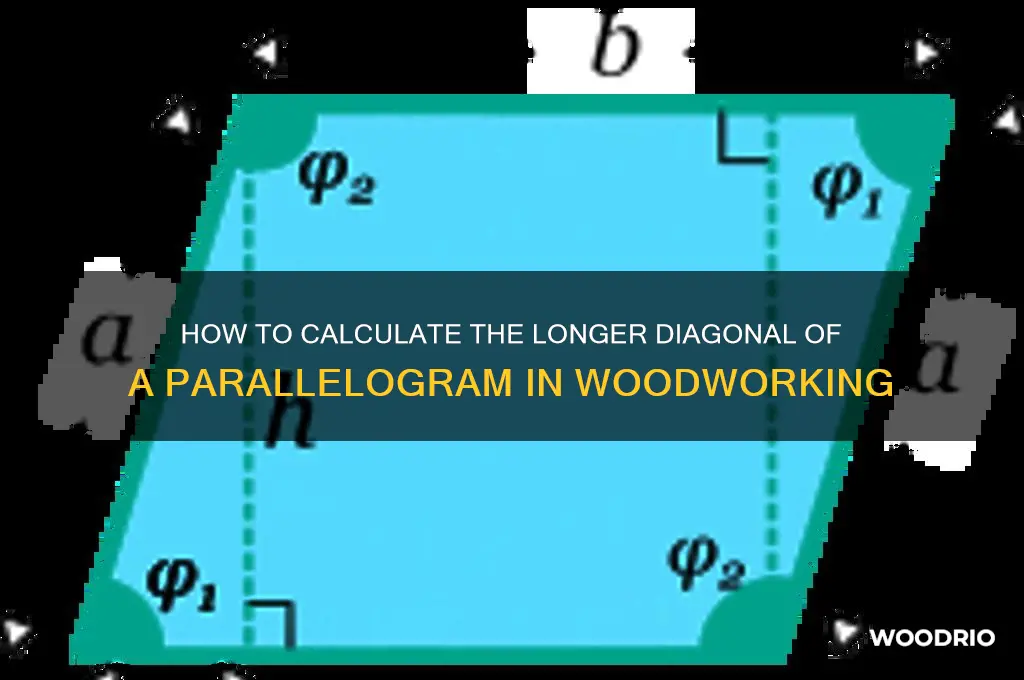

The longer diagonal of a parallelogram in woodworking is a critical measurement that determines the structural integrity and aesthetic appeal of the piece. In a parallelogram, the diagonals bisect each other, but their lengths differ based on the shape's dimensions. The longer diagonal is particularly important in woodworking projects, as it often dictates the maximum span or reach of the structure, influencing design choices and material selection. Understanding how to calculate and utilize this diagonal ensures precise craftsmanship and optimal functionality in various wooden creations, from furniture to architectural elements.

| Characteristics | Values |

|---|---|

| Definition | The longer diagonal of a parallelogram in woodwork refers to the line segment connecting two opposite vertices of the parallelogram, which is longer than the other diagonal. |

| Formula | Can be calculated using the formula: d = √(a² + b² + 2ab sin(θ)), where a and b are the lengths of the sides, and θ is the angle between them. |

| Properties | 1. It divides the parallelogram into two congruent triangles. 2. Its length is greater than the shorter diagonal. 3. It bisects the parallelogram's area. |

| Application | Used in woodwork for measuring, cutting, and designing parallelogram-shaped pieces, ensuring accuracy and symmetry. |

| Units | Typically measured in millimeters (mm), centimeters (cm), inches (in), or feet (ft), depending on the project's scale. |

| Tools | Measured using a tape measure, ruler, or digital caliper for precise calculations in woodwork. |

| Importance | Essential for maintaining structural integrity, aesthetic appeal, and functional design in parallelogram-based woodwork projects. |

Explore related products

What You'll Learn

- Diagonal Formula Derivation: Understanding the mathematical formula to calculate the longer diagonal of a parallelogram

- Woodwork Applications: Practical use of diagonal measurements in woodworking projects and designs

- Properties of Parallelograms: Key geometric properties affecting diagonal lengths in parallelogram structures

- Measurement Techniques: Tools and methods for accurately measuring diagonals in woodwork

- Diagonal vs. Sides: Comparing diagonal length with side lengths and angles in parallelograms

Diagonal Formula Derivation: Understanding the mathematical formula to calculate the longer diagonal of a parallelogram

The longer diagonal of a parallelogram is a critical measurement in woodworking, ensuring structural integrity and aesthetic alignment in projects like frames, tabletops, or cabinetry. To calculate it, we derive a formula rooted in geometry, leveraging the properties of parallelograms and the Pythagorean theorem. This formula not only simplifies measurements but also minimizes material waste and errors in precision-dependent tasks.

