Storing long pieces of wood efficiently and organized is essential for maintaining a safe and functional workspace, whether in a professional workshop or a home garage. Proper storage not only maximizes space but also prevents damage to the wood and reduces the risk of accidents. Key strategies include utilizing vertical storage solutions like wall-mounted racks or freestanding lumber carts, which keep wood off the floor and easily accessible. Additionally, categorizing wood by type, length, and thickness ensures quick retrieval for projects. Implementing labeling systems and using protective covers can further safeguard the wood from moisture, pests, and warping. By adopting these methods, you can create a tidy, organized storage system that enhances productivity and prolongs the life of your materials.

| Characteristics | Values |

|---|---|

| Storage Method | Vertical Rack, Horizontal Rack, Wall-Mounted Rack, Ceiling-Mounted Rack, Lean-To Storage, Rolling Cart, Wood Storage Bin, Outdoor Wood Rack |

| Space Requirements | Varies based on method; vertical and ceiling-mounted racks save floor space |

| Capacity | Depends on rack size; can hold 5–50+ pieces of wood |

| Accessibility | Vertical and horizontal racks offer easy access; ceiling-mounted racks may require tools |

| Stability | Wall-mounted and ceiling-mounted racks require secure installation; freestanding racks need a stable base |

| Protection | Outdoor racks should be weather-resistant; indoor racks may include covers or bins for dust protection |

| Cost | DIY options ($20–$100), pre-made racks ($50–$300+), professional installation ($200–$500+) |

| Material | Wood, metal, PVC, or combination; choose based on durability and environment |

| Organization | Labeling, color-coding, or categorizing by size/type enhances organization |

| Portability | Rolling carts offer mobility; other methods are typically stationary |

| Safety | Ensure racks are securely anchored to prevent tipping; avoid overloading |

| DIY Feasibility | Vertical and horizontal racks are beginner-friendly; ceiling-mounted racks may require advanced skills |

| Maintenance | Regularly inspect for wear, rust, or damage; clean as needed |

| Sustainability | Use recycled materials or sustainably sourced wood for eco-friendly options |

| Aesthetics | Choose designs that complement your workspace or outdoor area |

| Scalability | Modular systems allow for expansion as wood collection grows |

Explore related products

$38.24 $49.99

What You'll Learn

Vertical Storage Racks

When selecting or building a vertical storage rack, prioritize stability and weight distribution. A well-designed rack should have a wide base and secure anchoring to prevent tipping, especially when loaded with heavy hardwoods. Adjustable dividers or slots are essential for accommodating different wood thicknesses and lengths, ensuring each piece remains upright and secure. For DIY enthusiasts, constructing a rack from 2x4s and plywood is cost-effective, but pre-fabricated metal options provide durability for professional settings. Always ensure the rack’s height aligns with your ceiling clearance and that it’s placed against a sturdy wall for added support.

One of the standout advantages of vertical storage racks is their ability to improve workflow efficiency. By storing wood vertically, you eliminate the need to shuffle through horizontal piles, saving time and reducing frustration. Labeling each slot or section by wood type or project can further streamline organization, making it easier to locate specific pieces. For those with limited space, consider adding wheels to the rack’s base for mobility, allowing it to be moved as needed without compromising stability.

However, vertical racks aren’t without limitations. They’re less ideal for extremely long or heavy pieces, which may require additional bracing or alternative storage methods. Overloading the rack can compromise its integrity, so adhere to weight limits and distribute materials evenly. Regularly inspect the rack for signs of wear or damage, particularly in high-traffic areas, to ensure long-term safety. Despite these considerations, when used correctly, vertical storage racks offer a sleek, efficient solution for wood organization that’s hard to beat.

