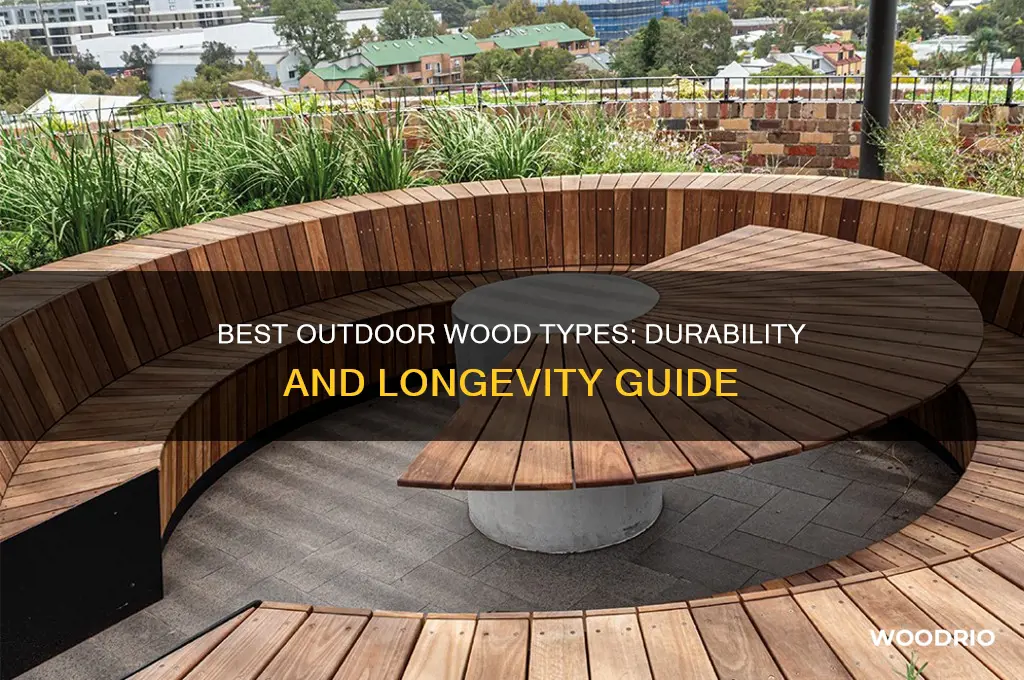

When considering which type of wood will last longer outdoors, it's essential to focus on durability, resistance to decay, and tolerance to weather conditions. Hardwoods like teak, cedar, and redwood are popular choices due to their natural oils and resins that repel moisture, insects, and rot. Teak, for instance, is highly resistant to warping and cracking, making it ideal for outdoor furniture and decking. Cedar and redwood also contain tannins and natural preservatives that deter pests and fungi, ensuring longevity in humid or wet environments. Additionally, pressure-treated pine, though a softwood, is chemically treated to enhance its resistance to decay and insect damage, making it a cost-effective option for outdoor structures. Ultimately, the choice depends on the specific climate, intended use, and maintenance preferences, but these woods generally offer the best balance of durability and aesthetics for outdoor applications.

Explore related products

What You'll Learn

- Durable Hardwoods: Teak, cedar, and ipe resist decay and insects, ideal for outdoor use

- Pressure-Treated Lumber: Chemically treated wood resists rot, insects, and moisture effectively

- Rot-Resistant Woods: Naturally durable woods like cypress and redwood thrive outdoors

- Tropical Hardwoods: Dense, oily woods like mahogany and balau withstand harsh weather

- Maintenance Tips: Sealants, stains, and regular cleaning extend outdoor wood lifespan

Durable Hardwoods: Teak, cedar, and ipe resist decay and insects, ideal for outdoor use

Teak, cedar, and ipe stand out as the trifecta of durable hardwoods for outdoor applications, each boasting unique properties that resist decay, repel insects, and endure harsh weather conditions. Teak, prized for its natural oils, forms a protective patina over time, making it virtually impervious to moisture and pests. Cedar contains innate preservatives that deter rot and insects, while ipe’s extreme density and high oil content create a barrier against environmental damage. These woods are not just long-lasting; they age gracefully, developing rich patinas that enhance their aesthetic appeal over decades.

