Choosing the right laser wood engraver depends on your specific needs, budget, and the scale of your projects. Entry-level hobbyists may opt for a compact, affordable CO2 laser engraver, which is ideal for small, detailed designs on thin wood pieces. Professionals or small businesses might prefer a more powerful machine with a larger engraving area, higher precision, and additional features like rotary attachments for cylindrical objects. Consider factors such as laser power (measured in watts), engraving speed, software compatibility, and safety features like air filtration systems. Researching brands, reading reviews, and comparing warranties can also help ensure you invest in a reliable and durable machine that meets your long-term goals.

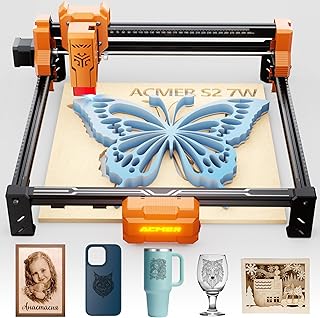

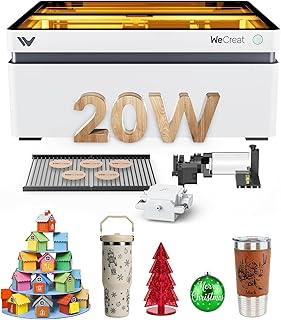

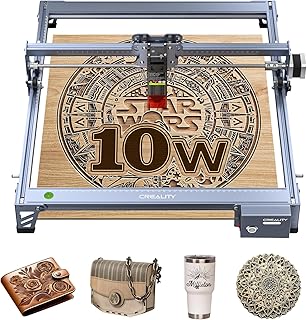

Explore related products

What You'll Learn

- Power Requirements: Determine wattage based on material thickness and engraving depth needs

- Engraving Area: Choose size based on project dimensions and workspace availability

- Software Compatibility: Ensure the laser works with your design software and operating system

- Budget Considerations: Balance features, quality, and cost for your specific requirements

- Safety Features: Look for emergency stops, protective covers, and ventilation systems

Power Requirements: Determine wattage based on material thickness and engraving depth needs

The power of a laser engraver, measured in watts, directly correlates with its ability to cut through or engrave wood. A 5-watt laser might suffice for shallow engravings on thin balsa wood, but attempting to engrave a dense hardwood like oak to a depth of 3mm would require a significantly more powerful machine, likely in the 20-watt range or higher.

Understanding this relationship between wattage, material thickness, and desired engraving depth is crucial for achieving clean, precise results.

Let's break down the process. First, consider the type of wood you'll primarily work with. Softwoods like pine or cedar are easier to engrave and require less power than hardwoods like maple or walnut. Next, determine the typical thickness of your projects. Engraving a design on a 1/8" wooden plaque demands far less power than cutting through a 1/2" thick board. Finally, decide on the desired engraving depth. A surface-level etch needs less power than a deep, V-shaped groove.

Once you have these parameters, consult the specifications of various laser engravers. Manufacturers often provide guidelines on the materials and thicknesses their machines can handle at different power settings.

It's tempting to opt for the most powerful laser within your budget, but higher wattage often comes with a steeper price tag and increased safety considerations. A 50-watt laser, while capable of cutting through thick wood, requires more stringent ventilation and safety protocols compared to a 10-watt model. Consider your project scope and frequency of use. If you're a hobbyist creating small, intricate designs on thin wood, a lower-wattage machine might be perfectly adequate and more cost-effective.

For professionals tackling larger projects or working with thicker, denser woods, investing in a higher-wattage laser will save time and frustration in the long run.

Remember, wattage isn't the sole determinant of engraving quality. Other factors like laser focus, beam quality, and software capabilities play significant roles. However, understanding the relationship between power, material, and depth is fundamental to making an informed decision when choosing the right laser wood engraver for your needs.