Understanding Standard Wood Lengths: A Comprehensive Guide to Lumber Sizes

You may want to see also

Explore related products

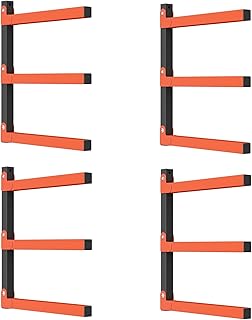

Wall-Mounted Wood Holders

Installing a wall-mounted wood holder requires careful planning. Start by assessing the weight and length of the wood you intend to store. For heavier pieces, opt for metal brackets or reinforced wooden racks that can handle the load. Ensure the wall studs are located and marked before drilling to provide a solid anchor. A common mistake is underestimating the weight of long wood pieces, leading to sagging or failure. Use a level to align the brackets evenly, and consider adding a slight backward tilt to prevent wood from sliding forward. For added stability, incorporate adjustable arms or stoppers to keep the wood in place.

One of the standout advantages of wall-mounted holders is their versatility. They can be customized to fit various wood lengths and thicknesses, making them suitable for hobbyists and professionals alike. For example, adjustable bracket systems allow you to reposition holders as your storage needs change. Additionally, these setups can be combined with labeling systems or color-coding for easy identification of different wood types. This level of organization not only saves time but also enhances workflow efficiency, especially in busy workshops.

While wall-mounted wood holders offer numerous benefits, they’re not without limitations. They require a sturdy wall capable of supporting the weight, which may not be feasible in all spaces. Renters or those with limited wall space might find this solution restrictive. Moreover, very long pieces of wood may extend too far outward, creating a hazard if not properly secured. To mitigate this, consider pairing wall-mounted holders with ceiling-mounted systems for exceptionally long items. Regularly inspect the brackets and anchors for wear and tear to ensure long-term safety and functionality.

In conclusion, wall-mounted wood holders are a practical and space-saving solution for organizing long pieces of wood. With proper installation and customization, they can transform cluttered spaces into efficient storage areas. Whether you’re a DIY enthusiast or a professional woodworker, this method offers a blend of accessibility, protection, and adaptability. By addressing potential challenges and tailoring the setup to your needs, you can create a storage system that not only works but excels in keeping your workspace tidy and functional.

Vinyl vs. Wood Windows: Which Material Offers Longer Durability?

You may want to see also

Explore related products

$30.09 $42.99

$99.99 $119.99

Ceiling Suspension Systems

Installation Steps: Begin by assessing your ceiling’s load-bearing capacity to ensure it can support the weight of the system and stored wood. Install heavy-duty tracks or rails parallel to the length of the wood you intend to store. Use lag bolts or structural screws for secure mounting, especially in concrete or steel ceilings. Attach adjustable hooks or slings to the tracks, spaced evenly to distribute weight and prevent sagging. For added stability, consider cross-bracing the system with additional supports.

Material Considerations: Choose suspension components rated for the weight and length of your wood. Galvanized steel or powder-coated aluminum hooks are durable and resistant to corrosion, ideal for humid environments. For softer woods prone to denting, use padded slings or cradles to minimize pressure points. Ensure all hardware is compatible with the track system to avoid slippage or failure.

Safety and Accessibility: Always store wood with the lightest pieces at the highest points to reduce the risk of injury from falling materials. Incorporate a pulley or winch system for easier lifting and lowering of heavier planks. Regularly inspect the suspension system for wear, tightening bolts and replacing damaged components as needed. Label storage zones by wood type or project to streamline retrieval.

Comparative Advantage: Unlike wall-mounted racks or floor stands, ceiling suspension systems maximize space efficiency by utilizing a dimension often overlooked. They are particularly advantageous in small workshops or high-ceilinged areas, where vertical storage minimizes clutter. While initial installation requires more effort than horizontal solutions, the long-term benefits in organization and accessibility make it a worthwhile investment for serious woodworkers or professionals.

Durability of Cemented Wood Posts: Lifespan and Maintenance Tips

You may want to see also

Explore related products

Horizontal Floor Organizers

Storing long pieces of wood horizontally on the floor is a practical solution for workshops with limited wall space or renters who cannot install permanent fixtures. This method maximizes floor area while keeping materials accessible. To implement this system, start by selecting a dedicated zone in your workspace, ideally near the entrance for easy loading and unloading. Use sturdy wooden or metal racks designed to handle the weight of lumber, ensuring they are anchored to the floor for stability.

