Maintaining a smooth wood planer is essential for achieving clean, precise cuts and prolonging the tool's lifespan. To keep your wood planer in optimal condition, it's crucial to invest in the right accessories and maintenance supplies. Key items to consider include high-quality planer blades made from durable materials like carbide or high-speed steel, as they stay sharper longer and reduce the frequency of replacements. Additionally, a blade sharpener or sharpening stones are indispensable for maintaining blade edges, ensuring consistent performance. A blade setting jig can help align blades accurately, minimizing tear-out and improving finish quality. Regular cleaning tools, such as a brush or compressed air, are necessary to remove dust and debris from the planer's interior, while a rust inhibitor or lubricant can protect the machine from corrosion and ensure smooth operation. Lastly, a set of replacement drive belts and a wrench kit for adjustments will help address wear and tear over time. By equipping yourself with these essentials, you can keep your wood planer running smoothly and efficiently for years to come.

| Characteristics | Values |

|---|---|

| Product Type | Planer Blade Sharpener, Planer Blade Lapping Plate, Planer Blade Honing Oil, Planer Blade Cleaning Brush, Planer Blade Storage Case |

| Material | Diamond, Aluminum Oxide, Silicon Carbide, Synthetic Oil, Nylon Bristles |

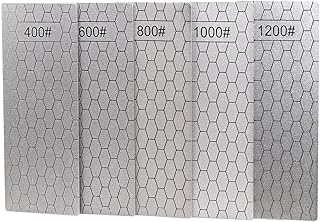

| Grit Size | 400, 600, 800, 1000 (for sharpening plates/stones) |

| Compatibility | Universal (fits most planer blades), Brand-specific (e.g., DeWalt, Makita) |

| Purpose | Sharpening, Cleaning, Lubricating, Protecting planer blades |

| Durability | High (diamond plates), Medium (aluminum oxide), Low (disposable brushes) |

| Ease of Use | Easy (brushes, oil), Moderate (sharpeners), Requires Skill (lapping plates) |

| Price Range | $10–$50 (brushes/oil), $50–$150 (sharpeners/plates), $200+ (professional kits) |

| Maintenance Required | Low (oil, brushes), Moderate (sharpeners), High (lapping plates) |

| Portability | High (brushes, oil), Medium (compact sharpeners), Low (large plates) |

| Additional Features | Non-slip base (plates), Ergonomic handle (brushes), Rust-resistant coating |

| Recommended Brands | Veritas, Tormek, Trend, DeWalt, Makita |

| User Reviews | 4.5/5 (average for diamond sharpeners), 4.0/5 (brushes/oil) |

| Warranty | 1–2 years (most tools), Lifetime (select brands like Veritas) |

Explore related products

What You'll Learn

Choosing the Right Planer Blades

Planer blades are the heart of your wood planer, and their quality directly impacts the smoothness of your work. Dull or low-quality blades leave tear-out, splintering, and uneven surfaces. Choosing the right blades involves understanding material, thickness, and compatibility with your planer model.

High-speed steel (HSS) blades offer durability and heat resistance, making them ideal for hardwoods and extended use. Carbide-tipped blades, while pricier, last significantly longer and maintain sharpness through tougher materials. Always check your planer's manual for recommended blade size and type to ensure a proper fit.

Beyond material, blade thickness plays a crucial role. Thicker blades (e.g., 1.1mm) provide rigidity and reduce chatter, resulting in smoother cuts. However, they may require more powerful planers to handle the increased resistance. Thinner blades (e.g., 0.8mm) are more flexible and suitable for lighter-duty planers but may vibrate more, leading to less precise results. Consider your planer's capabilities and the type of wood you typically work with when selecting thickness.

Don’t overlook the importance of blade sharpness and maintenance. Even the best blades dull over time. Invest in a blade sharpener or sharpening service to extend their lifespan. Regularly inspect blades for chips or damage, as imperfections will mar your work. Keep a spare set of blades on hand to minimize downtime during projects. Properly maintained blades not only ensure smoother cuts but also save you money in the long run.

Finally, compatibility is non-negotiable. Planer blades are not universal; they vary by brand, model, and design. Using the wrong blades can damage your tool or compromise safety. Double-check measurements, mounting holes, and specifications before purchasing. Many manufacturers offer blade kits tailored to their models, simplifying the selection process. When in doubt, consult the manufacturer or a trusted woodworking supplier for guidance.

Colored Wood Fencing Options: Can You Buy Them Pre-Painted?

