Traveling with long pieces of wood requires careful planning and preparation to ensure both the safety of the wood and compliance with transportation regulations. Whether you're transporting lumber for a project or moving wooden items, it's essential to measure the wood and verify the size restrictions of your chosen mode of travel, such as airlines, trains, or vehicles. Securely packaging the wood in protective materials like bubble wrap or cardboard and using sturdy straps or ropes to prevent shifting during transit is crucial. Additionally, consider disassembling or cutting the wood to more manageable lengths if possible, and always check with transportation authorities for any specific guidelines or permits required for carrying oversized items. Proper planning will minimize the risk of damage and ensure a smooth journey.

| Characteristics | Values |

|---|---|

| Transport Method | Truck, trailer, van, or specialized lumber carrier |

| Wood Length | Typically up to 20 feet (6 meters) for standard vehicles, longer lengths require specialized transport |

| Securing Method | Ratchet straps, bungee cords, rope, or specialized lumber racks |

| Placement | Wood should be placed lengthwise, centered, and secured to prevent shifting |

| Vehicle Requirements | Vehicle must have sufficient length, width, and weight capacity to accommodate the wood |

| Legal Requirements | Check local laws for maximum length, width, and load limits; may require flags or lights for overhanging loads |

| Safety Precautions | Ensure wood is securely fastened, avoid overloading, and use padding to prevent damage to vehicle or wood |

| Loading/Unloading | Use proper lifting techniques, ramps, or forklifts for heavy or long pieces |

| Weather Considerations | Protect wood from moisture with tarps or waterproof covers |

| Cost | Varies based on transport method, distance, and specialized equipment needs |

| Environmental Impact | Consider fuel efficiency and emissions when choosing transport method |

| Insurance | Ensure adequate coverage for transported goods and potential liabilities |

| Alternative Methods | Shipping via freight, rail, or sea for long distances or large quantities |

| Packaging | Use crates, pallets, or wrapping for added protection during transport |

| Documentation | Keep records of load details, permits, and inspections as required |

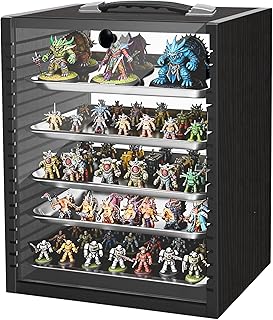

Explore related products

What You'll Learn

- Secure Packaging: Use bubble wrap, foam, and sturdy cardboard to protect wood from damage during transit

- Transport Options: Choose between personal vehicle, freight services, or specialized carriers for long wood pieces

- Legal Compliance: Check local laws and permits required for transporting oversized wooden items across regions

- Handling Techniques: Use straps, ropes, and padding to safely load and unload long wood without breakage

- Storage Solutions: Store wood horizontally on flat surfaces or in racks to prevent warping during travel

Secure Packaging: Use bubble wrap, foam, and sturdy cardboard to protect wood from damage during transit

Long pieces of wood are inherently vulnerable during transit due to their length and rigidity. Even minor impacts can cause cracks, splinters, or warping, compromising both aesthetics and structural integrity. To mitigate these risks, secure packaging is non-negotiable. Bubble wrap, foam, and sturdy cardboard form the trifecta of protection, each material serving a distinct purpose in safeguarding your wood.

Bubble wrap, with its air-filled pockets, excels at absorbing shock and preventing surface scratches. For long wood pieces, use a layer of large-bubble wrap (bubble diameter of at least 1 inch) to cover the entire length, securing it with tape at regular intervals. This initial layer acts as a cushion against bumps and vibrations during transport.

Foam, particularly closed-cell varieties like polyethylene or EVA, provides a denser, more rigid barrier. Cut foam sheets to fit the wood's dimensions, creating a snug enclosure. For added protection, consider using foam planks or tubes along the wood's length, especially if it has a delicate grain or finish. This internal framework distributes pressure evenly, minimizing the risk of localized damage.

