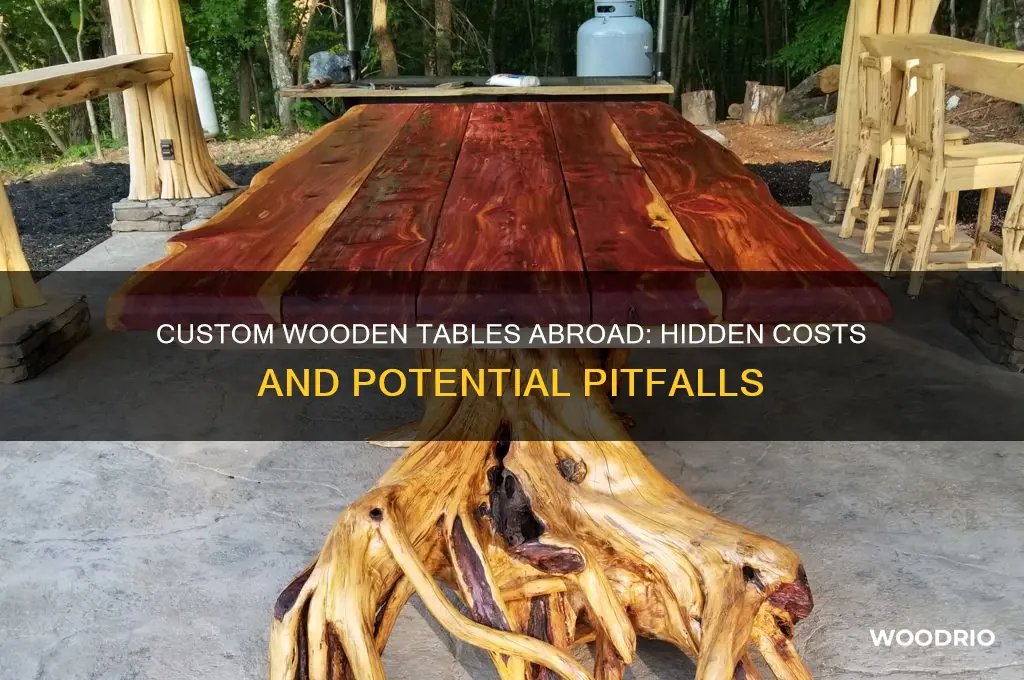

Buying a custom wooden table from abroad can come with several disadvantages that potential buyers should consider. One major drawback is the high shipping costs, which can significantly increase the overall price, often negating the initial cost savings of purchasing internationally. Additionally, long shipping times can lead to delays, and the risk of damage during transit is higher due to the fragile nature of wooden furniture. Customs duties and import taxes can also add unexpected expenses, making the final cost unpredictable. Communication barriers with overseas sellers may result in misunderstandings about design specifications, materials, or delivery expectations. Lastly, resolving issues such as defects or returns can be complicated and costly due to international logistics and differing consumer protection laws.

| Characteristics | Values |

|---|---|

| Higher Costs | Increased shipping fees, import taxes, and customs duties can significantly raise the overall price. |

| Longer Lead Times | Production and international shipping can extend delivery times, often taking several weeks or months. |

| Quality Control Issues | Difficulty in inspecting the product before purchase may lead to discrepancies in quality or craftsmanship. |

| Communication Barriers | Language differences or time zone challenges can complicate discussions about design, specifications, and expectations. |

| Limited Recourse | Resolving disputes or returns can be difficult due to international laws and distance. |

| Environmental Impact | Higher carbon footprint due to long-distance shipping and potential unsustainable sourcing practices. |

| Customization Limitations | Misunderstandings in design details or material preferences may result in a product that doesn’t meet expectations. |

| Currency Fluctuations | Exchange rate changes can affect the final cost unpredictably. |

| Warranty and Support | Limited or no warranty coverage and after-sales support due to geographical constraints. |

| Cultural Design Differences | Aesthetic or functional differences may not align with local preferences or standards. |