You may want to see also

Explore related products

Using Blade Sharpeners and Tools

Maintaining the sharpness of your wood planer blades is crucial for achieving smooth, clean cuts. Dull blades not only produce rough surfaces but also increase the risk of tear-out and reduce the tool’s efficiency. Blade sharpeners and tools are essential investments for any woodworker looking to prolong the life of their planer and ensure consistent performance. From manual sharpening jigs to powered systems, the market offers a variety of options tailored to different skill levels and needs.

Analyzing the Tools: Manual vs. Powered Sharpeners

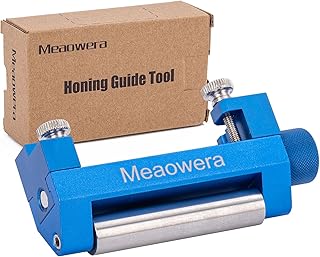

Manual sharpeners, such as honing guides and waterstones, are cost-effective and portable, making them ideal for beginners or those with limited workspace. They require patience and precision but allow for fine control over the blade’s edge. Powered sharpeners, on the other hand, automate the process, reducing the learning curve and saving time. Systems like the Work Sharp or Tormek offer consistent results but come at a higher price point. The choice depends on your budget, frequency of use, and preference for hands-on versus automated methods.

Step-by-Step Sharpening Process

To sharpen planer blades effectively, start by removing them from the machine and securing them in a sharpening jig. For manual sharpening, use a coarse-grit stone to remove nicks and dull spots, followed by a finer grit to refine the edge. Maintain a consistent angle, typically between 25° and 35°, depending on the blade type. Powered systems often include angle guides, simplifying this step. Finish with a leather strop and honing compound for a razor-sharp edge. Always clean and dry the blades before reinstalling them to prevent rust.

Cautions and Common Mistakes

Overheating blades during sharpening can alter their temper, rendering them useless. Avoid applying excessive pressure or sharpening for too long in one spot. When using powered tools, ensure the blade is securely clamped to prevent slipping. Another common mistake is neglecting to sharpen the relief angle, which can lead to friction and burning during planing. Always refer to the manufacturer’s guidelines for your specific blade and sharpener.

While the initial cost of blade sharpeners and tools may seem steep, they pay for themselves by extending the life of your planer blades and improving the quality of your work. Whether you opt for manual precision or the convenience of a powered system, regular sharpening is non-negotiable for maintaining a smooth planer. Pair your sharpener with a blade storage case and rust inhibitor to protect your investment further. With the right tools and techniques, you’ll ensure your planer delivers professional results every time.

Where to Buy Wood Paneling: Top Retailers and Online Stores

You may want to see also

Explore related products

Applying Lubricants and Rust Preventers

Lubrication is critical for maintaining the smooth operation of a wood planer, reducing friction between moving parts and minimizing wear. For the cutter head and feed rollers, a high-quality silicone-based lubricant is ideal. Silicone lubricants resist dust and debris buildup, which can otherwise create abrasive compounds that damage surfaces. Apply a thin, even coat using a brush or spray bottle, ensuring coverage without excess that could attract sawdust. Reapply every 20-30 hours of use, or whenever resistance increases during operation.

Rust prevention is equally vital, especially in humid environments where moisture accelerates corrosion. A rust inhibitor like Boeshield T-9 or WD-40 Specialist Corrosion Inhibitor should be applied to exposed metal surfaces monthly. These products displace moisture and form a protective barrier. For best results, clean the planer thoroughly before application, removing any existing rust with steel wool or a wire brush. Focus on areas prone to moisture accumulation, such as the table surface and cutter head bearings.

When choosing lubricants, avoid petroleum-based products, as they can degrade plastic components and attract more dust. Instead, opt for dry lubricants like PTFE (Teflon) or molybdenum disulfide for gears and bearings. These provide long-lasting protection without leaving a residue. For rust prevention, consider using desiccant packs inside storage areas to reduce ambient moisture levels, complementing the liquid inhibitors.

A systematic approach yields the best results. After each use, wipe down the planer with a tack cloth to remove dust and debris. Monthly, perform a deeper clean with a degreaser, followed by lubricant and rust inhibitor application. Store the tool in a dry, climate-controlled space to maximize the effectiveness of these treatments. By integrating these practices, you’ll extend the planer’s lifespan and ensure consistent performance.

