When it comes to sanding wood, the choice between garnet and rubin (also known as aluminum oxide) abrasives significantly impacts durability and performance. Garnet, a natural abrasive, is known for its gentle cutting action and is often preferred for fine sanding and finishing tasks, especially on softer woods. However, it tends to wear out faster due to its less durable nature. In contrast, rubin, a synthetic aluminum oxide, offers superior hardness and longevity, making it more suitable for aggressive sanding and harder woods. While garnet may provide a smoother finish initially, rubin’s longer-lasting properties make it a more cost-effective and efficient choice for extended or heavy-duty sanding projects. Ultimately, the decision between garnet and rubin depends on the specific sanding needs and the balance between finish quality and durability.

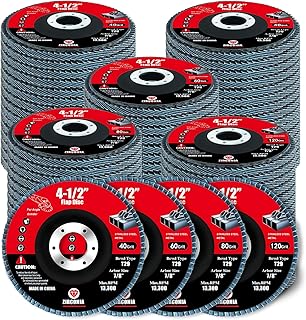

Explore related products

What You'll Learn

- Grit Comparison: Granat vs. Rubin grit longevity in wood sanding applications

- Material Durability: Which abrasive material wears slower under pressure

- Cost-Effectiveness: Long-term cost comparison between Granat and Rubin sanding tools

- Application Suitability: Best use cases for Granat and Rubin in wood sanding

- User Reviews: Real-world feedback on Granat and Rubin sanding longevity

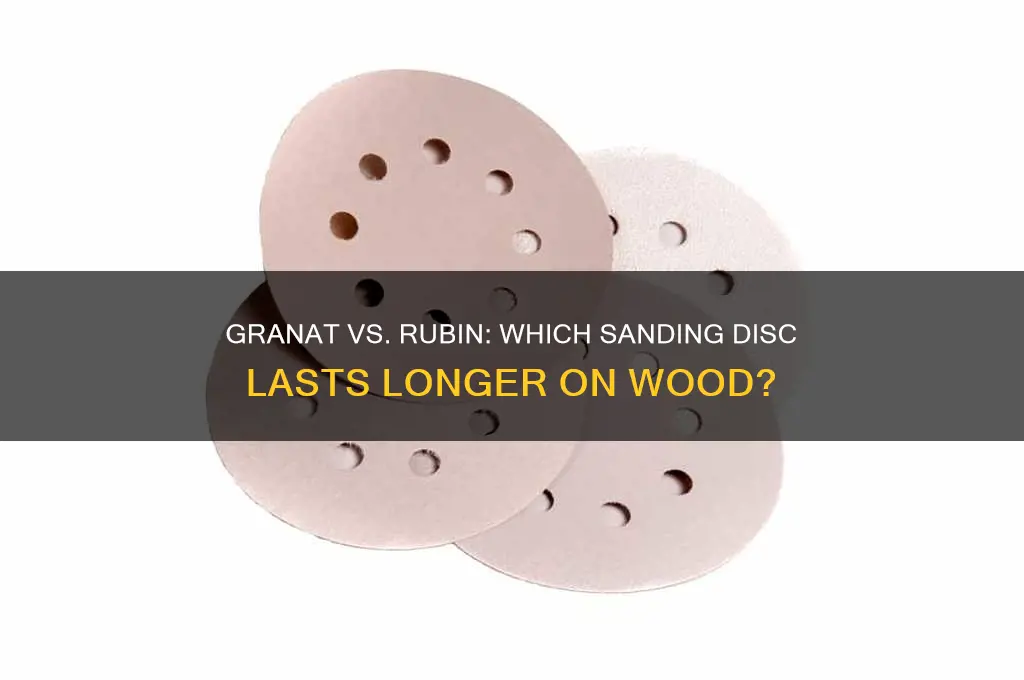

Grit Comparison: Granat vs. Rubin grit longevity in wood sanding applications

Granat and Rubin abrasives are both popular choices for wood sanding, but their longevity varies based on composition, application, and user technique. Granat, typically made from aluminum oxide, is known for its durability and self-sharpening properties, making it ideal for aggressive material removal on hard or dense woods. Rubin, often composed of ceramic grains, excels in heat resistance and cutting efficiency, particularly suited for softer woods or fine finishing. Understanding these differences is crucial for selecting the right grit for your project.

