Mounting a long, flat piece of wood to a wall requires careful planning and execution to ensure stability and durability. Begin by selecting the appropriate tools and materials, such as screws, wall anchors, a level, and a stud finder, to determine the best mounting points. Locate the wall studs for maximum support, or use wall anchors if studs are not available. Measure and mark the positions for the wood, ensuring it is level and aligned with your desired placement. Pre-drill holes in the wood to prevent splitting, then secure it to the wall using screws driven into the studs or anchors. Double-check the alignment and stability before fully tightening the screws, and consider adding additional support brackets for longer pieces to distribute weight evenly and prevent sagging.

| Characteristics | Values |

|---|---|

| Mounting Method | French cleat, Z-clips, brackets, wall studs, or adhesive mounting. |

| Tools Required | Drill, level, measuring tape, screwdriver, stud finder, pencil, and safety gear. |

| Materials Needed | Wood piece, screws, wall anchors (if no studs), French cleat hardware, or Z-clips. |

| Wall Type Compatibility | Drywall, plaster, concrete, or wood walls. |

| Weight Capacity | Depends on mounting method and wall type (e.g., French cleat supports heavy wood). |

| Alignment Technique | Use a level to ensure the wood is straight before securing. |

| Hidden vs. Visible Mounting | French cleat and Z-clips are hidden; brackets are visible. |

| Difficulty Level | Moderate (requires basic DIY skills and precision). |

| Cost | Low to moderate (depends on hardware choice). |

| Time Required | 30 minutes to 2 hours (varies by method and wall type). |

| Maintenance | Minimal; check screws periodically for tightness. |

| Aesthetic Impact | Clean, modern look with hidden mounts; brackets add a visible industrial style. |

| Safety Considerations | Ensure screws are anchored securely; avoid overloading the mount. |

| Customization Options | Paint or stain wood to match decor; choose bracket styles for visible mounts. |

| Environmental Impact | Minimal; use sustainable wood and hardware if desired. |

| Alternative Methods | Adhesive strips for lightweight wood, or professional installation for complex setups. |

Explore related products

What You'll Learn

- Choose Mounting Hardware: Select brackets, French cleats, or Z-clips based on wood weight and wall type

- Measure and Mark: Ensure level placement, mark stud locations, and verify alignment for secure installation

- Prepare the Wood: Drill pilot holes, sand edges, and apply finish for a polished, wall-ready appearance

- Attach Mounting System: Secure brackets or cleats to both wood and wall using appropriate screws or anchors

- Hang and Level: Lift wood onto mounts, check alignment, and adjust for stability and straightness

Choose Mounting Hardware: Select brackets, French cleats, or Z-clips based on wood weight and wall type

Selecting the right mounting hardware is crucial for ensuring your long, flat piece of wood stays securely attached to the wall. The weight of the wood and the type of wall you’re working with are the two primary factors that dictate your choice. Brackets, French cleats, and Z-clips each offer distinct advantages, but their suitability varies depending on these conditions. For instance, a heavy hardwood plank mounted on drywall will require a different approach than a lightweight pine board on a concrete wall. Understanding these nuances will prevent damage, ensure stability, and save you from costly mistakes.

Brackets are a versatile option, ideal for heavier pieces or when you want the hardware to be visible as part of the design. They distribute weight effectively and can be adjusted for leveling. However, they require more wall space and may not suit minimalist aesthetics. For drywall, use hollow wall anchors to secure the brackets, ensuring they can bear the load. On concrete or brick walls, masonry screws provide a robust hold. Always check the weight capacity of the brackets—a 12-inch bracket can typically support 50–100 pounds, depending on the material and installation quality.

French cleats are a sleek, nearly invisible solution, perfect for mounting long pieces of wood flush against the wall. They consist of two interlocking strips: one attached to the wall and the other to the wood. This system is highly effective for distributing weight evenly, making it suitable for heavier items. However, installation requires precision, as the cleats must align perfectly. For drywall, reinforce the area with a stud or use heavy-duty anchors. On solid walls like concrete, ensure the cleat is securely fastened with appropriate screws. French cleats are particularly useful for floating shelves or artwork, providing a clean, professional look.

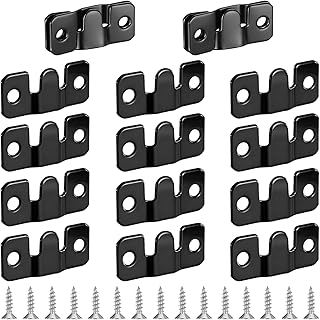

Z-clips offer a nearly invisible mounting solution, ideal for lightweight to medium-weight wood pieces. They consist of two interlocking metal clips: one attached to the wall and the other to the wood. This system allows the wood to sit flush against the wall, creating a seamless appearance. However, Z-clips have limited weight capacity—typically up to 50 pounds—and are best suited for drywall or wood walls. Avoid using them on concrete or brick unless paired with specialized anchors. Their simplicity makes them a favorite for mounting decorative panels or lightweight shelves, but they lack the adjustability of brackets or the weight-bearing capacity of French cleats.