Where to Buy Oxalic Acid Wood Bleach for Effective Restoration

You may want to see also

Explore related products

Engraving Area: Choose size based on project dimensions and workspace availability

The size of your laser wood engraver's engraving area is a critical decision that hinges on two key factors: the dimensions of your projects and the physical space you have available. A common mistake is to underestimate the size needed, leading to frustration when larger projects can't fit. For instance, if you plan to engrave intricate designs on small wooden coasters, a compact 12" x 8" engraving area might suffice. However, if you're aiming to personalize larger items like cutting boards or furniture pieces, you’ll need a machine with a larger bed, such as 20" x 12" or even 40" x 24" for industrial-scale projects. Always measure your intended projects and add a buffer to ensure they fit comfortably within the engraving area.

Consider your workspace constraints as well. A larger engraving area often means a bulkier machine, which may not fit in a small home studio or garage. For example, a 40" x 24" engraver typically requires a dedicated table or bench and ample clearance around it for safe operation. If space is limited, opt for a smaller machine with a 12" x 8" or 16" x 10" engraving area, which can often be placed on a desk or shelf. Remember, the machine’s footprint isn’t just about the engraving bed—it includes the laser tube, exhaust system, and any additional components.

A practical tip is to map out your workspace before purchasing. Use painter’s tape to outline the machine’s dimensions on the floor or workbench to visualize how it will fit. Also, consider future projects. If you anticipate scaling up your work, investing in a larger engraver now might save you from upgrading later. However, if your projects remain small and space is tight, a compact machine will serve you well without unnecessary bulk.

Finally, balance your needs with your budget. Larger engraving areas often come with higher price tags due to increased material and engineering costs. For hobbyists or small business owners, a mid-sized engraver (e.g., 20" x 12") offers versatility without breaking the bank. If you’re unsure, start with a machine that accommodates your current projects and leave room for growth. This approach ensures you get the most value without overcommitting to a size you don’t need.

Reviving Retro Charm: Where to Find Wood Paneling Today

You may want to see also

Explore related products

Software Compatibility: Ensure the laser works with your design software and operating system

Before investing in a laser wood engraver, scrutinize its software compatibility to avoid costly mismatches. Most engravers rely on specific drivers or proprietary software that must align with your operating system—Windows, macOS, or Linux. For instance, some machines only support Windows 7 or newer, while others may require macOS 10.14 or later. Verify these details in the product specifications or consult the manufacturer directly. Ignoring this step could render your engraver unusable or force you to upgrade your computer, adding unexpected expenses.

Compatibility extends beyond the operating system to your design software. Popular programs like Adobe Illustrator, CorelDRAW, and AutoCAD often integrate seamlessly with laser engravers, but not all machines support them. Some engravers work exclusively with their bundled software, which may lack advanced features or limit file formats to SVG, DXF, or BMP. If you rely on specific design tools or file types, ensure the engraver supports them. For example, if you frequently use Photoshop for intricate designs, confirm the machine accepts PSD files or can work with exported formats like PNG or JPEG.

Consider the engraver’s communication protocol as well. USB, Ethernet, and Wi-Fi are common connections, but not all are universally compatible. USB-connected engravers typically require drivers specific to your OS, while Wi-Fi-enabled models may need a stable network and compatible app. For instance, a machine with a proprietary app might only work on Android 9.0+ or iOS 13.0+, excluding older devices. Test the connection method on your system before purchase to avoid connectivity issues during operation.

Finally, future-proof your investment by choosing an engraver with broad software compatibility and regular updates. Some manufacturers release firmware updates to support newer OS versions or additional design software, ensuring longevity. For example, a machine compatible with both LightBurn and LaserGRBL offers flexibility, allowing you to switch software without changing hardware. Prioritize engravers with active community forums or user groups, as these often provide workarounds or solutions for compatibility issues, enhancing your overall experience.

Choosing the Perfect Wood Baseball Bat: A Comprehensive Buyer's Guide

You may want to see also

Explore related products

Budget Considerations: Balance features, quality, and cost for your specific requirements

Laser engravers vary widely in price, from a few hundred to several thousand dollars, making budget considerations critical. Before diving into features, assess your needs: Are you a hobbyist engraving small wooden crafts, or a professional producing large-scale custom furniture? Entry-level machines (under $500) like the Ortur Laser Master 2 offer basic functionality for light-duty projects, but lack power and precision for intricate designs or thicker materials. Mid-range options ($500–$2,000), such as the Glowforge Pro, balance affordability with advanced features like autofocus and larger work areas. High-end industrial models (over $2,000) provide unmatched speed, precision, and durability but are overkill for casual users. Define your project scope to avoid overspending or settling for inadequate tools.