Derivation Steps: Begin by identifying the sides of the parallelogram as *a* and *b*, with an included angle *θ*. Drop a perpendicular from one vertex to the opposite side, creating a right triangle. The base of this triangle is *b* cos(*θ*), and the height is *b* sin(*θ*). The longer diagonal (*d*) forms the hypotenuse of a larger right triangle with sides *a* and the height *b* sin(*θ*). Applying the Pythagorean theorem:

\[ d = \sqrt{a^2 + (b \sin(\theta))^2} \]

However, a more practical formula uses the cosine rule for the parallelogram’s sides and angle:

\[ d = \sqrt{a^2 + b^2 - 2ab \cos(\theta)} \]

This equation accounts for all configurations, ensuring accuracy regardless of angle or side lengths.

Practical Application in Woodworking: When crafting a parallelogram-shaped frame with sides *a = 24* inches and *b = 18* inches at a *60°* angle, substitute into the formula:

\[ d = \sqrt{24^2 + 18^2 - 2 \cdot 24 \cdot 18 \cdot \cos(60°)} \]

Since \(\cos(60°) = 0.5\), the calculation simplifies to:

\[ d = \sqrt{576 + 324 - 432} = \sqrt{468} \approx 21.63 \text{ inches} \]

This precise measurement ensures the diagonal aligns perfectly with design specifications.

Cautions and Tips: Always verify angle measurements using a protractor or digital angle finder, as small errors amplify in diagonal calculations. For irregular wood grains, add 1/8 inch to the diagonal length to account for material flexibility during assembly. Use a calculator or woodworking app to avoid trigonometric errors, especially with non-standard angles.

Durability of Wooden Fence Posts: Lifespan and Maintenance Tips

You may want to see also

Explore related products

Woodwork Applications: Practical use of diagonal measurements in woodworking projects and designs

In woodworking, understanding the longer diagonal of a parallelogram is crucial for projects requiring precise alignment and structural integrity. This diagonal, which spans the longest distance between opposite corners, serves as a key reference for ensuring symmetry and stability in designs like frames, tabletops, and cabinetry. By calculating this measurement—using the formula \( \sqrt{a^2 + b^2 + 2ab \cdot \sin(\theta)} \), where \( a \) and \( b \) are the side lengths and \( \theta \) is the angle between them—craftsmen can avoid misalignments that compromise both aesthetics and functionality.

Consider a dovetail joint in a drawer construction. The longer diagonal acts as a guide for marking out the joint’s angle and ensuring the tails and pins interlock seamlessly. Without accurate diagonal measurements, the joint may weaken under stress, leading to premature failure. Similarly, in building a parallelogram-shaped picture frame, the longer diagonal helps align miter cuts at the corners, preventing gaps or uneven edges. This precision is especially critical in fine woodworking, where tolerances are minimal.

For practical application, start by measuring the sides of the parallelogram and the included angle. Use a calculator or woodworking app to determine the diagonal length. Transfer this measurement to your workpiece using a tape measure and marking gauge. Always double-check alignment with a carpenter’s square or sliding bevel to ensure accuracy. When cutting, account for blade kerf and material thickness, particularly in joinery work. For example, in a 24” x 30” tabletop with a 10-degree angle, the longer diagonal would be approximately 38.4 inches—a measurement that dictates the placement of supports or decorative elements.

One common mistake is neglecting the angle’s impact on diagonal length. A slight miscalculation in \( \theta \) can result in significant errors, particularly in larger projects. To mitigate this, use digital angle finders for precise readings and verify measurements before cutting. Additionally, when working with wood prone to warping, such as oak or walnut, clamp and secure pieces along the diagonal during assembly to maintain shape. This technique is especially useful in constructing parallelogram-shaped doors or panels, where warping can distort the entire structure.

