Strengthening the bottom of a long wooden box is essential to ensure its durability and load-bearing capacity, especially if it will be used to store heavy items or subjected to frequent movement. The process typically involves reinforcing the existing structure with additional materials such as plywood, hardwood strips, or metal brackets. One effective method is to attach a secondary layer of wood, such as marine-grade plywood, to the underside of the box, securing it with screws or nails spaced evenly to distribute weight evenly. Alternatively, adding corner braces or metal straps along the joints can enhance stability and prevent warping. For added strength, consider using epoxy or wood glue to bond the layers together, followed by sanding and sealing to protect against moisture and wear. Proper reinforcement not only extends the box's lifespan but also ensures it remains functional and safe for its intended use.

| Characteristics | Values |

|---|---|

| Material Reinforcement | - Plywood sheets (1/4" to 1/2" thickness) - Metal brackets or angle irons - Wooden battens or cleats - Fiberglass or carbon fiber strips |

| Structural Support | - Additional wooden ribs or braces - Metal or wooden cross-bracing - Doubling up existing bottom boards |

| Fastening Methods | - Screws (wood or metal) - Nails (galvanized for outdoor use) - Construction adhesive - Wood glue |

| Design Considerations | - Distribute weight evenly across the bottom - Avoid concentrated loads - Consider the box's intended use and weight capacity |

| Additional Techniques | - Apply a waterproof sealant to the bottom - Use a stronger wood species for the bottom - Add a layer of rubber or foam padding for shock absorption |

Explore related products

What You'll Learn

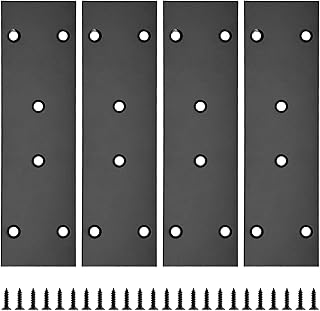

- Reinforce with metal brackets for added structural support and durability under heavy loads

- Apply wood glue and clamps to secure loose joints and prevent wobbling

- Add plywood or hardwood panels to increase thickness and rigidity of the base

- Install corner blocks to distribute weight evenly and reduce stress points

- Use epoxy resin to fill cracks and strengthen weakened areas effectively

Reinforce with metal brackets for added structural support and durability under heavy loads

Metal brackets offer a robust solution for reinforcing the bottom of a long wooden box, particularly when it needs to withstand heavy loads. By strategically placing these brackets at critical stress points—such as the corners and along the length of the box—you can distribute weight more evenly and prevent the wood from warping or splitting. This method is especially effective for boxes used in industrial settings, storage, or transportation, where durability is paramount.

To implement this reinforcement, begin by selecting L-shaped or flat metal brackets made from steel or aluminum, as these materials provide excellent strength-to-weight ratios. Measure and mark the positions where the brackets will be attached, ensuring they align with the box’s structural framework. Use wood screws or bolts designed for metal-to-wood applications to secure the brackets firmly. Pre-drilling holes is essential to avoid splitting the wood, particularly if it’s dry or brittle. For added stability, consider using brackets with a wider base or incorporating additional cross-bracing along the box’s underside.

A comparative analysis reveals that metal brackets outperform alternatives like wooden battens or adhesive reinforcements in terms of load-bearing capacity and longevity. While wooden battens may blend aesthetically, they lack the tensile strength of metal and are prone to rot or insect damage over time. Adhesives, though convenient, can fail under prolonged stress or in humid conditions. Metal brackets, however, maintain their integrity across diverse environments, making them a superior choice for heavy-duty applications.

When executing this reinforcement, caution should be taken to avoid overloading the box beyond its design capacity, even with brackets in place. Regularly inspect the brackets and screws for signs of wear or loosening, especially if the box is subjected to frequent movement or vibration. For boxes exposed to outdoor conditions, opt for galvanized or stainless steel brackets to prevent rust. This proactive approach ensures the reinforcement remains effective and extends the box’s lifespan significantly.

In conclusion, reinforcing the bottom of a long wooden box with metal brackets is a practical and efficient way to enhance its structural integrity and durability. By following precise installation steps and selecting appropriate materials, you can create a reliable solution tailored to heavy loads. This method not only strengthens the box but also provides peace of mind, knowing it can handle demanding tasks without compromise.

Optimal Wood Therapy Duration: Mastering At-Home Sessions for Best Results

You may want to see also

Explore related products

Apply wood glue and clamps to secure loose joints and prevent wobbling

Loose joints are a common culprit behind wobbly wooden boxes, compromising both stability and longevity. Wood glue, when applied correctly, acts as a powerful adhesive, filling gaps and creating a bond stronger than the wood itself. Clamps, acting as temporary vices, ensure even pressure during drying, preventing warping and guaranteeing a tight fit. This simple yet effective technique is a cornerstone of woodworking, transforming a shaky structure into a sturdy, reliable container.

