucial for anyone working with wood, as it directly impacts dimensional stability in furniture, flooring, or construction projects.

To mitigate shrinkage, controlling the environment is key. For indoor applications, maintaining a consistent relative humidity between 40% and 60% is ideal. This range minimizes moisture loss without promoting mold growth. Humidifiers or dehumidifiers can help achieve this balance, especially in climates with extreme seasonal changes. For example, in arid regions like the southwestern U.S., where humidity often drops below 20%, using a humidifier during the dry season can prevent rapid wood shrinkage. Conversely, in tropical areas with humidity exceeding 80%, a dehumidifier is essential to avoid swelling and subsequent shrinkage when conditions normalize.

Temperature also plays a significant role, though its effect is secondary to humidity. Rapid temperature fluctuations can accelerate moisture movement within wood, exacerbating shrinkage. For instance, wood stored in an unheated garage during winter may shrink more dramatically when exposed to cold, dry air compared to wood kept in a temperature-controlled environment. To counteract this, acclimate wood to its intended environment before use. Allow lumber to sit in the space where it will be installed for at least one week, or longer for thicker pieces. This practice ensures the wood reaches equilibrium moisture content (EMC), reducing the risk of future shrinkage.

A comparative analysis of wood species reveals varying sensitivities to environmental conditions. Dense hardwoods like oak or maple shrink more slowly and to a lesser degree than softwoods like pine or cedar, which are more porous and lose moisture faster. For outdoor projects, choose species naturally resistant to shrinkage, such as teak or ipe, which have high natural oils that slow moisture absorption and release. Alternatively, apply sealants or finishes to create a barrier against humidity fluctuations. Water-based polyurethanes or epoxy coatings are effective, but reapplication every 1–2 years is necessary to maintain protection.

In practical terms, monitoring environmental conditions is as important as selecting the right wood. Use a moisture meter to measure wood’s moisture content before and after installation, aiming for a reading within 2–4 percentage points of the local EMC. For example, if the EMC in your area is 10%, ensure the wood’s moisture content is between 8% and 12%. Additionally, avoid stacking wood directly on concrete floors, as this can wick moisture into the material. Instead, use stickers or pallets to elevate the wood and promote airflow. By proactively managing humidity, temperature, and material selection, you can significantly reduce the time and extent of wood shrinkage, ensuring longevity and stability in your projects.

Robert Wagner and Natalie Wood's Yacht Ownership Timeline Revealed

You may want to see also

Explore related products

Accelerating or Slowing Shrinkage

Wood shrinkage is a natural process influenced by moisture content, temperature, and environmental conditions. However, the rate at which wood shrinks can be manipulated through specific techniques. Accelerating shrinkage can be achieved by exposing wood to higher temperatures or reducing humidity levels, which forces moisture to evaporate more quickly. For instance, placing wood in a kiln at 120°F (49°C) can expedite moisture loss, shrinking a 1-inch thick board in days rather than weeks. Conversely, slowing shrinkage involves maintaining consistent humidity levels, typically between 40-60%, and avoiding sudden temperature changes. Using a dehumidifier or humidifier can help regulate these conditions, especially in indoor environments.

To accelerate shrinkage effectively, consider the wood species and its initial moisture content. Hardwoods like oak or maple shrink more slowly than softwoods like pine due to their denser cellular structure. Applying heat directly, such as with a heat gun, can target specific areas but requires caution to avoid warping or cracking. For larger projects, a kiln-drying process is ideal, as it provides uniform heat distribution. However, this method is resource-intensive and best suited for professional settings. Alternatively, air-drying in a controlled environment with fans to circulate air can moderately speed up shrinkage while minimizing risk.

Slowing shrinkage is particularly useful for preserving wood dimensions in furniture or construction. One practical method is sealing the wood with a moisture-resistant finish, such as polyurethane or varnish, which creates a barrier against rapid moisture exchange. For unfinished wood, storing it in a climate-controlled space with a stable humidity level is essential. Adding silica gel packets to storage areas can absorb excess moisture, further stabilizing the wood. Additionally, acclimating wood to its intended environment for 2-4 weeks before use allows it to adjust gradually, reducing the risk of post-installation shrinkage.

Comparing these approaches reveals trade-offs between speed and precision. Accelerating shrinkage is efficient but demands careful monitoring to prevent damage, while slowing shrinkage prioritizes stability but requires patience and planning. For example, a woodworker crafting a custom table might accelerate shrinkage for quick turnaround but slow it for the final assembly to ensure longevity. Understanding these techniques enables better control over wood’s behavior, tailoring the process to specific project needs. Whether speeding up or slowing down, the key lies in balancing environmental factors with the wood’s natural properties.

Wood Drying Time: Factors Affecting Moisture Loss and Optimal Conditions

You may want to see also

Frequently asked questions

The time it takes for wood to shrink depends on factors like wood species, moisture content, humidity, and temperature. Generally, wood can take weeks to months to stabilize and reach equilibrium moisture content (EMC).

Wood shrinks faster in dry conditions because it loses moisture more quickly. In humid environments, the process is slower as the wood retains moisture longer.

While shrinkage cannot be entirely prevented, it can be minimized by properly drying and seasoning the wood, storing it in a controlled environment, and using sealants or finishes to reduce moisture absorption.

Wood shrinkage varies by species but typically ranges from 2% to 10% in width and thickness. Tangential shrinkage (width) is usually greater than radial shrinkage (thickness).