Sturdy cardboard serves as the outer shell, providing structural integrity and a final layer of defense. Choose double-walled corrugated cardboard for maximum strength. When constructing the box, ensure the wood fits snugly but not tightly, allowing space for the bubble wrap and foam layers. Reinforce corners and edges with additional cardboard strips or packing tape for added durability.

When assembling your packaging, follow a systematic approach: start with the bubble wrap, add the foam layers, and finally, enclose everything in the cardboard box. Secure all seams and openings with high-quality packing tape, paying extra attention to stress points. Label the package clearly, indicating its fragility and the correct orientation for handling.

While this method requires time and materials, the investment is justified by the peace of mind it provides. Proper packaging not only protects your wood but also demonstrates professionalism and care, whether you're shipping a custom furniture piece or transporting a prized woodworking project. Remember, the goal is not just to survive the journey but to arrive in pristine condition, ready to fulfill its intended purpose.

Seasoning Gumball Wood: Understanding the Timeframe for Optimal Results

You may want to see also

Explore related products

Transport Options: Choose between personal vehicle, freight services, or specialized carriers for long wood pieces

Transporting long wood pieces requires careful consideration of size, weight, and destination. Each transport option—personal vehicle, freight services, or specialized carriers—offers distinct advantages and limitations. Understanding these can help you make an informed decision tailored to your needs.

Personal Vehicle: Feasibility and Preparation

Using your own vehicle is often the most cost-effective option for shorter distances or smaller quantities. However, it demands meticulous planning. Measure the wood and your vehicle’s interior to ensure compatibility. For lengths exceeding your vehicle’s size, consider roof racks or trailers, but verify local regulations and weight limits. Secure the wood with ratchet straps or bungee cords, padding contact points to prevent damage. Drive cautiously, avoiding sharp turns and sudden stops. This method is ideal for DIY enthusiasts transporting wood for personal projects, but it’s impractical for oversized or heavy loads.

Freight Services: Balancing Cost and Convenience

Freight services are a middle ground for longer distances or larger volumes. Companies like FedEx Freight or UPS Freight offer less-than-truckload (LTL) options, which are cost-effective for partial shipments. Prepare the wood by bundling it securely and wrapping it in protective materials like shrink wrap or cardboard. Clearly label dimensions and weight to avoid delays. Freight services often require loading docks or forklifts, so ensure your pickup and drop-off locations are equipped. While affordable, this option may involve longer transit times and less personalized handling, making it less suitable for fragile or high-value wood.

Specialized Carriers: Precision for Oversized Loads

For exceptionally long or heavy wood pieces, specialized carriers are the safest choice. These professionals use flatbed trucks or custom trailers designed to handle oversized cargo. They manage permits, route planning, and securement, ensuring compliance with transportation laws. Specialized carriers are ideal for commercial projects or high-value materials like timber beams or exotic hardwoods. While more expensive, they minimize the risk of damage and legal complications. If your wood exceeds 16 feet in length or weighs over 2,000 pounds, this option is often non-negotiable.

Comparative Analysis: Choosing the Right Fit

The decision hinges on three factors: distance, volume, and value. Personal vehicles suit short hauls of moderate-sized wood, while freight services excel for mid-range needs. Specialized carriers are reserved for extreme cases. Always weigh the cost against potential risks—damage, delays, or legal issues. For instance, saving $200 by using a personal vehicle might not justify the risk of damaging a $1,000 hardwood plank. Prioritize safety and practicality, and don’t hesitate to consult professionals for oversized loads.

Practical Tips for All Methods

Regardless of your choice, always measure twice and plan once. Use weather-resistant covers for outdoor transport and inspect all equipment before loading. For freight and specialized carriers, document the wood’s condition pre-shipment to resolve disputes. Finally, communicate clearly with service providers about your needs to avoid surprises. With the right approach, transporting long wood can be seamless, whether you’re a hobbyist or a professional.

