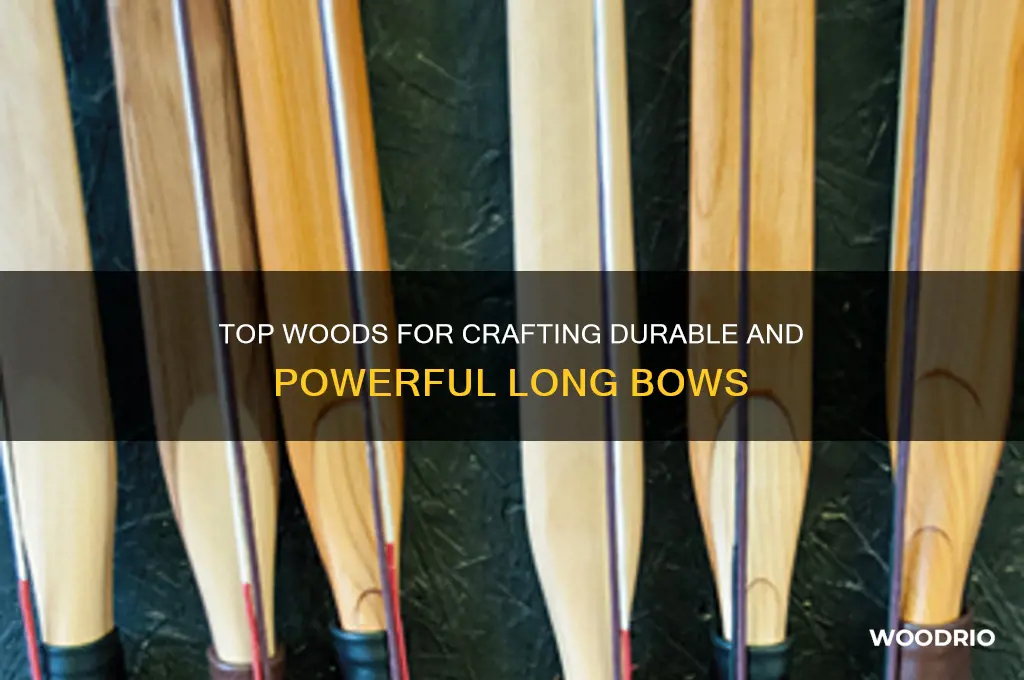

Choosing the best wood for crafting a longbow is a critical decision that balances strength, flexibility, and durability. Traditional bowyers often favor woods like yew, which has been used for centuries due to its unique combination of a strong heartwood and flexible sapwood, allowing for excellent resilience and power. Other popular options include Osage orange, known for its natural strength and ability to retain its shape, and hickory, prized for its toughness and shock resistance. Each wood type has distinct characteristics, such as grain pattern, density, and workability, which influence the bow's performance and longevity. Ultimately, the best wood depends on the archer's preferences, the intended use of the bow, and the availability of materials.

| Characteristics | Values |

|---|---|

| Wood Type | Osage Orange, Yew, Hickory, Lemonwood, Mulberry, Ash, Bamboo (technically a grass but often used) |

| Flexibility | High (Osage Orange, Yew, Hickory), Medium (Lemonwood, Mulberry), Low (Ash) |

| Strength | Osage Orange > Hickory > Yew > Lemonwood > Mulberry > Ash |

| Workability | Yew > Mulberry > Ash > Lemonwood > Hickory > Osage Orange |

| Durability | Osage Orange > Hickory > Yew > Ash > Lemonwood > Mulberry |

| Weight | Light (Yew, Mulberry), Medium (Ash, Lemonwood), Heavy (Osage Orange, Hickory) |

| Grain Pattern | Straight (Osage Orange, Yew), Interlocked (Hickory, Ash) |

| Availability | Common (Ash, Mulberry), Rare (Osage Orange, Lemonwood) |

| Cost | Low (Ash, Mulberry), High (Osage Orange, Lemonwood) |

| Traditional Use | Yew (European longbows), Osage Orange (Native American bows) |

| Resistance to Splitting | High (Osage Orange, Hickory), Medium (Yew, Ash), Low (Lemonwood, Mulberry) |

| Elasticity | Osage Orange > Yew > Hickory > Ash > Lemonwood > Mulberry |

| Seasoning Time | Long (Osage Orange, Hickory), Short (Yew, Ash) |

| Aesthetic Appeal | High (Yew, Mulberry), Medium (Ash, Lemonwood), Low (Osage Orange, Hickory) |

| Environmental Impact | Sustainable (Ash, Mulberry), Less Sustainable (Osage Orange, Lemonwood) |