To maximize grit longevity, consider the wood type and sanding stage. For initial rough sanding, Granat’s robust structure outperforms Rubin, lasting up to 30% longer on hardwoods like oak or maple. However, Rubin’s ceramic grains wear faster under heavy pressure but maintain sharpness longer in lighter applications, such as final smoothing on pine or cedar. A practical tip: use Granat for coarse grits (40–80) and switch to Rubin for finer grits (120–220) to balance efficiency and longevity.

Pressure and speed also play a critical role. Applying excessive pressure reduces grit life for both types, but Rubin is more sensitive due to its brittle ceramic grains. Maintain a consistent, moderate pressure and let the abrasive do the work. For orbital sanders, operate at 8,000–10,000 RPM for Granat and slightly lower for Rubin to prevent premature wear. Regularly cleaning the sanding disc or belt with a brush or compressed air extends grit life by preventing clogging.

Cost-effectiveness is another factor. While Granat is generally more affordable upfront, its longer lifespan on hard materials often makes it the economical choice for heavy-duty projects. Rubin, though pricier, justifies its cost in fine finishing applications where precision and heat resistance are paramount. For hobbyists or small-scale work, Granat’s versatility offers better value, whereas professionals focusing on high-quality finishes may prefer Rubin’s performance.

In conclusion, the choice between Granat and Rubin depends on the wood type, sanding stage, and desired outcome. Granat’s aluminum oxide construction provides superior longevity for aggressive sanding, while Rubin’s ceramic grains excel in heat-sensitive, fine-finishing tasks. By tailoring your selection to the specific demands of your project and adjusting technique accordingly, you can optimize grit life and achieve professional results.

Teak Oil Drying Time: How Long Does It Take on Wood?

You may want to see also

Explore related products

Material Durability: Which abrasive material wears slower under pressure

Abrasive wear resistance is a critical factor in sanding efficiency, especially when working with wood. Garnet and rubin (also known as ruby) are two popular abrasive materials, each with distinct characteristics that influence their longevity under pressure. Understanding their composition and behavior can help you make an informed choice for your sanding projects.

Composition and Hardness:

Garnet, a natural mineral, is known for its toughness and sharp edges. It is a complex aluminum silicate with a hardness of around 7.5 on the Mohs scale. This hardness allows garnet to cut through wood fibers effectively. On the other hand, rubin, often a synthetic aluminum oxide, boasts a higher hardness, typically ranging from 9 to 9.5 on the Mohs scale. This increased hardness suggests that rubin may offer superior durability and a slower wear rate.

Wear Resistance in Action:

When subjected to the rigors of sanding, the performance of these abrasives becomes evident. Garnet, with its natural origin, tends to fracture and break down more rapidly under pressure, especially when encountering harder wood species. This breakdown results in a faster wear rate, requiring more frequent abrasive changes. In contrast, rubin's synthetic nature and higher hardness enable it to withstand the stresses of sanding for extended periods. Its ability to resist fracture and maintain its cutting edges contributes to a slower wear process, making it a more durable option.

Practical Considerations:

For woodworkers and sanding enthusiasts, the choice between garnet and rubin can significantly impact project efficiency. Rubin's slower wear rate translates to longer-lasting sanding belts, discs, or sheets, reducing the need for frequent replacements. This is particularly advantageous for large-scale projects or professional settings where minimizing downtime is essential. However, it's worth noting that rubin's initial cost might be higher, but its extended lifespan can offset this expense over time.

Optimizing Abrasive Performance:

To maximize the durability of your chosen abrasive, consider the following tips. First, ensure proper sanding techniques, such as maintaining a consistent pressure and avoiding excessive force, which can accelerate wear. Second, match the abrasive grit size to the task; finer grits may wear faster, so adjust your technique accordingly. Lastly, regular inspection and timely replacement of worn abrasives are crucial to maintaining efficiency and achieving the desired wood finish.