Wood glue selection is crucial. Opt for a high-quality, waterproof PVA (polyvinyl acetate) glue suitable for woodworking. Apply a generous amount to both joint surfaces, ensuring complete coverage. Avoid over-application, as excess glue will squeeze out and require cleanup. Clamping pressure should be firm but not excessive, as too much force can damage the wood. Aim for a pressure that closes the joint tightly without causing distortion.

The clamping time depends on the glue's drying instructions, typically ranging from 30 minutes to several hours. Patience is key; rushing the process can lead to weak bonds. Once dry, remove the clamps and inspect the joint. If any gaps remain, reapply glue and reclamp, ensuring a complete seal. This meticulous approach guarantees a robust connection, eliminating wobble and ensuring the box's structural integrity.

For best results, consider using a combination of clamps, such as F-clamps for even pressure distribution and bar clamps for longer reaches. Additionally, reinforcing the joint with wooden dowels or screws can provide extra strength, especially for heavily used boxes. By combining the adhesive power of wood glue with the precision of clamping, you can effectively secure loose joints, transforming a wobbly wooden box into a sturdy and reliable storage solution.

Clearcoat Drying Time on Wood: Factors Affecting Cure and Finish

You may want to see also

Explore related products

Add plywood or hardwood panels to increase thickness and rigidity of the base

One effective method to reinforce the bottom of a long wooden box is to add plywood or hardwood panels, which significantly increase both thickness and rigidity. This approach is particularly useful for boxes that bear heavy loads or require enhanced durability. By layering additional material, you distribute weight more evenly and reduce the risk of warping or cracking under pressure. For optimal results, select a panel thickness that complements the existing base without adding excessive weight—typically, a ¼-inch to ½-inch panel works well for most applications.

When implementing this technique, precision is key. Begin by measuring the interior dimensions of the box’s base to ensure the panel fits snugly. Use a table saw or circular saw to cut the plywood or hardwood to size, allowing for a slight margin (about 1/16-inch) to account for expansion due to humidity. Secure the panel using wood glue and reinforced screws or nails spaced every 6 to 8 inches along the edges and center. Pre-drilling holes prevents splitting, especially when working with hardwood. Sand any rough edges to ensure a smooth, seamless integration with the existing structure.

Comparing plywood to hardwood reveals distinct advantages for each. Plywood, with its layered construction, offers excellent resistance to moisture and is more flexible, making it ideal for boxes exposed to varying environmental conditions. Hardwood, on the other hand, provides superior strength and a more refined aesthetic, though it is heavier and more expensive. The choice depends on the box’s intended use—plywood for practicality, hardwood for premium applications. Both materials, when properly installed, transform a weak base into a robust foundation capable of withstanding significant stress.

A practical tip for maximizing this reinforcement method is to consider the box’s overall design. If the sides are thin or flexible, adding a thicker base alone may not suffice; instead, pair this technique with corner bracing or additional side supports for comprehensive strength. Additionally, applying a coat of polyurethane or varnish after installation protects the new panel from moisture and wear, extending the box’s lifespan. With careful planning and execution, adding plywood or hardwood panels not only strengthens the bottom but also elevates the box’s functionality and appearance.

Mastering Wood Bending: Techniques, Time, and Tips for Perfect Curves

You may want to see also

Explore related products

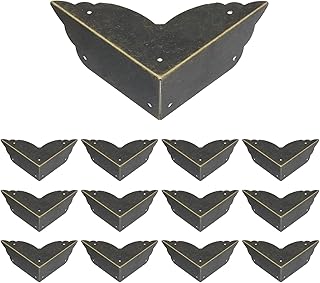

Install corner blocks to distribute weight evenly and reduce stress points

Long wooden boxes, especially those subjected to heavy loads or frequent movement, often suffer from stress points at their corners. These weak spots can lead to cracking, warping, or even structural failure over time. Installing corner blocks is a simple yet effective solution to mitigate this issue. By strategically placing solid wooden blocks at each corner, you redistribute the weight more evenly across the box's bottom, reducing the concentrated pressure that typically accumulates at these angles.

The process begins with selecting the right material for your corner blocks. Hardwoods like oak or maple are ideal due to their strength and durability, but softer woods can suffice for lighter applications. Ensure the blocks are cut to fit snugly into the corners, with dimensions that match the box's thickness and depth. For a 12-inch deep box, for example, a 2x2-inch block extending the full height of the side panels would provide ample support. Secure each block using wood glue and reinforced screws, ensuring a tight bond that can withstand the box's intended load.