When evaluating features, prioritize those aligned with your goals. For instance, a 40W laser offers faster engraving on hardwoods compared to a 10W model but costs significantly more. Similarly, a larger engraving area (e.g., 400x400mm vs. 200x200mm) increases versatility but adds to the price. Software compatibility is another factor—some machines require proprietary software, while others integrate with open-source platforms like LightBurn. Consider long-term costs, such as replacement parts (laser tubes degrade over time) and maintenance. A cheaper machine with higher upkeep costs may not save you money in the long run.

Quality is non-negotiable, especially for safety and durability. Look for machines with robust frames, proper ventilation systems, and safety certifications (e.g., FDA approval). Cheaper models often cut corners on materials or lack safety features like emergency stops or laser shutters, posing risks during operation. Testimonials and reviews can reveal recurring issues like misalignment or overheating, helping you avoid low-quality options. Remember, a slightly higher upfront investment in a reliable machine can prevent costly repairs or replacements later.

Finally, explore cost-saving strategies without compromising quality. Consider refurbished or open-box models from reputable sellers, which often come with warranties and significant discounts. Joining online communities or forums can provide access to group buys or secondhand deals. If your budget is tight, start with a basic model and upgrade components (e.g., a more powerful laser tube) as needed. Renting a professional-grade machine for occasional large projects is another option. By balancing immediate needs with future scalability, you can maximize value without overspending.

Where to Buy CND Spa Gardenia Woods Lotion: Top Retailers

You may want to see also

Explore related products

Safety Features: Look for emergency stops, protective covers, and ventilation systems

Laser engravers, while powerful tools, demand respect for their potential hazards. Safety features aren't optional add-ons; they're essential safeguards against accidents and injuries. Think of them as your first line of defense against the intense beam, flying debris, and harmful fumes.

Emergency stops are your immediate escape hatch. A clearly marked, easily accessible button should halt the laser instantly, no questions asked. This is crucial in case of unexpected movements, material jams, or any situation where the engraver poses an immediate threat. Don't settle for a machine that requires fumbling through menus or complicated procedures to shut down.

Protective covers act as a physical barrier, shielding you from the laser beam's direct path. Look for enclosures that completely surround the engraving area, made from materials specifically designed to block the laser's wavelength. Remember, even a brief exposure to a laser beam can cause severe eye damage. Don't underestimate the importance of this simple yet vital safety measure.

Ventilation systems are often overlooked, but they're crucial for your health. Laser engraving on wood releases fine particulate matter and potentially harmful fumes. A proper ventilation system, ideally with a fume extractor and filtration system, removes these airborne contaminants, preventing respiratory issues and ensuring a healthier working environment. Consider the size of your workspace and the type of materials you'll be engraving when choosing a ventilation system.

When comparing models, prioritize machines that integrate these safety features seamlessly into their design. Don't be swayed by flashy extras if they compromise on fundamental safety measures. Remember, a safe engraver is a reliable engraver, allowing you to focus on your creativity without constantly worrying about potential hazards.

Best Pesticides for Treating Barn Wood Infested with Bugs

You may want to see also

Frequently asked questions

Consider the engraving area size, laser power (measured in watts), software compatibility, ease of use, and your budget. Higher power allows for deeper and faster engraving, while larger engraving areas accommodate bigger projects.

CO2 lasers are generally better for wood engraving due to their higher power and precision, making them ideal for detailed and deep cuts. Diode lasers are more affordable and portable but are better suited for lighter engraving tasks.

For most wood engraving projects, a laser power between 40W and 100W is ideal. Beginners can start with a 40W machine, while professionals or those working on larger projects may need 60W or higher.

An autofocus feature is highly recommended, especially for beginners, as it ensures precise focusing without manual adjustments. This saves time and reduces errors in engraving depth and quality.

Desktop engravers are compact, affordable, and suitable for small-scale projects or hobbyists. Standalone machines are larger, more powerful, and better for professional or industrial use, but they require more space and a higher budget.