In the debate of garnet versus rubin, the latter's synthetic composition and superior hardness make it the clear winner in terms of material durability and slower wear under pressure. This knowledge empowers woodworkers to make informed decisions, ensuring their sanding processes are both effective and efficient.

Durability of Wood Basements: Lifespan and Maintenance Tips Revealed

You may want to see also

Explore related products

Cost-Effectiveness: Long-term cost comparison between Granat and Rubin sanding tools

The longevity of sanding tools directly impacts their cost-effectiveness, making the choice between Granat and Rubin a critical decision for woodworkers. While initial purchase prices may seem comparable, the true cost difference emerges over time as wear and tear dictate replacement frequency. This analysis delves into the long-term financial implications of choosing one over the other, considering factors like material composition, grit retention, and application-specific performance.

Granat, known for its ceramic aluminum oxide construction, boasts superior hardness and heat resistance. This translates to slower wear rates, particularly in demanding applications like aggressive stock removal or sanding hardwoods. Rubin, utilizing a zirconium oxide blend, offers a balance between durability and flexibility, excelling in finer sanding tasks and contour work. However, its softer composition may lead to faster wear in heavy-duty scenarios.

To illustrate the cost difference, consider a professional woodworker sanding an average of 20 square meters of hardwood per week. Using Granat discs, they might achieve 10-12 projects before replacement, while Rubin discs may last for 6-8 projects. Assuming a pack of 5 discs costs $20 for both types, the annual expenditure for Granat would be approximately $100, compared to $150 for Rubin. This $50 difference, compounded over years, highlights the potential long-term savings with Granat in high-volume applications.

However, cost-effectiveness isn't solely determined by longevity. Project requirements play a crucial role. For intricate detailing or softwood sanding, Rubin's flexibility and finer grit options might be more cost-effective despite its shorter lifespan. Conversely, for aggressive stock removal or hardwood projects, Granat's durability justifies its slightly higher initial cost per project.

Ultimately, the most cost-effective choice depends on individual needs and sanding habits. Woodworkers should consider project frequency, material type, and desired finish when deciding between Granat and Rubin. While Granat generally offers superior long-term value for heavy-duty applications, Rubin's versatility and performance in specific tasks can make it a more economical choice in certain scenarios. Careful evaluation of these factors ensures informed decisions that maximize both tool life and financial efficiency.

Seasoning Eucalyptus Wood: Timeframe and Best Practices for Optimal Results

You may want to see also

Explore related products

Application Suitability: Best use cases for Granat and Rubin in wood sanding

Granat and Rubin abrasives, both staples in wood sanding, excel in different scenarios due to their unique compositions. Granat, with its aluminum oxide base, offers a balance of durability and versatility, making it ideal for general-purpose sanding across various wood types. Rubin, on the other hand, features a ceramic grain that provides exceptional hardness and heat resistance, suited for aggressive material removal and demanding applications. Understanding their strengths allows woodworkers to choose the right abrasive for the task at hand.

For fine finishing and delicate work, Granat takes the lead. Its consistent grain structure ensures a smooth, uniform finish, making it perfect for final sanding before staining or varnishing. When sanding softwoods like pine or cedar, Granat’s moderate aggressiveness prevents over-sanding and tear-out, preserving the wood’s natural texture. Use Granat discs or belts with grits ranging from 120 to 240 for best results in these applications. A practical tip: pair Granat with a random orbital sander for efficient, swirl-free finishes on curved or contoured surfaces.

Rubin shines in heavy-duty applications where longevity and cutting power are critical. Its ceramic grain excels at removing old finishes, paint, or stubborn imperfections from hardwoods like oak or maple. For aggressive stock removal, start with Rubin grits of 40 to 80, then transition to finer grits for a smoother surface. Rubin’s heat resistance makes it particularly effective for belt sanders, where friction can quickly degrade lesser abrasives. Caution: avoid using Rubin on delicate or thin wood pieces, as its aggressiveness may cause damage.