For those embarking on outdoor projects, selecting the right wood is a critical decision that balances longevity, maintenance, and cost. Teak, though expensive, requires minimal upkeep—a simple annual cleaning suffices to maintain its appearance. Cedar is more budget-friendly and lightweight, making it ideal for DIY projects like decking or garden furniture. Ipe, the densest of the three, is best suited for high-traffic areas like pool decks or commercial spaces, though its hardness demands specialized tools for installation. Each wood offers a distinct advantage, depending on the project’s scope and the user’s priorities.

A comparative analysis reveals why these hardwoods outperform alternatives like pine or fir, which lack natural resistance and require chemical treatments to survive outdoors. Teak’s durability stems from its high silica content, which shields it from fungal decay and warping. Cedar’s aromatic oils act as a natural insect repellent, while ipe’s interlocking grain structure prevents water absorption. Unlike pressure-treated woods, which leach chemicals over time, these hardwoods are eco-friendly and safe for contact with soil and water. Their longevity reduces the need for frequent replacements, making them a sustainable choice in the long run.

Practical tips for maximizing the lifespan of these woods include proper installation and routine care. When using ipe, pre-drill holes to prevent splitting due to its density. For teak and cedar, ensure adequate spacing between boards to allow airflow and prevent moisture buildup. Applying a sealant can enhance cedar’s lifespan, though it’s optional for teak and ipe. Avoid harsh cleaners that strip natural oils; instead, use mild soap and water for annual cleaning. With these measures, teak, cedar, and ipe can easily last 25–50 years outdoors, making them investments that pay dividends in durability and beauty.

Into the Woods Justin Timberlake Show Duration: A Complete Guide

You may want to see also

Explore related products

Pressure-Treated Lumber: Chemically treated wood resists rot, insects, and moisture effectively

Pressure-treated lumber stands as a cornerstone in outdoor construction, engineered to defy the elements that typically degrade wood. Through a process of chemical infusion, this material gains remarkable resistance to rot, insect damage, and moisture absorption. The treatment involves immersing the wood in a preservative solution, often containing copper azole, alkaline copper quat (ACQ), or chromated copper arsenate (CCA, though less common today due to health concerns). These chemicals penetrate deep into the wood fibers, creating a barrier that repels fungi, termites, and other pests while minimizing water retention. For homeowners and builders, this means structures like decks, fences, and garden beds can endure decades of exposure to rain, snow, and sun without premature deterioration.

Choosing pressure-treated lumber requires understanding its grading system, which indicates the wood’s intended use and treatment level. Ground-contact rated lumber, for instance, contains higher chemical concentrations (typically 0.40 pounds of preservative per cubic foot) to withstand direct soil contact, while above-ground lumber (0.25 pounds per cubic foot) is suitable for structures elevated from the ground. Always verify the treatment tag or stamp on the wood to ensure it matches your project’s needs. For example, using above-ground lumber in a soil-embedded fence post will result in rapid decay, negating the benefits of the treatment.

Despite its durability, pressure-treated lumber demands thoughtful handling and maintenance. Wear gloves and a mask during cutting or sanding to avoid exposure to chemicals, and seal all cut ends with a preservative to prevent moisture intrusion. While the wood is naturally resistant to decay, applying a water-repellent sealant every few years enhances its longevity and appearance. Additionally, avoid placing hot objects directly on the surface, as the chemicals can leach out under high temperatures, compromising both the wood and the surrounding environment.

Comparatively, untreated woods like cedar or redwood offer natural resistance to decay but pale in longevity when pitted against pressure-treated lumber in harsh conditions. While cedar’s oils deter insects and fungi, it still absorbs moisture over time, leading to warping and splitting. Pressure-treated lumber, on the other hand, maintains structural integrity even in humid climates or waterlogged environments. For projects requiring both durability and affordability, pressure-treated lumber often emerges as the superior choice, outperforming even exotic hardwoods in terms of cost-effectiveness and lifespan.