A critical aspect of this method is proper alignment. Misaligned corner blocks can create new stress points rather than alleviating them. Use a square to ensure each block is perfectly perpendicular to the sides and bottom of the box. Additionally, pre-drilling screw holes prevents the wood from splitting, especially when working with hardwoods. For added stability, consider reinforcing the blocks with metal brackets or plates, particularly if the box will bear significant weight or endure rough handling.

Comparing this approach to other reinforcement methods, such as adding a solid plywood base or using metal straps, corner blocks offer a balance of simplicity and effectiveness. While a solid base provides uniform support, it adds considerable weight and material cost. Metal straps, on the other hand, may not address the corner stress points as directly as blocks do. Corner blocks, when installed correctly, enhance structural integrity without overcomplicating the design or significantly increasing the box's weight.

In practice, this technique is particularly useful for DIY enthusiasts or professionals crafting storage crates, toolboxes, or even planter boxes. For instance, a 4-foot long wooden planter filled with soil can weigh several hundred pounds, placing immense strain on its corners. By installing 3-inch hardwood blocks at each corner, you not only distribute this weight more evenly but also extend the planter's lifespan. Regularly inspect the blocks for signs of wear, especially if the box is exposed to moisture, and reapply wood sealant as needed to maintain their durability.

Spider Wood Durability: Lifespan and Maintenance Tips for Aquarium Use

You may want to see also

Explore related products

Use epoxy resin to fill cracks and strengthen weakened areas effectively

Epoxy resin stands out as a versatile and durable solution for reinforcing the bottom of a long wooden box, particularly in areas weakened by cracks or wear. Its adhesive properties and ability to form a rigid, waterproof bond make it ideal for structural repairs. When applied correctly, epoxy not only fills gaps but also distributes stress evenly, preventing further damage. This method is especially effective for wooden boxes subjected to heavy loads or environmental stress, ensuring longevity without compromising aesthetics.

To begin, prepare the damaged area by cleaning it thoroughly. Remove any debris, dust, or loose wood fibers using a stiff brush or compressed air. For deeper cracks, use a rotary tool with a sanding drum to widen the gap slightly, creating a better surface for adhesion. Mix the epoxy resin according to the manufacturer’s instructions, typically combining equal parts resin and hardener. For small repairs, a 1:1 ratio by volume is common, but always verify the specific product guidelines. Apply the mixture generously into the crack, using a putty knife or spatula to ensure it penetrates fully. For larger areas, consider adding fiberglass mesh or wooden dowels coated in epoxy to enhance structural integrity.

One of the key advantages of epoxy resin is its adaptability to various conditions. Unlike traditional wood fillers, epoxy cures to a harder finish, making it resistant to moisture and temperature fluctuations. This is particularly beneficial for wooden boxes used outdoors or in humid environments. However, caution must be exercised during application. Epoxy has a limited working time, typically 20–40 minutes depending on the product, after which it begins to harden. Plan your repair in stages if dealing with extensive damage, and work in a well-ventilated area to avoid inhaling fumes.

For optimal results, consider sanding the cured epoxy to achieve a smooth finish. Once hardened, epoxy can be sanded, painted, or stained to match the surrounding wood. If the box’s bottom will bear significant weight, reinforce the repair by attaching a thin plywood or hardwood sheet underneath, secured with epoxy and screws. This dual approach combines the strength of epoxy with the stability of additional material, creating a robust solution. Regularly inspect the box post-repair, especially if used in demanding conditions, to ensure the epoxy remains intact and effective.

In comparison to alternatives like wood glue or metal brackets, epoxy resin offers a more seamless and permanent fix. While wood glue may suffice for minor cracks, it lacks the structural resilience of epoxy. Metal brackets, though strong, can alter the box’s appearance and add unnecessary weight. Epoxy, on the other hand, remains invisible once cured and maintains the box’s original design. By choosing epoxy resin, you invest in a repair that not only strengthens weakened areas but also preserves the wooden box’s functionality and aesthetic appeal for years to come.

Heating Your Pool with Wood: Time Estimates and Tips

You may want to see also

Frequently asked questions

You can use plywood, hardwood boards, metal sheets, or fiberglass to reinforce the bottom of the box, depending on the desired strength and durability.

Use wood glue, screws, or brackets to securely attach additional wooden slats, battens, or a thicker base panel to the existing bottom for added strength.

Yes, installing metal or wooden corner braces at the joints can help distribute weight and reinforce the bottom, especially if the box is prone to sagging.

Adding a second layer of plywood or hardwood can significantly strengthen the bottom, especially if the box will carry heavy loads or be used frequently.

Apply a waterproof sealant or paint to protect the wood from moisture, and ensure the box is stored in a dry environment to minimize warping.