Where to Buy Poplar Wood: Top Suppliers and Online Stores

You may want to see also

Explore related products

Selecting Quality Planer Accessories

Maintaining a smooth finish with your wood planer requires more than just the machine itself—it demands thoughtful selection of accessories that enhance performance and longevity. Among the most critical are planer blades, which directly impact the quality of your cuts. Opt for high-speed steel (HSS) or carbide-tipped blades for durability and sharpness. HSS blades are cost-effective and suitable for softer woods, while carbide-tipped blades offer superior hardness and longevity, ideal for hardwoods and frequent use. Always ensure blades are compatible with your planer model and replace them when dullness becomes evident, typically after 10–15 hours of use for HSS and 20–30 hours for carbide.

Another essential accessory is a planer stand, which stabilizes the machine and reduces vibrations that can mar the smoothness of your work. Look for stands with adjustable height settings and non-slip feet for added stability. A well-designed stand not only improves accuracy but also protects your planer from accidental damage. Pair this with an anti-vibration mat placed beneath the machine to further minimize unwanted movement and noise, ensuring a consistent, smooth finish.

Dust collection systems are often overlooked but play a pivotal role in maintaining planer performance. Wood chips and dust can clog the machine, leading to uneven cuts and premature wear. Invest in a dust extractor with a minimum airflow of 500 CFM for efficient debris removal. Attach it securely to your planer’s dust port, and regularly inspect hoses for blockages. For smaller workshops, consider a portable dust collector with a HEPA filter to maintain air quality while keeping your planer running smoothly.

Finally, don’t underestimate the value of a blade sharpening system. While replacing blades is straightforward, sharpening them extends their lifespan and saves costs. A diamond sharpening stone or a dedicated blade sharpener ensures precision, restoring edges to factory sharpness. Sharpen blades after every 8–10 hours of use, following the manufacturer’s angle recommendations. Properly maintained blades not only deliver smoother cuts but also reduce strain on the planer motor, prolonging its life.

By strategically selecting these accessories—blades, stands, dust collection systems, and sharpening tools—you’ll optimize your planer’s performance and achieve consistently smooth results. Each accessory serves a unique purpose, and together, they form a comprehensive toolkit for any woodworker committed to precision and quality.

Cathie Wood's Latest Buys: Uncovering Her Top Investment Picks

You may want to see also

Explore related products

$11.99

$26.99

Regular Cleaning and Maintenance Tips

Wood planers are precision tools, and their performance hinges on cleanliness and maintenance. Dust buildup in the cutter head, chip ejection system, and tables not only diminishes cut quality but also accelerates wear on critical components. Regular cleaning prevents pitch accumulation, rust formation, and the clogging of internal mechanisms, ensuring consistent results and prolonging the tool’s lifespan.

Begin by unplugging the planer and allowing the blades to stop completely. Use a soft-bristle brush or compressed air (at 60–90 PSI) to remove wood chips and dust from the cutter head, chip chute, and table surfaces. For stubborn pitch or resin, apply a citrus-based solvent or specialized pitch cleaner, letting it sit for 5–10 minutes before wiping clean with a lint-free cloth. Avoid harsh chemicals that can damage seals or coatings.

After cleaning, inspect the cutter head blades for dullness or uneven wear. Rotate or replace blades as needed, ensuring they’re securely tightened to the manufacturer’s torque specifications (typically 30–40 ft-lbs). Lubricate bearings and moving parts with a dry Teflon-based lubricant or machine oil, avoiding excess that could attract dust. Check the chip ejection system for obstructions and ensure the dust collection port is clear for efficient chip removal.

Incorporate a maintenance schedule into your workflow: clean the planer after every 2–3 hours of use or daily in high-volume settings. Monthly, disassemble the cutter head for a thorough inspection and cleaning. Semi-annually, check the table alignment and adjust if necessary using a straightedge and feeler gauge. Consistent upkeep not only maintains cutting precision but also reduces the risk of mid-project malfunctions, saving time and frustration.

Catherine Wood's Latest Buys: Unveiling Her Top Investment Picks

You may want to see also

Frequently asked questions

Use a mild solvent or mineral spirits to remove pitch and resin buildup, followed by a clean, dry cloth to wipe down the surfaces.

Clean your wood planer after every use or at least once a week if used frequently to prevent buildup and ensure optimal performance.

Apply a light machine oil or silicone-based lubricant to the blades and moving parts to reduce friction and maintain smoothness.

Invest in a blade sharpener, cleaning brushes, and a scraper to remove stubborn residue and keep the planer in top condition.

Avoid wax or polish on the planer’s surfaces, as they can interfere with wood feeding. Focus on cleaning and lubricating instead.