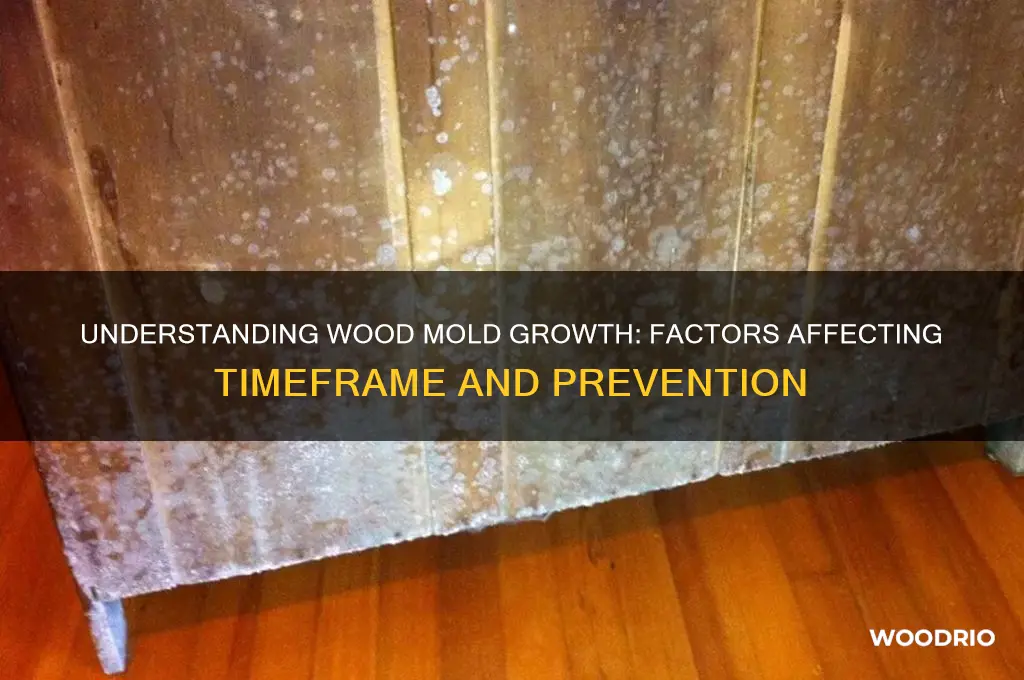

Wood mold growth is influenced by several factors, including moisture levels, temperature, and the type of wood. Generally, mold can begin to develop on wood within 24 to 48 hours if the conditions are ideal, such as when the wood is exposed to high humidity (above 60%) and warm temperatures (between 77°F and 86°F). However, in less favorable environments, it may take several days or even weeks for mold to become visible. Softwoods, like pine, are more susceptible to mold than hardwoods, like oak, due to their higher moisture absorption rates. Preventing mold involves keeping wood dry, ensuring proper ventilation, and addressing any water damage promptly. Understanding these factors is crucial for protecting wooden structures and materials from mold-related deterioration.

| Characteristics | Values |

|---|---|

| Optimal Conditions for Mold Growth | Warm (77°F/25°C), humid (70-90% relative humidity), and damp wood |

| Time to Mold Formation | 24-48 hours under optimal conditions |

| Factors Affecting Mold Growth | Moisture content, temperature, airflow, wood type, and spore presence |

| Moisture Content Threshold | Wood with >20% moisture content is highly susceptible to mold |

| Wood Type Influence | Softwoods (e.g., pine) mold faster than hardwoods (e.g., oak) |

| Preventive Measures | Keep wood dry, ensure proper ventilation, and use mold-resistant treatments |

| Mold Detection | Visible discoloration, musty odor, or surface fuzziness |

| Health Risks | Allergies, respiratory issues, and potential structural damage to wood |

| Remediation Time | 1-3 days for surface mold; longer for deep-seated mold |

| Long-Term Prevention | Regular inspection, moisture control, and prompt drying of wet wood |