Explore related products

What You'll Learn

- High shipping costs due to large size and weight of custom wooden tables

- Risk of damage during international transportation and handling

- Long lead times for production and delivery from overseas suppliers

- Limited ability to inspect quality before purchasing or receiving the item

- Potential customs duties and import taxes increasing overall purchase cost

High shipping costs due to large size and weight of custom wooden tables

One of the most immediate and significant drawbacks of purchasing a custom wooden table from abroad is the exorbitant shipping cost. Unlike smaller, lightweight items, wooden tables are bulky and heavy, often weighing hundreds of pounds. Freight companies calculate shipping fees based on dimensional weight (size) and actual weight, whichever is greater. For a 6-foot solid oak dining table, this can translate to shipping costs that rival or even exceed the table’s purchase price. For instance, shipping a 300-pound table from Italy to the U.S. might cost $800–$1,500, depending on the carrier and service level. This financial burden is a critical factor to weigh against the allure of a bespoke piece.

To mitigate these costs, some buyers consider disassembling the table for transport, but this approach is not without risks. Custom wooden tables are often designed as single, sturdy units, and disassembly can compromise structural integrity or void warranties. Even if the table can be broken down, reassembly requires skill and precision, potentially adding labor costs or the risk of damage. Alternatively, opting for sea freight instead of air freight can reduce expenses but significantly extends delivery time—often by several weeks. Neither option eliminates the high cost entirely, leaving buyers with a difficult trade-off between time, money, and product integrity.

A comparative analysis reveals that local artisans often offer competitive pricing when shipping costs are factored in. A custom table from a domestic craftsman might be 20–30% more expensive upfront but eliminates international shipping fees, customs duties, and the risk of transit damage. For example, a $2,500 table from Germany could cost $3,500 by the time it arrives in California, while a $3,000 table from a local woodworker in Oregon would be delivered for the quoted price. This comparison underscores the hidden expenses of international purchases and highlights the value of exploring local options before committing to an overseas transaction.

Practical tips for managing shipping costs include negotiating with the seller to include freight in the purchase price or researching consolidated shipping services that combine multiple items into a single container. However, these strategies are not foolproof. Consolidated shipping may delay delivery, and sellers are often unwilling to absorb shipping costs due to their already slim margins on custom work. Ultimately, buyers must carefully evaluate whether the unique design or craftsmanship of an overseas table justifies the substantial additional expense and logistical challenges. Without thorough planning, the dream of owning a custom wooden table from abroad can quickly turn into a financial and logistical nightmare.

Where to Find Juniper Wood in South Florida: A Buyer's Guide

You may want to see also

Explore related products

Risk of damage during international transportation and handling

International shipping of bulky, fragile items like custom wooden tables poses significant risks due to the multiple handling points and varying transportation conditions. From the workshop to your doorstep, a table may pass through several warehouses, cargo holds, and delivery trucks, each stage presenting opportunities for damage. For instance, rough handling during loading and unloading, stacking errors, or exposure to extreme temperatures can compromise the integrity of the wood. Unlike smaller, more durable goods, wooden furniture is particularly susceptible to cracks, warping, or breakage, especially if not properly packaged or secured.

To mitigate these risks, consider the packaging and shipping methods offered by the seller. Ideal packaging includes custom crates with cushioning materials like foam or bubble wrap, reinforced corners, and moisture barriers. However, such protective measures often increase shipping costs, sometimes significantly. Additionally, inspect the seller’s track record for handling fragile items and their insurance policies. While insurance can cover damage, filing claims can be time-consuming and may not fully compensate for the loss, especially if the table is custom-made and irreplaceable.

A comparative analysis reveals that domestic purchases often involve shorter, more controlled supply chains, reducing the likelihood of damage. Local artisans or retailers typically handle delivery themselves or use specialized furniture couriers, minimizing transit risks. In contrast, international shipments rely on third-party logistics providers, whose handling practices may vary widely. For example, a table shipped from Europe to the U.S. might endure weeks at sea, where humidity and temperature fluctuations can cause wood to expand or contract, leading to structural issues.

