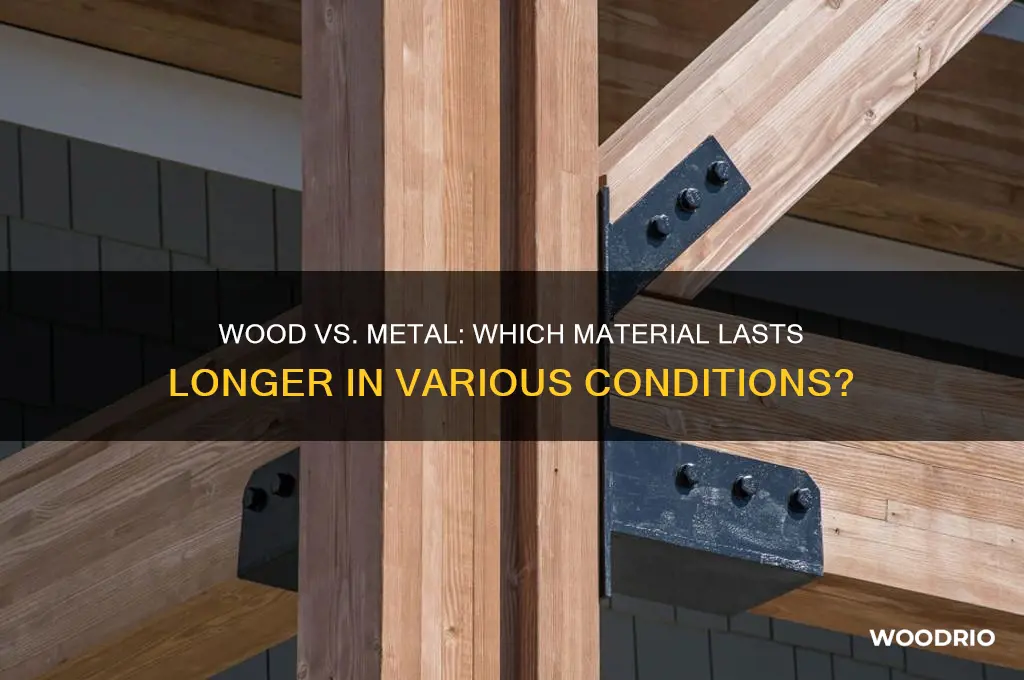

When considering durability and longevity, the question of whether wood or metal lasts longer depends largely on the specific conditions and applications. Metal, particularly stainless steel or aluminum, generally outperforms wood in environments exposed to moisture, pests, and extreme weather due to its resistance to corrosion and decay. However, wood can be highly durable when treated with preservatives, sealed properly, or used in controlled settings, making it a viable long-term option for certain purposes. Ultimately, the lifespan of either material is influenced by factors such as maintenance, environmental exposure, and intended use.

| Characteristics | Values |

|---|---|

| Durability | Metal generally lasts longer than wood due to its resistance to rot, pests, and moisture. However, treated wood can extend its lifespan significantly. |

| Maintenance | Metal requires less maintenance, as it doesn't need regular sealing or staining. Wood requires periodic treatment to prevent decay. |

| Resistance to Elements | Metal is more resistant to weather, UV rays, and temperature fluctuations. Wood is prone to warping, cracking, and fading over time. |

| Pest Resistance | Metal is naturally resistant to termites and other pests. Wood is susceptible to insect damage unless treated. |

| Corrosion | Metal can corrode over time, especially in humid or salty environments, but stainless steel or galvanized metal offers better resistance. Wood does not corrode but can rot. |

| Lifespan | Metal structures can last 50+ years with minimal maintenance. Untreated wood may last 5-10 years, while treated wood can last 20-30 years or more. |

| Environmental Impact | Wood is biodegradable and renewable but requires deforestation. Metal production is energy-intensive but can be recycled indefinitely. |

| Cost | Initial costs vary; metal is often more expensive upfront, but wood may require higher long-term maintenance costs. |

| Aesthetic Appeal | Wood is often preferred for its natural look, while metal offers a modern or industrial aesthetic. |

| Repairability | Wood is easier to repair or replace sections, while metal may require welding or specialized tools. |