In conclusion, mastering diagonal measurements in parallelogram woodwork elevates both the craftsmanship and durability of projects. Whether crafting intricate joinery or assembling large-scale pieces, this skill ensures accuracy and professionalism. By integrating mathematical precision with practical techniques, woodworkers can transform complex designs into functional, long-lasting creations. Remember: the longer diagonal isn’t just a measurement—it’s a blueprint for structural harmony.

Durability of Wooden Haul Boats: Lifespan and Maintenance Tips

You may want to see also

Explore related products

Properties of Parallelograms: Key geometric properties affecting diagonal lengths in parallelogram structures

Parallelograms, with their opposite sides parallel and equal in length, exhibit unique geometric properties that directly influence the lengths of their diagonals. One key property is the relationship between the sides and angles of the parallelogram. The diagonals of a parallelogram bisect each other, meaning they intersect at their midpoints. This property is crucial in understanding why the diagonals differ in length. In any parallelogram, the longer diagonal is associated with the larger angle between the sides it connects. For instance, in a woodworking project, if you’re designing a parallelogram-shaped frame, the diagonal spanning the obtuse angle will always be longer than the one spanning the acute angle.

To determine the length of the longer diagonal in a parallelogram, you can use the formula derived from the Law of Cosines. For a parallelogram with sides of lengths *a* and *b*, and an included angle *θ*, the length of the diagonal *d* can be calculated as:

\[ d = \sqrt{a^2 + b^2 - 2ab \cos(\theta)} \]

When *θ* is greater than 90 degrees, the diagonal will be longer. In woodworking, this formula can be applied to ensure precise measurements, especially when crafting joints or aligning pieces. For example, if you’re building a parallelogram-shaped table with sides of 3 feet and 4 feet, and an angle of 120 degrees, the longer diagonal would be approximately 6.08 feet.

Another critical property affecting diagonal lengths is the shape’s symmetry. In a rectangle or square (special cases of parallelograms), the diagonals are equal in length because all angles are 90 degrees. However, in a general parallelogram, the lack of right angles results in diagonals of unequal lengths. This distinction is vital in woodworking, as it influences structural stability and aesthetic alignment. For instance, when constructing a parallelogram-shaped shelf, ensuring the longer diagonal aligns with the intended visual or load-bearing direction can enhance both form and function.

Practical tips for woodworking with parallelograms include using a protractor to measure angles accurately and double-checking diagonal lengths with the formula before cutting materials. Additionally, consider the grain direction of the wood when aligning diagonals, as this can affect strength and durability. For complex projects, sketching the parallelogram and labeling angles and side lengths can prevent costly mistakes. By leveraging these geometric properties, woodworkers can create precise, visually appealing, and structurally sound parallelogram structures.

Preserving Chicken of the Woods: Long-Term Storage Tips and Tricks

You may want to see also

Explore related products

Measurement Techniques: Tools and methods for accurately measuring diagonals in woodwork

Accurate diagonal measurement in woodwork is critical for ensuring structural integrity and aesthetic precision, particularly in parallelogram-shaped pieces. The longer diagonal of a parallelogram is not just a theoretical concept but a practical element that influences joinery, material usage, and overall design. To measure it effectively, one must combine the right tools with precise methods, accounting for the unique angles and dimensions of the shape.

Tools for the Task:

A combination square, sliding bevel, and precision tape measure form the core toolkit for diagonal measurement. The combination square ensures straight lines and accurate 90-degree references, while the sliding bevel transfers angles from the parallelogram’s corners. For longer diagonals, a tape measure with a rigid blade (up to 3 meters) minimizes sagging, ensuring a straight line between opposite corners. Digital calipers, though less common, can verify smaller segments or thicknesses contributing to diagonal length.

Step-by-Step Measurement Method:

- Mark the Corners: Use a sharp pencil to clearly mark the inner and outer edges of the parallelogram’s corners. Precision here prevents parallax errors.

- Align the Tool: Place the combination square along one side, ensuring the ruler aligns with the edge. Transfer the 90-degree mark to the adjacent side to create a reference point.

- Transfer Angles: Adjust the sliding bevel to match the parallelogram’s corner angle, then replicate this angle at the opposite corner to guide diagonal alignment.

- Measure the Diagonal: Extend the tape measure from one marked corner to its opposite, keeping the blade taut and aligned with the bevel’s angle. Record the length to the nearest millimeter.

