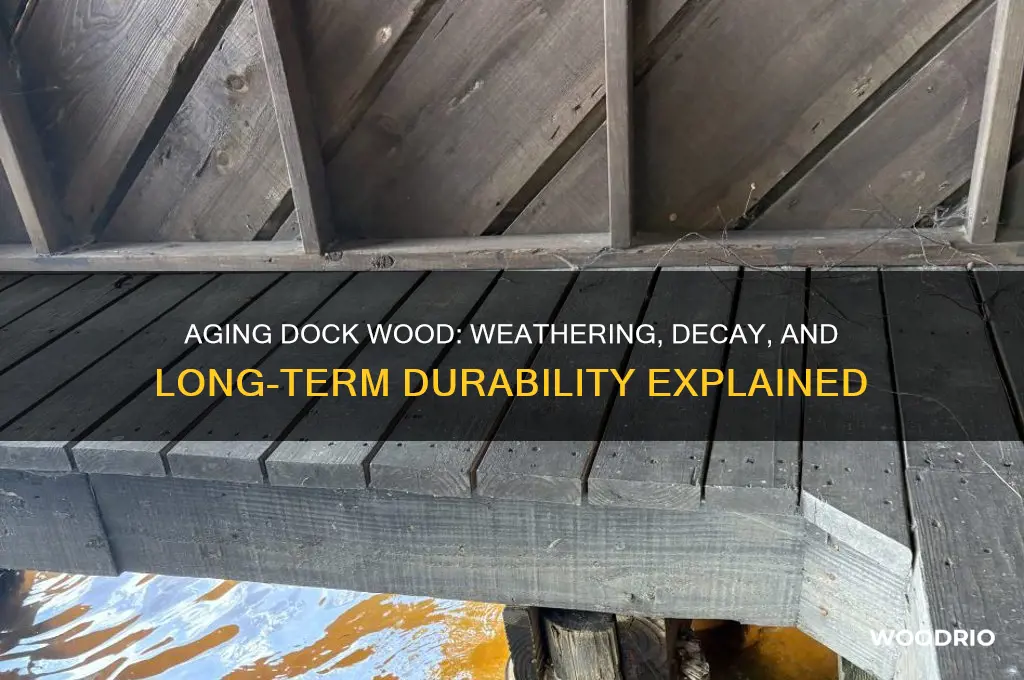

Over time, wood on a dock is subjected to a variety of environmental factors that can significantly impact its condition and durability. Prolonged exposure to water, sunlight, and fluctuating temperatures causes the wood to deteriorate, with processes like rotting, warping, and splintering becoming increasingly evident. Constant moisture can lead to the growth of mold, mildew, and algae, while UV rays from the sun break down the wood’s fibers, making it brittle and prone to cracking. Additionally, marine organisms such as barnacles and termites may infest the wood, further weakening its structure. Without proper maintenance, such as regular sealing or treatment, the wood on a dock will eventually lose its integrity, posing safety risks and requiring replacement or repair.

| Characteristics | Values |

|---|---|

| Weathering | Exposure to sun, rain, and wind causes wood to fade, crack, and warp over time. |

| Rot and Decay | Moisture absorption leads to fungal growth and wood rot, especially in areas with poor drainage. |

| Insect Damage | Termites, beetles, and marine borers can infest and weaken the wood structure. |

| Warping and Splitting | Fluctuations in moisture levels cause wood to expand and contract, leading to warping, splitting, and cupping. |

| UV Degradation | Prolonged exposure to sunlight breaks down lignin in the wood, causing it to become brittle and discolored. |

| Corrosion of Fasteners | Metal fasteners (e.g., nails, screws) can rust, leading to weakened connections and potential structural failure. |

| Marine Organism Growth | Algae, barnacles, and other marine organisms can attach to submerged wood, increasing weight and reducing structural integrity. |

| Loss of Resin and Oils | Natural protective resins and oils in wood leach out over time, reducing its resistance to moisture and pests. |

| Surface Erosion | Constant exposure to water and foot traffic wears down the wood surface, making it rough and uneven. |

| Structural Weakening | Cumulative effects of weathering, rot, and insect damage compromise the wood's load-bearing capacity. |

Explore related products

What You'll Learn

Weathering and Graying of Wood

Wood exposed to the elements, like that on a dock, undergoes a transformation over time, a process both beautiful and destructive. The relentless combination of sunlight, rain, wind, and fluctuating temperatures leads to weathering and graying, a natural phenomenon that alters the wood's appearance and structural integrity. This process is not merely a surface-level change; it penetrates the wood's fibers, breaking down its cellular structure. The result? A once vibrant, warm-toned dock gradually turns into a weathered, silver-gray relic, bearing the marks of its exposure to the environment.