In conclusion, the choice between brackets, French cleats, and Z-clips hinges on the specific demands of your project. For heavy pieces or when visibility is desired, brackets are a reliable choice. French cleats excel in weight distribution and invisibility, making them ideal for larger, flush-mounted items. Z-clips, while limited in weight capacity, provide a minimalist solution for lighter applications. Always consider the wall type and use appropriate anchors or screws to ensure a secure installation. By matching the hardware to the task, you’ll achieve a safe, durable, and aesthetically pleasing result.

Durability of Wood Computer Desks: Lifespan and Maintenance Tips

You may want to see also

Explore related products

Measure and Mark: Ensure level placement, mark stud locations, and verify alignment for secure installation

Precision in measurement and marking is the cornerstone of a successful wall-mounting project, especially when dealing with long, flat pieces of wood. The first step is to determine the desired height and position of the wood on the wall. Use a tape measure to find the midpoint of the wall and the midpoint of the wood, ensuring symmetry. This initial measurement sets the foundation for a balanced and aesthetically pleasing installation. For instance, if you're mounting a wooden shelf, aligning its center with the wall's center creates a visually appealing composition.

Leveling for Perfection: Achieving a level placement is crucial to avoid a crooked or uneven finish. Utilize a spirit level, placing it on top of the wood to check for horizontal alignment. Adjust the position until the bubble is centered, indicating a perfect level. Mark this spot with a pencil, ensuring the wood's edges are flush with the wall. This step is particularly vital for longer pieces, as any tilt will become more noticeable with increased length.

The structural integrity of your installation relies on locating and marking the wall studs. Studs are the vertical framing members behind the wall, providing a secure anchor for screws or nails. Use a stud finder to detect these studs, marking their positions with tape or a pencil. Typically, studs are spaced 16 or 24 inches apart, so measure accordingly to locate them accurately. For a long piece of wood, aim to secure it to at least two studs for maximum stability.

Alignment Verification: Before drilling or nailing, double-check the alignment. Place the wood against the marked spots, ensuring it aligns with the level marks and stud locations. Use a helper to hold the wood in place while you step back and assess the alignment from a distance. This visual check ensures the wood is straight and positioned as intended. If adjustments are needed, make them now to avoid the hassle of correcting mistakes later.

In the context of wall mounting, the 'measure twice, cut once' adage holds true. Accurate measurements and meticulous marking are the keys to a professional-looking installation. By ensuring level placement, identifying stud locations, and verifying alignment, you guarantee a secure and visually appealing result. This process demands patience and attention to detail, but the outcome is a sturdy and perfectly positioned wooden feature on your wall.

Durability of Wood Wedding Rings: Lifespan and Care Tips

You may want to see also

Explore related products

$7.59 $8.99

Prepare the Wood: Drill pilot holes, sand edges, and apply finish for a polished, wall-ready appearance

Before mounting a long, flat piece of wood to the wall, proper preparation ensures durability, safety, and aesthetic appeal. Start by drilling pilot holes to prevent splitting, especially in hardwoods like oak or walnut. Use a drill bit slightly smaller than your screw diameter, spacing holes evenly along the wood’s length to distribute weight. For a 6-foot piece, aim for 4–6 holes, depending on thickness and wall stud placement. This step is critical when working with dense or brittle materials, as it minimizes the risk of damage during installation.

Next, sanding the edges transforms raw wood into a refined, wall-ready piece. Begin with 120-grit sandpaper to remove rough spots and splinters, then progress to 220-grit for a smooth finish. Pay special attention to corners and ends, where splinters are most likely to occur. For a professional touch, round slightly sharp edges to create a softer profile. This not only enhances safety but also ensures the wood sits flush against the wall, eliminating gaps that could detract from its appearance.

Applying a finish is the final step in preparing the wood, protecting it from moisture, stains, and wear while enhancing its natural beauty. Choose a finish based on the desired look and the wood’s exposure—polyurethane for durability, stain for color enhancement, or wax for a matte, natural finish. Apply in thin, even coats, allowing each layer to dry fully before sanding lightly (400-grit) between applications. Two to three coats are typically sufficient, but high-traffic areas may benefit from an additional layer. This process not only preserves the wood but also elevates its visual appeal, making it a standout feature in any space.

While these steps may seem time-consuming, they are essential for a polished and long-lasting installation. Skipping pilot holes risks structural integrity, rough edges compromise safety and aesthetics, and unfinished wood is prone to damage. By investing effort in preparation, you ensure the wood not only mounts securely but also remains a striking addition to your wall for years to come. Think of it as laying the foundation for a piece that’s as functional as it is beautiful.

