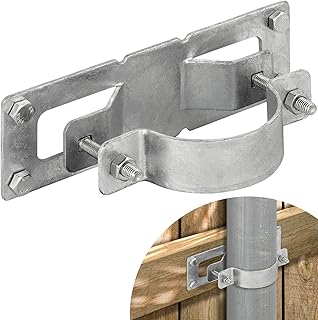

When it comes to building or repairing wood fences, one essential aspect often overlooked is the importance of securing the right materials, such as C-posts and brackets. These components play a crucial role in ensuring the stability, durability, and overall structural integrity of the fence. C-posts, typically made of galvanized steel, provide a sturdy foundation for the fence, while brackets act as connectors, securely fastening the wooden panels or rails to the posts. For those who were too busy to purchase these items earlier, it’s never too late to invest in high-quality C-posts and brackets, as they can significantly extend the lifespan of a wood fence and reduce the need for frequent repairs. Whether you’re a DIY enthusiast or hiring professionals, sourcing these materials from reliable suppliers ensures your fence remains robust and functional for years to come.

Explore related products

$29.99 $31.99

What You'll Learn

- C-Post Types & Sizes: Different sizes and materials for C-posts to suit various wood fence needs

- Bracket Compatibility: Ensuring brackets fit C-posts and wood fence rails for secure installation

- Installation Tips: Step-by-step guide for attaching C-posts and brackets to wood fences efficiently

- Cost Comparison: Analyzing prices of C-posts and brackets for budget-friendly wood fence projects

- Durability Factors: Evaluating materials and coatings for long-lasting C-posts and brackets in wood fences

C-Post Types & Sizes: Different sizes and materials for C-posts to suit various wood fence needs

C-posts, also known as line posts or fence posts, are the backbone of any wood fence, providing structural integrity and longevity. When selecting C-posts, understanding the different types and sizes is crucial to ensure your fence meets both functional and aesthetic requirements. The most common materials for C-posts include galvanized steel, aluminum, and pressure-treated wood, each offering unique benefits. Galvanized steel is highly durable and resistant to rust, making it ideal for humid or coastal areas. Aluminum, while lighter and more corrosion-resistant, is better suited for less demanding environments. Pressure-treated wood, though traditional, requires regular maintenance to prevent rot and insect damage.

The size of your C-post depends on the height and weight of your fence, as well as local soil conditions. Standard C-post sizes range from 6 to 8 feet in length, with widths varying from 2 to 4 inches. For a 6-foot tall fence, an 8-foot post is recommended to allow for proper grounding—burying at least 2 feet in the ground with concrete for stability. Thicker posts (3 to 4 inches) are ideal for heavier fence materials like cedar or redwood, while thinner posts (2 inches) suffice for lighter picket fences. Always check local building codes, as some areas mandate specific post sizes or depths for safety and durability.

When comparing materials, consider both initial cost and long-term maintenance. Galvanized steel posts are more expensive upfront but require minimal upkeep, making them a cost-effective choice over time. Aluminum posts are similarly low-maintenance but may bend under heavy pressure, limiting their use in high-wind areas. Pressure-treated wood posts are the most affordable initially but demand regular staining or sealing to prevent deterioration. For DIY installers, aluminum and wood posts are easier to handle due to their lighter weight, while steel posts may require additional tools for cutting and installation.

For specialized applications, there are C-posts designed to address specific challenges. For example, adjustable C-posts allow for easy alignment during installation, reducing the need for precise measurements. Reinforced posts with thicker walls are available for fences in high-traffic areas or regions prone to strong winds. Additionally, some manufacturers offer posts with pre-drilled holes for brackets, streamlining the attachment of fence rails. When selecting brackets, ensure they are compatible with your post material—steel brackets for steel posts, aluminum brackets for aluminum, and galvanized or stainless steel brackets for wood to prevent corrosion.

In conclusion, choosing the right C-post involves balancing material durability, size requirements, and environmental factors. Assess your fence’s height, weight, and exposure to elements before deciding. For most homeowners, galvanized steel offers the best combination of strength and longevity, while aluminum is a lightweight alternative for milder climates. Pressure-treated wood remains a viable option for those willing to invest in ongoing maintenance. By carefully considering these factors, you can ensure your wood fence stands strong and looks great for years to come.

Discover the Best Places to Buy Authentic Olive Wood Products

You may want to see also

Explore related products

Bracket Compatibility: Ensuring brackets fit C-posts and wood fence rails for secure installation

Brackets act as the unsung heroes of wood fence installations, bridging the gap between C-posts and rails. Their compatibility with both components is critical for structural integrity. Mismatched brackets can lead to wobbly fences, premature wear, or even collapse under stress. To avoid these pitfalls, start by verifying the diameter of your C-posts and the width of your fence rails. Most C-posts range from 2 to 4 inches in diameter, while rails typically measure 2x4 or 2x6 inches. Brackets designed for these dimensions ensure a snug fit, minimizing movement and maximizing stability.