The graying of wood is primarily caused by the sun's ultraviolet (UV) rays. UV radiation breaks down the lignin, a key component in wood that gives it color and strength. As lignin degrades, the wood loses its natural hue, revealing the lighter cellulose beneath. This process is accelerated in coastal areas, where salt in the air and water acts as an additional abrasive agent, speeding up the breakdown of wood fibers. For instance, a dock in the Caribbean might show signs of graying within a year, while one in a freshwater lake could take several years to exhibit similar changes.

Preventing or slowing this process requires proactive measures. Applying a UV-protective sealant or stain can significantly extend the life of dock wood. These products act as a barrier, shielding the wood from harmful rays and moisture. For optimal results, apply a high-quality marine-grade sealant every 1-2 years, depending on exposure levels. Additionally, regular cleaning to remove salt, algae, and mildew can prevent surface degradation. Pressure washing, however, should be done cautiously, as excessive force can damage the wood’s surface.

While graying is often seen as a sign of deterioration, it’s also celebrated for its aesthetic appeal. Many homeowners intentionally weather wood to achieve a rustic, coastal look. This can be done by using products like wood accelerators or simply allowing the wood to age naturally. However, it’s crucial to monitor structural integrity, as weathered wood may become brittle or prone to splintering. For docks, safety should always take precedence over appearance, and compromised planks should be replaced promptly.

In conclusion, weathering and graying are inevitable for wood exposed to the elements, but their impact can be managed. Whether you aim to preserve the wood’s original beauty or embrace its aged charm, understanding the process allows for informed decisions. By combining protective treatments with regular maintenance, dock owners can strike a balance between longevity and the timeless allure of weathered wood.

Hickory Wood Petrification: Understanding the Timeframe for Fossilization

You may want to see also

Explore related products

$28.99

Rot and Decay from Moisture

Wood exposed to moisture, as is common on docks, undergoes a relentless assault that leads to rot and decay. This process is driven by fungi and bacteria that thrive in damp environments, breaking down the wood’s cellular structure over time. The constant presence of water, whether from submersion, rain, or humidity, creates ideal conditions for these microorganisms to flourish. Without intervention, the wood weakens, loses structural integrity, and eventually becomes unsafe for use.

To combat this, consider preventive measures such as applying marine-grade sealants or pressure-treated wood during construction. Sealants act as a barrier, reducing moisture absorption, while pressure-treated wood contains preservatives that deter fungal growth. For existing docks, regular inspections are crucial. Look for signs of discoloration, softness, or splintering, which indicate early stages of decay. Addressing these issues promptly can extend the lifespan of the structure.

A comparative analysis reveals that hardwoods like cedar or cypress naturally resist rot better than softwoods due to their higher density and natural oils. However, even these species are not immune to prolonged moisture exposure. For maximum durability, combine material selection with proper maintenance. Elevating wooden components above water level, ensuring adequate drainage, and using galvanized or stainless steel hardware to prevent rust-induced damage are additional strategies.

From a practical standpoint, treating wood with borate solutions can be highly effective. Borates penetrate the wood, killing existing fungi and preventing future infestations. Apply a 1:1 solution of borax and water, ensuring thorough saturation. Reapply every 2–3 years, especially in high-moisture environments. For severe cases, replacing compromised sections with composite materials, which are impervious to rot, may be more cost-effective than continuous repairs.

In conclusion, moisture-induced rot is a predictable yet manageable challenge for wooden docks. By understanding the mechanisms of decay and implementing targeted solutions, owners can preserve both functionality and aesthetics. Proactive measures, from material choice to regular treatments, are far less costly than rebuilding an entire structure. The key lies in consistent care and adapting strategies to the specific demands of the environment.