Crafting a Sleek, Long Simple Wood Desk: DIY Guide

You may want to see also

Explore related products

Legal Compliance: Check local laws and permits required for transporting oversized wooden items across regions

Transporting oversized wooden items across regions isn’t just a logistical challenge—it’s a legal minefield. Local laws vary widely, and what’s permissible in one area might be prohibited in another. For instance, some jurisdictions classify wood over 12 feet in length as "oversized cargo," requiring special permits or escorts. Ignoring these regulations can result in hefty fines, impoundment of your vehicle, or even legal action. Before hitting the road, research the specific laws of every region you’ll traverse, including state, county, and municipal regulations.

Start by identifying the dimensions and weight of your wooden cargo. Measure its length, width, and height, and calculate its total weight, including any packaging or securing materials. Cross-reference these details with local transportation codes, which often specify maximum allowable dimensions without a permit. For example, in California, wood exceeding 4 inches in diameter and 8 feet in length may require a permit, while in Texas, the threshold is 10 feet. Online resources like state DOT websites or transportation law databases can provide precise guidelines.

Once you’ve determined permit requirements, apply well in advance. Permits for oversized loads often involve fees ranging from $25 to $500, depending on the region and cargo size. Some areas mandate additional documentation, such as route plans or proof of insurance. Be prepared for potential delays—processing times can take anywhere from 24 hours to several weeks. If your route crosses international borders, consult customs regulations and consider hiring a freight forwarder to navigate complex paperwork.

Securing your cargo isn’t just about safety—it’s a legal obligation. Most regions require oversized wood to be properly marked with flags, lights, or reflective tape to enhance visibility. For example, in New York, loads over 8 feet wide must display red flags during daylight and red lights at night. Failure to comply can void your permit and lead to penalties. Invest in high-quality tie-downs, straps, and padding to prevent shifting during transit, and ensure your vehicle’s load capacity isn’t exceeded.

Finally, consider hiring a professional transporter if the legal and logistical hurdles seem overwhelming. Specialized carriers are well-versed in regional laws and often have pre-established relationships with permitting agencies. While this option may increase costs by 20–50%, it minimizes the risk of non-compliance and ensures a smoother journey. Whether you choose to DIY or outsource, prioritizing legal compliance isn’t just about avoiding trouble—it’s about protecting your cargo, your vehicle, and everyone sharing the road.

Elle Woods' Class Skipping Habits: Uncovering Her Academic Absences

You may want to see also

Explore related products

Handling Techniques: Use straps, ropes, and padding to safely load and unload long wood without breakage

Long pieces of wood are notoriously prone to cracking or warping when mishandled during transport. Their length amplifies leverage forces, turning minor bumps into major stress points. To counteract this, securing them with straps, ropes, and padding isn’t just a suggestion—it’s a necessity. Straps distribute pressure evenly along the wood’s length, while ropes provide additional restraint against shifting. Padding, such as foam or blankets, absorbs shocks and prevents surface damage. Together, these tools form a protective system that minimizes the risk of breakage, ensuring your wood arrives intact.

Consider the loading process as a step-by-step procedure requiring precision. First, lay padding along the truck bed or trailer floor to create a cushioned base. Position the wood lengthwise, ensuring it doesn’t overhang the vehicle’s edges, as this increases the risk of bending or snapping. Next, secure the wood with straps placed at regular intervals—every 3 to 4 feet is ideal. Tighten them firmly, but not so much that they dent the wood. Use ropes as secondary ties, crisscrossing them over the load to prevent lateral movement. For extra stability, add vertical supports or braces if transporting exceptionally long pieces, like 16-foot planks.

While these techniques are effective, they’re not foolproof without proper caution. Over-tightening straps can cause compression damage, while under-tightening allows dangerous shifting. Always test the load’s stability by gently rocking it before driving. Avoid sharp turns or sudden stops, as these can dislodge even well-secured wood. If transporting in a pickup truck, consider adding a header board at the cab end to prevent forward movement. For longer hauls, periodically stop to inspect the straps and padding, adjusting as needed to maintain tension and protection.

