When considering what to buy for a wooden frame, it’s essential to focus on both functionality and aesthetics to enhance its durability and visual appeal. Start with high-quality wood preservatives or sealants to protect the frame from moisture, pests, and UV damage, ensuring longevity. If the frame is for a specific purpose, such as a picture or mirror, invest in sturdy hanging hardware like D-rings or sawtooth hangers for secure mounting. For decorative touches, consider adding corner splices or embellishments that complement the wood’s natural grain. Additionally, if the frame is for outdoor use, opt for weather-resistant finishes or paints to withstand environmental elements. Finally, tools like sandpaper, wood glue, or a miter saw can be useful for customization or repairs, ensuring the frame remains both functional and beautiful.

Explore related products

What You'll Learn

- Hardware Essentials: Screws, brackets, hinges, and corner braces for assembly and reinforcement

- Finishing Supplies: Sandpaper, wood filler, stain, varnish, and brushes for smooth, polished results

- Joinery Tools: Clamps, drill bits, dowels, and biscuits for precise and sturdy connections

- Decorative Elements: Carving tools, molding, inlays, and stencils for personalized, artistic touches

- Safety Gear: Gloves, goggles, dust masks, and ear protection for safe construction and finishing

Hardware Essentials: Screws, brackets, hinges, and corner braces for assembly and reinforcement

Screws are the backbone of any wooden frame assembly, providing the necessary strength and stability. When selecting screws, consider the wood type and the load the frame will bear. For softwoods like pine, use coarse-threaded screws, while hardwoods like oak require fine-threaded varieties to prevent splitting. Length matters too—a general rule is to use a screw that penetrates at least half the thickness of the overlapping wood piece. For a 1-inch thick frame, a 1.5-inch screw ensures a secure hold. Always pre-drill pilot holes to avoid wood cracking, especially in hardwoods or near the edges.

Brackets and corner braces serve as the unsung heroes of frame reinforcement, distributing weight and preventing joints from weakening over time. L-brackets are ideal for right-angle joints, while T-brackets offer additional support for heavier structures. Corner braces, often made of metal, are particularly useful for large frames or those subjected to frequent movement, such as doors or gates. When installing, ensure brackets are aligned flush with the wood surface and secured with screws at each mounting hole. For maximum durability, use galvanized or stainless steel brackets to resist rust and corrosion.

Hinges are critical for frames that require movement, such as cabinet doors or folding screens. Butt hinges are the most common type, available in various sizes to accommodate different frame weights. For heavier applications, consider using strap hinges, which provide greater support and a more rustic aesthetic. When installing hinges, ensure the knuckles are aligned and the pins are securely seated. Use screws appropriate for the hinge material—typically smaller screws for the hinge itself and longer screws for attaching it to the wood. Proper alignment is key to smooth operation, so take time to mark and measure before drilling.

Combining these hardware essentials requires careful planning to ensure both functionality and longevity. Start by sketching a detailed assembly plan, noting where screws, brackets, hinges, and corner braces will be placed. For complex frames, consider using a combination of these elements—for example, reinforcing a hinged joint with both brackets and corner braces. Always test the frame’s stability after assembly, making adjustments as needed. Remember, the goal is not just to hold the frame together but to ensure it remains sturdy and reliable under its intended use. With the right hardware and thoughtful installation, your wooden frame will stand the test of time.

Cathie Wood's SoFi Stock Purchase: What Investors Need to Know

You may want to see also

Explore related products

Finishing Supplies: Sandpaper, wood filler, stain, varnish, and brushes for smooth, polished results

Achieving a professional finish on a wooden frame requires more than just assembly. The right finishing supplies transform raw wood into a polished, durable masterpiece. Sandpaper, wood filler, stain, varnish, and brushes are the cornerstone of this process, each playing a distinct role in refining texture, correcting imperfections, enhancing color, and sealing the surface.

Sandpaper: The Foundation of Smoothness

Begin with sandpaper, the unsung hero of woodworking. Start with a coarse grit (80–120) to remove rough surfaces, splinters, or old finishes. Progress to medium grit (150–180) for smoothing, and finish with fine grit (220–320) for a glass-like surface. Always sand in the direction of the wood grain to avoid scratches. For tight corners or intricate details, use sanding sponges or folded paper for precision.

Wood Filler: Concealing Imperfections

Even the most carefully selected wood may have knots, cracks, or gaps. Wood filler is your ally here. Choose a filler that matches the wood’s natural color or opt for a stainable variety if you plan to alter the hue. Apply a thin layer with a putty knife, pressing it firmly into the defect. Allow it to dry completely, then sand the area smooth. Overfilling can lead to uneven surfaces, so apply sparingly and build up in layers if needed.