Optimal Clamping Time for Gorilla Wood Glue: A Comprehensive Guide

You may want to see also

Explore related products

Splitting and Warping Due to Sun

Prolonged exposure to sunlight causes wood to undergo a process known as photodegradation, where ultraviolet (UV) rays break down lignin, a key component in wood’s structural integrity. This degradation weakens the wood’s fibers, making it more susceptible to splitting. Docks, constantly exposed to direct sunlight, experience this effect more intensely than structures in shaded areas. For instance, wooden planks on a lakeside dock may develop deep cracks within 3–5 years without proper UV protection, compared to 7–10 years for shaded wood.

The splitting process is exacerbated by the wood’s moisture content fluctuations. During the day, sunlight heats the wood, causing surface moisture to evaporate rapidly. At night, cooler temperatures allow moisture to reabsorb from the surrounding environment. This daily cycle of expansion and contraction stresses the wood, creating hairline fractures that widen over time. Tropical hardwoods like ipe or teak, while more resistant, are not immune—they may split after 5–7 years without maintenance, whereas softer woods like pine can show signs of splitting in as little as 2 years.

Warping occurs as the wood’s cells shrink unevenly due to UV-induced drying. Sunlight exposure is most intense on the top surface of dock planks, causing them to dry faster than the underside. This imbalance leads to cupping (edges curling upward) or crowning (center swelling). Over time, warped planks create tripping hazards and compromise the dock’s structural stability. A practical tip: apply a UV-resistant sealant annually, reapplying every 6 months in high-sun regions like Florida or Arizona, to mitigate this effect.

To combat splitting and warping, consider a two-pronged approach: prevention and maintenance. Use pressure-treated wood or naturally UV-resistant species, and install the dock with proper spacing (1/4 inch between planks) to allow for expansion. For existing docks, sand warped areas and apply a marine-grade epoxy to stabilize cracks. Regularly inspect for early signs of damage, such as small splits or uneven surfaces, and address them immediately. While no solution is permanent, proactive care can extend a dock’s lifespan by 50% or more.

Comparatively, docks in regions with less sunlight, such as the Pacific Northwest, experience slower degradation but still require protection. Here, moisture-related issues like rot dominate, while in sun-drenched areas like the Mediterranean, UV damage is the primary concern. Understanding your climate’s specific challenges allows for tailored solutions. For example, a dock in Greece would benefit from a silicone-based sealant for UV protection, whereas one in Seattle might prioritize a water-repellent treatment.

In conclusion, splitting and warping due to sun exposure are inevitable but manageable. By understanding the mechanisms behind these issues and implementing targeted strategies, dock owners can preserve both functionality and aesthetics. The key lies in consistent maintenance and material selection, ensuring the dock withstands the test of time and elements.

Mastering Wooden Spoon Carving: Time, Techniques, and Tips for Beginners

You may want to see also

Explore related products

Marine Organism Damage (Barnacles, Algae)

Wooden docks, constantly submerged in water, become prime real estate for marine organisms seeking a stable surface to attach and thrive. Among the most persistent colonizers are barnacles and algae, each contributing uniquely to the deterioration of the wood. Barnacles, with their calcium carbonate shells, act like tiny woodpeckers, drilling microscopic holes into the surface as they settle and grow. Over time, these holes weaken the wood's structural integrity, making it more susceptible to cracking and splintering. Algae, while less directly destructive, form slippery films that accelerate moisture absorption, fostering rot and decay. Together, these organisms create a feedback loop of degradation, turning once-sturdy wooden structures into fragile, hazardous eyesores.

To combat barnacle infestations, proactive measures are essential. Regular inspections, ideally every three to six months, allow for early detection and removal. For small-scale docks, manual scraping with a putty knife or wire brush can be effective, though labor-intensive. For larger structures, consider investing in a pressure washer with a wide nozzle attachment, which can dislodge barnacles without damaging the wood. Chemical treatments, such as antifouling paints containing copper or zinc, provide longer-term protection but require careful application to avoid environmental harm. Always wear gloves and a mask when handling these substances, and apply them in dry, well-ventilated conditions for optimal adhesion.