In practice, pressure-treated lumber’s versatility shines in applications ranging from backyard decks to playground structures. Its ability to resist termite infestations makes it ideal for regions prone to these pests, while its moisture resistance ensures it won’t rot in damp, shaded areas. However, it’s not invincible—poor installation, such as inadequate drainage or improper fastening, can still lead to failure. By following manufacturer guidelines and incorporating best practices, such as using corrosion-resistant hardware, you can maximize the wood’s performance. Whether you’re a DIY enthusiast or a professional builder, pressure-treated lumber offers a reliable, long-term solution for outdoor projects that demand resilience.

Wet Wood Warping Timeline: Factors Affecting Drying and Distortion

You may want to see also

Explore related products

Rot-Resistant Woods: Naturally durable woods like cypress and redwood thrive outdoors

Cypress and redwood stand out as natural champions in the battle against outdoor decay. These woods possess inherent rot-resistant properties, making them ideal for structures exposed to the elements. Their secret lies in natural oils and tannins that repel moisture, fungi, and insects, the primary culprits behind wood deterioration. This built-in defense mechanism allows them to endure decades, even centuries, with minimal maintenance.

For instance, ancient redwood bridges in California still stand strong after over a century, a testament to the wood's longevity. Similarly, cypress has been a staple in boatbuilding and outdoor furniture for generations, prized for its ability to resist warping and cracking.

Choosing cypress or redwood for outdoor projects is a wise investment. Their durability translates to lower long-term costs compared to less resistant woods that require frequent replacement or treatment. While the initial cost might be higher, the savings in maintenance and replacement far outweigh the upfront expense. Consider using cypress for decking, fencing, or garden structures, and redwood for furniture, pergolas, or siding. Both woods weather beautifully, developing a rich patina over time, adding to their aesthetic appeal.

Remember, proper installation and periodic sealing can further enhance their lifespan, ensuring your outdoor creations remain sturdy and beautiful for years to come.

Wood Acclimation Time: Essential Tips for Proper Wood Adjustment

You may want to see also

Explore related products

$15

Tropical Hardwoods: Dense, oily woods like mahogany and balau withstand harsh weather

Tropical hardwoods, such as mahogany and balau, are nature's answer to the challenge of outdoor durability. These woods possess a unique combination of density and natural oils that make them exceptionally resistant to the elements. Imagine a deck or outdoor furniture that remains sturdy and beautiful despite years of exposure to rain, sun, and wind. This is not a fantasy but a reality with these tropical species, which have evolved in some of the harshest climates on Earth. Their dense structure minimizes moisture absorption, while the natural oils act as a protective barrier against decay and insect damage.

When selecting wood for outdoor projects, consider the specific qualities of tropical hardwoods. Mahogany, for instance, is renowned for its stability and resistance to warping, making it ideal for boat building and outdoor furniture. Balau, on the other hand, is often used for decking and structural applications due to its high strength-to-weight ratio and natural resistance to rot. Both woods require minimal maintenance, typically needing only periodic cleaning and the occasional application of a protective sealant to maintain their appearance. For best results, apply a UV-resistant oil or sealant every 12–18 months, depending on exposure levels.

The longevity of tropical hardwoods is not just a matter of their physical properties but also their sustainability. While these woods are durable, it’s crucial to source them responsibly to ensure environmental stewardship. Look for certifications like FSC (Forest Stewardship Council) when purchasing, as this guarantees the wood comes from well-managed forests. Properly sourced tropical hardwoods can last 25–40 years outdoors, outperforming many other materials in terms of both durability and aesthetic appeal.