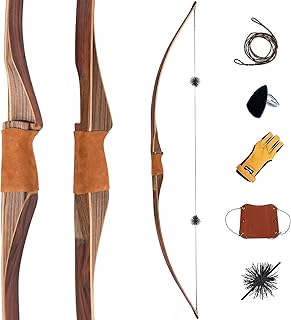

Explore related products

What You'll Learn

- Wood Density & Strength: Ideal woods balance density for power with flexibility to prevent breakage during use

- Grain Pattern Importance: Straight, even grain ensures consistency and reduces risk of splitting under tension

- Traditional vs. Modern Woods: Compare historical choices like yew with contemporary options such as osage orange

- Workability & Carving: Easier-to-shape woods like hickory save time but may sacrifice durability or performance

- Moisture Resistance: Woods like black locust resist warping, ensuring longevity in varying environmental conditions

Wood Density & Strength: Ideal woods balance density for power with flexibility to prevent breakage during use

The quest for the perfect longbow wood hinges on a delicate dance between density and flexibility. Imagine a tightrope walker: too much weight, and they plummet; too little, and they lose control. Similarly, a bow wood must be dense enough to store and release energy efficiently, yet flexible enough to bend without snapping. This balance is the holy grail for bowyers, ensuring a powerful yet durable weapon.

Osage orange, prized by Native American archers, exemplifies this duality. Its dense, heavy nature provides exceptional power, while its natural flexibility allows it to withstand the stress of repeated draws.

While density is crucial for power, it's not a simple "more is better" equation. Yew, another historical favorite, boasts a lower density than Osage orange but compensates with a unique cellular structure. Its outer layers, rich in flexible springwood, provide the necessary bend, while the denser heartwood contributes strength. This natural layering creates a built-in stress distribution system, preventing weak points and potential breakage.

Understanding this interplay between density and internal structure is key. Woods like hickory, though dense, lack the inherent flexibility of yew or Osage orange, making them prone to cracking under the strain of a full draw.

Modern bowyers often turn to laminating techniques, combining different woods to achieve the ideal balance. A dense core wood, like hickory or ash, provides the backbone for power, while thinner layers of flexible woods like maple or bamboo add the necessary bend. This engineered approach allows for precise control over density and flexibility, tailoring the bow to specific draw weights and shooting styles.

However, traditionalists argue that the natural balance found in woods like yew or Osage orange offers a unique feel and performance that laminated bows struggle to replicate.

Ultimately, the "best" wood for a longbow depends on the archer's needs and preferences. For raw power, dense woods like Osage orange reign supreme. For a balance of strength and flexibility, yew's natural layering is hard to beat. And for those seeking customization, laminated bows offer a world of possibilities. The key lies in understanding the intricate relationship between density and flexibility, allowing the bowyer to harness the wood's natural properties to create a bow that is both powerful and enduring.

Minwax Wood Filler Durability: Outdoor Lifespan and Longevity Explained

You may want to see also

Explore related products

Grain Pattern Importance: Straight, even grain ensures consistency and reduces risk of splitting under tension

The grain pattern of wood is a critical factor in the performance and durability of a longbow. A straight, even grain ensures that the wood fibers align uniformly, distributing stress evenly when the bow is drawn. This consistency is essential because it minimizes weak points where the wood might split under tension. For instance, woods like Osage orange and yew are prized for their naturally straight grains, which have been historically favored by bowyers for their reliability in crafting powerful, long-lasting bows.

To understand why grain pattern matters, consider the mechanics of a longbow. When drawn, the bow’s limbs are subjected to immense tension on the belly (inner curve) and compression on the back (outer curve). A straight grain acts as a natural reinforcement, allowing the wood to flex smoothly without localized stress concentrations. Conversely, irregular or interlocked grain patterns can create weak spots, increasing the risk of failure. For example, a bow with wavy or spiral grain may appear strong but is more likely to crack or delaminate under repeated use.