Practical tips for buyers include requesting detailed photos of the packaging before shipment, opting for sellers who provide real-time tracking, and ensuring the table is disassembled if possible to reduce its vulnerability. If damage occurs, document it immediately with clear photos and contact the seller and shipping company within the specified timeframe. While these steps can help, they do not eliminate the inherent risks of international transportation, making this a critical consideration for anyone contemplating such a purchase.

Veneer vs. Solid Wood: Which Furniture Investment is Right for You?

You may want to see also

Explore related products

Long lead times for production and delivery from overseas suppliers

One of the most immediate drawbacks of purchasing a custom wooden table from an overseas supplier is the extended lead time. Unlike local artisans who can often deliver within weeks, international orders typically require 8–12 weeks for production and an additional 4–6 weeks for shipping, depending on the origin country and your location. This timeline can stretch even longer during peak seasons or if customs inspections are involved. For those planning a specific event or needing the table by a certain date, this delay can be a deal-breaker.

Consider the logistics: a custom table ordered from a workshop in Indonesia or Poland isn’t just sitting on a shelf waiting to ship. It’s crafted to your specifications, which involves sourcing materials, carving, finishing, and drying processes that cannot be rushed without compromising quality. Add to this the unpredictability of international shipping—port congestion, weather delays, or geopolitical disruptions—and you’re looking at a timeline that’s far less certain than domestic alternatives. If you’re working with a tight schedule, this uncertainty can introduce unnecessary stress.

From a practical standpoint, long lead times require meticulous planning. Start by confirming production and shipping estimates in writing, as verbal assurances can be vague. Factor in an additional 2–3 weeks as a buffer for unexpected delays. If the table is part of a larger project, such as a home renovation, communicate the extended timeline to contractors to avoid scheduling conflicts. For those who value instant gratification or lack storage space for a table that arrives months later, this waiting period can be a significant inconvenience.

Finally, the financial implications of long lead times shouldn’t be overlooked. While overseas suppliers often offer lower prices, the extended timeline can tie up your budget for months. If you’re paying a deposit upfront, ensure the supplier has a clear refund policy in case of delays or defects. Additionally, consider the opportunity cost: the time spent waiting could be used to source a local alternative that aligns better with your timeline. For those who prioritize speed and certainty, the cost savings of an overseas purchase may not outweigh the drawbacks of a prolonged wait.

Pre-Stained Wood Planks: Pros, Cons, and Buying Tips for Your Project

You may want to see also

Explore related products

Limited ability to inspect quality before purchasing or receiving the item

One of the most significant drawbacks of purchasing a custom wooden table from abroad is the inability to physically inspect the item before committing to the purchase. Unlike buying locally, where you can visit a showroom or workshop to assess the craftsmanship, material quality, and finish, international transactions often rely on digital images and descriptions. These representations, while helpful, can be misleading. Lighting, angles, and photo editing may obscure defects such as knots, uneven grain, or subpar joinery. Without a hands-on evaluation, you risk receiving a table that falls short of your expectations in terms of durability, aesthetics, or structural integrity.

Consider the example of a buyer who ordered a custom oak dining table from a European artisan. The online listing showcased a flawless, richly stained surface. However, upon arrival, the table exhibited noticeable scratches, uneven staining, and loose joints. The buyer had no recourse to verify these details beforehand, as the transaction was conducted entirely through emails and photos. This scenario underscores the importance of tactile inspection, which is nearly impossible when dealing with international vendors. Even detailed specifications and high-resolution images cannot fully substitute for the assurance of seeing and touching the product in person.

To mitigate this risk, buyers should adopt a proactive approach. Request detailed, unedited photos from multiple angles, including close-ups of joints, edges, and surfaces. Ask for videos or live video calls to observe the table in real-time lighting conditions. Inquire about the wood’s origin, treatment processes, and finishing techniques to gauge the artisan’s expertise. Additionally, research the seller’s reputation through reviews, testimonials, and past projects. While these steps cannot replicate a physical inspection, they provide a more comprehensive understanding of what to expect.