Explore related products

What You'll Learn

Humidity and Mold Growth Rate

Mold spores are ever-present in the environment, but their transformation into visible colonies on wood depends critically on humidity levels. Relative humidity (RH) above 60% creates ideal conditions for mold growth, as it provides the moisture necessary for spores to germinate and thrive. Wood, being hygroscopic, readily absorbs moisture from the air, making it particularly susceptible when RH exceeds this threshold. In environments with RH consistently above 70%, mold can begin to develop on wood within 24 to 48 hours, especially if the wood is already damp or compromised.

To mitigate this risk, maintaining indoor humidity below 50% is essential. Dehumidifiers are effective tools for controlling moisture levels, particularly in basements, attics, or areas prone to dampness. Regularly monitoring humidity with a hygrometer allows for proactive adjustments before conditions become conducive to mold. Additionally, ensuring proper ventilation in enclosed spaces reduces stagnant moisture, further safeguarding wood surfaces from rapid mold colonization.

Comparatively, wood in dry climates with RH below 40% is far less likely to mold, as the lack of moisture inhibits spore activation. However, even in arid environments, localized humidity spikes—such as near leaks or in poorly ventilated bathrooms—can create microclimates where mold flourishes. For instance, a wooden vanity exposed to steam from daily showers may develop mold within days if not properly sealed or ventilated.

Practical steps include sealing wood surfaces with water-resistant finishes, such as polyurethane or varnish, to create a barrier against moisture absorption. For outdoor wood structures, using pressure-treated lumber or naturally resistant species like cedar can significantly delay mold onset. If mold does appear, immediate action is crucial: scrub the affected area with a mixture of bleach and water (1 cup bleach per gallon of water), allow it to dry thoroughly, and reapply sealant to prevent recurrence.

In summary, humidity is the linchpin in mold’s rapid colonization of wood. By controlling moisture levels, sealing surfaces, and addressing vulnerabilities, the timeline for mold growth can be extended from days to years, preserving both the aesthetic and structural integrity of wooden materials.

Durability of Wood Planters: Lifespan and Maintenance Tips Revealed

You may want to see also

Explore related products

Wood Type and Susceptibility

Wood species vary dramatically in their resistance to mold, a critical factor for builders, craftsmen, and homeowners alike. Dense, resinous woods like cedar and redwood naturally repel fungi due to their high tannin and oil content, often lasting decades without treatment in humid environments. In contrast, softwoods such as pine and spruce, with lower natural defenses, can show mold growth within weeks under the same conditions. This inherent disparity underscores the importance of matching wood type to its intended use, particularly in moisture-prone areas like bathrooms or outdoor structures.

Consider the role of wood porosity in mold susceptibility. Open-grained woods like oak, with larger vessels for water absorption, provide more surface area for mold spores to anchor and thrive. Conversely, close-grained woods such as maple or cherry, with tighter cell structures, resist moisture penetration more effectively, delaying mold onset. For instance, an oak deck left untreated in a rainy climate may develop mold within 3–6 months, while a cherry deck could remain mold-free for 1–2 years under identical conditions. Understanding these structural differences allows for proactive material selection and maintenance strategies.

Humidity and temperature act as accelerants, but wood type remains the foundational variable in mold timelines. Tropical hardwoods like teak and ipe, prized for their density and natural oils, can withstand 90% humidity levels for years without molding, making them ideal for saunas or coastal furniture. Meanwhile, engineered woods (e.g., MDF or particleboard) lack natural defenses and absorb moisture rapidly, often showing mold within 24–48 hours of water exposure. This highlights the trade-off between cost and durability: cheaper materials may require frequent replacement or vigilant waterproofing to combat mold.