Selecting wood with the right grain pattern requires careful inspection. Look for planks where the grain runs parallel to the length of the board, with minimal deviation or knots. Hand-selecting wood from reputable suppliers or harvesting it yourself allows you to assess the grain firsthand. Tools like a grain highlighter (a solution of water and vinegar) can reveal subtle patterns, ensuring you choose the best material. Remember, a small investment in high-quality wood upfront can save time and frustration later.

While straight grain is ideal, not all woods naturally possess this trait. Some species, like hickory or ash, can have excellent strength but may exhibit more variable grain patterns. In such cases, bowyers often employ techniques like quarter-sawing or rift-sawing to maximize the alignment of the grain. These methods yield boards with tighter, more uniform grain, reducing the risk of splitting. However, they also produce less lumber per log, making them more expensive—a trade-off worth considering for serious bowmakers.

Finally, the importance of grain pattern extends beyond initial construction to long-term maintenance. A bow with straight, even grain is less likely to warp or twist over time, ensuring consistent performance. Regularly inspect your bow for signs of stress, such as cracks or unusual bending, and address issues promptly. Proper storage—away from extreme temperatures and humidity—can also preserve the integrity of the grain. By prioritizing grain quality from the start, you’ll craft a bow that not only performs well but stands the test of time.

Optimal Wood Drying Time: Ensuring Quality and Durability for Projects

You may want to see also

Explore related products

Traditional vs. Modern Woods: Compare historical choices like yew with contemporary options such as osage orange

The choice of wood for crafting a longbow has evolved significantly over centuries, reflecting both the availability of materials and advancements in understanding wood properties. Historically, yew (Taxus baccata) dominated as the premier choice for European longbows due to its unique combination of strength, flexibility, and resilience. Its heartwood provides exceptional tensile strength, while the sapwood offers elasticity, creating a natural composite ideal for the bow's bending and recoil. However, yew's slow growth and dwindling availability have spurred modern archers and bowyers to explore alternatives like osage orange (Maclura pomifera), a North American hardwood prized for its density, stiffness, and shock resistance.

From a practical standpoint, selecting between yew and osage orange hinges on specific performance needs and resource constraints. Yew's self-bow design—where a single piece of wood forms the entire bow—remains a benchmark for traditionalists, offering a harmonious balance of power and elegance. However, its scarcity and legal restrictions (due to conservation efforts) make it less accessible. Osage orange, by contrast, is more readily available and boasts a higher compressive strength, making it ideal for modern recurve designs or laminated bows. For beginners, osage orange's workability and durability provide a forgiving learning curve, though its heavier weight may require adjustments in handling.

A comparative analysis reveals distinct advantages and trade-offs. Yew's historical reputation is rooted in its ability to store and release energy efficiently, a trait that modern tests still validate. Its natural grain structure allows for precise tuning, but its susceptibility to moisture and slow seasoning time demand meticulous care. Osage orange, meanwhile, excels in resilience and ease of sourcing, though its lack of natural elasticity often necessitates lamination with more flexible woods like hickory or lemonwood. For instance, a laminated osage orange bow with a hickory core can achieve a yew-like performance profile, blending tradition with innovation.

Persuasively, the choice between yew and osage orange ultimately boils down to intent: purists seeking historical authenticity will gravitate toward yew, while pragmatists prioritizing durability and availability will favor osage orange. For those undecided, a hybrid approach—using osage orange limbs with a yew core—offers a middle ground, though this requires advanced craftsmanship. Regardless of choice, both woods demand respect for their unique characteristics, emphasizing the importance of proper seasoning, grain orientation, and moisture control. In the end, the "best" wood is not universal but rather the one that aligns with the archer's goals, skill level, and commitment to tradition or modernity.

Wood Bison Endangered Status: A Historical Overview of Their Conservation

You may want to see also

Explore related products

$129.99

Workability & Carving: Easier-to-shape woods like hickory save time but may sacrifice durability or performance

Hickory's reputation as a bow-making wood hinges on its workability. Its straight grain and moderate hardness make it a carver's dream, allowing for quicker shaping and less frustration compared to denser woods like Osage orange or yew. This is particularly appealing to beginners or those short on time, as hickory readily takes on the desired bow shape with relative ease.

Imagine whittling away at a block of wood, the shavings curling effortlessly as the bow's graceful curve emerges. This is the reality with hickory, its cooperative nature a welcome contrast to the stubborn resistance of harder woods.