Explore related products

$14.79 $18.98

What You'll Learn

Durability in Outdoor Conditions

Outdoor durability is a critical factor when choosing between wood and metal for structures like fences, furniture, or decking. Metal, particularly aluminum and galvanized steel, boasts superior resistance to moisture, a primary culprit in material degradation. Unlike wood, which can warp, rot, or attract pests when exposed to rain and humidity, metal remains structurally intact. For instance, aluminum’s natural oxide layer acts as a protective barrier against corrosion, while galvanized steel’s zinc coating sacrifices itself to shield the underlying metal. This makes metal ideal for regions with high rainfall or coastal areas where salt air accelerates deterioration.

However, wood’s durability outdoors isn’t entirely dismissible. Treated lumber, infused with preservatives like chromated copper arsenate (CCA) or alkaline copper quaternary (ACQ), can rival metal’s longevity. These treatments penetrate the wood’s cellular structure, inhibiting fungal growth and insect damage. For optimal results, use pressure-treated wood rated for ground contact in areas prone to moisture accumulation, such as posts buried in soil. Additionally, hardwoods like cedar and redwood contain natural oils that resist decay, though they still require periodic sealing to maintain their integrity.

Despite wood’s potential, metal outshines it in low-maintenance scenarios. While wood demands regular staining, sealing, or painting every 1–3 years to combat UV damage and moisture absorption, metal requires minimal upkeep. A simple wash with soapy water and occasional inspection for scratches or chips in the protective coating suffices. For example, powder-coated aluminum combines durability with aesthetic versatility, offering a wide range of colors and finishes that withstand fading from sunlight.

The choice between wood and metal ultimately hinges on specific environmental conditions and maintenance commitment. In arid climates with minimal rainfall, untreated wood may perform adequately with basic care. Conversely, metal’s resilience makes it the safer bet in harsh, wet, or coastal environments. For those seeking a middle ground, composite materials—blending wood fibers with plastic—offer enhanced durability with a wood-like appearance, though at a higher cost. Assess your local climate, budget, and willingness to maintain the material before deciding.

Treated Wood Wrapping: Optimal Waiting Time for Best Results

You may want to see also

Explore related products

Resistance to Moisture and Rot

Moisture is the arch-nemesis of wood, seeping into its porous structure and setting the stage for decay. Wood’s natural fibers absorb water, swelling and weakening over time. Fungi and bacteria thrive in damp conditions, breaking down cellulose and lignin—wood’s primary components. Left unchecked, rot reduces wood to a crumbly, unusable state. Metal, by contrast, is inherently non-porous. While some metals corrode when exposed to moisture, their structural integrity remains far superior to wood’s under the same conditions. This fundamental difference in material behavior underscores why metal often outlasts wood in damp environments.

To mitigate wood’s susceptibility to moisture, treatments like pressure-treating with copper azole or alkaline copper quaternary (ACQ) are essential. These chemicals penetrate deep into the wood, creating a toxic environment for fungi and insects. For optimal results, ensure the wood reaches a retention level of 0.4 pounds per cubic foot for above-ground use or 0.6 pounds per cubic foot for ground contact. Sealants and waterproof coatings provide an additional barrier, but they must be reapplied every 2–3 years to remain effective. Metal, particularly stainless steel or galvanized steel, requires no such interventions. Its resistance to moisture is intrinsic, making it a low-maintenance choice for humid or wet environments.

Consider the application: in coastal areas, where salt air accelerates corrosion, aluminum or stainless steel outperforms even treated wood. In landscaping, metal edging resists rot better than wooden borders, especially in regions with high rainfall. For structural elements like beams or posts, metal’s longevity is unmatched. Wood, however, remains a viable option when properly treated and maintained. The key lies in understanding the environment and selecting materials accordingly. Moisture resistance isn’t just about survival—it’s about preserving functionality and aesthetics over decades.

A comparative analysis reveals that while wood can be engineered to resist moisture, metal’s natural properties make it inherently superior. Wood’s reliance on chemical treatments and sealants introduces variables like cost, labor, and environmental impact. Metal, though often more expensive upfront, offers a predictable lifespan with minimal upkeep. For projects where longevity is critical, metal’s resistance to moisture and rot makes it the unequivocal choice. Yet, wood’s warmth and versatility keep it relevant, provided it’s used judiciously and maintained rigorously. The decision ultimately hinges on balancing durability, aesthetics, and budget.