Cautions and Corrections:

Wood movement due to moisture or temperature can skew measurements. Measure at a consistent humidity level (ideally 40-60% RH) and allow the wood to acclimate for 48 hours. Avoid measuring warped or uneven surfaces; plane or sand the piece beforehand. For irregular parallelograms, verify the diagonal by measuring both diagonals—they should differ in length, with the longer diagonal spanning the obtuse angle.

Advanced Techniques for Precision:

Laser distance measurers (accurate to ±1.5 mm) offer a modern alternative, especially for large pieces. Pair this with a digital angle finder to confirm corner angles before measuring. For intricate projects, triangulation—measuring two sides and the included angle, then calculating the diagonal using the Law of Cosines—provides a mathematical cross-check.

Mastering these techniques transforms diagonal measurement from guesswork into a repeatable science, ensuring every parallelogram in your woodwork aligns with both design intent and structural demands.

Abatron Wood Epoxy Drying Time: A Comprehensive Guide for Woodworkers

You may want to see also

Explore related products

Diagonal vs. Sides: Comparing diagonal length with side lengths and angles in parallelograms

In a parallelogram, the diagonals bisect each other, creating a unique interplay between diagonal lengths, side lengths, and angles. This geometric property is crucial in woodworking, where precision in measurements ensures structural integrity and aesthetic appeal. For instance, when crafting a parallelogram-shaped frame, understanding how the longer diagonal relates to the sides can prevent warping or misalignment. The longer diagonal, often the focal point in design, is inherently tied to the side lengths and the angle between them, governed by the cosine rule: *d* = √(2*a*² + 2*b*² - 4*ab*cos(θ)), where *d* is the diagonal, *a* and *b* are the sides, and θ is the angle between them.

To illustrate, consider a parallelogram with sides of 8 inches and 6 inches, and an angle of 60 degrees between them. Applying the formula, the longer diagonal would be approximately 12.31 inches. This calculation is vital in woodworking to ensure the diagonal fits within the intended design space. However, relying solely on formulas can be misleading without practical verification. Always measure and mark the diagonal on the wood before cutting, accounting for material thickness and tool precision. A miter saw set at the correct angle can then be used to achieve clean, accurate cuts.

Comparatively, the relationship between diagonals and sides highlights the importance of angle selection in design. A smaller angle between sides results in a longer diagonal, which can either enhance or detract from the piece’s visual balance. For example, a narrow parallelogram with a 30-degree angle between sides of 10 inches and 8 inches yields a diagonal of approximately 17.32 inches—a dramatic length that may dominate the design. In contrast, a 90-degree angle (forming a rectangle) minimizes diagonal length, offering a more subdued aesthetic. Woodworkers must weigh these trade-offs, considering both structural stability and visual impact.

Persuasively, mastering diagonal-side relationships elevates craftsmanship from functional to exceptional. For intricate projects like parquet flooring or geometric wall art, understanding these dynamics ensures seamless integration of parallelogram elements. For instance, when laying out a herringbone pattern, the diagonals of individual parallelograms must align harmoniously with adjacent pieces. A discrepancy of even 1/16th of an inch can disrupt the entire pattern. Thus, meticulous planning—including mock-ups and test cuts—is indispensable. Tools like laser guides or angle finders can aid in achieving precision, but the foundational knowledge of diagonal-side interplay remains paramount.

In conclusion, the longer diagonal of a parallelogram in woodworking is not just a geometric curiosity but a critical design element. By comparing diagonal lengths with side lengths and angles, woodworkers can anticipate structural challenges, refine aesthetic choices, and execute projects with confidence. Whether crafting furniture, flooring, or decorative pieces, this understanding bridges the gap between theoretical geometry and practical application, ensuring both beauty and durability in every creation. Always measure twice, cut once, and let the mathematics of diagonals guide your craftsmanship.

Transporting Oversized Wood: Practical Tips for Moving Long Lumber Safely

You may want to see also

Frequently asked questions

The longer diagonal of a parallelogram in woodworking is the line segment connecting two opposite vertices that spans the greater distance across the shape.

The longer diagonal can be calculated using the formula: √(a² + b² + 2ab cos(θ)), where 'a' and 'b' are the side lengths, and 'θ' is the angle between them.

The longer diagonal is crucial for measuring, cutting, and aligning wooden pieces accurately, especially when creating frames, joints, or decorative patterns in parallelogram shapes.

No, the longer diagonal is always greater than the shorter diagonal unless the parallelogram is a rectangle, in which case both diagonals are equal.