Stain: Adding Depth and Character

Stain not only enhances the wood’s natural beauty but also protects it from UV damage. Test the stain on a scrap piece or hidden area to ensure the color meets your vision. Apply with a brush or cloth, working in the direction of the grain. For deeper color, allow the first coat to dry and apply a second. Wipe off excess stain immediately to avoid blotching. Water-based stains dry faster and emit fewer fumes, while oil-based options penetrate deeper for richer tones.

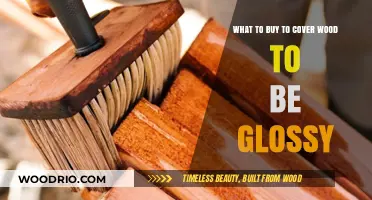

Varnish: The Protective Seal

Varnish is the final shield, guarding your frame against moisture, heat, and wear. Choose between matte, satin, or gloss finishes based on your desired aesthetic. Apply thin, even coats with a high-quality brush, allowing each layer to dry fully (typically 24 hours) before sanding lightly with 320-grit paper and adding the next coat. Two to three coats are usually sufficient for optimal protection. Avoid overbrushing, as this can leave bubbles or streaks.

Brushes: The Tools of Precision

The right brush can make or break your finish. Natural-bristle brushes work best with oil-based products, while synthetic brushes are ideal for water-based stains and varnishes. For small frames, consider foam brushes for even application and easy cleanup. Clean brushes immediately after use to preserve their shape and longevity. A well-maintained brush ensures smooth, streak-free results every time.

By mastering these finishing supplies, you’ll elevate your wooden frame from functional to exceptional. Each step builds upon the last, creating a seamless blend of craftsmanship and artistry. Invest in quality materials and take your time—the polished result will be well worth the effort.

Choosing the Perfect Wood Stove Insert: A Comprehensive Buying Guide

You may want to see also

Explore related products

Joinery Tools: Clamps, drill bits, dowels, and biscuits for precise and sturdy connections

Clamps are the unsung heroes of woodworking, holding pieces together with precision while glue dries or joints set. For a wooden frame, consider F-clamps or bar clamps for larger surfaces and quick-grip clamps for smaller, more delicate work. The key is even pressure: too little, and the joint weakens; too much, and the wood warps. Aim for 100–150 psi, using a pressure gauge if available. Pro tip: Place a scrap piece of wood between the clamp and the frame to avoid marring the surface. Without proper clamping, even the most meticulously cut joints will fail under stress.

Drill bits are the backbone of dowel joinery, a method prized for its strength and simplicity. For a wooden frame, invest in a set of brad-point bits, which self-center and reduce splintering. Match the bit diameter to your dowel size—typically ¼” or ⅜” for frames. Depth is critical: mark your drill bit with tape to ensure consistent hole depth, usually ¾ the thickness of the wood. Pair this with a drill press for accuracy, or use a handheld drill with a depth stop. Dowel joints, when executed precisely, rival even mortise-and-tenon connections in strength.

Biscuit joinery offers a modern twist on traditional techniques, using oval-shaped biscuits to align and reinforce joints. For a wooden frame, a plate joiner (biscuit jointer) is essential. Choose biscuits based on wood thickness: #0 for ½” stock, #20 for 1” stock. Apply glue sparingly to the biscuit and slot—too much, and it’ll expand, causing misalignment. This method is ideal for 90-degree corners, where clamps alone struggle to maintain alignment. The result? A joint that’s both invisible and incredibly strong, perfect for frames bearing weight or stress.

Comparing these tools, clamps are versatile but passive, holding while other elements work. Drill bits and dowels create mechanical bonds, relying on fit and glue for strength. Biscuits, meanwhile, act as alignment keys, enhancing both precision and load-bearing capacity. For a wooden frame, combining these tools—clamps for pressure, drill bits for dowel holes, and biscuits for alignment—yields connections that outlast the wood itself. The takeaway? Invest in quality tools and master their use; the integrity of your frame depends on it.

Prefab Wood Garage Door Bottom: Buying Options and Installation Tips

You may want to see also

Explore related products

Decorative Elements: Carving tools, molding, inlays, and stencils for personalized, artistic touches

Wooden frames offer a canvas for creativity, and decorative elements like carving tools, molding, inlays, and stencils can transform a simple structure into a personalized masterpiece. Carving tools, for instance, allow you to add intricate designs directly into the wood. From basic chip carving knives to detail gouges, these tools enable you to create textures, patterns, or even figurative motifs. For beginners, start with a V-shaped chisel for clean lines and gradually explore U-shaped or round gouges for more complex designs. Always work with the grain of the wood to avoid splintering, and practice on scrap pieces before tackling your frame.