Selecting the right bracket material is equally vital. Galvanized steel brackets resist rust and corrosion, making them ideal for outdoor use. Stainless steel offers superior durability but comes at a higher cost. For budget-conscious projects, powder-coated steel provides decent protection against the elements. Avoid aluminum brackets unless your fence is in a low-moisture environment, as they are prone to bending under pressure. Always check the weight capacity of the brackets to ensure they can support the combined load of the rails, pickets, and environmental stresses like wind or snow.

Installation precision is key to bracket compatibility. Begin by aligning the bracket’s C-post slot with the post’s centerline, using a level to ensure vertical accuracy. Secure the bracket with screws or bolts designed for outdoor use, such as stainless steel or hot-dipped galvanized fasteners. For wood rails, pre-drill holes to prevent splitting, especially in hardwoods like cedar or redwood. Position the rail firmly into the bracket’s cradle, ensuring it sits flush against the backstop. Double-check all connections before tightening to avoid misalignment.

A common mistake is overlooking the bracket’s angle compatibility. If your fence follows a slope or curve, adjustable brackets are essential. These allow for angle variations, typically up to 30 degrees, ensuring a seamless fit along uneven terrain. For straight fences, fixed-angle brackets provide added rigidity. Always test the bracket’s flexibility before installation by simulating the rail’s angle to confirm it accommodates the fence’s design without compromising stability.

Regular maintenance extends the life of your bracket-post-rail system. Inspect brackets annually for signs of rust, loosening fasteners, or cracks in the welds. Tighten any loose screws and replace damaged brackets immediately. Applying a rust-inhibiting primer or paint to steel brackets can provide an extra layer of protection. For wood rails, seal the ends with a water-repellent preservative to prevent rot at the bracket interface. By prioritizing compatibility and care, your fence will stand strong for years to come.

Where to Buy Bamboo Wood: A Sustainable and Stylish Choice

You may want to see also

Explore related products

Installation Tips: Step-by-step guide for attaching C-posts and brackets to wood fences efficiently

Attaching C-posts and brackets to wood fences requires precision and the right tools to ensure durability and stability. Begin by gathering your materials: C-posts, brackets, galvanized screws, a drill, a level, and a tape measure. Measure the fence layout to determine post spacing, typically 6 to 8 feet apart, depending on local building codes and fence height. Mark these positions clearly on the ground to guide your installation.

Once your layout is marked, dig holes for the C-posts using a post-hole digger or auger. Each hole should be at least 3 feet deep for a 6-foot fence to provide adequate support. Pour 6 inches of gravel into the bottom of each hole for drainage, then set the C-post in place. Use a level to ensure the post is plumb before backfilling with soil or concrete. For added stability, mix concrete according to the manufacturer’s instructions and fill the hole to within 6 inches of the top, allowing it to cure for 24–48 hours.

With the posts securely in place, attach the brackets to the fence rails. Position the first bracket at the bottom of the post, aligning it with the bottom rail. Secure it with galvanized screws, ensuring the bracket is flush against the post. Repeat this process for the middle and top rails, maintaining consistent spacing. Use a level to verify that each rail is straight before tightening the screws fully. This step is critical for preventing sagging and ensuring the fence’s structural integrity.

Finally, attach the wood fence boards to the brackets. Start at one end of the fence line, sliding the first board into the bottom bracket and securing it with screws or nails. Work your way up, ensuring each board is level and evenly spaced. For a polished look, use a spacer to maintain consistent gaps between boards. Once all boards are attached, inspect the fence for any loose screws or misaligned boards, making adjustments as needed. Proper installation not only enhances the fence’s appearance but also extends its lifespan.

Where to Buy a PAT Connect Card Near Wood Street?

You may want to see also

Explore related products

Cost Comparison: Analyzing prices of C-posts and brackets for budget-friendly wood fence projects

C-posts and brackets are the backbone of any wood fence project, but their costs can vary widely depending on material, brand, and retailer. A quick search reveals that galvanized steel C-posts typically range from $10 to $25 each, while brackets can cost between $2 and $8 per piece. For a standard 100-foot fence requiring approximately 10 posts and 20 brackets, the total material cost for these components alone could range from $140 to $330. This initial price disparity underscores the importance of a detailed cost comparison to stay within budget.