Practical steps can mitigate susceptibility regardless of wood type. For softwoods or porous species, apply fungicidal treatments or sealants to create a moisture barrier, reducing mold risk by up to 70%. In high-humidity zones, pair vulnerable woods with ventilation systems or dehumidifiers to maintain relative humidity below 60%, the threshold for mold proliferation. Regular inspections, especially after water leaks or seasonal changes, allow early detection of mold precursors like discoloration or musty odors. By aligning wood selection with environmental demands and implementing targeted maintenance, even susceptible species can perform reliably in challenging conditions.

Drying Fresh Mesquite Wood: Timeframe and Best Practices Explained

You may want to see also

Explore related products

Temperature Impact on Mold

Mold growth on wood is a race against time, and temperature acts as the starting pistol. Optimal conditions for mold spores to germinate and thrive fall between 77°F and 88°F (25°C and 31°C). At these temperatures, mold can begin to colonize wood within 24 to 48 hours if moisture is present. This narrow range highlights why warm, humid environments are particularly susceptible to mold infestations.

Consider the scenario of a damp basement in summer. If the temperature hovers around 80°F (27°C) and humidity exceeds 60%, mold spores on wooden surfaces can sprout hyphae—the thread-like structures of mold—within a day. Conversely, temperatures below 60°F (15°C) significantly slow this process, acting as a natural inhibitor. For instance, wood stored in a cool, dry garage at 55°F (13°C) is far less likely to mold, even if exposed to occasional moisture.

To mitigate mold growth, temperature control is a critical strategy. In high-risk areas like bathrooms or kitchens, maintaining temperatures below 75°F (24°C) can disrupt mold’s ideal conditions. Pair this with humidity control—ideally below 50%—using dehumidifiers or proper ventilation. For outdoor wood structures, strategic placement in shaded areas can reduce heat exposure, while indoor wood should be stored in climate-controlled spaces to prevent temperature fluctuations.

A comparative analysis reveals that temperature’s role in mold growth is not just about speed but also persistence. While extreme heat above 100°F (38°C) can kill mold spores, it rarely eliminates the problem entirely, as spores can remain dormant until conditions improve. Similarly, freezing temperatures below 32°F (0°C) halt mold growth but do not eradicate existing colonies. This underscores the importance of consistent temperature management rather than relying on temporary extremes.

In practical terms, homeowners and woodworkers can leverage temperature to their advantage. For instance, pre-treating wood with heat—such as kiln-drying at 140°F (60°C) for 24 hours—can eliminate moisture and spores before storage. Additionally, monitoring indoor temperatures with smart thermostats ensures environments remain hostile to mold. By understanding temperature’s dual role as both catalyst and inhibitor, one can proactively protect wood from mold’s relentless advance.

How Long Does 2 Bundles of Firewood Typically Last?

You may want to see also

Explore related products

Moisture Exposure Duration

Wood begins to mold when moisture levels exceed 20% and remain elevated for 48–72 hours. This critical window is the tipping point where mold spores, ever-present in the environment, find the ideal conditions to germinate and colonize. In high-humidity environments (above 60%), this process accelerates, often visible within 5–10 days. Conversely, wood kept below 12% moisture content rarely molds, even in spore-rich settings. The duration of exposure matters more than the initial moisture spike—prolonged dampness, not fleeting wetness, triggers mold growth.

Consider a flooded basement scenario: if wood flooring is dried within 24–48 hours, mold risk drops significantly. However, if water persists for 72+ hours, mold becomes nearly inevitable. Temperature plays a role too; warmer conditions (70–90°F) shorten the timeline, while cooler temperatures (below 60°F) may delay but not prevent growth. Practical tip: use dehumidifiers and fans to reduce moisture within the first 24 hours of water exposure, targeting a relative humidity below 50% to halt mold initiation.

Comparatively, outdoor wood structures face a different challenge. Rain exposure alone rarely causes mold if water sheds quickly. The danger arises when wood remains damp for days, such as in shaded areas or where water pools. For example, untreated deck boards in a perpetually shaded corner may show mold within 2–3 weeks of consistent moisture exposure, while those in full sun rarely do. Solution: ensure proper drainage, apply water-repellent sealants, and space boards to allow airflow, reducing moisture retention time.