A key advantage of horizontal floor organizers is their scalability. Begin with a single rack and add more as your collection grows. For added organization, label each rack with the type or size of wood it holds. Incorporate dividers or adjustable arms to prevent pieces from shifting or toppling. This setup is particularly effective for storing lumber of varying lengths, as it allows for flexible arrangement without the constraints of fixed compartments.

However, horizontal storage requires careful planning to avoid clutter and safety hazards. Maintain a clear pathway around the racks to ensure safe movement within the workspace. Regularly inspect the system for signs of wear or instability, especially if storing heavy hardwoods. For added protection, place rubber mats or anti-slip pads beneath the racks to prevent floor damage and improve grip.

To optimize space further, consider stacking shorter pieces vertically within the horizontal racks using brackets or supports. This hybrid approach combines the accessibility of horizontal storage with the vertical efficiency often seen in wall-mounted systems. For those with uneven floors, use adjustable feet on the racks to ensure a level setup. With proper installation and maintenance, horizontal floor organizers offer a durable, adaptable solution for long-term wood storage.

Yellowjackets' Survival Timeline: How Long Do They Thrive in the Woods?

You may want to see also

Explore related products

Labeling and Categorizing Methods

Effective labeling and categorizing methods are the backbone of any organized wood storage system. Without a clear system, long pieces of wood can quickly become a tangled mess, making it difficult to find the right piece when you need it. Start by categorizing your wood based on type (hardwood vs. softwood), length, and thickness. Use color-coded labels or tags to differentiate between categories, ensuring that even at a glance, you can identify where each piece belongs. For example, red tags for hardwoods, blue for softwoods, and green for specialty woods like plywood or MDF.

Once categorized, implement a labeling system that includes essential details such as wood species, dimensions, and intended use. For instance, a label might read: "Oak, 2x4x8, Furniture Project." This level of specificity saves time and reduces errors when selecting wood for a project. Consider using weather-resistant labels or engraving tools for outdoor storage to ensure longevity. If you’re storing wood in a digital inventory system, sync your physical labels with a barcode or QR code for quick access to additional details like purchase date or supplier information.

A comparative analysis of labeling methods reveals that digital systems, while efficient, may not be practical for all users. For smaller workshops or hobbyists, a simple handwritten label with a permanent marker on a plastic tag can be just as effective. However, for larger operations, investing in a label maker or software-based system can streamline organization and scalability. The key is to choose a method that aligns with your workflow and the volume of wood you handle.

Persuasively, the benefits of a well-executed labeling and categorizing system cannot be overstated. It not only saves time but also minimizes waste by preventing the accidental use of the wrong piece of wood. Additionally, it enhances safety by ensuring that long pieces are stored securely and accessibly, reducing the risk of accidents. For example, clearly labeled racks or bins allow you to quickly identify where to return a piece after use, maintaining order in your workspace.

Instructively, begin by auditing your current wood inventory to determine the most relevant categories for your needs. Then, allocate storage space accordingly, ensuring each category has a designated area. Label both the storage location and the wood itself for consistency. Regularly review and update your system as your inventory or projects evolve. For instance, if you start working with new types of wood, adjust your color-coding or labeling criteria to accommodate them. This proactive approach ensures your system remains functional and efficient over time.

Durability of Eucalyptus Wood: Lifespan of Your Outdoor Table

You may want to see also

Frequently asked questions

The best way is to use vertical storage solutions like wall-mounted racks, leaning racks, or freestanding wood storage systems. These methods save space and keep the wood pieces upright and easy to retrieve.

Store wood in a dry, climate-controlled area to prevent moisture absorption, which can cause warping. Use supports or brackets to distribute weight evenly and avoid placing heavy objects on top of the wood.

DIY solutions include building a simple leaning rack using 2x4s, creating a wall-mounted storage system with pegs or hooks, or using PVC pipes as vertical supports to hold the wood in place.

Use labels or tags to indicate the type, size, and length of the wood. Group similar pieces together and arrange them by frequency of use, placing the most commonly used wood in the most accessible spots.