When analyzing prices, consider the long-term value of materials. Galvanized steel C-posts, though pricier upfront, offer superior rust resistance compared to untreated steel, potentially saving money on replacements down the line. Similarly, stainless steel brackets, priced at the higher end, provide durability that cheaper alternatives may lack. For budget-friendly projects, weigh the trade-off between initial savings and future maintenance costs. For instance, opting for mid-range galvanized posts and standard brackets could strike a balance, ensuring longevity without breaking the bank.

Retailers play a significant role in cost variation. Big-box stores like Home Depot or Lowe’s often offer competitive pricing but may have limited selection. Online platforms such as Amazon or specialty fencing suppliers provide a broader range of options, including bulk discounts, which can significantly reduce costs for larger projects. However, factor in shipping fees, which can negate savings, especially for heavy items like C-posts. Local hardware stores, while sometimes pricier, may offer personalized advice and immediate availability, which can be invaluable for time-sensitive projects.

To maximize savings, consider purchasing in bulk or during seasonal sales. Many retailers offer discounts on fencing materials in late winter or early spring, anticipating the peak DIY season. Additionally, explore secondhand options or surplus stores, where slightly used or overstocked materials can be found at a fraction of the cost. Always inspect these items for damage or wear, as compromised materials could lead to structural issues later.

In conclusion, a budget-friendly wood fence project requires more than just finding the cheapest C-posts and brackets. It involves a strategic approach to material selection, retailer choice, and timing. By prioritizing durability, comparing prices across multiple sources, and leveraging discounts, homeowners can achieve a sturdy, cost-effective fence without sacrificing quality. This thoughtful cost comparison ensures that every dollar spent contributes to a long-lasting and functional outdoor structure.

Is Wood Veneer Furniture Worth It? Pros, Cons, and Buying Tips

You may want to see also

Explore related products

Durability Factors: Evaluating materials and coatings for long-lasting C-posts and brackets in wood fences

Galvanized steel stands as the gold standard for C-posts and brackets in wood fences due to its inherent corrosion resistance. The zinc coating acts as a sacrificial layer, oxidizing before the underlying steel, which significantly extends the material’s lifespan. For coastal or high-humidity areas, consider hot-dip galvanization, where the steel is submerged in molten zinc at 850°F (455°C), creating a thicker, more durable coating. Alternatively, stainless steel, particularly grade 316, offers superior resistance to chloride corrosion, making it ideal for saltwater environments, though at a higher cost.

Coatings play a pivotal role in enhancing durability, but not all are created equal. Powder coating, applied electrostatically and cured under heat, provides a hard finish resistant to chipping, fading, and scratching. It’s available in various colors, allowing for aesthetic customization. For brackets, consider zinc-rich primers, which offer additional corrosion protection by releasing zinc ions when exposed to moisture. However, avoid oil-based paints or thin coatings, as they lack the thickness and adhesion needed to withstand outdoor conditions.

Environmental factors dictate material and coating choices. In regions with extreme temperature fluctuations, materials like aluminum or fiberglass-reinforced polymers (FRP) offer thermal stability, preventing warping or cracking. For areas prone to wildfires, galvanized steel or FRP brackets are non-combustible, reducing fire risk. Always assess local climate data—average rainfall, UV exposure, and salinity levels—to tailor your selection.

Maintenance is key to maximizing longevity. Inspect C-posts and brackets annually for signs of rust, wear, or damage. Clean with a mild detergent and water, avoiding abrasive tools that could compromise coatings. Reapply touch-up paint or zinc spray to exposed areas promptly. For added protection, consider periodic applications of rust inhibitors or sealants, especially in corrosive environments.

Cost versus longevity is a critical trade-off. While galvanized steel and stainless steel carry higher upfront costs, their extended lifespan often offsets the initial investment. Cheaper alternatives like untreated steel or low-grade coatings may save money initially but require frequent replacements, increasing long-term expenses. Calculate the total cost of ownership, factoring in maintenance, replacement frequency, and environmental impact to make an informed decision.

Top Sources for Heat-Treated Wood: Where to Buy Quality Options

You may want to see also

Frequently asked questions

You can purchase C-posts and brackets at local hardware stores like Home Depot, Lowe's, or Menards. Online retailers such as Amazon, Grainger, or specialty fencing suppliers like Hoover Fence also offer these products.

C-posts and brackets are usually made from galvanized steel or aluminum to ensure durability and resistance to rust and corrosion, making them suitable for outdoor use with wood fences.

Measure the thickness of your fence rails and posts to ensure compatibility. C-posts and brackets come in various sizes, so match them to your fence dimensions. Consult the manufacturer’s guidelines or ask a hardware store expert for assistance.