For indoor applications, the age and treatment of wood influence its resistance. Freshly cut lumber, with higher natural moisture, molds faster than kiln-dried wood. Pressure-treated wood, infused with preservatives, resists mold for months even in damp conditions. However, once the protective layer wears off, untreated areas become vulnerable. Pro tip: inspect older wooden structures seasonally, focusing on joints and crevices where moisture accumulates, and reapply sealants every 2–3 years to maintain protection.

In summary, mold growth on wood is a race against time and moisture. The key is not just to reduce moisture but to do so swiftly and consistently. Whether dealing with indoor furniture, outdoor decks, or structural beams, the goal is to keep wood dry or dry it fast. By understanding the 48–72 hour critical period and acting within it, you can prevent mold from taking hold, saving both material and effort in the long run.

Understanding the Duration of Woods Raids in Escape from Tarkov

You may want to see also

Explore related products

Preventing Mold on Wood

Wood is particularly susceptible to mold growth when exposed to moisture and warmth for extended periods. Mold spores, ever-present in the environment, only need the right conditions to colonize and thrive. Understanding this vulnerability is the first step in preventing mold on wood surfaces.

Controlling Moisture: The Key to Prevention

The primary defense against mold on wood is moisture control. Wood's porous nature allows it to absorb and retain moisture, creating an ideal environment for mold. Aim to keep wood surfaces below 20% moisture content. Use a moisture meter to accurately measure moisture levels, especially in areas prone to dampness like basements, bathrooms, and kitchens.

Dehumidifiers are invaluable tools in maintaining optimal humidity levels, ideally between 30-50%. Ventilation is equally crucial; ensure proper airflow by using exhaust fans, opening windows, and avoiding overcrowding furniture.

Proactive Measures for Long-Term Protection

Preventative measures are far more effective than dealing with established mold growth. Seal wood surfaces with a high-quality, mold-resistant sealant or paint. This creates a barrier, preventing moisture absorption and making it harder for mold spores to take hold. Regularly inspect wood for any signs of moisture damage, such as warping, discoloration, or musty odors. Address leaks and water intrusion promptly to prevent moisture from reaching wood surfaces.

Consider using mold-resistant wood species like cedar or redwood for areas prone to dampness. These naturally contain oils that inhibit mold growth.

Cleaning and Maintenance: A Continuous Effort

Regular cleaning is essential for preventing mold on wood. Wipe down surfaces with a mild detergent solution and dry thoroughly. Avoid using excessive water, as this can contribute to moisture problems. For areas with high humidity, consider using a mold-inhibiting cleaner specifically formulated for wood surfaces. Be mindful of organic materials like dust and dirt, which can provide food for mold. Regular dusting and vacuuming can significantly reduce the risk of mold growth.

Remember, preventing mold on wood is an ongoing process. By controlling moisture, taking proactive measures, and maintaining regular cleaning routines, you can effectively safeguard your wood surfaces from the damaging effects of mold.

Winter Wood Supply: How Long Does a Cord of Wood Last?

You may want to see also

Frequently asked questions

Under normal conditions (high humidity, warmth, and moisture), wood can begin to mold within 24 to 48 hours if it remains damp. However, visible mold growth typically takes 5 to 10 days to become noticeable.

A: Wood is less likely to mold in dry environments, as mold requires moisture to grow. In very dry conditions (below 50% humidity), mold growth is significantly slowed or prevented, and it may take weeks or even months for mold to develop.

A: Yes, the type of wood can influence how quickly it molds. Softwoods, like pine, are more susceptible to mold due to their porous nature, while hardwoods, like oak, are more resistant. Properly treated or sealed wood also resists mold growth better than untreated wood.