Molding, on the other hand, offers a quicker way to add elegance and dimension. Pre-made wooden moldings come in various profiles, from simple rounded edges to ornate baroque styles. Choose a molding that complements the frame’s size and purpose—delicate profiles for small frames, bold designs for larger pieces. Attach the molding using wood glue and brad nails, ensuring precise mitered corners for a professional finish. For a cohesive look, consider painting or staining the molding to match or contrast with the frame.

Inlays introduce a tactile and visual contrast by embedding materials like metal, shell, or contrasting wood into the frame’s surface. This technique requires precision; use a router or Dremel tool to create recesses that fit your inlay material snugly. For a seamless finish, sand the inlay flush with the frame and apply a protective coat of varnish. Inlays are ideal for highlighting corners, borders, or central motifs, adding a luxurious touch without overwhelming the design.

Stencils offer versatility for those who prefer paint or stain over carving or inlays. Choose from pre-made designs or create custom stencils using adhesive vinyl or cardstock. Secure the stencil firmly to the frame with tape, then apply paint or stain with a stippling brush to avoid bleeding. Layer multiple stencils for depth, or combine stenciling with other techniques—for example, stencil a floral pattern and carve highlights into the petals. This method is forgiving and allows for experimentation, making it perfect for all skill levels.

By combining these decorative elements, you can create a wooden frame that tells a story or reflects your style. Start with one technique and gradually incorporate others as your confidence grows. Whether you’re crafting a gift or enhancing your home decor, these tools and materials offer endless possibilities for artistic expression.

Top Wood Pellet Stoves: Ultimate Guide to Choosing the Best

You may want to see also

Explore related products

Safety Gear: Gloves, goggles, dust masks, and ear protection for safe construction and finishing

Woodworking, especially when constructing a wooden frame, exposes you to sharp tools, flying debris, and harmful dust. Safety gear isn’t optional—it’s essential. Gloves protect your hands from splinters, cuts, and abrasions while handling rough lumber or power tools. Opt for durable, fitted gloves that maintain dexterity, like those made from leather or reinforced fabric. Avoid bulky options that hinder grip or control, as they increase the risk of accidents.

Eye injuries are a real threat when wood chips or dust become airborne. Safety goggles with impact-resistant lenses shield your eyes from projectiles and fine particles. Look for ANSI Z87.1 certification to ensure they meet safety standards. For added comfort, choose goggles with anti-fog coatings or adjustable straps. Remember, prescription glasses aren’t a substitute—wear goggles over them or invest in prescription safety lenses.

Wood dust, a byproduct of sanding and cutting, poses respiratory risks, especially with prolonged exposure. A properly fitted dust mask or respirator filters out harmful particles, preventing lung irritation or long-term conditions like asthma. For light sanding, a disposable N95 mask suffices, but heavy-duty projects require a reusable respirator with replaceable filters. Ensure a tight seal around your nose and mouth for maximum protection.

Power tools generate noise levels that can damage hearing over time. Ear protection, such as foam earplugs or earmuffs, reduces decibel exposure to safe levels. For intermittent noise, reusable earplugs are convenient, but earmuffs offer better protection during extended use. Combine both for maximum noise reduction in loud environments. Always check the Noise Reduction Rating (NRR) to ensure adequate protection—aim for an NRR of at least 25 dB for woodworking tasks.

Investing in quality safety gear isn’t just about compliance—it’s about preserving your health and productivity. Gloves, goggles, dust masks, and ear protection form the foundation of a safe woodworking practice. Prioritize gear that fits well, meets industry standards, and suits the specific demands of your project. By safeguarding yourself, you ensure that crafting your wooden frame remains a rewarding, injury-free experience.

Are Classic Wooden Boats Still Available for Purchase Today?

You may want to see also

Frequently asked questions

The best wood for a wooden frame depends on its use and aesthetic preference. Hardwoods like oak, maple, and walnut are durable and high-end, while softwoods like pine are affordable and easy to work with.

Essential tools include a saw (hand or power saw), measuring tape, square, clamps, drill, screwdriver, sandpaper, and a wood glue. A miter saw is useful for precise angle cuts.

Pre-cut wood saves time and ensures accuracy, especially for beginners. Raw lumber is more cost-effective and allows for custom sizing but requires more skill and tools to prepare.

Choose a finish based on durability and appearance. Polyurethane is durable and versatile, stain enhances the wood’s natural color, and paint provides a custom look. Always buy a finish suitable for indoor or outdoor use as needed.

Yes, hardware like corner braces, screws, or hanging kits may be necessary. For picture frames, buy D-rings or sawtooth hangers. For furniture frames, consider brackets or joinery hardware for stability.