DIY Wood Panel Installation: Timeframe and Tips for Beginners

You may want to see also

Explore related products

Impact of Temperature Changes

Temperature fluctuations can significantly alter the longevity of both wood and metal, but their responses to heat and cold differ markedly. Wood, being a natural material, expands and contracts with changes in moisture content, which is directly influenced by temperature. For instance, in humid conditions, wood absorbs moisture and swells, while in dry heat, it loses moisture and shrinks. This cyclical stress can lead to warping, cracking, or splitting over time. Metal, on the other hand, expands and contracts based on thermal conductivity. Extreme temperature shifts can cause metal to fatigue, especially in alloys, leading to structural weaknesses or even failure in critical components like fasteners or load-bearing elements.

To mitigate these effects, consider the environment in which wood or metal will be used. For outdoor wooden structures, apply a high-quality sealant or paint to create a barrier against moisture infiltration. Reapply every 2–3 years, especially in regions with drastic seasonal changes. For metal, choose materials with low thermal expansion coefficients, such as stainless steel or aluminum, for areas prone to temperature extremes. Additionally, incorporate expansion joints in metal structures to allow for movement without causing stress fractures.

A comparative analysis reveals that metal generally outperforms wood in temperature-stable environments, particularly in industrial or high-stress applications. However, wood’s natural insulation properties make it more resilient in moderate climates with gradual temperature shifts. For example, wooden beams in a well-ventilated attic experience less thermal stress than metal beams exposed to direct sunlight. Conversely, metal’s durability shines in environments like deserts or polar regions, where temperature swings are extreme and unpredictable.

Practical tips for homeowners and builders include monitoring indoor humidity levels between 30–50% to minimize wood’s moisture absorption. Use dehumidifiers in damp climates and humidifiers in dry ones. For metal, avoid placing it in direct contact with materials that retain heat, such as dark-colored roofing or asphalt. Instead, use insulating layers or reflective coatings to reduce heat absorption. Regular inspections for signs of thermal damage, like rust on metal or hairline cracks in wood, can catch issues before they escalate.

Ultimately, the impact of temperature changes on wood and metal underscores the importance of material selection based on environmental conditions. While metal excels in durability under extreme temperatures, wood’s adaptability makes it a viable choice in milder climates. By understanding these dynamics and implementing proactive measures, you can maximize the lifespan of either material, ensuring long-term structural integrity and aesthetic appeal.

Transporting Oversized Wood: Practical Tips for Moving Long Lumber Safely

You may want to see also

Explore related products

Maintenance Requirements Over Time

Metal's longevity often hinges on its resistance to corrosion, a battle largely fought through maintenance. Unlike wood, which naturally degrades from moisture and pests, metal's primary enemy is oxidation. For instance, steel structures require regular inspections for rust, especially in humid environments. A proactive approach involves applying rust-inhibiting primers and paints every 3-5 years, depending on exposure. Galvanization, a process that coats steel with zinc, offers a 20-50 year protection window but still demands periodic checks for wear. Neglecting these steps can lead to structural failure, as seen in bridges where rust compromises integrity. The takeaway? Metal’s durability is not inherent but earned through vigilant upkeep.

Wood, on the other hand, demands a different maintenance rhythm, one dictated by its organic nature. Initial treatments like pressure-treating with copper azole or alkaline copper quaternary (ACQ) extend lifespan by 40+ years, but this isn’t a one-time fix. Annual inspections for cracks, warping, or insect damage are critical, particularly in climates with high moisture or termite activity. Sealants and stains should be reapplied every 2-3 years to prevent water absorption, which accelerates rot. For decks or outdoor furniture, sanding and refinishing every 5 years can restore both appearance and structural integrity. The key with wood is consistency—small, regular interventions prevent the need for costly replacements.

Comparing the two materials reveals a trade-off between frequency and intensity of maintenance. Metal typically requires less frequent attention but demands more specialized care, such as welding repairs or chemical treatments. Wood, while more forgiving in terms of expertise, needs constant vigilance against biological threats. For example, a metal fence might need repainting every 5 years, while a wooden one requires annual staining and bi-annual inspections for rot. This comparison underscores that neither material “wins” outright—the choice depends on the owner’s capacity for either sporadic, technical maintenance or routine, hands-on care.