Boiling Palo Azul Wood Chips: Optimal Time for Best Results

You may want to see also

Explore related products

Attach Mounting System: Secure brackets or cleats to both wood and wall using appropriate screws or anchors

Securing a long, flat piece of wood to a wall requires a mounting system that balances strength and precision. Brackets or cleats are the backbone of this setup, acting as the intermediary between the wood and the wall. The key lies in choosing the right hardware—screws for wood and anchors for walls—to ensure a stable and lasting connection. For instance, using 2-inch wood screws for the brackets and wall anchors rated for the weight of the wood can prevent sagging or detachment over time. Always pre-drill holes in both the wood and the wall to avoid splitting or damaging the materials.

The process begins with positioning the brackets or cleats along the length of the wood. A common rule of thumb is to place one bracket every 16 to 24 inches, depending on the wood’s weight and the wall’s material. For heavier pieces or weaker walls, err on the side of closer spacing. Once the brackets are aligned, mark the screw holes on both the wood and the wall. If mounting on drywall, use anchors like plastic wall plugs or toggle bolts to ensure the screws grip securely. For concrete or brick walls, masonry anchors and a hammer drill are essential to penetrate the surface without cracking it.

A persuasive argument for this method is its versatility and reliability. Unlike adhesive solutions, which can fail under weight or over time, brackets and cleats provide a mechanical bond that distributes the load evenly. This approach is particularly advantageous for long pieces of wood, which are prone to warping or bending. By securing multiple points along the length, you minimize stress on any single attachment, prolonging the life of the installation. Plus, this method allows for easy removal or repositioning if needed, making it a practical choice for both permanent and temporary applications.

One cautionary note: always consider the wall’s structural integrity before drilling. Avoid mounting near electrical wires or plumbing, and use a stud finder to locate wall studs for added support. If studs aren’t available, ensure the anchors are rated for the weight of the wood. For example, a 10-pound piece of wood might require anchors with a minimum holding capacity of 20 pounds to account for movement or additional stress. Testing the setup by gently pulling or pushing on the wood after installation can confirm its stability before fully loading it.

In conclusion, attaching a mounting system with brackets or cleats is a straightforward yet effective way to secure a long, flat piece of wood to a wall. By selecting the appropriate screws and anchors, spacing the brackets correctly, and considering the wall’s material, you can achieve a durable and safe installation. This method not only ensures the wood remains level and secure but also provides flexibility for future adjustments. Whether for shelving, decor, or functional purposes, this approach combines practicality with peace of mind.

Optimal Fireplace Wood Storage: How Long to Keep It Dry

You may want to see also

Explore related products

Hang and Level: Lift wood onto mounts, check alignment, and adjust for stability and straightness

Once your wall mounts are securely in place, the moment of truth arrives: hanging your wood. This is where precision and patience pay off. Begin by lifting the wood onto the mounts, ensuring it rests firmly on the supports. A helper is invaluable here, especially for longer pieces, to prevent accidental drops or damage. With the wood in position, step back and assess its alignment. Use a level to check both horizontal and vertical straightness. Even a slight tilt can detract from the overall aesthetic, so take your time.

Alignment isn’t just about looks—it’s about stability. A crooked piece of wood can shift over time, potentially leading to damage or injury. If the wood isn’t level, adjust the mounts slightly by loosening the screws, realigning, and retightening. For added precision, mark the wall with a pencil where adjustments are needed. Small tweaks can make a big difference, so work incrementally. If the wood feels wobbly, double-check that the mounts are evenly spaced and securely anchored.

Consider using shims or felt pads between the wood and mounts to fine-tune alignment and prevent scratching. These small additions can compensate for minor imperfections in the wall or wood surface. Once aligned, test the stability by gently pressing on the wood from various angles. It should feel solid and immovable. If it shifts, recheck the mounts and tighten any loose screws. Stability is non-negotiable, especially for heavier pieces or high-traffic areas.

Finally, take a step back and admire your work. A perfectly hung piece of wood transforms a space, adding warmth and character. This phase requires attention to detail, but the payoff is worth it. Remember, the goal isn’t just to hang wood—it’s to create a seamless, professional finish that enhances your wall. With careful leveling and adjustment, you’ll achieve a result that’s both functional and visually striking.

Understanding Wood Glue Setting Time: A Quick Guide for DIY Enthusiasts

You may want to see also

Frequently asked questions

You’ll need a stud finder, level, drill, screws, wall anchors (if not mounting into studs), measuring tape, pencil, and a screwdriver or drill bit.

Use a level to check both horizontally and vertically before marking the screw locations. Adjust until the bubble is centered.

Mount into studs for maximum strength. If studs aren’t available, use heavy-duty wall anchors rated for the weight of the wood and any items it will hold.

Place screws no more than 16–24 inches apart for even support, especially for longer pieces of wood.

Use adhesive strips or French cleats for minimal damage, but note these methods may not support heavy weights as well as screws or anchors.