Comparatively, softer woods like pine or cedar, though popular for outdoor use, often require more frequent treatment and are prone to deterioration within 10–15 years. Tropical hardwoods, while initially more expensive, offer a longer lifespan and lower maintenance costs over time. For example, a balau deck may cost 20–30% more upfront than a cedar deck but will likely outlast it by decades, making it a more cost-effective choice in the long run.

In practice, incorporating tropical hardwoods into outdoor projects requires thoughtful planning. Avoid using them in areas with constant water exposure, as even these durable woods can degrade under such conditions. Instead, prioritize their use in raised structures like decks, pergolas, or furniture. When installing, ensure proper ventilation to prevent moisture buildup, and use stainless steel fasteners to avoid corrosion. With these precautions, tropical hardwoods will not only withstand harsh weather but also add a touch of natural elegance to any outdoor space.

The Timeless Endurance of Wooden Sailing Ships: Secrets to Their Longevity

You may want to see also

Explore related products

Maintenance Tips: Sealants, stains, and regular cleaning extend outdoor wood lifespan

Outdoor wood, whether it’s decking, furniture, or structural elements, faces relentless assault from UV rays, moisture, temperature swings, and pests. Without intervention, even the most durable species like teak or cedar will degrade over time. Maintenance isn’t optional—it’s the difference between wood that lasts decades and wood that splinters in a few years. Sealants, stains, and regular cleaning form the trifecta of protection, each addressing specific vulnerabilities in the wood’s lifecycle.

Sealants act as the first line of defense, creating a barrier against water intrusion, which is the primary cause of rot, warping, and mold. Water-based sealants are eco-friendly and dry quickly, but they may require more frequent reapplication. Oil-based sealants penetrate deeper, offering longer-lasting protection but with stronger fumes and longer drying times. For maximum efficacy, apply sealants every 1–3 years, depending on exposure. Start by cleaning the wood thoroughly, then apply two thin coats with a brush or sprayer, allowing proper drying time between layers. Avoid over-application, as it can lead to peeling or a sticky surface.

Stains serve a dual purpose: they enhance the wood’s natural beauty while adding a protective layer against UV damage. Unlike sealants, stains contain pigments or dyes that mitigate color fading caused by sunlight. Semi-transparent stains allow the wood grain to show through, while solid stains provide fuller coverage but resemble paint. Reapply stains every 2–4 years, depending on wear. For best results, sand the wood lightly before application to ensure even absorption. Choose a stain with UV inhibitors for added protection, especially in sunny climates.

Regular cleaning is the unsung hero of wood maintenance, preventing the buildup of dirt, mildew, and debris that can trap moisture and accelerate decay. Use a mild detergent mixed with water and a soft-bristle brush to scrub surfaces, rinsing thoroughly afterward. For stubborn stains or mildew, a solution of oxygen bleach and water is effective and safe for most wood types. Clean at least twice a year, or more frequently in humid or leafy environments. Neglecting this step can render even the best sealants and stains ineffective.

Combining these practices creates a synergistic effect, significantly extending the lifespan of outdoor wood. Sealants prevent moisture penetration, stains block UV damage, and cleaning removes harmful surface contaminants. Together, they address the three primary threats to wood longevity. While the initial effort may seem labor-intensive, the payoff is wood that retains its structural integrity and aesthetic appeal for years. Think of it as an investment—a few hours of maintenance annually can save thousands in replacement costs down the line.

Wood Gloss Drying Time: Factors Affecting Cure and Finish Durability

You may want to see also

Frequently asked questions

Naturally rot-resistant woods like cedar, redwood, teak, and cypress are ideal for outdoor use due to their natural oils and resins that repel moisture and insects.

Yes, pressure-treated wood is chemically treated to resist rot, decay, and insect damage, making it highly durable for outdoor applications.

Hardwoods like teak and ipe are generally more durable outdoors due to their density and natural resistance, but some softwoods like cedar and redwood also perform well.

Tropical hardwoods like ipe, teak, and cumaru are extremely dense and naturally resistant to decay, making them among the longest-lasting options for outdoor projects.