The choice of materials matters as much as the technique. Use ratchet straps with wide, flat hooks to minimize indentations, and opt for natural fiber ropes that grip better than slippery synthetics. For padding, closed-cell foam is superior to blankets, as it resists moisture and maintains its shape. If reusing materials, inspect them for wear—frayed ropes or cracked straps can fail mid-transit. Investing in high-quality tools not only protects your wood but also saves time and frustration in the long run.

In practice, these handling techniques transform a precarious task into a manageable one. A carpenter transporting 12-foot oak beams, for instance, might use four straps and two layers of foam padding, securing the load in under 15 minutes. By contrast, neglecting these steps could result in cracked wood, wasted materials, and potential safety hazards. The key takeaway? Treat securing long wood as a skill to master, not a chore to rush. With the right tools and attention to detail, you can ensure safe, damage-free transport every time.

Driftwood vs. Stone: Which Natural Material Outlasts the Other?

You may want to see also

Explore related products

Storage Solutions: Store wood horizontally on flat surfaces or in racks to prevent warping during travel

Storing wood horizontally is a critical practice to maintain its integrity during travel, particularly for long pieces prone to warping. Vertical storage can cause stress along the length of the wood, leading to bending or twisting over time. By laying wood flat on a stable surface or securing it in a horizontal rack, you distribute its weight evenly, reducing the risk of deformation. This method is especially vital for hardwoods like oak or maple, which are denser and more susceptible to warping under their own weight.

Consider the surface where the wood will rest. A flat, dry, and clean area is essential to prevent moisture absorption or surface damage. Plywood sheets or specialized wood storage racks with slatted designs are ideal, as they allow air circulation and minimize contact points that could create pressure marks. For added protection, place a layer of foam or felt beneath the wood to cushion it from rough surfaces. If using racks, ensure the supports are evenly spaced—no more than 24 inches apart for longer pieces—to provide adequate support along the entire length.

Racks designed for horizontal storage are a practical investment for frequent travelers or professionals. These systems often feature adjustable arms or tiers to accommodate varying lengths and thicknesses of wood. When constructing your own rack, use galvanized steel or treated wood to prevent rust or rot, especially if the storage area is exposed to humidity. Secure the wood with straps or bungee cords, but avoid over-tightening, as this can create tension and lead to warping. Always inspect the rack’s stability before loading to ensure it can bear the weight without tipping.

A comparative analysis of horizontal versus vertical storage reveals significant advantages for the former. Vertical storage, while space-efficient, places the entire weight of the wood on its lower end, causing stress that accumulates during travel. Horizontal storage, on the other hand, spreads the weight across the entire length, preserving the wood’s natural shape. For example, a 12-foot plank stored vertically for a week may show noticeable warping, whereas the same plank stored horizontally remains straight and usable. This difference underscores the importance of prioritizing structural integrity over convenience.

In conclusion, horizontal storage on flat surfaces or in racks is a proven method to prevent warping during travel. By focusing on even weight distribution, proper surface preparation, and secure racking systems, you can safeguard your wood’s quality and usability. Whether you’re a hobbyist or a professional, adopting this storage solution ensures your materials arrive in the same condition they left, ready for your next project.

Perfect Timing: When to Use Wood After Placing It in Your Wber

You may want to see also

Frequently asked questions

Use roof racks with proper straps or tie-downs, ensure the wood is padded to prevent damage, and secure it tightly to avoid shifting during transit.

Yes, check local laws for length limits and flagging requirements for overhanging loads. Most regions require red flags or lights for visibility if the load extends beyond the vehicle.

Cover the wood with waterproof tarps, use sealants on exposed ends to prevent moisture absorption, and ensure it’s securely tied to avoid movement that could cause damage.