Algae control demands a different strategy, focusing on prevention and environmental manipulation. Trimming overhanging vegetation reduces shade, which algae thrive in, while installing water circulation systems can minimize nutrient buildup that fuels their growth. For existing algae, a solution of 1 part household bleach to 10 parts water, applied with a sprayer, effectively kills the organisms. However, this method should be used sparingly, as excessive bleach can harm aquatic life and discolor the wood. Alternatively, eco-friendly algae inhibitors, often containing natural enzymes, offer a safer, though pricier, solution. Reapplication every 3–4 months is typically sufficient to maintain a clean surface.

Comparing the two threats, barnacles pose a more immediate structural risk, while algae contribute to long-term decay. This distinction informs maintenance priorities: prioritize barnacle removal to preserve strength, but don’t neglect algae management to prevent rot. Combining physical, chemical, and environmental strategies creates a holistic defense against marine organism damage. For instance, pairing antifouling paint with regular algae treatments and shade reduction maximizes protection. While no solution is permanent, consistent effort can significantly extend a wooden dock’s lifespan, ensuring it remains safe and functional for years to come.

How Long Does Burnt Wood Smell Linger and How to Eliminate It

You may want to see also

Explore related products

Wear from Foot Traffic and Friction

Wooden docks, despite their sturdy appearance, are not immune to the relentless forces of foot traffic and friction. Every step taken, every boat tied, and every piece of equipment dragged across the surface contributes to a gradual breakdown of the wood’s integrity. High-traffic areas, such as walkways and boarding zones, often show the earliest signs of wear—smoothing of grain, splintering, and even structural weakening. This wear is not merely cosmetic; it compromises the dock’s safety and functionality over time. Understanding the mechanisms behind this deterioration is the first step in mitigating its effects.

To combat wear from foot traffic, consider the type of wood and its finish. Hardwoods like ipe or cumaru are naturally more resistant to abrasion, while softer woods like pine or cedar require protective coatings. Applying marine-grade sealants or paints can significantly reduce friction-related damage by creating a barrier between the wood and external forces. For high-traffic areas, installing sacrificial strips or composite decking can extend the life of the dock. These materials absorb the brunt of the wear, allowing the underlying structure to remain intact. Regular inspections are crucial; replace worn boards promptly to prevent further damage.

Friction from dragging heavy objects, such as boats or coolers, exacerbates wear on wooden docks. The repetitive motion grinds away at the wood’s surface, creating grooves and weak points. To minimize this, use protective pads or sliders under heavy loads. Alternatively, designate specific areas for loading and unloading, reinforced with harder materials or metal plates. Educating users about proper handling techniques can also reduce unnecessary damage. For example, lifting objects instead of dragging them can significantly decrease friction-related wear.

A comparative analysis reveals that docks with proactive maintenance plans suffer far less from foot traffic and friction. Docks treated annually with sealants and inspected bi-annually for wear show a 40% reduction in damage compared to untreated structures. Similarly, docks with designated high-traffic zones reinforced with composite materials last up to 15 years longer than those without. These statistics underscore the importance of preventative measures. By investing time and resources upfront, dock owners can avoid costly repairs and ensure longevity.

In conclusion, wear from foot traffic and friction is a predictable yet manageable challenge for wooden docks. Through strategic material choices, protective finishes, and mindful usage, the impact of these forces can be minimized. Regular maintenance and user education play pivotal roles in preserving the dock’s structural integrity. By addressing these factors head-on, dock owners can enjoy a safe, functional, and aesthetically pleasing structure for years to come.

Extend Wooden Chair Legs: Simple DIY Height Adjustment Guide

You may want to see also

Frequently asked questions

Wood on a dock deteriorates over time due to exposure to water, sunlight, and weather conditions. It can warp, crack, rot, or become infested with marine organisms like barnacles or termites.

Saltwater accelerates the degradation of wood by causing corrosion, increasing moisture absorption, and promoting the growth of fungi and bacteria. This leads to faster rotting and weakening of the wood structure.

Yes, wood on a dock can be preserved by using pressure-treated lumber, applying waterproof sealants or stains, and regularly inspecting and maintaining the structure to address issues like cracks or rot early on.