Another practical tip is to specify contractual terms that address quality concerns. Include clauses that allow for returns or refunds if the delivered item deviates significantly from the agreed-upon specifications. Some buyers even hire local inspectors or third-party services in the seller’s country to assess the table before shipment. While this adds to the cost, it can save money and frustration in the long run by ensuring the product meets your standards.

Ultimately, the limited ability to inspect quality before purchasing or receiving a custom wooden table from abroad is a trade-off for the unique design and craftsmanship that international artisans offer. By combining thorough research, clear communication, and protective measures, buyers can minimize risks and increase the likelihood of a satisfactory outcome. However, it’s essential to acknowledge that some uncertainty will always remain, making this option best suited for those who prioritize customization over immediate assurance.

Top Wood Stove Pellet Suppliers in Texas: Where to Buy

You may want to see also

Explore related products

Potential customs duties and import taxes increasing overall purchase cost

One of the most overlooked yet significant drawbacks of purchasing a custom wooden table from abroad is the potential for customs duties and import taxes to inflate the final cost. These additional fees, often calculated as a percentage of the item’s declared value, can turn a seemingly affordable international purchase into an unexpectedly expensive one. For instance, a $1,500 table might incur duties ranging from 3% to 20%, depending on the country of origin and destination, adding $45 to $300 to the total expense. This variability underscores the importance of researching tariff rates before committing to an overseas buy.

To mitigate this financial surprise, buyers should familiarize themselves with the Harmonized System (HS) code for wooden furniture, typically falling under HS code 9403. This code determines the duty rate applied by customs authorities. For example, importing a wooden table from the EU to the U.S. might attract a duty rate of 4.8%, while the same item from China could face up to 25% due to trade policies. Online tools like the U.S. International Trade Commission’s Tariff Database or the EU’s Market Access Database can provide country-specific rates, enabling buyers to estimate additional costs accurately.

Another critical factor is the valuation method used by customs. Duties are often calculated based on the table’s cost, insurance, and freight (CIF) value, which includes shipping and insurance expenses. For a $1,500 table with $200 shipping and $50 insurance, the CIF value would be $1,750. At a 10% duty rate, this adds $175 to the cost. Some sellers might underdeclare the item’s value to reduce duties, but this practice is illegal and risks penalties or seizure of the item. Transparency in valuation is therefore essential to avoid legal complications.

Beyond duties, buyers must also account for value-added tax (VAT) or goods and services tax (GST) in many countries. These taxes, applied after duties are calculated, can range from 5% to 25%, depending on the destination. For example, a table imported into the UK would incur 20% VAT on the total value, including duties. In some cases, de minimis thresholds—values below which no duties or taxes are applied—can offer relief. For instance, the U.S. has a de minimis threshold of $800, while the EU’s threshold is €150. However, these limits vary widely, making it crucial to verify them for each destination.

In conclusion, while the allure of a custom wooden table from abroad may be strong, the hidden costs of customs duties and import taxes can significantly alter the purchase’s affordability. Proactive research, accurate valuation, and awareness of tax thresholds are essential tools for buyers aiming to navigate this financial minefield. By factoring in these additional expenses upfront, consumers can make informed decisions and avoid unwelcome surprises at the border.

Wood Chipper Buying Guide: Cost Factors and Price Ranges

You may want to see also

Frequently asked questions

Shipping costs can be significantly higher due to the table's size and weight, and international shipping may include additional fees like customs duties and taxes. There’s also a risk of damage during transit, as wooden furniture is fragile and may not be handled properly.

It’s challenging to verify the quality firsthand, as you can’t inspect the table in person before purchase. Relying on photos or descriptions may not reveal defects, and there’s a risk of receiving a product that doesn’t meet your expectations.

Returning or repairing a defective table from abroad is often complicated and costly. International sellers may have different policies, and shipping the item back could be expensive. Additionally, repair options may be limited if the craftsmanship or materials are not locally available.

Currency exchange rates can fluctuate, potentially increasing the final cost unexpectedly. Payment methods may also incur additional fees, such as international transaction charges, and there’s a risk of fraud or payment disputes when dealing with overseas sellers.