However, this ease of carving comes at a cost. Hickory, while strong, lacks the inherent toughness and density of traditional bow woods. This translates to a bow that may be more susceptible to limb failure under heavy draw weights or prolonged use. Think of it like choosing between a flexible, lightweight hiking shoe and a sturdy, heavy-duty boot. The shoe might be more comfortable for a short walk, but the boot will provide better support and durability for a long trek.

Similarly, while hickory's workability is a boon for the maker, it's crucial to consider the intended use of the bow. For target shooting or light recreational use, hickory's trade-off might be acceptable. But for hunting or demanding applications, the potential sacrifice in durability and performance becomes a significant factor.

Ultimately, the choice of wood depends on the archer's priorities. If speed of construction and ease of carving are paramount, hickory presents a compelling option. However, for those seeking a bow that will withstand the test of time and rigorous use, harder, denser woods, despite their carving challenges, may be the wiser investment.

Seasoning Wood: Understanding the Ideal Time for Perfectly Dried Lumber

You may want to see also

Explore related products

Moisture Resistance: Woods like black locust resist warping, ensuring longevity in varying environmental conditions

Black locust wood stands out in the realm of longbow craftsmanship for its exceptional moisture resistance, a trait that directly translates to durability and performance. Unlike softer woods that succumb to humidity and dampness, black locust’s dense grain structure naturally repels moisture, minimizing the risk of warping, cracking, or splitting. This resilience makes it ideal for archers who practice outdoors, where exposure to rain, dew, or high humidity is inevitable. For instance, a longbow crafted from black locust can maintain its shape and tension even after being left in a damp environment overnight, a scenario that might compromise the integrity of less resistant woods like hickory or maple.

The science behind black locust’s moisture resistance lies in its high silica content, which acts as a natural barrier against water absorption. This silica also contributes to the wood’s hardness, making it less prone to fungal decay or insect damage—common issues in wetter climates. When selecting black locust for a longbow, look for heartwood, which is darker and more silica-rich than the sapwood. Heartwood not only offers superior moisture resistance but also provides a more consistent density, crucial for even bending and strength distribution in the bow.

Crafting a longbow from black locust requires careful consideration of its moisture-resistant properties during the seasoning process. While the wood’s natural resistance reduces the risk of warping, improper drying can still lead to internal stresses. Air-dry black locust for at least 12–18 months, ensuring the wood’s moisture content drops below 12% for optimal stability. Avoid kiln-drying, as the rapid temperature changes can cause the silica-rich wood to crack. Once seasoned, the wood’s moisture resistance becomes a permanent asset, allowing the bow to withstand years of use without significant deformation.

For archers in humid regions, black locust’s moisture resistance is not just a benefit—it’s a necessity. Traditional woods like yew or Osage orange may excel in flexibility and strength, but they lack black locust’s ability to endure prolonged exposure to moisture. A black locust longbow can retain its draw weight and accuracy even after being stored in a garage or shed without climate control, a practical advantage for hobbyists and hunters alike. Pairing this wood with a protective finish, such as linseed oil or spar varnish, further enhances its resistance, ensuring the bow remains functional and aesthetically pleasing despite environmental challenges.

In conclusion, black locust’s moisture resistance is a game-changer for longbow makers and users, offering a level of reliability that few other woods can match. Its natural ability to resist warping and decay ensures the bow’s longevity, making it a wise investment for anyone seeking a durable, high-performance archery tool. By understanding and leveraging this unique property, craftsmen can create longbows that not only excel in function but also stand the test of time, regardless of the environment in which they are used.

How Long Blood Stains Last in Wood: A Comprehensive Guide

You may want to see also

Frequently asked questions

The best wood for a longbow is typically osage orange, known for its strength, flexibility, and durability. Other excellent choices include yew, which has been historically favored for its balance of strength and elasticity, and hickory, which is strong but requires careful seasoning.

Not all woods are suitable for longbows. The wood must have the right combination of strength, flexibility, and workability. Avoid softwoods like pine or cedar, as they lack the necessary resilience. Stick to proven options like osage orange, yew, hickory, or ash for best results.

The wood’s density, grain pattern, and natural flexibility directly impact the bow’s power, speed, and durability. Harder woods like osage orange provide more power but require precise craftsmanship, while yew offers a balanced performance. Poorly chosen wood can result in a weak or brittle bow that may fail under tension.