A persuasive argument for metal’s edge in low-maintenance longevity lies in its predictability. Once properly treated, metal’s degradation follows a linear path, making it easier to schedule and budget for upkeep. Wood’s deterioration, however, can be unpredictable, with factors like fungal growth or termite infestations accelerating decay rapidly. For large-scale projects like industrial buildings or public infrastructure, this predictability reduces long-term costs and liability risks. While wood’s aesthetic appeal is undeniable, metal’s maintenance profile aligns better with scenarios where reliability and minimal surprise interventions are non-negotiable.

Ultimately, the maintenance requirements of wood and metal over time boil down to a choice between organic warmth and industrial resilience. Wood’s beauty comes with a calendar of tasks—staining, sealing, inspecting—that must be religiously followed. Metal, while initially more resource-intensive to protect, offers a more hands-off relationship once safeguards are in place. Practical tip: For homeowners, consider the time you’re willing to invest; for businesses, factor in the cost of specialized labor versus frequent material replacements. Both materials can outlast generations, but only if their unique maintenance needs are met with precision and dedication.

Understanding Wood Furniture Off-Gassing: Duration and Health Considerations

You may want to see also

Explore related products

Susceptibility to Corrosion and Decay

Corrosion and decay are natural processes that degrade materials over time, but they affect wood and metal in fundamentally different ways. Metal, particularly iron and steel, is highly susceptible to corrosion when exposed to moisture and oxygen, leading to rust formation. This oxidative process weakens the material, reducing its structural integrity and lifespan. For instance, a steel beam in a humid environment can show signs of rust within months, while the same beam in a dry climate might remain intact for decades. Wood, on the other hand, decays primarily through biological agents like fungi and insects, which thrive in damp, warm conditions. While both materials face degradation, the mechanisms and environmental triggers differ, making one more vulnerable than the other depending on the setting.

To mitigate corrosion in metal, protective coatings such as paint, galvanization, or powder coating are essential. For example, applying a zinc coating to steel (galvanization) can extend its lifespan by up to 50 years in moderate climates. Regular maintenance, including inspections and reapplication of coatings, is crucial for high-moisture environments like coastal areas. Wood, however, benefits from treatments like pressure-treating with chemicals (e.g., chromated copper arsenate) or using naturally resistant species like cedar or redwood. These methods can double or triple wood’s lifespan, making it comparable to metal in certain applications. The key takeaway is that proactive measures tailored to the material and environment are critical for longevity.

Comparing the two, metal’s susceptibility to corrosion is more predictable and manageable with the right interventions. Wood’s decay, while slower in ideal conditions, can be more insidious due to hidden infestations or fungal growth. For outdoor structures, metal often outperforms wood in longevity when properly maintained, but wood remains a viable choice for its aesthetic appeal and cost-effectiveness. A practical tip: for projects requiring durability in wet conditions, opt for stainless steel or treated wood, and always consider the long-term maintenance requirements.

Instructively, understanding the root causes of corrosion and decay allows for better material selection and care. For metal, monitor for rust spots and address them immediately by sanding and recoating. For wood, ensure proper ventilation and keep moisture levels below 20% to deter fungal growth. Both materials require periodic inspections, but the focus areas differ—metal needs protection from moisture, while wood needs protection from biological threats. By addressing these specific vulnerabilities, you can maximize the lifespan of either material in any given application.

Optimal Wood Setting Time for Durable Furniture Crafting

You may want to see also

Frequently asked questions

Metal generally lasts longer than wood due to its resistance to rot, pests, and moisture, though durability depends on the specific type of metal and environmental conditions.

Metal typically withstands outdoor conditions better than wood, as it is less susceptible to weathering, decay, and insect damage.

The longevity of wood versus metal depends on factors like exposure to moisture, temperature fluctuations, maintenance, and the specific type of wood or metal used.

Wood can be treated with preservatives, sealants, or coatings to extend its lifespan, but it still generally won’t match the longevity of metal in harsh environments.