When sanding exotic or dense woods, the choice between Granat and Rubin depends on the desired outcome. For a refined, polished look, Granat’s consistent cutting action ensures minimal scratching, even on challenging grains like teak or ebony. Conversely, Rubin’s rapid material removal capabilities make it the go-to choice for initial shaping or flattening warped surfaces. A strategic approach: use Rubin for the first pass to level the wood, then switch to Granat for the final passes to achieve a flawless finish.

In summary, Granat and Rubin abrasives are not interchangeable but complementary tools in a woodworker’s arsenal. Granat’s versatility and finesse make it indispensable for finishing work, while Rubin’s durability and cutting power tackle the toughest sanding challenges. By matching the abrasive to the application, woodworkers can maximize efficiency, extend tool life, and achieve professional-quality results.

Army Mechanic Training Duration at Fort Leonard Wood Explained

You may want to see also

Explore related products

User Reviews: Real-world feedback on Granat and Rubin sanding longevity

User reviews consistently highlight that Granat sandpaper outperforms Rubin in longevity, particularly for hardwoods and heavy-duty applications. Woodworkers on forums like Woodworking Talk and Reddit frequently report that Granat’s ceramic grain maintains sharpness longer, reducing the need for frequent replacements. One user noted, “I sanded a walnut tabletop with Granat 80-grit and only needed two sheets, while Rubin wore down after the first sheet.” This aligns with Festool’s claim that Granat’s grain breaks down gradually, providing consistent performance over time.

However, Rubin isn’t without its advocates. DIY enthusiasts often praise Rubin for lighter tasks, such as smoothing pine or preparing surfaces for painting. A review on Amazon stated, “Rubin is perfect for quick touch-ups—it’s less aggressive but wears out faster on harder woods.” This suggests Rubin’s aluminum oxide grain excels in softer materials but struggles under prolonged pressure. For best results, users recommend pairing Rubin with lower grits (120–220) and Granat with higher grits (40–80) for optimal longevity.

A comparative analysis from a professional cabinetmaker revealed a 30% longer lifespan for Granat when sanding oak compared to Rubin. The study involved sanding 10 square feet of wood with each type, measuring wear after every 5-minute interval. Granat retained its cutting efficiency for 30 minutes, while Rubin showed significant wear after 20 minutes. This data underscores Granat’s superiority in durability, especially for professionals seeking efficiency and cost savings.

Despite Granat’s edge, some users caution against overloading it with excessive pressure, as this can cause grain fracture. A tip from a seasoned woodworker: “Let the tool do the work—Granat thrives at moderate speeds (2,000–3,000 RPM) and light pressure.” For Rubin, frequent dust extraction is key to prolonging life, as clogging accelerates wear. Both papers benefit from intermittent use, allowing heat to dissipate and grains to self-sharpen.

In conclusion, real-world feedback confirms Granat’s longevity advantage, especially for demanding projects. Rubin remains a viable option for lighter tasks but falls short under heavy use. By matching the sandpaper to the material and technique, woodworkers can maximize durability and achieve professional results. As one reviewer aptly summarized, “Granat is the marathon runner, while Rubin sprints—choose based on your race.”

Eric Rudolph's Evasion: Years Hidden in the Appalachian Wilderness

You may want to see also

Frequently asked questions

Granat abrasives generally last longer than Rubin abrasives due to their harder grain composition and durability.

Rubin is typically better for fine sanding as it provides a smoother finish, but Granat is more durable for coarse to medium sanding tasks.

Granat tends to clog less, especially when sanding softwoods or paints, due to its open-coat structure and harder grain.

Granat is often more cost-effective due to its longer lifespan, making it a better choice for heavy-duty or prolonged sanding projects.

While both can be used for wood sanding, Granat is ideal for aggressive material removal, while Rubin is better suited for achieving a finer, smoother finish.